This type of welding is used in various fields:

- construction of hydraulic structures;

- ship repair work;

- construction of special technical structures;

- laying of pipelines;

- construction of berths and port facilities;

- construction of platforms, drilling rigs, dams.

In this article we will look at the technological features of such a unique phenomenon as underwater welding.

Underwater welding: types

Welding metal underwater can be done in several ways. They can also be divided into two types, which differ significantly from a technological point of view: dry and wet welding .

The first category involves the use of special equipment. This equipment creates conditions under which the contractor has the opportunity to use devices and materials used on land. This includes underwater cameras, boxes, compartments, bells .

Wet welding is the making of a connection directly in an aqueous environment. In this case, both the work object and the welder are in the same element. Here, additional devices include electrodes for underwater welding and equipment, as well as the knowledge and experience of the performer.

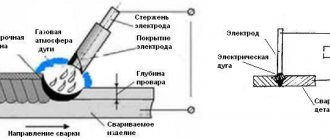

This technology uses arc welding due to its widespread use among specialists. When working at depth, the welding arc releases a large amount of thermal energy and evaporates the water around it. This allows you to create a kind of sphere filled with gas. In this area, the arc continues to burn steadily, even under pressure.

Advantages : time saving; absence of large financial costs; The specialist is guaranteed freedom of movement. Disadvantage - the quality of the seam is much lower than when welding in a dry environment.

This species is also divided into two subspecies:

1. Semi-automatic welding . The specialist manually adjusts the direction of the mechanical supply of the electrode wire. Advantages: duration, continuity and better visibility of the process, the absence of coating on the wire allows better control over the formation of the seam, which ensures a more accurate and even connection, and also eliminates the formation of pores and the appearance of inclusions.

2. Manual welding . The contractor uses electrodes for underwater welding and mobile welding equipment to work in hard-to-reach places. To carry out such a complex process, special materials are used, developed and adapted to harsh conditions . Electrodes for welding in water have a waterproof coating, which is a film. The composition of the coating is supplemented with the following elements: resins, paraffin and celluloid varnish. These compositions do not allow the coating to become limp from exposure to water , and also create a protective layer.

Wet welding technology is used more often than dry welding method. The second method is less popular for several reasons:

- impressive financial costs;

- a long time for the construction and preparation of additional equipment.

However , the technology of underwater dry welding has the main advantage - the quality of the seam is at the same high level as a connection made on land.

Dry welding has several subtypes :

1. Welding in a deep underwater chamber (caisson/diving bell) . This technology involves submerging the camera under water. The caisson is hermetically secured around the work area. The contractor makes the connection inside the structure, in which atmospheric pressure is maintained by filling it with gas and displacing water. Advantages: a dry environment guarantees a high-quality seam; gradual cooling of the metal provides good impact strength.

Video

Here's what it might look like, watch the video.

[ads-pc-2][ads-mob-2]

2. The connection is made in a mobile dry box (hyperbaric welding/hydraulic welding). The hydrobox must be completely or partially made of transparent material, and must also fit tightly to the work area and ensure tightness. The box maintains a gaseous environment that displaces water. The base of the box is open for insertion of the welding head. Transparent walls allow the performer to control the process.

Safety precautions

Water creates many problems not only for welding, but also for the health of the welder himself. After all, direct contact with electric current never ends well. Therefore, only equipment that is protected from water according to international standards can be used for underwater welding.

The welder must also take into account that he will have to be both a welder and a diver at the same time. And divers have their own occupational diseases. The most common is decompression sickness, where inhaling large amounts of gas from a cylinder can lead to blockage of blood flow. To avoid this, you need to use special methods of lifting from the bottom to land, which achieve a decompression effect.

Features of underwater welding

Welding, performed under a thick layer of water, is a difficult and dangerous task for the performer. The welder is completely in a conductive environment. The body experiences overload due to fluid pressure. This procedure also has a number of other features. Having become familiar with these specific characteristics, it will be clear how various structures are welded under water:

the welding arc is difficult to ignite with the electrode due to the presence of corrosion on the metal and due to the density of water;- the walls of the sphere that the arc forms are pressed with considerable force by the aquatic environment . Thanks to this, the seams have deep penetration.

