Their difference from conventional profile beams is that they are lighter in weight and have a unique shape, which makes them faster to install.

I-beams are made of wood and metal, but they are also found in the form of reinforced concrete products.

What are the main features of I-beams, what their design consists of, what regulatory requirements are imposed on products, the nuances of installation and the average market value in the Russian Federation, we suggest you find out from the presented article.

Features of I-beams

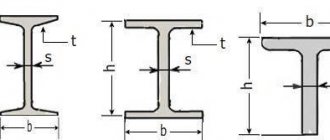

The main feature of products of this type is that they are made in the form of a horizontal beam, which, with a schematic representation of the thickness (section), in section, resembles a beech T on a substrate , or, if you turn the beam in the other direction, a thick letter H. Also, the appearance of some experts consider it vaguely similar to rails.

The shape of the products in the form of the letter H is made for ease of installation of various types of structures in which I-beams play an important reinforcing and load-bearing role. But they are of particular importance as one of the elements of the foundation of the floors of any structure being built.

The standard size of an I-beam is: 14.0 x 73 x 7.5 (cm) , but there are other varieties.

Each product has its own marking, in the form of alphanumeric designations. I-beams have good quality characteristics, the most important of which are strength, stability and the ability to support load-bearing structures.

In construction, beams are resistant to high loads and external manifestations of atmospheric changes . They also do not respond to mechanical stress, have high compression density, and ideally adhere to various types of substances. The listed features allow the products to be used in the construction of structural elements of frame buildings and structures.

I-beams are widely used not only in the construction of private houses, but also in the construction of industrial buildings. The products are indispensable when working with reinforced concrete slabs, stairs, spans, and roofing.

I-beams are light in weight, which is convenient for transportation and installation. For fastening materials, angles, anchors, rivets, bolts, welding, metal hooks, and logs are used.

Advantages

Design advantages:

- the versatility of the building material lies in the fact that it is used to form the supporting frame of the roof, subfloors and floor formwork;

- the weight of wooden I-beams (1 linear meter ranges from 3.2 to 5.8 kg) allows the installation of structures without the use of lifting mechanisms;

- high speed of installation of floors reduces the time of low-rise construction;

- strength characteristics are not inferior to those of similar structures made of metal and concrete;

- DDB cover spans up to 15 m long;

- high sound insulation and low thermal conductivity provide comfortable living conditions for people in the house;

- the ease of manufacturing beams allows you to organize their production in a home workshop;

- impregnation with antiseptics and fire retardants significantly increases the safety of structures;

- the cross-sectional shape makes it possible to lay communications for various purposes in the longitudinal openings of the beams, which increases the volume and usable area of the premises;

- prices for DDB are significantly lower than the cost of similar products made from other materials.

Kinds

The most common I-beams are metal and wooden . Precast concrete products are made to order for panel houses made of monolith and reinforced concrete. The first type is made from good profiles (high-quality steel grades), they are divided into:

- hot rolled;

- welded

Hot-rolled beams are produced in factory products by smelting at high temperatures (rolling mill), from carbon and rolled steel, as well as aluminum alloys.

Welded ones are formed in workshops using a special welding technique, which gives the products a characteristic shape that is not subject to twisting. The advantages of products made from hot woven material are :

- no seams (monolithic):

- large selection of standard sizes;

- availability for sale (always available on the market).

Wooden ones are cut on factory machines using carpentry tools .

They can be either solid or formed from three parts. Reinforced concrete I-beams are prepared in special molds by pouring high-grade concrete (M300, 400, 500) over reinforced rods.

Each of the presented I-beams, depending on the type, is suitable for the construction of civil and industrial facilities, and therefore has appropriate technical characteristics, which include strength, density, resistance to temperature and mechanical influences, water and fire.

For example, wood products are impregnated with special compounds that prevent fire , and may not ignite for a long time if a fire breaks out in the building.

The most popular reusable I-beam made of coniferous trees in construction is BDK-1. It has a cross section of 40 x 80 (mm), and the following standard dimensions:

- 1,500-4,500 (mm) – length;

- 80 (mm) – width;

- 200 (mm) – height.

In this case, the insertion of teeth into wood or dense plywood is 13 (mm). In this case, wooden I-beams are attached not only to fasteners, but also to glue of the highest density (D4000), for example, “KESTOKOL”.

The disadvantages of metal I-beams are considered to be an increase in the weight of the structure and the load on the foundation ; for welded ones, the labor intensity of the process is considered.

Also, according to the classification, in addition to standard (B), there are wide-flange I-beams (W), column (K), monorail (M), special (S), narrow-flange (U), additional (D), which are widely used in the national economy for the construction buildings of varying nature and complexity.

