On welding equipment, in addition to the usual surface deposition and welding of parts, operations are also carried out to separate them. One of them is metal gouging. This is removing a strip on the surface of a part, creating a groove or removing a defective seam. The technology is similar to cutting and is used on the same equipment. Gouging is used mainly in metallurgy and in the repair of welded structures.

Types of carbon electrodes

When welding with a carbon electrode at home and in factories, different types of consumables can be used, which may differ in cross-sectional shape.

The most optimal and in demand are the following types of carbon electrodes:

- Round . They can be used unlimitedly. The diameter of the electrodes ranges from 3.2 to 19 mm.

- Round endless . The tips got their name due to their low consumption; they are the most economical. The diameter size can be from 8 to 25 mm. To carry out the welding process with these electrodes, a special machine is used.

- Flat . The cross-section of rods of this type has a rectangular shape, sometimes square. The size ranges from 8 to 25 mm. They are mainly used to seal external defects on the surface of steel castings.

- Semicircular . They have a cross-sectional size from 10 to 19 mm. They are popular carbon rods that are used for welding and cutting metal parts. During the welding process, they contribute to the formation of a correct and even seam.

- Hollow . They allow you to form a U-shaped groove. The diameter ranges from 5 to 13 mm.

Process Features

Welding with a carbon electrode and an inverter allows you to obtain a strong welded joint without defects and irregularities. Moreover, this technology allows you to work with different types of metal.

Electrodes made of carbon differ from metal rods in that they are refractory. It follows that during the welding process they act as a conductor of electricity, but at the same time they become part of the weld pool.

During operation, the carbon rods heat up to very high temperatures. And if you continue heating, they will immediately go from a molten state to a boiling state.

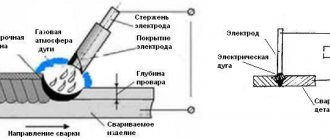

When carrying out the welding process, it is recommended to use direct electric current with straight polarity. In this case, the minus (cathode) should be on the electrode, and the plus (anode) on the metal surface of the product.

When welding with carbon rods, the welder is required to use filler elements. The welding process can be performed in two ways:

- From left to right (filler components are located behind the electrodes);

- From right to left (additive components are in front).

It is worth noting! During the welding process at home, you can use a homemade machine for welding and soldering with carbon electrodes. Due to the fact that the desired rods have low thermal conductivity, it will be possible to create an arc with a current of only 3-5 Amperes.

Gouging metal with a plasma cutter

Air plasma cutting is one of the most common methods of cutting metal and the process is relatively cheap. Metal cutting occurs using a plasma jet, which melts and blows the metal out of the cutting zone. Air supplied to the plasma torch from the compressor-receiver system or the general production air line is used as a plasma-forming gas during air-plasma gouging. The plasma flow is generated in the plasma torch as a result of the passage of an intense air flow through the arc discharge between the electrode and the nozzle, and its temperature reaches 25,000 degrees Kelvin.

One of the types of plasma cutting is plasma gouging of metal. The difference in the physics of the process lies in the shape of the plasma arc. Thus, with plasma cutting, the arc is compressed to increase its concentration and narrow the cutting zone, and with plasma planing, the arc is wider with less intensity. If you use a compressed arc, as when cutting, the groove will turn out to be deep and narrow, which will not give the necessary quality when processing metal. When gouging, the plasma torch is positioned at an angle to the surface of the product, thereby ensuring melting and blowing of the metal. Plasma gouging is used to remove defective welds, flashes, sprues, and deposited layer for further processing, during repair and restoration work.

Plasma gouging, compared to other alternative methods (air-arc gouging, mechanical, etc.), has a number of advantages, in particular: reduced smoke and gas emissions, reduced release of metal in a gaseous state, significantly better groove formation and quality , low process cost, reduced noise level. The reduced gas release is due to the fact that the base metal is removed by a plasma flow and does not interact with the atmosphere. After plasma planing, a sufficiently high-quality groove is formed without metallic and non-metallic inclusions, which does not require additional processing. For example, during air-arc gouging with a carbon electrode, the carbon that remains from the electrode can dissolve in the surface layer of the part, forming a layer with reduced ductility and increased carbon content, which causes problems during welding and contributes to the formation of cracks. High productivity of plasma gouging, low price of power source and consumables (the service life of the electrode and nozzle can reach 6-7 hours of machine time), efficient use of electrical energy makes the process cheap and 3-4 times faster than air-arc or mechanical gouging .