- the connection acquires a rough scaly structure due to pressure and fairly rapid cooling of the metal;

- evaporating gases foam the water and interfere with visibility , so a common defect is the displacement of the center of the seam ;

- the resulting compounds are characterized by low impact strength ;

- vertical seams should be formed “from top to bottom” due to the force of attraction;

- Welding under water is characterized by the use of increased current modes .

https://youtu.be/-HsT2aJBGaI

Welding work under water should be carried out with constant voltage so that the arc burns more stable. The current strength should be higher than when welding on land.

Optimal parameters for working with 4-5 mm electrodes. are 200-250 A.

The voltage during underwater welding operations should not exceed 35 V. This measure guarantees the safety of the specialist.

[ads-pc-3][ads-mob-3]

Materials and equipment

Power equipment for underwater welding - transformers, converters - may be no different from those used for conventional welding. The exception is structures that are intended to operate at great depths. Sometimes the cooling system of such devices is changed.

Hoses and cables

Hoses and cables must be carefully selected and their integrity checked. This need is due to both electrical safety requirements and work technology.

Welding is very often carried out in sea water, which has a high salt content. Such water is a good conductor of electricity, so if the cables are not sealed, it can leak, which can have a negative impact on the quality of the arc.

Spacesuit

Obviously, underwater equipment is necessary to protect the welder. For work at great depths, the suit or spacesuit can be metal. Here lies another catch.

In salt water, the arc can ignite at a considerable distance from the metal, without even touching it. And since positive conductivity can be established in water between the part being welded and the welder’s suit, a discharge can occur at a small distance between the electrode and the suit.

Electrodes and wire

Electrodes for underwater welding deserve special attention. They must be made of material that is not exposed to water. Welding under water is performed using low-carbon steel electrodes.

The coating is coated with special compounds that prevent its destruction for a long time, creating a waterproof layer on the surface.

Paraffin, wax, celluloid dissolved in acetone can be used as such compositions. The diameter of the electrodes for underwater welding is 4-6 millimeters. There are special brands - Sv-08, Sv-08A, Sv-08GA, Sv-08G2.

When welding semi-automatically, the following grades of welding wire are used: SV-08G2S, PPS-AN1.

Difficult work conditions require proper organization of the workplace and compliance with all safety measures. The workplace must be selected in such a way that waves and currents do not interfere with the welder.

There should be no floating loose objects near the work site. Electrodes should only be changed when the power is turned off.

Compliance with all the rules and technology of underwater welding will allow you to get excellent results when constructing and repairing hydraulic structures, ships, and installing underwater equipment.

Underwater welding technology

The wet welding method is the most popular due to the savings in financial and time resources. This technology is based on the ability of the welding arc to burn in an underwater gas sphere. The welder’s work takes place in stages :

- the electrode fixed in the electrode holder is in the hands of the performer;

- the welder “leads” the electric arc with hand movements, thereby performing the joining procedure;

- when the rod burns out, the process stops;

- the new rod is fixed in the holder;

- then welding is resumed.

Advantages:

- no need for additional devices;

- the specialist receives greater freedom of movement;

- efficiency of work.

Flaws:

- low productivity;

- the presence of a significant amount of the gas phase and mechanical cocking makes it difficult to visually monitor the welding process;

- The resulting compounds are heterogeneous.

Distillation

During distillation, seawater is heated using various types of energy. Water molecules have greater mobility than ions of dissolved salts; they more easily pass into the gas phase (evaporate), which is removed with the subsequent condensation of pure water from it.

During this process, energy is spent both on the transition of water into the gas phase and on the transition of the gas phase to the liquid phase.