Advantages

Floors on wooden beams assembled from I-beams, due to their low weight, do not place a significant load on the supports, while they themselves have a high load capacity. Lightweight and durable wooden span beams, unlike reinforced concrete ones, do not require the use of heavy lifting equipment. They can be used in any climatic conditions. Structures built from wooden I-beams can withstand strong squally winds and seismic waves. Fully comply with SNiP. Flooring, for example, can be done much faster with their help; the floors do not spring or creak.

Other advantages of I-beams:

- environmentally friendly;

- fireproof;

- have a long service life;

- increased strength allows use on large spans;

- no changes in geometric parameters: twisting, deformation, drying out;

- completely replaces metal elements, providing a smooth floor or ceiling;

- universal, multifunctional use;

- ease and speed of installation;

- short period of work, saving labor costs due to this;

- Possibility of use for flooring without concrete screed.

I-beams can be easily sawed without requiring special saws. The unique strength of I-beams, however, makes it possible to make the necessary holes, and the design is convenient for laying internal communications.

Important! The wooden I-beam floor strictly maintains the specified dimensions, not being affected by natural precipitation and temperature changes throughout its entire service life.

The cost of beams is low and depends on their length and cross-sectional height. To build an attic floor using wooden beams, it is better to use wooden I-beams; this will protect your house from shrinkage, cracks and extend its service life.

Basic requirements for products

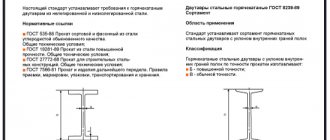

Important technical requirements for I-beams are indicated in technical standards, which include:

For metal ones:- GOST 19425-74;

- GOST 26020-83;

- GOST 8239-89;

- GOST R 57837-2017.

- For wooden ones:

- GOST 4981-87;

- GOST 30244-94;

- SNiP 2.08.01-89.

- For reinforced concrete products:

- GOST 20372-90;

- GOST 24893.0-81.

The listed technical standards in the initial sections always offer references to other GOSTs, SNiPs and STOs. They relate to the material used, calculations, size distribution, storage conditions and other important nuances. But what all requirements have in common is that they must be:

- strong and durable;

- marked, depending on the type;

- stable after installation;

- adhere well to various substances and fasteners used for construction and finishing work;

correctly distribute the load, taking into account the impact on the foundation;- be fire-resistant, earthquake-resistant, water-resistant and frost-resistant;

- used simultaneously with vapor barrier and waterproofing;

- have different standard sizes;

- be made of high-quality materials produced in the factory;

- have durability during operation.

Requirements may be supplemented and changed as construction technologies develop and expand every year. Finished products can always be purchased in specialized stores , on manufacturers' websites or from their direct partners.

The length of the I-beam can reach 12-15 (m). If longer I-beams are needed for the construction of an industrial facility, the company makes an individual order for the customer.

Specifications and Dimensions

These qualities relate to such concepts as strength, dimensions and weight of products, the requirements for which are specified in regulatory documents - GOSTs and SNiPs (listed in the section above). I-beams, according to their technical characteristics, must have the following qualities:

- Ensure sufficient strength, stability and rigidity of the entire structure.

- Securely fix individual frame elements.

- Reduce the load and distribute it evenly in relation to the foundation base.

- Be frost-resistant and fireproof.

- Correspond to the markings (N, W, M, K, S, A, V, B) and length distribution: measured, unmeasured, multiple.

- The curvature of an I-beam cannot be more than 2% of the length.

- The wall deflection, designated in calculations as f, cannot be more than 0.15 (S).

The technical specifications table for an I-beam can be presented as in the photo below:

The photo shows the length, width, number of products per 1 ton, cross-section, and factory assigned number. By marking the beam, not only the height of the product is determined, but also its performance, as well as the sequence of calculations.

Safety regulations

When performing installation work on installing I-beams, they must initially be secured using temporary elements, which are then replaced with permanent stationary fasteners. Due to safety precautions, it is strictly forbidden to start using the beams until the craftsmen provide them with strapping and the temporary holders are removed.

Dismantling can be carried out only after the craftsmen verify the presence of strapping on the beams. Fixed exclusively with temporary clamps, I-beams can only support the weight of workers and installation equipment. It is very important to know that defective or deformed beams cannot be repaired with your own hands or in production and cannot be installed in their seats under any circumstances.

Calculation principle

Carrying out calculations of I-beams is based on the fact that the bottom works in tension, and the top works in compression . In this case, the walls accept transverse force loads.

Made of wood

The characteristics and indicators of wooden I-beams are indicated in the appendices of GOST standards, and are in the form of tables, as in the figure below:

Using table data characterizing wood, the following values are used in calculations:

- overall height;

- thickness;

- moduli - tensile, bending, compression and elasticity;

- groove depth;

- the length of the span itself;

- beam pitch;

- standard load indicator;

- percentage operating conditions of the product, depending on humidity and other atmospheric variables.

