Making ceramics with your own hands is a hobby for refined natures

Ceramic vases, pots, tea sets, candlesticks, plates, whistles and even musical instruments - you can create all this yourself.

To learn how to make ceramics with your own hands, the main thing is desire. Before becoming a ceramicist, try making a simple trinket out of clay, and you will understand whether it is worth spending money on buying equipment for the work. If something doesn’t work out, it doesn’t matter, soak the scrap and make a new figure out of it; before baking, the product can be modified endlessly.

- What is ceramics made from and where to get materials for work

- Methods for making ceramic products

- Pottery kiln - types and preferences

- How to choose a pottery wheel

- Benefits and pleasure from the ceramic hobby

What is ceramics made from and where to get materials for work

Ceramics is fired clay, which is the main material in the work of a ceramist. Unlike polymer clay, natural clay is of natural origin; it is extracted from the depths of the earth without being subjected to chemical or other types of processing.

Experienced craftsmen, in order to save money, extract and prepare raw materials themselves. This process involves several stages and is unlikely to deserve attention if you are just starting out and live in the city.

Clay for making ceramics must be greasy and free of pebbles and other debris, otherwise the craft will crack during baking. The finished mass is stored under certain humidity conditions.

Natural clay comes in different types :

- White is the most common, initially has a grayish tint, and after heat treatment it acquires a pleasant ivory shade.

- Red – contains iron oxide, which gives the raw material a greenish tint. The main color of the raw material is brown, after firing the products become red. It lends itself well to modeling, does not crumble, and is ideal for sculptures and large items.

- Porcelain – gray when raw and white after baking.

- Blue - more often used in cosmetology and folk medicine.

- Black or dark brown ceramic mass is the hardest clay, taking on an ivory hue after being kilned.

Red clay

Clays for ceramics are also classified according to processing temperature into low-melting, medium-melting, and refractory.

It is most convenient to buy ready-made pottery clay, focusing on the fraction size, color after firing at different temperatures and other characteristics and quality indicators. The cost depends on the manufacturer, packaging, texture. There are ready-made masses with additives for various tasks - modeling, molding, potter's wheel.

In addition to clay, you need glazes and enamels to coat products, pigments to give hand-made ceramics the desired shade, special additives to improve properties and heat treatment.

To glue the parts together, a slip mass - a kind of glue made from diluted clay. If you simply connect the elements, they may fall off when heated. All this is sold in specialized stores for ceramists.

Methods for making ceramic products

There are several ways to transform clay into a beautiful ceramic product.

Modeling is the most affordable way to make ceramic products with your own hands at home. Souvenirs, sculptures, dishes, toys or other crafts are sculpted by hand, as if from plasticine, helping themselves with special stacks or improvised devices.

Pottery making requires a turning wheel. With the help of this ancient craft, vases, jugs, pots, plates, and cups are still created today.

Knocking is the easiest option for making ceramics for beginners. The work uses a plaster mold, into which soft clay is placed, and after hardening, the figured product is removed. Plaster molds are attractive because they absorb excess moisture, helping the clay product to harden and dry.

Casting – molds are also used here, but of a different type. The diluted clay is poured into molds, the blanks are dried, removed and painted.

Clay crafts gain strength only after firing - processing in pottery kilns at temperatures from 900 to 1300 degrees. Finished souvenirs are coated with acrylic paints or a special glassy glaze for ceramics. In the case of glazes, another firing is required after coloring.

If you want to get a natural shade, use milking - cover an unpainted baked ceramic figurine with milk in several layers and bake again at lower temperatures.

Pottery kiln - types and preferences

Previously, kilns for firing ceramics were furnaces dug in the ground and heated exclusively with wood. Modern pottery kilns come in gas, electric and wood. The latter, as a rule, are made by hand and are suitable for use in private households. In apartment conditions, it is most convenient to work with electric ovens; for larger volumes, you can choose a gas oven.

The metal body of such furnaces contains a refractory brick or other material that retains heat and is not afraid of heat. Ventilation holes are provided to remove moisture; the ceramic firing process is controlled by a program controller. Electric pottery kilns are not a cheap pleasure. The price depends on the manufacturer, volume, power.

