| Place | Name | Characteristics in the rating |

| The best foreign manufacturers of drills |

| 1 | Metabo | High strength |

| 2 | Haisser | The most durable drills |

| 3 | DeWALT | The best ratio of price and quality |

| 4 | DIAGER | The most popular drills in the European Union |

| 5 | Ruko | Best Step Drills |

| The best domestic manufacturers of drills |

| 1 | Ineterskol | Best Performance |

| 2 | Anchor | Buyer's choice |

| 3 | Tulamash | High performance drills |

| 4 | Bison | Optimal combination of quality and price |

| 5 | Attack | Highest strength |

Today there are drills from different manufacturers on the market, and not all of them are distinguished by their reliability and quality - there are even some that cannot make even one hole. To understand the kaleidoscope of companies and find the most effective product on the market, it is not at all necessary to conduct your own research - just read our review.

The rating of the best manufacturers of drills for wood, concrete or metal took into account the characteristics of the products and the opinions of professionals who prefer a tool from one of the companies presented here.

Best DEWALT DW Titanium Drill Bits

DEWALT Pilot Point Titanium Drill Bit Set

- Featuring heavy-duty titanium guide points that start on contact and help prevent the drill from moving in different directions. DEWALT kits include commonly used drill bits for a range of metal and wood drilling applications.

- Non-scrolling cylinders help prevent drill bits from slipping, while the tapered blade increases life and helps reduce the risk of breakage.

- The durable carrying case keeps your drill bits ready to go. Titanium pilot point is made to provide 2x longer life than black oxide.

- Patented tip prevents slipping

- Titanium coating applied to increase service life.

Irwin Tools Drill Set

- The Irwin 29 Piece Cobalt M-35 Metal Index Drill Bit Set includes drill sizes ranging from 1/16" to 1/2" in 1/64" increments.

- Made with blade material for strength and durability, and cobalt steel to extend cutting edge life.

- 135 degree split tips start drilling on contact and cut with less force

- The smaller shank above the 3/8-inch point allows you to use a larger drill bit in a 3/8-inch chuck, and you can select the right size using a handy tap and drill selection chart.

- The rubber remolded box protects against damage from accidental drops, and you can remove the cartridges to easily transfer bits from the case to the job site.

- The best set of drills and bits VonHaus 100-Piece for any material

VonHaus drill set 100pcs

This very practical and essential set of tools is designed to meet everyday drilling needs in a variety of materials: wood, masonry, concrete and metal.

- Titanium coated chrome vanadium steel drill bits are designed for maximum speed and clean, precise drilling.

- Includes a durable storage case with molded cores and clear markings for easy identification of drills and bits

- The drills are arranged in a logical and color-coordinated sequence so you can quickly find the drill you need.

- Clear viewing window.

- Convenient mounting and ergonomic curved handle for easy storage and transportation.

Best Drill and Bit Set BLACK + DECKER BDA

BLACK & DECKER BDA Combination set contains drill bits for perfectly precise hole sizes and frequent use.

- Offers a variety of drill bits for the most common materials: wood, metal, plastic and masonry.

- Along with drill bits, it also contains a variety of 2" and 1" screwdrivers for everyday use.

- Comes with a durable, portable hard case for extra storage.

Drill set Makita T-01725

The Makita T-01725 Drilling Tool Set, consisting of 70 bits, offers a complete range of solutions for drilling and other construction applications.

- Each drill and bit is coated in black oxide to resist corrosion, with a proprietary heat treatment designed to extend bit life. Manufactured with a 1/4" Ultra-Lok hex shank.

- Made from high speed steel with precision tips spaced at 135 degrees to prevent slipping on surfaces.

- Professional, maximum magnetic 3" bit holder and impact wrenches provide super strong fastener retention.

Bosch 34-piece drill set

This set comes with a wide selection of both drills, bits and more.

- The drill bits in the set are suitable for different materials: wood, metal, concrete

- The tips are designed with better gripping force to hold the drill bit.