A reduction in the amount of heat input required for evaporation can be achieved using the vacuum distillation method, which differs from the classical scheme in the vacuum created in the evaporator. The boiling point of water decreases as the pressure decreases, which reduces energy costs and increases the efficiency of the installation as a whole.

To make more complete use of thermal energy, a multi-stage distillation process (flash distillation) is used, during which evaporation occurs in a rarefied environment, and thermal energy is used to the maximum (utilization of heat carried away by the flow of condensed water).

This technology allows for more efficient use of energy, since when the pressure of the gas phase decreases over the liquid phase, the boiling point of the latter decreases, and the movement of product flows in a countercurrent allows minimizing heat loss from both the purified water and the removed residue.

Another option for carrying out the purification process by evaporation/condensation of water is thermocompression distillation. When implementing this purification method, the source water is converted into a gaseous state due to the energy released during the condensation of purified water. To do this, the water that has turned into steam is pumped out of the evaporator with a special compressor, which also serves to create increased steam pressure in the condenser.

Due to the difference in pressure in the evaporator and condenser, the energy released during condensation (at elevated pressure) is sufficient to transfer the source water into the gas phase (at reduced pressure) and there is practically no need to consume external energy to carry out such a transition.

Welding on water

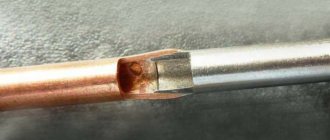

Welding pipes is a responsible and complex process, which implies that these structures will work for a long time. Therefore, all connections must be made efficiently, in compliance with all requirements:

- maintaining slopes for natural coolant movement;

- Sufficient distance should be left between the pipes being welded and the walls. This provides convenience and comfort for the performer;

- Several passes are made to ensure tightness.

However, despite the implementation of all the listed rules, there may be a need for welding work on an already functioning pipeline .

Welding of this kind is complicated by the presence of liquid in the pipes , which are also under pressure.

Features of welding pipelines under pressure:

- the pressure of the liquid cools the weld pool, which interferes with the adhesion of the base and deposited metal;

- “touching” the liquid to the hot metal leads to the formation of steam , which prevents the specialist from seeing the work area;

- when working with ceiling joints, water flows onto the welder. The mittens and mask get wet, while the performer touches the product being welded. All this can lead to small electric shocks. Working in such conditions is extremely inconvenient.

Video

We invite you to watch a video in which a professional repairman shares his experience with beginners.

The current strength when welding with the presence of liquid should be higher than usual. Electrodes of the UONI-13/55 brand are suitable for welding. Before carrying out work, the materials should be calcined and the working surface should be heated with a burner. We also recommend looking at electrodes for welding pipes; it will be easier to weld with rutile ones.

The choice of voltage type depends on the personal preferences of the performer. Alternating current contributes to the stability of the arc and it performs well when welding in such conditions. But the connection quality is worse. Direct current is less stable when operating in a humid environment, but the penetration of molten metal is higher. [ads-pc-4][ads-mob-4]

Semi-automatic method

Due to the fact that a large amount of hydrogen is present in the water during welding, the seam becomes porous. At the same time, increased cooling of the material with water has a negative effect.

The seam turns out to be fragile and unstable to bending. To obtain a satisfactory result, it is necessary to take into account a large margin of safety and reliability when calculating structures.

Welding under water in an argon environment does not produce a noticeable effect, since it only slightly reduces the hydrogen content in the weld.

A good result is obtained by using semi-automatic welding using flux-cored wire. It has a smaller diameter than the electrode.

When welding with a semi-automatic machine, it is possible to organize a constant and continuous mechanized wire feed, which, in combination with the use of non-consumable electrodes, will make it possible to obtain uniform seams of long length.

The welding wire is uncoated, making it easier to control the welding process under water.

Electrodes for underwater welding

There are several brands of suitable welding consumables on the market. Domestic and foreign manufacturers offer customers the following electrodes:

Welding electrodes OZS-3

OZS-3 are suitable for working with critical structures made of carbon steel. Advantages: high welding performance; connection of oxidized surfaces is allowed.