There are also numerous coefficients used by professional engineers. For I-beams, formulas such as :

Xd = kmod x Xk/γm – determination of strength and calculation of resistance, where:

- Хk – strength standard;

- kmod – coefficient of load and moisture content;

- γm – coefficient characterizing the material.

Ed = Emean / γm – elemental stiffness, where:

- Ed —hardness index;

- Emean – average elastic modulus.

The partial coefficient used (γm), according to the standards, is most often equal to 1.2 . Since I-beams differ from each other in terms of wood quality, their calculations are not the same. Great importance is given to additional coefficients and indicators, for example, the flexibility of the I-beam element λ, which is calculated by the formula:

λ = SQR(12) x (Lc/b) , where:

- Lc is the length of the surface between sections if compression occurs;

- b – beam width indicator.

Example:

Calculate the flange flexibility if the I-beams have a pitch of 1.25 (m). It is indicated that they have no intermediate struts between them, with the exception of the ends.

Solution:

According to the conditions of the problem, the length of the surface between sections under compression is Lc = L = 4 (m). Based on the general formula, we determine the shelf flexibility coefficient:

λ = 3.464 * 4 / 0.075 = 185

Answer: the coefficient is 185.

Metal

For metal I-beams, deflection and bending are most often calculated, which are used for beam types, numbers 1-6. Here you can use a convenient calculation calculator; if you don’t have time, you can use online calculators for the types of I-beams. For example, a website can help with this.

When calculating metal I-beams, indicators are always used:

- A and B – distances from the main support to the load point;

- L – span length (minimum);

- Fmax – maximum beam deflection, according to the technical table below:

In calculations with steel I-beams, the following quantities are also used: quantity (K), Ry - resistance indicator, Fbeams - deflection and reserve (Z), section (M).

To make mathematical calculations easier, online calculators are often used, one of which is here. This calculator carries out calculations for cantilever and support beams, where q is also used - the mass of the product in kg/m. Example :

It is necessary to calculate the deflection for the beams - the maximum moment of resistance of the section Mu, if L = 4.5 (m) is laid parallel to a short wall, q = 6, the number of beams is 8.

Solution:

According to the formula, taking into account weight according to the SNiP table:

My = (q x L2) /8 = 6 x 4502/8 = 151875 (kgf/cm2).

Answer: 151875 (kgf x cm).

Example 2 , which can be combined with the indicator of the first example.

The maximum moment of resistance of the beam Wy, given the specified design steel resistance condition (2150 kgf/cm2), can be easily calculated based on dividing the bending moment by the steel resistance index. According to the formula, it will look like this:

Wy = 151875 / 2150 = 70.6 (cm3).

Answer: 70.6 (cm3) - the maximum resistance of an I-beam of this type.

The quantities used in various calculations of I-beams are as follows:

You can use this calculator for work.

When choosing the dimensions of an I-beam, the type and characteristics of the object being built, as well as the loads on the building structure, are taken into account.

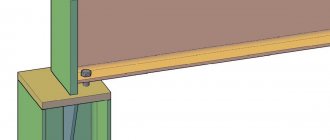

Hemming the ceiling

The next stage is extremely simple: a hemming board of arbitrary thickness is placed on the lower shelves of the wooden I-beam, which is fixed in any way. Boards can also be laid with a gap, using the rough backing as a support for thermal insulation, especially when it comes to dense materials like stone wool or EPS. This will slightly reduce the dead weight of the ceiling.

The boards should not be fitted too tightly; leave a gap of 3–5 mm for deformation during drying. If you want to immediately lay the lining under varnish, leaving the beams open, take the trouble to insulate the insulation from spillage and weathering, leave a gap at the ends of the slats of at least 2-3 mm.

You can also refuse to lay boards like this and hem the ceiling with, say, chipboard. However, the described approach allows you to avoid downtime: after all, the finished ceiling is not installed quickly, and the ceiling must be used.

DIY installation process

The stages of installation of I-beams made of wood according to technical standards include the following steps:

- Boards are laid on the cement screed of load-bearing walls or wooden pads, which are secured to pre-installed structures (fences) using anchors.

- Beams with a pitch of 50-60 (cm), or another, according to the project, but not less than the presented values, are laid on them.

- The beams are attached to the boards using nails and self-tapping screws; their ends must be wrapped with waterproofing material.

- Transverse connections between products are formed by sawing the beam into segments.

- The bottom is hemmed with OSB sheets or thick plywood.

All other work with the arrangement of layers is carried out according to the accepted work plan. Sometimes, in houses made of rounded logs, beams can be installed using a tie-in or notch. To do this, openings of a given depth and thickness are formed in the walls. Beams are strengthened with profiled products, plates, and anchor connections.

