What is the difference between carbon steel and stainless steel?

Steel, a term that actually describes the entire family of metal alloys, is a versatile and common type of metal with a wide range of uses and applications. There are many grades, but most types of steel fall into two broad categories: carbon steels and stainless steels. Although they have the same basic composition of iron and carbon, types of steel typically contain many alloying elements. Carbon steel typically has less than 10.5% chromium content, but steel must contain at least 10.5% chromium to be considered stainless. These differences give each type of steel its corresponding properties.

About instrumental

Tool steel is an alloy of hard steels from which cutting tools are made. The following brands are used to make knives:

- D2 (57 HRC). This steel is quite tough and wear-resistant and is made in the USA. It is used to make large industrial tools, with which softer shapes are cut and stamped. Unlike carbon D2, it is more resistant to corrosion. It is worth noting that to sharpen a D2 knife you will need the appropriate equipment. It is noteworthy that steel is absolutely resistant to corrosion processes. In Russia, the analogue of D2 was the X12MF.

- Elmax (Austrian made). Initially, this chrome-molybdenum-vanadium powder tool steel was used to make cutting elements for equipment used to process plastics. Later it began to be used as knife steel. The blades are characterized by high corrosion resistance, strength and ease of sharpening. The blade remains sharp for a long time. The hardness of Elmax knives on the Rockwell scale varies from 58 to 62 units. According to experts, Elmax is similar in its characteristics to the RWL34 and S30V brands, and in its composition - to 440C (59 HRC). Due to the presence of vanadium, which is not provided for 440C, Elmax blades hold sharpening well at various angles and are perfectly polished. The disadvantage of knives is that they do not withstand impacts and breaking loads well.

- ZDP-189. This powder tool steel has been produced in Japan since 1996. The advantages of the brand are its high impact resistance and corrosion resistance. It is worth noting that some knife manufacturers carry out a hardening procedure, after which the cutting products have a hardness of 69 units. It is noteworthy that such blades should be protected from impacts and heavy loads. Japan produces a similar steel known as Cowry-X.

What is stainless steel

Stainless steel refers to a type of steel that is defined by the addition of chromium and some other alloying elements such as nickel. It is sometimes called stainless steel because it is designed to resist oxidation and is therefore "non-oxidizing." When exposed to oxygen, iron oxidizes, causing rust, but chromium can be exposed to oxygen without undergoing this process. Therefore, a protective layer of chromium is applied to stainless steel, which creates a barrier between ambient oxygen and the iron content of the metal. This allows it to resist corrosion or rust and makes it "stainless".

Which is better: stainless steel or carbon?

Disputes on this topic have been going on for a long time. But this formulation of the question is not entirely correct: the word “carbon” refers to the percentage of carbon in the alloy, and the definition “stainless” emphasizes the ability of the material to resist corrosion.

The fundamental (but not the only!) difference between one substance and another is rust resistance. In addition, structures made of carbon steel quickly absorb foreign odors, while stainless steel is not susceptible to this. This can be especially important when choosing household steel products (for example, when purchasing kitchen knives).

A composition with a high carbon content has better cutting properties. Its pliable structure lends itself better to sharpening, and its cutting edge will be thinner than an edge made from a non-corrosive alloy.

The areas of application of the two steels are also different. Carbon is used to produce small parts and tools that do not require the improved properties of the metal. It is in demand in areas where durable metal is needed in large quantities: for example, when laying highway networks.

Structures that work with aggressive mixtures are made on the basis of stainless steel. They are installed in the chemical, oil and gas industries. Stainless steel is preferred when creating parts with improved strength and durability (medicine, aircraft, and shipbuilding).

© ZSPA - pipeline parts, 2022 Supply of pipeline fittings throughout Russia and the CIS

Source

Types of stainless steel

Different levels of chromium in stainless steel give it different properties, with lower chromium content generally resulting in cheaper but less strong steel. There are different types of stainless steel, including:

- Austenitic , the most widely used type of stainless steel with low yield strength but high corrosion and heat resistance, commonly used in household cookware, industrial piping and tanks, construction, and architectural facades—it is the largest family of stainless steel, accounting for about two-thirds of all stainless steel production become

- Ferritic steel is generally nickel-free, often has better resistance to corrosion, heat and cracking than more common types, and is often used in washing machines, boilers and interior architecture.

