As any specialist knows, for welding performed in an argon environment, tungsten electrodes are used, which are classified as non-consumable. They are distinguished by a wide variety of types, each of which is identified by markings applied to these products during the production process.

Types of tungsten electrodes

Understanding the characteristics of tungsten electrodes

Tungsten electrodes are refractory rods, with the help of which an electric arc is formed, which is necessary to melt the edges of the parts being joined and the filler material during the welding process. Such electrodes are used primarily for welding in a protective argon environment. They are used to weld various structures, including tubular ones. Tungsten was not chosen for this by chance, because it is the most refractory metal of all those found in nature.

Requirements for markings applied to tungsten rods during their production are specified in international standards, which makes it possible to classify these products as a certain type, no matter in which country in the world they were produced. According to these requirements, the marking of the electrode must reflect not only its type, but also its chemical composition.

Tungsten electrodes can be identified by the first letter “W” (tungsten) included in their designation. Most of these rods contain a small amount of alloying additives. The latter improve the technical characteristics of the product and increase its service life. The type of alloying element contained in the tungsten electrode is indicated by the second letter in the marking.

In the designation of tungsten rods you can find the following letters, which indicate certain alloying additives.

C (cerium oxide)

Tungsten electrodes containing this alloying additive are universal products; they are used for welding with any type of current and support stable arc burning even at low current values.

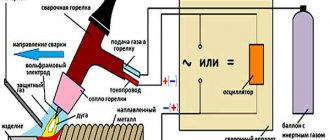

Diagram of an argon welding process using

Z (zirconium oxide)

Tungsten electrodes containing cerium oxide are used for welding carried out with alternating current. When using them, you must be very careful to ensure that the weld pool is not exposed to even minimal contamination. The arc created with the help of such rods is characterized by stability and high power. Compared to other types of products, tungsten electrodes with zirconium oxide can withstand significant current loads.

L (lanthanum oxide)

Products containing this alloying additive ensure easy ignition of the welding arc and its high stability, as well as rapid re-ignition. When using such rods, the risk of burning through the parts being connected is reduced, and the operating current is significantly increased. These electrodes are durable; they pollute the weld pool less when compared with products made from pure tungsten.

Welding modes of aluminum alloys (alternating current)

T (thorium oxide)

Tungsten electrodes containing thorium oxide are very popular, as they have many advantages. Most often, such products are used to connect stainless steel workpieces produced using direct current. Meanwhile, these tungsten electrodes also have a number of disadvantages. When using them for welding in enclosed spaces and when sharpening, the workplace should be equipped with exhaust ventilation, since thorium is a radioactive metal, the vapors and dust of which can have a negative impact on human health. In addition, when welding with such electrodes, carried out on alternating current, the arc can jump over protruding surfaces, which leads to a deterioration in the quality of the joint being formed.

Y (yttrium)

Products of this type are considered the most stable of all tungsten electrodes, which is why they are used for welding especially critical structures. Welding with their use is carried out using direct current.

P (pure tungsten)

This letter, present in the marking, indicates that the product is made of 99.5% tungsten. Tungsten electrodes, which do not contain alloying additives, ensure arc stability when welding carried out using alternating current. These are the rods that are used when welding aluminum parts in an argon environment.

In order for a specialist to obtain more complete information about tungsten electrodes, their markings also contain digital designations.

The first numbers after the letters indicate the exact content of the alloying additive as a percentage. Thus, the number 20 means that the electrode material contains 2.0% of the corresponding additive, the number 15 means 1.5%, etc. The second numbers in the rod designation, separated from the first by a hyphen, indicate the length of the product, expressed in millimeters.

The most common length is 175 mm, but electrodes are also available in lengths of 50, 75 and 150 mm. Parts with different geometric parameters are welded with tungsten electrodes of different sections, the value of which can be 1; 1.6; 2; 2.4; 3; 3.2; 4; 4.8; 5.6; 6.4 mm.

Table for choosing the diameter of a tungsten electrode for welding in argon, taking into account the strength and type of current

For example, let's decipher the marking of the WL 10-75 electrode. In addition to tungsten, it contains 1.0% lanthanum oxide. The length of this product, according to its designation, is 175 mm.

In order to be able to determine at first glance what type of tungsten electrode it is and what it can be used for, the ends of products of different brands are painted in different colors. Such marks can be applied in one of the following colors:

- green – products made of pure tungsten, designated by the letters WP;

- gray – WC 20 electrodes containing 2% cerium oxide;

- gold – products of the WL 15 brand, their composition is supplemented with 1.5% lanthanum oxide;

- black – WL 10 rods, which contain 1% lanthanum oxide;

- blue – WL 20, such electrodes contain 2% lanthanum oxide;

- white – WZ 8 electrodes, the composition of which is enriched with 0.8% zirconium oxide;

- yellow – WT 10 electrodes containing 1% thorium oxide;

- red – WT 20 rods, which contain 2% thorium oxide;

- purple – WT 30 electrodes containing 3% thorium oxide;

- orange – WT 40 brand products containing 4% thorium oxide;

- dark blue – tungsten electrodes WY 20, which contain 2% yttrium.

Color coding of tungsten electrodes

WY-20

Tungsten electrodes

WY-20

(in addition to pure tungsten, it contains 2% yttrium oxide) belong to the same group as WT-20, as they are designed for

DC .