- The drill bits included in the kit work with materials such as wood, metal and concrete.

- Provides a versatile case for users who want accessories easily accessible for everyday tasks.

Solid Cobalt Drill Set

Premium Hard Cobalt M42 Super Fast Steel.

- From 1/16" to 1/2" in 1/64 increments (you won't miss any dimensions).

- Hardness with high heat treatment 68-70 HRC.

- The 135 degree split point prevents "walking".

- The triangle shank prevents the Chuck from rotating.

Set of 20 DEWALT DW1177 drill bits

DEWALT DW1177 20-Piece Drill Bit Set contains 1/16" to 1/2" drill bits.

- Black oxide coating for greater wear protection and durability.

- The parabolic design also gives these bits greater strength.

- 135 degree split design, which reduces sliding and walking, and makes it easier to launch without slipping.

- The bit set includes a durable hard case for storing the bits.

- The hard case includes a soft-grip sliding lock that holds the case securely to prevent bits from getting lost.

- Ideal for drilling in metal, wood and plastic.

Cobalt drill bit set CO-Z 5-pcs. (50 sizes)

The CO-Z 5 piece step drill bit set replaces 50 individual drill bits.

- Dual-channel design allows for faster and smoother drilling.

- Cobalt steel along with titanium coating ensures this set has outstanding durability and these drill bits will stay sharp for years to come.

- Ideal for cutting holes on steel, aluminum sheets, etc. d.

- The well-organized box provides users with easy storage and transportation.

America Drill 29 Piece Drill Set

The Drill America DWD29J-CO-PC Qualtech drill bit set contains 29 gold oxide coated cobalt steel drill bits in sizes ranging from 1/16" to 1/2" (in 1/64" increments).

- The self-centering 135 degree split point penetrates solid material without a pilot hole and produces smaller chips that reduce clogging compared to the 118 degree point.

- Cobalt steel provides longer tool life than high-speed steel drills and maintains tool strength and hardness at high drilling temperatures.

- The gold oxide finish acts as a lubricant and provides wear resistance, and the round shank accommodates most drill chucks.

- The set comes in a plastic case with labeled compartments for identification and organization.

Main types of concrete drills

A distinctive feature of a concrete drill from others is soldering. It is created from a strong alloy, due to which a hardness similar to diamond stones is achieved. Craftsmen call these types pobedit; these products differ in strength from other types that are created for metal or wood.

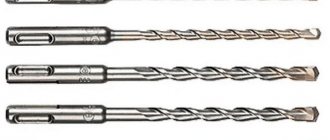

There are 2 main types by which concrete drills are classified:

- for a drill - consist of a shank for a nozzle, which is made in a cylindrical or multifaceted shape. The dimensions are small, the product is suitable for creating holes in many hard materials, for example, brick, foam block. It is recommended to use a high-power drill, which will allow you to drill into concrete,

- for a hammer drill - the drill is cylindrical in shape, has a shank, designations SDS PLUS or SDS MAX. The goods themselves are quite large and long, suitable for reinforced concrete structures.

If you need to create holes in a reinforced concrete structure using a simple drill, then it is not always possible to solve the problem with just a drill. You need to use a hammer drill, and for this tool, drills are divided into the following types:

- screw - used to create deep holes,

- spiral - suitable for large holes,

- flat - used for drilling passages of different sizes and depths.

For proper operation, you will need to not just insert the drill into the chuck, but snap it into place. To make this task easier, the products have a slight thickening at the very end. It should also be noted that the products are considered professional tools, since they can be used to create holes from 4 mm to 3 cm in diameter.

If you need a larger hole, then the crown type will come to the rescue. Such products make it possible to make a recess of 12 cm in diameter. The products are very durable and are produced in several versions:

- diamond - visually made in the form of a pipe or crown, mounted on a rod, the edges are coated with diamond, which ensures high strength,

- pobedit - similar to an attachment, the main difference from diamond is the absence of sputtering; it is replaced by special teeth made from pobedit.

