The corrugated sheeting must be secured with self-tapping screws (to metal surfaces or a wooden frame) and rivets (sheet to sheet).

To install a profiled sheet, in most cases a frame is made. The structure is made from a metal profiled pipe (square, rectangle), wooden slats, a plasterboard profile, and an ordinary corner. Sometimes they make wall cladding by mounting the sheets directly to the brick or stone.

How and with what in each specific case to fix the corrugated sheet?

Self-tapping screws (self-tapping) for metal with a metal washer and rubber seal

A self-tapping screw (commonly a self-tapping screw) is made in the form of a rod with a tip resembling a drill, a triangular thread and a head for a wrench or a screwdriver. In addition to screws with a drill tip, screws with a sharp tip are produced. To fasten the corrugated sheet, complete with a screw, use a press washer and a rubber sealing gasket.

We apply:

- for attaching corrugated sheets to metal surfaces;

- with steel thickness up to 12.5 mm;

- without pre-drilling holes;

- for installation of corrugated sheets on roofs, for cladding facades, pediments, making gates, wickets, etc.

We do not use:

- for fastening sheets to tool and high-carbon steels;

- for binding metal profiled sheets together;

- for fastening to wooden structures;

- for fastening to metal less than 1 mm thick.

How do we determine quality?

When purchasing, we require a quality certificate that reflects the characteristics according to the DIN standard, including:

- material – steel S1022;

- zinc coating with a thickness of 12-12.5 microns for premium self-tapping screws (letter M on the screw head) and 7.7-8.2 in the standard version (letters MC);

- a layer of coloring polymer protection is applied to the head on top of the zinc;

For fastening to a frame with a thickness of 2.32 mm, we use products for drill No. 1, with a diameter of 4.8 mm, pitch 2.12. For metal, 5.5 mm drill No. 3, 8.5 mm - No. 4, 12.5 mm - No. 5. Thread pitch 1.8. Self-tapping screws of large diameters must be coated with zinc with a thickness of at least 12 microns.

We select the length of the self-tapping screws depending on the purpose. To attach the profiled sheet to the lower wave, choose a size larger than the materials being joined by 3mm. When screwed into the upper wave, for example, to attach skates, the length increases by the height of the profile.

The industry produces 3 types of self-tapping screws according to the shape of the head:

- hexagonal;

- cruciform;

- anti-vandal.

For normal installation, it is easier to work with a hexagonal head shape. We use anti-vandal screws for fences and cladding, the removal of which from the outside will provide free access to the room or territory. Installation of products is done with a special tool.

Important nuances when attaching corrugated sheets with self-tapping screws:

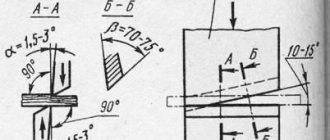

- We tighten the screws with a washer and a rubber gasket strictly perpendicular to the plane of the sheet.

- According to the characteristics, the screws are suggested to be screwed in at 2500 rpm, but it is difficult to calculate the force by touch. Tighten the screws so as not to squeeze the rubber washer. A flattened seal will crack over time and will not create a tight seal.

- We do not use rubber seals where monolithic fastening is required.

- In places where unauthorized access to fasteners is possible, we use anti-vandal screws or use self-tapping screws with a notch that prevents arbitrary unscrewing.

Fastening corrugated sheets with self-tapping screws: high-quality installation technology

If you use self-tapping screws rather than rivets, then you should take into account the fact that it is better to refuse to use a drill without a torque and rotation speed regulator. The reason is that this fastener requires a rotation speed of 1500 rpm to screw in. In this case, the installation of self-tapping screws to the surface should take place at an angle of 90 degrees.

Additional drilling of the material should not be used if the profile thickness of the metal purlins is up to 2 mm.

For the construction of wall structures, fences and fencing, it is advisable to use self-tapping screws of larger diameter. This fastening element is more durable, which allows it to easily withstand high wind loads. For roofing work, a self-tapping screw of a smaller diameter is used, and the reason is that the self-tapping screw in this case works in shear.

How to attach profiled sheets to a wooden frame?

For roofs mounted on wooden sheathing, there is no alternative to traditional metal screws. Select screws with the largest thread pitch. The larger this parameter, the more reliable the mount.

Vertically located profiled sheets that do not require a hermetic fastening, in order to save money, are fastened with galvanized self-tapping screws with a monolithic press washer. In everyday life it is an ordinary self-tapping screw with a wide head. For screwing, a Phillips screwdriver is inserted into the screwdriver.

If the sheathing is made of DVL, chipboard, etc., we use screws with double-threaded threads. For the roof, we make a set of washers and cuffs ourselves, selecting the diameter of the screw.

We do not recommend:

- Use standard wood screws, including those intended for fastening plasterboard sheets. This fastener has a countersunk head and, when screwed in, will damage the surface of the corrugated sheet.

- Use screws with a drill tip. Wood does not require drilling, a sharp self-tapping screw is screwed in more securely, and the passage through corrugated sheets makes it acceptable for a large amount of work.

Static rigid bonding of metals

Applicable in structures that are not subject to dynamic deformation. The mixtures used for such gluing form a very hard and durable seam that can withstand heavy loads. In fact, two parts after such gluing form a monolithic structure that is very resistant to shear rupture. In this case, glue such as PURAFLEX 9155 or Maple-812 is used.

The disadvantage of a rigid connection of parts is the fragility of the seam, therefore those structures that are subject to deformation require deformation gluing and the choice of a different adhesive.

Rigid bonding is most widely used in construction and machine tool production.

Preparing surfaces for gluing

Is it possible to attach corrugated sheeting to shell rock (limestone, brick)?