EPS-52 are intended for repair of ship structures made of steel grades SHL-4 and MS-1.

ANO-1 are used for welding structures made of carbon and low-alloy steels. It is recommended to use this brand when working with thick sheet metal.

MGM-50K are suitable for treating surfaces that have not been cleaned of rust and other contaminants.

TsM-7S electrodes are used for welding butt, tee and lap joints.

A popular category is the products of the American company Broco. The manufacturer offers two groups of materials for underwater welding: EasyTouch and SofTouch. A popular brand is UW/EZ-2. These electrodes are intended for welding carbon non-structural steels.

Each contractor will be able to decide for himself which underwater electrode is best for specific work.

Application area

Underwater welding technique is used:

- during the construction of bridges;

- for quick repair of pipelines laid along the bottom of reservoirs;

- during emergencies on oil platforms, hydraulic structures, dams;

- when there is an urgent need to restore the integrity of ship propellers or ship plating after damage.

The technology was developed for operational action in a combat situation, but is now increasingly being used for peaceful purposes.

Underwater welder salary

According to the website www.proprof.ru, the minimum wage for a welder in Russia in 2016 was 20 thousand rubles, the average – 49 thousand rubles . The salary depends on the rank of the specialist, as well as on his skills. In addition, the salary may vary depending on the region and place of employment.

In Moscow, the minimum income of a specialist in this profession is 30 thousand rubles, the average is 60 thousand .

One of the reasons for choosing an underwater welder specialty is the salary, which will be fixed and stable. The salary ranges from 90 to 110 thousand rubles . This indicator is the average for Russia. This value is influenced by the main factors: the rank and skills of the performer, the region of work, the fame and scale of the company.

One of the most difficult and dangerous types of welding work is underwater welding, the salary of specialists in this profession clearly demonstrates this.

Manufacturer

The creation and improvement of this device is being carried out by one of the leaders of the domestic scientific and technical market. The company has been operating since 2001 and during this time has achieved significant success in the production of mobile plasma complexes.

Today, Gorynych sells to 11 countries around the world and the number of orders increases from year to year. This device can be officially purchased from nine dealers in Russia and the CIS countries. In addition to sales, dealers provide service and warranty service if necessary, and also distribute related products.

Education

The profession of an underwater welder has many risks and difficulties. The master must have a certain set of skills and knowledge, and also be able to carefully follow safety precautions. To become an expert in this industry, you need to obtain a diploma in the specialty “welder” and “technical diver” from a technical school. Then, those wishing to obtain the specialty “underwater welding” undergo training in specialized training centers.

After receiving these specializations, as well as acquiring a professional base, it will be possible to continue education at an underwater welding school. Courses in schools have different durations, varying significantly. After this, the master will be able to work in the acquired specialty.

Underwater welding courses

Experience and knowledge in the field of underwater welding can be obtained in many institutions: training centers; diving schools; specialist training centers; companies operating in the relevant industry. The duration of courses can vary from 2 weeks to 2 years. Depending on the duration of training, the future welder receives knowledge of varying scope and depth. The short course includes lectures on the following topics: labor protection, safety precautions, basic welding processes. The best option would be to have theoretical and practical classes.

The most popular courses are underwater welding in St. Petersburg. This is facilitated by the presence of large shipbuilding enterprises. Training is provided by the following institutions:

POU “SPb Maritime School RO DOSAAF Russia SPb” offers training courses for underwater cutting and welding specialists for divers of 6-7 categories. Groups of 6-12 people. Number of hours – 101. Upon completion of training, Russian-style documents are issued.

The educational and training center of the Federal Budgetary Institution “Marine Rescue Service of Rosmorrechflot” (Moscow) offers a training course “Diver Welder-Cutter”. Number of hours – 210.

DONPODVODSTROYMONTAZH LLC (Rostov-on-Don) offers the course “Training of divers, welders and cutters”. Details should be clarified with company specialists.