There are models with vertical and horizontal loading and bell-type ones on sale. According to the type of location of the heating element, pottery kilns are divided into muffle and chamber kilns. In muffle systems it is located around a container made of refractory material (muffle). In chamber heaters, the heater is located inside, which reduces heat loss and makes the equipment more economical.

With a little effort, you can make a kiln for firing ceramics at home with your own hands, using refractory bricks and something for the body, for example, an old washing machine.

Baking is the most important process that does not forgive mistakes. Sometimes even experienced craftsmen see a worthless defect instead of the expected masterpiece. The products are never taken out immediately; they must cool in the oven.

How to choose a pottery wheel

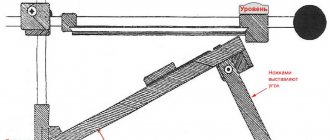

Pottery wheels are needed for sculpting round objects, so you don’t have to buy this tool right away. If you are just learning ceramics, start with sculpting or kneading. Circles come with manual, foot and electric control.

The latter are the most convenient and practical; they are most often purchased by ceramists who make ceramics at home. It takes several hours to learn how to operate an electric circle. It will take several months to master a manually operated tool.

When choosing a potter's wheel, it is important to pay attention to the type of motor :

- The collector type is the simplest and is often found in compact models; it smoothly regulates the rotation speed, but is very noisy.

- Asynchronous - rotates in both directions, makes less noise, but requires skills to adjust the speed.

- A brushless DC motor is the best choice for serious jobs. It is distinguished by reliability and low noise level.

Modifications differ in the diameter of the faceplate, its rotation speed, engine power, and equipment dimensions. The price also depends on the manufacturer.

When choosing a potter's wheel for making home ceramics with your own hands, pay attention to the convenience of the position of your hands while working and sitting at it. If you don’t have a personal workshop, don’t forget about compactness. It is advisable not to rely on advertising, but to ask for advice from those who have been involved in ceramics for a long time.

Good equipment can be found even among children’s models; they can be used to make full-fledged, albeit small, products.

Benefits and pleasure from the ceramic hobby

Initially, ceramics was mainly practiced by men, but today, thanks to automatic circles and electronic kilns, it is a female hobby that requires patience, creativity, and artistic talent.

Pottery cannot be called very profitable, especially considering the purchase of expensive equipment. Rather, they do it for pleasure. Modeling is calming, and contemplation of work on a potter's wheel has a magical effect.

Of course, you can sell handmade ceramics. Souvenirs, dishes, and decorative items are in demand. However, it is unlikely that you will be able to get rich from this hobby - it takes a lot of time to make, and only those who understand the difference between stamping and the individual work of a craftsman can appreciate the prices of handmade products.

If you want to try sculpting but aren't ready to buy a kiln, start with cold porcelain, polymer clay, or salt dough. Of course, these materials are not suitable for making dishes, but they make very beautiful souvenirs and jewelry, for example, a necklace or necklace.

Well, if you decide to become a ceramist, then start with theory, watch video lessons, learn from the experience of masters. Good luck to you and creative success in this and other women's hobbies.

Investments

In ancient times, clay pots were made in almost every village. Beginning entrepreneurs who want to set up their own ceramic production can either use long-standing traditions or come up with something of their own. The main advantage of this type of activity is that it does not require significant capital investments.

The fact is that to start work, only skillful hands and raw materials are needed. No special equipment is required for the production of ceramic tableware - a kiln and a dryer are enough - you will have to pay the most for it. You can purchase it or build it yourself.

In the first case, you will have to spend about 50 thousand rubles. As for making a stove, you can order it from some craftsman, and it will be much cheaper than buying a ready-made one. It should be noted that they come in two types - tunnel (have continuous action) and forges (differ in periodic action).