- Martensite , which tends to be magnetic and less corrosion resistant than other stainless steels due to its low chromium content - these materials are very hard and strong and are used to make knives and turbine blades.

- Duplex , a composite of austenitic and ferritic steels, making it strong and flexible, with twice the yield strength of austenitic stainless steel used in the paper, pulp, shipbuilding and petrochemical industries.

- Precipitation , which has the corrosion resistance of austenitic metals, but can be strengthened to higher strength, and can therefore be extremely strong when other elements such as aluminum, copper and niobium are added.

Advantages

- Corrosive properties

- High and low temperature resistance

- There is a wide variety of types

- Durable and very durable

- Low maintenance and easy to clean

- Durable at relatively low life cycle cost

- Can be given a special finish if an attractive cosmetic appearance is desired and will not tarnish easily

- Eco-friendly and recyclable

Flaws

- High cost especially with initial costs

- Metal can be difficult to handle, especially without the most high-tech machinery and technology.

- Often leads to costly waste and rework

Applications

Stainless steel has a wide range of uses and industrial applications, depending on the type of steel used. Stainless steel was first used in the automotive industry in the 1930s by Ford and has been used in automobile exhaust systems, grilles, trim, and structural components ever since. This extends to the aircraft industry, where it is used in aircraft bodies, jet engines and landing gear. Its corrosion resistance, low maintenance and ease of cleaning make it useful for transport and handling chemicals, and it is often used in clean and sterile environments. Thus, medical technology is also widely used.

The strength, durability and flexibility of some stainless steels make them a common feature in architecture, which is also supported by its aesthetic features and attractive finishes. For example, stainless steel is often used in the Eurostar terminals in London and the Helix Bridge in Singapore.

One of the most common everyday uses of stainless steel is in the food and catering industry, where it is used to make cookware, cutlery, kitchen utensils and appliances. Cookware such as knives are made from less ductile grades of stainless steel, while more ductile grades are used for grills, ovens, pots and sinks.

STAINLESS STEEL QUALITY ASSESSMENT

Evaluation of the quality characteristics of stainless steel depends on various parameters, such as the amount of additives, joining method, etc. After welding at the seams, stainless steel loses its resistance to corrosion, which can lead to the formation of rust and then to its destruction. Painted stainless steel will need to be cleaned of rust and re-polished, which will cause the steel to lose its resistance to moisture. To evaluate stainless steel in advance, you need to resort to a salt solution: if the material is of high quality, there will be no stains on the steel.

Carbon steel

Carbon steel, on the other hand, has much lower levels of chromium and is instead a carbon-iron alloy with only a few other materials, if any, as part of its composition. As a result, it can be called "low alloy" steel. Both stainless steel and carbon steel have this basic composition, but carbon steel can be defined by its carbon content. This is usually around 2–2.5%, but often varies. Although carbon steel is susceptible to rust, unlike stainless steel, it is often cheaper and has its own mechanical properties depending on its carbon content.

Low carbon steels are weaker and softer, but are easy to machine and weld; whereas high-carbon steel is stronger, but much more difficult to machine.

Types of Carbon Steel

The defining element of any carbon steel alloy is its carbon content, which is why this is how the different types of carbon steel are ordered and classified.

- Low carbon steel : The most widely used form of carbon steel with less than 0.25% carbon content - they are typically relatively weaker and softer, but are easier to weld and ductile, and are therefore often used for low pressure machining and welding. Price

- Medium carbon steel : With a carbon content of 0.25-0.6% and a manganese content of 0.6-1.65%, these metals can be improved by heat treatment, although this can only be done on very thin sections unless additional is added alloying elements. - these steels are stronger, but less ductile than steels with low carbon content.

- High carbon steel : This is the hardest and strongest carbon steel, with the lowest ductility, very wear resistant and almost always quenched and tempered - they typically have a carbon content of 0.6-1.25% and a manganese content of 0.3-0.9 %.

Advantages

- Enhanced Strength

- Cheaper than stainless steel

- Wear-resistant

- Durable and shockproof

- Safe to handle and work compared to other metals

- Environmentally friendly and easy to recycle

Flaws

- Strong but sometimes difficult to work with

- Fragile, not easily bent or deformed

- More susceptible to rust and corrosion

- Less attractive appearance, stainless steel finish cannot be achieved

Applications

Different types of carbon steel are applicable in a wide range of industries and sectors. Low carbon steels can be used in automobile body parts, pipes, bridge structures and parts, and food cans. Medium carbon steel is used to make railway tracks, train wheels, crankshafts, gears and machine parts requiring higher strength and toughness and similarly high carbon steel is used in cutting tools, high tensile wire springs and dies due to its hardness .