But unlike thorium electrodes, yttrium electrodes

are safe for human health

.

They are considered the most resistant

to high welding currents among tungsten electrodes.

Do not contaminate the welding seam. Based on the totality of positive aspects, these electrodes are used when welding particularly critical structures.

Sharpening electrodes requires skill, as, according to reviews, problems arise with it.

Areas of use of tungsten electrodes of various brands

Tungsten electrodes belonging to each type have distinctive characteristics that determine their scope of application.

WP – green tip

Pure tungsten (WP) electrodes are used primarily for AC welding performed under argon. They are used to perform argon arc welding of products made of aluminum, aluminum bronze (copper-aluminum alloy), magnesium, nickel, and their alloys.

Electrodes of this type have the following characteristics:

- poor arc ignitability;

- short service life;

- poor tolerance of significant current load;

- safety for human health.

Copper welding modes with a tungsten electrode (for butt joints on a water-cooled copper pad or flux pad)

WC 20 - gray tip

WC 20 electrodes are also used for welding in an argon environment, but they are used to make connections between parts made of high-alloy materials, including stainless steels, highly alloying metals (molybdenum, tantalum, etc.), copper, nickel, titanium, as well as their alloys. Welding with such rods is carried out using direct current, connected in straight polarity.

The distinctive characteristics of tungsten electrodes of this type include:

- good arc ignitability;

- long service life;

- good tolerance of significant current loads;

- safety for human health.

Modes of argon-arc welding of titanium alloys

WL - blue tip

Electrodes marked WL (WL 10, WL 15, WL 20) are designed to perform work on alternating and direct current (straight polarity is used), with their help they carry out spraying, plasma welding, connection parts of small thickness made of ordinary and high-alloy steels.

We list the characteristics of tungsten electrodes of this type:

- satisfactory arc ignitability;

- long service life;

- good tolerance of current loads;

- safety for human health.

Modes for manual welding of stainless steel with a tungsten electrode

WZ - white tip

WZ 8 electrodes (white tip) are used for welding with alternating current in an argon environment. Using them, they perform argon arc welding of products made of aluminum, copper-aluminum alloys (aluminum bronze), magnesium, nickel and alloys of these metals.

The distinctive characteristics of tungsten products of this brand include:

- satisfactory ignitability of the welding arc;

- sufficiently long service life;

- good tolerance of current loads;

- safety for human health.

WT 20 – red tip

Products marked WT 20 are used for direct current argon arc welding (straight polarity is used). Such products are used to cook billets from high-alloy steels, high-alloying metals, copper, nickel, titanium, and their alloys.

Characteristics of tungsten electrodes of this type:

- good ignitability of the welding arc;

- sufficiently long service life;

- good tolerance of significant current loads;

- possible danger to human health.

The group of tungsten electrodes containing thorium also includes products of the WT 30 and WT 40 brands. Due to the significant content of this radioactive element in the electrodes, their use is not recommended; the vapors from them are harmful to the environment and human health.

WT-20

Tungsten electrodes

W T - 20

(the composition, in addition to pure tungsten, includes 2.0% thorium oxide) are most widespread in Russia, as for decades they have shown high efficiency, stability and relative versatility.

These electrodes are suitable for welding all types of steel, as well as tantalum, molybdenum and many other materials with direct current .

Technically they are capable of operating on alternating current, but are not designed for this.

They have easy arc ignition and relative durability. But a significant disadvantage of WT-20

at the moment reduces their consumption - thorium is

a radioactive

chemical element.

Dust from an electrode during sharpening, inhaled into a person's lungs, can have a significant impact on his health. Poorly ventilated areas intended for working with WT-20 and the long-term nature of the work themselves are also dangerous. All of the above does not mean that you should immediately abandon thorium tungsten electrodes, but it is advisable to strictly observe safety precautions

when working with them.

Criteria for selecting a tungsten electrode

When choosing tungsten rods, you need to focus on such parameters as:

- type, chemical composition and presence of alloying additives;

- diameter, which affects the thickness of the weld being formed;

- tip geometry, which determines many characteristics of the welding process;

- sharpening quality.

Naturally, the choice of a particular brand of electrode is significantly influenced by the characteristics of the parts being connected: dimensions, material composition, etc. When choosing tungsten rods, you can refer to reference tables or your own experience.

Basic criteria for selecting electrodes based on their properties

W.P.

Tungsten electrodes

WP

(contains at least 99.5% pure tungsten)

magnesium and their alloys using alternating current.

They have low resistance to welding current (its thermal effects) and durability.

Because of this, the electrode is sharpened in the form of a ball (rounding). Despite significant disadvantages, WP electrodes have an important advantage: they do not introduce any additives into the composition of the weld, since they consist of pure tungsten, for which they are very much appreciated in work where high demands are placed on the chemical composition of the seam.

Difference in light

Now you know why they put decals on electrical tungsten conductors. Let's look at the meaning of each color. But first you need to decide what exactly the color applied to the electrode means.

Each color shade carries information. The size of the tungsten rod, what material was used to make the conductor. If you learn the color codes like the multiplication table, you will instantly decide on a purchase.

Pay attention to this table, which deciphers all colors.

This table clearly shows that color implies numerical and alphabetic indicators.

It doesn’t matter what color the end of the electrical conductor is, the code begins with the letter W. After this, there is a letter responsible for the presence of additional metal from which the electrode is made. The letter value is followed by numbers.