Features of the Russian market

Despite the abundance of new solutions, ceramics remains the main material for making tableware in Russia. The consumer is accustomed to trusting the quality and environmental friendliness of products originally from the USSR, which has influenced the opinion of modern goods. But if 20-30 years ago the bulk of ceramic tableware was manufactured in domestic factories, today a significant volume is exported from China. This is not surprising, since the equipment available in the country is becoming obsolete without receiving proper modernization, and business owners are no longer able to maintain the ratio of price, appearance and consumer properties required by the consumer. The “aggravating” circumstance is the rise in price and problems with the supply of raw materials, which were previously mostly imported from Ukraine.

China, on the contrary, has all the necessary resources to produce large quantities of tableware of almost any quality: from the most budget options to goods in the elite segment. Also popular are products from the UK, Japan, Germany, the Czech Republic, and Poland. As a rule, in this case we are talking about high and medium price categories.

As for domestic ceramic tableware, the situation is twofold. On the one hand, the consumer is happy to purchase products from Russian brands, guided by the already mentioned opinion about their high quality and safety. On the other hand, the existing manufacturers themselves contribute to the decline in the image of the products they produce. Thus, only the degree of responsibility of the entrepreneur will determine the success of the new business. In this light, it is important to choose a high-quality recipe for the ceramic mixture, glaze, firing technology, and also to constantly keep your finger on the pulse of fashion trends. This is the only way to ensure a constant influx of customers.

Promotion

Our main customers are girls and women. Completely different ages. There are also men, but of course there are fewer of them. In percentage terms it is approximately 80/20.

1. Social networks. We operate under the Moonceramic brand. And this name is already quite famous on social networks. That’s why we are moving most actively there. And the main orders come from there.

Sometimes we advertise on VKontakte, but it is not very effective. Now we are focused on developing pages on Instagram – that’s where our main audience is. More than 5 thousand people subscribe to the Moonceramic page, almost 26 thousand to my page.

We try to develop groups on social networks ourselves. Therefore, we take into account the rules of these channels. For example, for Instagram we try to take good, high-quality photos and beautiful compositions. This is very important for promotion in this network. We also plan to provide paid advertising there.

Screenshot from Natalia Berdnikova’s Instagram page

2. Word of mouth. This channel always works great. People who come to our classes or buy dishes from us very often take photos and then post them on their pages and give links to us. This is how, in less than two years, we “accumulated” 31 thousand subscribers on Instagram, more than 17 thousand on VKontakte in the ceramics group and more than 15 thousand in our store group. 3. Exhibitions. We participate in almost all major specialized exhibitions in Belarus, and travel with our dishes to different cities. We have our own style, and people already recognize our dishes well.

4. Kitchenware store. It is located in Minsk in the Silhouette shopping center. We always hand out store business cards at exhibitions, thereby attracting buyers.

5. Website. He's not ready yet. But we are planning to launch it soon. We hope that the site will become another promotion channel and an opportunity for development.

Photo from the personal archive of Natalia Berdnikova

What difficulties have we encountered?

1. Rent. One of the main difficulties was renting a studio. In 5 or 6 places we were refused a lease due to fire safety regulations - because of our stove. And in general, everyone was afraid of the word ceramics... But then we were very lucky: we were accepted into the building of the Institute of Physics of the National Academy of Sciences. That's where we started our work. This was our first studio.

I had to get a bunch of permits, which was probably the hardest part!

2. Equipment. We decided for ourselves right away - let it be expensive, but of high quality, because... The quality of our work depends on this. After reading many reviews, I settled on German equipment. But I had to be nervous with its delivery...

Photo from the personal archive of Natalia Berdnikova

Our main “tool,” a German stove, was delivered to us across the Gulf of Finland by several transport services at once. Its weight is about 100 kg. There were some problems. When they were transporting it through Russia, the stove was slightly damaged. We spent a long time sorting out the insurance, but in the end the money was never paid to us - we could not find out which transport service was at fault.

It was unpleasant and disappointing that the long-awaited stove arrived in such a battered state... This did not affect the quality of the work, but aesthetically it was not very beautiful. The first stove cost us $2,500 plus $500 delivery to Minsk.

Now we already have three of them. But each one was delivered with problems.