How to distinguish stainless steel from other metals

Stainless steel is widely used in the production of products and equipment, the construction industry and many other industries. Consumers often wonder how to distinguish stainless steel from other metals, because at first glance they are very similar. To solve this problem, there are some expert tips that will help you understand exactly what kind of metal was used.

How to distinguish stainless steel from aluminum

One of the most popular types of metal in production is aluminum. It is often used to make household products. To determine exactly what kind of metal you have, use these tips and perform a few simple tests.

- The easiest way is to use a magnet. Aluminum is paramagnetic and practically non-magnetic. Even a child can carry out a test using a magnet at home.

- Using a plain piece of paper. To carry out the test, you will need to remove dirt from the surface of the object being tested and run it with paper, pressing firmly on the product. If you have stainless steel in front of you, then there will be no traces left on the sheet, but with aluminum, gray stripes will appear.

- Another criterion for distinguishing stainless steel from aluminum is the color of the metal. If the surface is smooth and shiny, then this is stainless steel; aluminum has a matte surface without a characteristic shine.

- Thermal conductivity indicators. To install metal accessories, simply pour water into a container and bring to a boil. In aluminum cookware, water will boil much faster, since the thermal conductivity of this metal is much higher.

- Separately, we can distinguish chemical methods for determining stainless steel using various acids and alkalis. When treating aluminum with alkali, brown spots remain on the surface; stainless steel will not have any visible changes.

- Exposure to copper sulfate. You can find this reagent in any agricultural store. After application to the aluminum surface, cloudy stains will certainly remain. Vitriol has no effect on stainless steel.

Using these methods will allow you to determine at home with 100% accuracy where the product is made of aluminum and where it is made of stainless steel.

How to distinguish stainless steel from other types of steel

In appearance, all steel grades are almost identical, but at the same time they have different technical characteristics. This means that products made from different types of steel behave differently. To distinguish stainless steel from another grade of steel, you can use several methods:

- Use of nitric acid. This chemical liquid helps distinguish stainless steel from carbon steel. If you apply a few drops to the surface of the steel, a reaction will begin in which caustic steam will be released. This reaction is typical for carbon steel; no changes will occur with stainless steel.

- Check the reflection on the surface. Stainless steel has bluish-yellow tints on its surface.

- Marking. Steel products are always marked with the type and grade of material used. If the numbers are preceded by the letters “STAINLESS”, this means the use of alloy steel.

These simple tips will help you accurately determine the presence of stainless steel.

How to distinguish stainless steel from non-ferrous metals

It is difficult for an ignorant person to separate stainless steel from non-ferrous metals. This will require complex chemical actions and reagents. Still, you can use some expert advice:

- Take a small piece of the sample and drill a hole. In duralumin, the chips move away in a spiral and do not stick to the drill.

- Hydrogen peroxide and 20% sodium sulfide can be used. When these reagents are applied to a cut, the surface of non-ferrous metals will darken.

Distinctive characteristics of food grade stainless steel from technical grade

It must be said that the division of stainless steel into two types has a special character, since they differ in areas of use. The main difference between them is the surface treatment. For the food type, the surface is of particular importance, since the metal will come into contact with food products.

Distinctive features of food grade stainless steel are a smooth surface with a high level of processing. Food grade stainless steel is a highly alloyed metal that is resistant to corrosion and rust.

The amount of additives affects the quality of product operation. The food grade is susceptible to the influence of an aggressive alkaline environment, so it adds more metal impurities.

Based on the composition and markings, you can accurately determine what type of stainless steel it is.

Results

To determine the type of metal and the distinctive features of stainless steel, it is enough to know the basics of chemistry and some characteristics of metals. By conducting simple chemical experiments or using simple household methods for installing stainless steel products, you can easily determine what type of metal was used.

We also recommend reading:

Do you want to ensure the durability of your construction? Choose an aluminum profile!

Aluminum pipes in our time: their advantages, practicality and scope of application.