It is recommended to use crown products for holes for sockets, switches or wiring, and other communications. To select a suitable concrete product for a drill, you will need to take into account not only the parameters of the element, but also the dimensions of the future hole. Based on this, the length of the drill is selected, which depends on the diameter:

- diameter 4 mm - length 5 cm,

- 5 mm - 10 cm,

- 6 mm - 15 cm,

- 8 mm - 25 cm,

- 10 mm - 54 cm,

- 12 mm or more - up to 100 cm.

It turns out that for large holes a long concrete drill is used. If you use thin instruments, there is a risk of damage due to increased load.

Useful tips for working with a concrete drill

It is important not only to choose the right device for creating holes in concrete surfaces, but also to have an idea of how to use it .

- Even before drilling, it is advisable to prepare a set of drills that will differ in their performance characteristics. You need to know that to effectively solve a particular problem, you should use concrete drills for a specific purpose with a drill or hammer drill. Thus, a home craftsman’s arsenal should include drills for working with concrete, ceramics, stone and other hard materials. However, it is possible that at the beginning of drilling the owner is forced to stop work due to the fact that the drill has reached the metal reinforcement. To cope with this obstacle, it is necessary to replace the concrete fixture with a metal drill at this stage of work. With its help, a hole is created in the reinforcement, and then they continue to drill the hole with a drill. At the same time, some craftsmen approach this problem a little differently: they simply perform a special sharpening of the drill, which allows them to work not only with concrete, but also with metal. However, only those who have sufficient experience and special skills can do this.

- When creating a hole in a concrete surface, you must prevent the drill from overheating . To do this, you need to take a break every 15 seconds of continuous drilling. The drill must cool naturally. In this case, the use of water or other liquid is considered unacceptable.

- There are situations when, having entered the thickness of a concrete surface, the drilling device encounters an obstacle in the form of a hard stone that it cannot cope with. To eliminate it, it is advisable to have a bump stop available. With its help, you can crush the stone, and then continue working with a drill on concrete again.

- Sometimes it happens that you have to create a hole in a load-bearing wall or ceiling. It is not advisable to work here with an impact drill; it is best to change it to a hammer drill. If you neglect this advice, it will not lead to anything good, because, despite the efforts and time spent, you will not be able to create a hole in this structure.

- When working with ceramics, you should use a product for concrete. In this case, it is necessary to disable the impact drill mode . Otherwise, there will be a risk that the tile will crack.

- If during operation the drilling device becomes dull, then to restore its performance characteristics, use a grinder in combination with a diamond blade. However, you can initially avoid such situations if you prepare a high-quality, expensive tool.

Sharpening

When drilling concrete surfaces, sooner or later there is a need to sharpen the working part, even if it is made of diamond or coated with diamond. For the procedure you will need to use a sharpener or a special machine. In addition, at home you can use a regular universal machine or sharpen attachments with a grinder.

It is important to inspect the drill tip before doing any work. It should have 2 “shelves” that are the same length. Otherwise, damage will occur during drilling, and the holes themselves will be of poor quality. The whole sharpening process is not complicated, the main thing is to ensure the evenness of the shelves:

- for concrete and other hard materials, the alpha angle is 200–300,

- the cutting edges must not touch the grinding wheel, otherwise there is a risk of breakage,

- When sharpening, it is forbidden to bring the drills to heat; from time to time you need to pause and cool the material; the use of water is allowed. If the working part is hot, then it must be left to cool in the usual way, since contact with water risks cracking the drill.

Sharpening a drill for concrete is a complex process that requires certain skills, so without knowledge it is better to turn to the experts.

How to choose a high-quality set of drills for metal, wood and concrete?

Many different materials are used for drills, depending on the required application (metal, wood or concrete). Hard materials such as carbides are versatile and can stay sharper longer, but they are much more brittle than steel and therefore more susceptible to fracture.

This is especially true if the drill bit is not held at a very constant angle to the workpiece. For example, when using a hand drill. Using a bench vise or, better yet, a drill press can help maintain a consistent angle while drilling.