Photo from the personal archive of Natalia Berdnikova

3. Legal registration. The husband is registered as an individual entrepreneur - for conducting master classes and operating a store. And I work as a craftsman - to make it easier to participate in all exhibitions. But for us at first it was very difficult to register correctly. They did not provide normal tax information, so I had to consult a lawyer. They helped arrange everything correctly. Therefore, now we confidently advise everyone: if you doubt your abilities, it is better to immediately seek legal help.

Photo from the personal archive of Natalia Berdnikova

Cookware certification

Ceramic cookware comes into contact with food products, and therefore is classified as a product subject to mandatory confirmation of conformity, for which you will need to issue a mandatory certificate of compliance with the state standard or a declaration of conformity (depending on the type of product). For some types of goods (children's, laboratory glassware), it is additionally necessary to obtain a certificate of state registration. A declaration is drawn up in accordance with clause 5 of Art. 24 Federal Law “On Technical Regulation”. The quality of ceramic tableware is regulated by GOST 28390-89 and GOST 28391-89. The procedure for labeling and packaging is GOST 28389-89.

Basic Operations

The production of ceramic tableware consists of several stages: preparing the clay mass, molding, drying, firing and decorating the finished products. At the first stage, it is necessary to clean the raw material from all kinds of mineral additives, then crush it, grind it and sift it using a special sieve. Next, we begin to form the future product. The mass can be anything - plastic or liquid.

The advantage of the first is that it makes it possible to produce products of different sizes. As for the second method, casting into plaster molds is performed from a liquid mass, which is also called slip. Its humidity is at least 35%. It is used in conditions of high complexity when no other method is suitable.

As soon as the future ceramic products are pre-dried, it will be necessary to attach handles, spouts and other elements to them using an adhesive mixture of slip and dextrin.

The production of ceramics involves drying, which will ensure mechanical strength and resistance to soaking. It should be noted that drying is carried out at a temperature of about 80 ° C in dryers.

The cookware acquires the specified physical and technical characteristics during firing. In addition, it allows you to attach decor and glaze to the surface. As a rule, they are fired twice, and if painting is applied to the glaze - three times. At the final stage, manual or semi-mechanized decoration is performed.

Investment size

To equip a small workshop with modern equipment you will need about 2.5 million rubles. The volume and composition of the required raw material reserves is determined on the basis of technological maps. Funds are also provided for registering an enterprise, certifying goods, renting and repairing premises, paying utility bills and wages, as well as unforeseen expenses. Actual figures for the listed items may vary significantly depending on the region, the planned scale of activity and other factors, but, as a rule, they fluctuate around 1-1.5 million rubles. The predicted payback period for investments is from 3 years, subject to the presence of stable sales markets.

How a hobby grew into a business

I studied ceramics from the age of 6 at the Brest Art School. I loved sculpting since childhood; it was a real hobby.

When I entered the Geography Department of BSU, I went to Minsk and abandoned my hobby for 3 years. But I still wanted to sculpt all the time. Then I found a studio in Minsk where I could sometimes come and study for myself. There I met my future husband Vitya. We got married and decided to connect our lives with ceramics - we wanted to do something that brought us together and that we both really liked.

Photo from the personal archive of Natalia Berdnikova

There was an understanding that we have few good ceramists - we can easily occupy this niche. Therefore, we decided to take a risk. The first thing we did was buy a kiln, a pottery wheel and rent a small studio. And they started working.

From the moment we started investing money in our hobby, it became a business for us.

Photo from the personal archive of Natalia Berdnikova

Raw materials for production

The manufacture of ceramic tableware requires the use of basic and auxiliary materials. The first of them includes raw materials for the preparation of ceramic masses, paints and glazes, and the second includes substances necessary for the production of capsules and plaster molds. But the main raw material in this case is sintering clay.

In addition, future ceramic products should include kaolin as an additive, which serves as a property regulator. You can add fragments of broken or failed objects, quartz sand and fireclay. The addition of alumina, talc, carborundum and dunite will significantly increase such indicators as strength, thermal conductivity and heat resistance.