Tips for choosing a cornice for the living room

Can stainless steel be welded to carbon steel?

While it is technically possible to weld these different types of metals together, it is widely believed that it is not recommended. Welding on carbon steel and stainless steel is not usually done because they have different levels of electrical conductivity. Carbon steel is usually preheated during resistance welding because it is more electrically conductive and does not heat up as quickly as stainless steel. Therefore, achieving the desired weld temperature is often extremely difficult. Therefore, it is generally recommended to weld steels of the same type rather than mixing and matching them.

About the properties of steel

According to experts, in a good knife, the blade steel should have the following basic properties:

- Hardness. This indicator is measured in HRC on the Rockwell scale. A high value indicates that the blade will not deform or break under physical stress.

- Flexural strength. Due to the impact strength of steel, cracks and chips do not form on the surface of the blade under load. It is noteworthy that strength is directly related to hardness. The higher the viscosity, the less rigid the alloy is.

- Wear resistance. This property indicates the steel’s resistance to damage from solid abrasive particles.

- Corrosion resistance. Steel is not susceptible to corrosion and rust under the influence of external factors, namely moisture and salts.

- A good knife should remain sharp for a long time. This blade maintains a sharp cutting edge even after several cuts.

Comparison of carbon steel with stainless steel

Ability to absorb odors

Carbon steel itself has a pleasant smell (especially when clean and freshly sharpened), but it quickly absorbs foreign odors. If we plan wood with a carbon knife, this is even great, but for cutting food it is not very good: the “aroma” of onions or smoked fish will take a long time to wash off the tool. There are no such problems with stainless steel; it itself is also odorless. For kitchen knives this is a definite plus.

Composition of alloy steel (stainless steel)

The composition of alloy steel (stainless steel) includes such basic elements as chromium, titanium, nickel, niobium. The duration of operation of products directly depends on the quality of the steel composition, as well as on the brand chosen by the manufacturer. Stainless steel is divided into different grades, and each grade has its own GOST.

It should be noted that stainless steel is gaining popularity due to its properties and quality of the alloy, namely: a high level of strength, ease and ease of maintenance, reliability and unshakable resistance to corrosion.

During its production, stainless steel goes through several stages of processing. After obtaining an alloyed alloy with the addition of all the necessary elements for strength, the alloy is processed through casting and cutting. In more detail, such processing can be of different types, that is, mechanical, milling and thermal.

Varieties

Stainless steels are divided into several types:

- ferritic;

- martensitic;

- austenitic.

Several types of stainless steel are used for knives.

Martensitic

Materials with a martensitic structure lend themselves well to hardening. These steels include grades 65Х13, 95Х18, 440С. They have a high degree of hardening compared to simple carbon alloys (1050-1100 versus 750-800), but their hardness is one or two Rockwell units lower. This is due to the fact that chromium has a binding effect on carbon, which reduces the hardening structure of martensite. This gave rise to the name.

Ferritic

The ferrite structure is soft and cannot be hardened. The corrosion resistance of this material is a solid C on a five-point scale. This includes brands 04Х13, 02Х18.

Austenitic or chromium-nickel steels

Austenitic stainless steels are steel grades: X12N8, X12N8T10. The material can be hardened, but at the same time the viscosity increases and the hardness decreases.

Main advantages:

- High corrosion resistance prevents rust from water, acids, and dirt.

- Does not fade over time.

- It has monstrous viscosity and plasticity. When the tensile load is applied, the wire elongates 16 times. Even brass and copper do not have this property. After deformation, it freely returns to its previous shape.

- During cold forging, the material is capable of strongly hardening (up to 45 Rockwell units) while maintaining viscosity.

Ferritic-austenitic or two-phase alloy

There is a separate group: ferritic-austenitic, otherwise such samples are called duplex or two-phase steels. Duplexes are approximately half ferrite and half austenite and have characteristics of both phases. To obtain such an alloy, in addition to chromium and nickel, molybdenum and vanadium are added to the mix. This is necessary to increase tensile strength and facilitate the welding process.

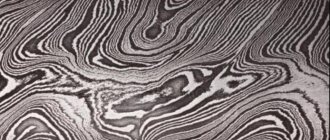

Knife made of two-phase alloy.

A very important indicator of duplexes is their unique strength. Due to its low price, as well as ease and flexibility in processing, it is successfully used in many industries.