Metal I-beams are installed more often in monolithic, brick and panel houses directly along the reinforced belt, taking into account the size of the steps:

- The belt seam can be welded and reinforced with large bolts along the holes made.

- All passages and openings are clamped with clamps and securely welded to the reinforcement of the structural wall.

- The bottom is hemmed with the material that is planned for the project, or formwork is formed and a subfloor is made from a monolith.

Reinforced concrete beams are fastened like metal ones . They have mounting loops, with which they can be conveniently laid, and then welded to the reinforced rods of the armored belt. Then they are engaged in arranging the ceiling and forming the layers of the attic pie.

During the work, it is necessary to strictly observe safety precautions and the sequence of installation actions. The quality of the formation of the rough surface of the attic, interfloor or staircase floor depends on the quality of the laid beams, taking into account construction nuances (marking, composition, fasteners).

Practical application of beams

The extensive use of wooden I-beams is obvious from the variety of their types and sizes. After treatment with fire retardant or water repellent compounds, beams acquire additional properties and become suitable for most “dry repair” projects. On them, in particular, you can build a good and very warm floor, walls, partitions or rafter system.

Almost immediately after installation, the structure is ready for plasterboard covering. In addition to gypsum plasterboard, it is not forbidden to use gypsum plaster, shingles and cement plaster or any type of siding.

As an example, consider the process of assembling a simple interfloor floor with a high-density mineral wool filler (120–140 kg/m3) 250 mm thick with a permissible load of 400 kg/m2 and a span length of 8 meters.

Pros and cons of using

Numerous reviews on social platforms regarding I-beams allow you to learn from experts and users the following advantages of any type of I-beam:

- Withstands loads and distributes them without affecting the foundation.

- Strength, rigidity and durability.

- Ease of transportation.

- Easy installation.

- Large selection of products, possibility of individual orders from manufacturers.

- Zero torque.

- Resistance to mechanical, seismic and atmospheric influences.

- Solidity and stability of seams in steel products.

- Affordability.

- High load-bearing capacity.

- No cracking or deformation.

Users consider the following to be disadvantages:

Wooden ones have a low fire resistance rating due to the characteristics of the material.- Metal ones are prone to corrosion.

- Reinforced concrete has gradual destruction.

- Possibility of producing products only at large enterprises.

Another advantage for I-beams is the fact that installation with them can be carried out all year round.

Common mistakes

Let's figure out what needs to be taken into account in order not to make dangerous mistakes, and what can go wrong during the production of beams.

Mistake #1

Purchase of unprepared raw materials. If you decide to make I-beams for flooring yourself, then you must not forget that in production conditions everything is made using a special technology, and calibrated dry fittings are used, which prevents the beams and boards from twisting and acquiring irregular shapes.

Mistake #2

Purchasing and using inappropriate or too cheap glue. For example, as attractive as choosing a resin adhesive may be, it is an absolute no-no when working with I-beams. Epoxy resin has very poor adhesive properties and takes too long to harden.

Of course, it is worth noting that PVA glue will not work, no matter what magical adhesive properties it may have. Moment glue is also inappropriate in this case.

Mistake #3

Incorrect pairing of the beams themselves. Here you need to understand that these are not simple wooden beams, but I-beams, and attaching them with an overlap is a big mistake. They must be placed end-to-end and secured with plates.

Do not use perforated tape to prevent the beams from tipping over later. You need to use accurate calculations using a calculator.

Mistake #4

Using incorrect fasteners. The most awkward thing seems to be the use of polyurethane foam by builders to seal holes. The bookmark must be strictly special. It is forbidden to use the wrong dougong, this will disrupt the load-bearing capacity of the floor, and the entire structure may collapse.

Ordinary screws are also not used for I-beams, since they themselves cannot withstand heavy loads. It should be remembered that screws are not structural parts - they can only attach something light in weight

Also pay attention to the dougong - if its height is insufficient, then it cannot be used. Size matters too - a small bracket is not acceptable

Mistake #5

Use of third-party parts not provided for in the design. There is no need for any additional reinforcement just “for insurance.” The usual fastening of I-beams is already tight and does not require unnecessary parts. The figure shows typical installation errors.

Average prices in the Russian Federation

The cost of all I-beam products as of March 2022 is, on average, in the Russian Federation:

- Steel:

- for 1 ton – 51,700 rubles;

- for 1 m – from 845 to 16,350 rubles.

- Wooden:

- 1 m – from 220, 300, 430 to 900 rubles.

- JB:

- 1 PC. - from 850 to 4,500 rubles, up to 22,340 - crane, the largest.

The total cost is affected by the size and number of I-beams. The country (manufacturer) and region of the Russian Federation also matter. The most expensive prices for I-beams are in the Moscow Region, St. Petersburg and the northern regions .

Price lists with prices are available on the websites of official manufacturers of I-beams.