To ensure high-quality plasma gouging, it is necessary to have special nozzles that will provide the appropriate arc shape. The current for gouging is usually 100A; at lower current values, only productivity will decrease, while quality will remain at a high level. You can also use special plasma torches with additional polymer protection against splashes of molten metal, which will extend the service life of the plasma torch itself. The size of the groove during gouging depends on the magnitude of the current, the gouging speed and the angle of inclination of the plasma torch. The most effective angle of inclination is 30-40° with an arc length of 12-25 millimeters, which removes a large amount of metal in one pass. To remove the top thin layer of metal from the surface, use a small angle of inclination of the plasma torch.

Plasma gouging has wide industrial applications also due to more convenient access to hard-to-reach places, high accuracy and easy control of gouging depth. Due to its advantages, plasma gouging has proven itself well in the repair of railway transport, in shipbuilding, maintenance of trucks, quarries, and armored vehicles, as well as in foundries and machine tool construction.

Carbon gouging

Carbon gouging is a metal cutting method that uses compressed air. An electric arc melts the metal, and a jet of compressed air directed at the welding area blows it out.

Air carbon arc gouging or gouging can be used to cut all types of metals. But mainly this technological process is used for cutting stainless steel, cast iron, nickel, aluminum and copper.

Carrying out welding work using suitable rods is used only in exceptional cases when it is necessary to make a strong and even weld. This technology has many important features that must be observed when performing it. But the selection of carbon rods used for welding is of particular importance.

Description of the process and its purpose

Gouging technology involves blowing out molten metal with a jet of compressed air. It is used to remove part of the metal from the surface entirely or in strips, including:

- for removing fragments in welded structures;

- creating grooves and understatements in thick-walled parts;

- cutting out defects;

- samples of poor-quality seams.

When gouging with a carbon electrode, its ability to melt metal with an arc is used. In this case, the graphite itself practically does not burn, only the copper coating melts near the arc. The holder of a special design, the planer, has holes for gas outlet next to the clamp. In addition to the power cable, a hose for compressed air, carbon dioxide or argon is connected to it. The air is pumped by a compressor, gas is supplied from a cylinder.

An electric arc heats and melts the metal, and air blows it out with a strong stream. At the site of the weld pool, a recess is formed in the metal. Electric arc gouging is used to create grooves and grooves in parts and remove defective seams.

Plasma gouging uses gas to simultaneously melt metal and blow it out. The plasma arc instantly heats the metal to its melting point and above. It literally evaporates from the gouging and cutting area.

Plasma gouging is the most productive of all other types of surface processing of parts. In one pass of the cutter, a strip up to 5 mm deep and 8 mm wide is selected.

The disadvantage of this treatment is the release of large amounts of harmful gases. The operation of the equipment is accompanied by loud noise.

The classic method of repairing welded structures and cutting defects is oxy-fuel cutting. The oldest and most productive method is based on the principle of heating using a gas burner. When welding, filler wire is added, which melts along with the edges. For gouging and cutting, it is enough to heat the steel so that it begins to oxidize. The liquid, molten metal is blown out along with the gas.

Oxygen gas cutting is used for cutting thick metal. It burns through a sheet 100–120 mm thick in a matter of seconds and continues to cut it without stopping along a given contour. When manually planing, a strip of 80 mm is selected in one pass. Special machines can remove a 300 mm strip on one cutter in one pass. In mass production, powerful equipment with several burners is used. The limit on the width of metal removal can reach 3000 mm. The maximum depth is limited to 15 mm.

With the development of electric arc and plasma welding, oxygen gas cutting is used to remove profits and accumulators from castings. Cracks, sinks, and sagging are washed out using a planer.

When gouging metal defects in castings, the flame of a gas burner is also used as a control tool for highlighting and eliminating cracks and cavities. In a stream of burning gas, the edges of the cracks heat up faster than the main body of the part and glow in narrow stripes of orange and yellow.

At the beginning of gas gouging, the starting point on the part is heated to red. In this case, the mouthpiece should be positioned at an angle of up to 70⁰, the flame core should touch the surface of the part. After heating the surface of the sheet, the nozzle rises by 15 mm, and after oxygen is released, the angle of inclination decreases depending on the gouging depth. The depth of the groove is also increased by increasing the oxygen pressure.

In the mass production of machines using the oxygen gas method, rough cuts of grooves and grooves are made in large parts for further cutting. They work mainly with low-alloy steels. Carbon and high-alloy steels after oxy-fuel gouging require heat treatment to relieve stress from local heating.

All types of gouging can be done in any position of the part. You just need to be extra careful when working on the ceiling so that molten metal does not drip onto the welder.

The thermal conductivity of carbon and alloy steels is lower than that of simple steels. When heated and sharply cooled, they become heated with a change in the crystal lattice. In this case, internal stresses arise, which can lead to destruction of the part. It is necessary to do normalization or annealing to align the structure and relieve stress.