We mount the sheets directly to the wall made of stone or brick using dowels and anchors. To install, pre-drill holes in the metal. We select fastener heads with a monolithic wide washer. The shape of a plastic insert with a shimmer that serves as a seal. We make the hole in the corrugated sheet 0.5 mm larger than the diameter of the insert.

We recommend:

- For quick installation, use dowels with impact screws. They differ from traditional screws and screws in the shape of the thread. Disadvantage: if struck, the surface of the sheet can be damaged.

- Do not attach sheets to surfaces with protrusions or uneven surfaces.

Improved bonding quality

As mentioned earlier, the preliminary preparation of surfaces has a great influence on how the composition will glue the metal. Using sandpaper, the surface must be thoroughly cleaned of rust and other solid contaminants. The cleaning process also requires removing paint, old glue, and other layers covering the bare metal surface. It is best to use 120–240 sandpaper grit; it will create the necessary scratches on which the glue will cling more strongly. After mechanical cleaning of the surface, it is thoroughly degreased using solvent or acetone. It is not recommended to use gasoline, kerosene or other paint thinners; they leave a thin layer of foreign material on the surface of the workpieces being glued, which will prevent them from gluing well.

Additional measures that will allow metal parts to be glued together better are the use of special primers. They are applied to the surface to be glued before they are directly glued and serve to improve adhesion between the adhesive composition and the material.

Glue BF-2

For example, no matter how good the adhesion between epoxy resin and a metal surface is, BF-2 glue has the greatest adhesion to metal among the available adhesives. Therefore, this primer is widely used among yachtsmen, where it is necessary that the epoxy firmly glues two parts together and the seam is not afraid of moisture. To do this, apply a thin layer of BF-2 to the carefully prepared areas to be glued. Its layer is dried for an hour and a half at a temperature of 130 to 180 degrees. The main thing is that the glue layer dries and does not burn or overheat. Next, you can glue it with epoxy resin according to the instructions; the glued seam with this connection will be much stronger than without the use of BF-2.

How to connect sheets of profiled metal to each other?

The standard thickness of profiled iron is 0.4 mm. It is unreliable to connect two sheets using self-tapping screws, for example at an overlap, since the fastening is fragile and depends on the thread pitch.

To solve the problem we use rivets. The fastener consists of two parts, which are made of aluminum. Rivets are installed in pre-prepared holes and do not require access to the reverse side. For installation we use a rivet device. In places where hidden installation of rivets is required, we use a hole punch (special pliers holders that pierce the corrugated sheet from the end of the wave).

Rivets can be used as fasteners for installing roofing, fence cladding, etc. The disadvantage is labor intensity. A through hole must be drilled for each rivet.

When installing the roof, we do not recommend using sealant in overlap areas. The material changes geometry with temperature changes and the seal will eventually cease to perform its intended function.

Sheet metal welding methods

Metal sheets of medium thickness are welded in a stepwise manner. The entire welding strip is conventionally divided into sections of 10-20 cm, after which these sections are welded alternately. Each subsequent seam overlaps the previous seam by 1 cm. This technology allows you to avoid temperature deformations of the metal.

Welding of thin sheets of metal is usually done end-to-end, with flanged edges. Butt joints on a lining, without flanging, are also allowed. There is welding of cylindrical products. For example, welding to a flanged bottom of a cylindrical body or welding to a flanged bottom body.

Welding thick metal (more than 4 mm) is performed in several passes. This is the so-called multilayer welding. The weld seam is filled several times. Before applying each subsequent layer, the previous layer is cleaned of scale. Multilayer welding is more reliable, but leads to an increase in consumables.

Other methods of installing corrugated sheets

Screw and bolt connection

The corrugated sheet is attached to metal surfaces using screws, for example, when used as casings on machines, for fastening to special steels. We drill holes in the sheet and the base on which installation is taking place, cut the threads and install.

A bolted connection is used in a similar way, but fastening requires drilling through holes both in the sheet and in the material to which the installation is taking place. Bolts are used to connect corrugated sheets to metal and wooden frames, preventing vandalism and unauthorized access.

Types of glue for metal products

Of the many types of glue designed to glue metal to metal, several groups can be distinguished:

- Double-sided tape. It is produced in the form of a synthetic tape of various thicknesses with an adhesive composition applied to both sides. The width of the tape is selected based on the desired width of the adhesive joint. It has a high degree of convenience for gluing metal parts. The thickness of the tape allows you to obtain a sealed glued seam in the event of a loose fitting of the parts. The disadvantages of double-sided tape include the low strength of the glued seam and low durability.

- One-component mixtures. Presented in the form of a variety of adhesives based on rubber or silicone. The composition that makes it possible to glue parts together polymerizes in air or under the influence of moisture in the air. The hardened composition resembles dense rubber. The most versatile in use, they allow you to glue not only metal, but also products made from other materials. Among the disadvantages, it is worth noting the low strength of the adhesive seam and the need for careful preparation of the surfaces to be bonded.

- Two-component adhesive. Polyurethane or epoxy resin is used as a base. Special hardeners are used for polymerization. They can be either liquid (for example, “moment” glue) or in the form of a paste (cold welding). It has excellent adhesive properties, the seam is strong and durable. Allows you to connect workpieces made of different materials. Two-component compounds form the strongest and most durable seam, which sets much faster than a one-component one.

Double sided adhesive

One-component mixture

Two-component adhesive

As you can see, in order to glue metal, there is a large assortment of adhesive mixtures presented by different manufacturers. Therefore, when answering the question of how you can glue metal to metal, you should consider in more detail all possible methods and options for implementing a connection using glue, and after that it will be possible to make an unambiguous conclusion about which glue is best suited in a particular case.