When the supply of water from a well becomes difficult due to its depth, an ejector for a pumping station comes to the rescue. Adaptation can be internal or external. Read to the end and you will understand how they differ from each other and what service they provide to the surface pump. And also what is the difference between an ejector and an injector.

External ejector in the pump Source ytimg.com

Design and types of pumps with ejectors

There are two options for including an ejector in the pump circuit:

- built-in;

- external node.

Functionally, these methods differ. The choice depends on the tasks that will be assigned to the pump. The built-in ejector is located in the pump design, so the suction of liquid and the creation of pressure occur inside the device. In this case, the pump, of course, is also immersed in the well.

On the one hand, this reduces the overall dimensions of the installation. Such a pumping station is capable of working with liquid containing sand and silt. However, the device itself is quite noisy, so it is not installed near a residential building. The maximum water intake depth of such a pump is only about 8 m.

A remote ejector involves equipment of a ground pumping station. The unit itself is placed in the pipeline at depth. A tank is placed on the surface, which facilitates the operation of the pump: it creates pressure and additional vacuum. Among the disadvantages of such a device is the need to lower the second pipe, which can be inconvenient if the well diameter is limited.

Difference from injector

Both of these devices are jet devices, that is, for suctioning liquid and gaseous substances.

An ejector is a device in which kinetic energy is transferred from a working medium at high speed to a non-working, that is, passive, medium through their displacement.

An injector is a device in which gases and liquids are compressed.

The main difference between these devices is the method of transmitting energy to the passive medium. For example, in an injector the supply occurs due to pressure, and in an ejector the supply occurs due to the creation of a self-priming effect.

Pros and cons of pumps with ejector

The ejector is economical and can work effectively with a relatively low-power engine. This is a mechanism that allows the transfer of kinetic energy from a fast medium to a slow one. In the most popular type of such pumps - with a remote ejector - part of the power is spent on water recirculation. At the outlet of the tap, the pressure is slightly less compared to what other types of pumps create.

Attention! A small amount of water is required to start the ejector. It forms a sufficient vacuum in the pipe and “leads” the main flow upward. The device should not run dry: this will lead to breakdown.

Disadvantages of the device:

- The width of the remote ejector is about 100 mm. It will not be possible to save on the diameter of the well.

- The performance of pumps with an ejector is lower than that of others.

- The cost is higher than classic devices for lifting water from depth.

Ejector pumps

The procedure for connecting an ejector as an independent device consists of two stages:

- An additional pipe is laid according to all the rules that were taken as the basis when installing the water supply pipeline. An additional pipe is needed to supply the injection medium.

- Connecting the pipe to the suction unit. It is necessary to install a coarse filter and a return pipe. It is recommended to install a valve to regulate the operation of the system.

The valve is necessary if the water level in the pit is higher than that for which the pump is designed. In this case, you can adjust the discharge flow.

Design features and principle of operation

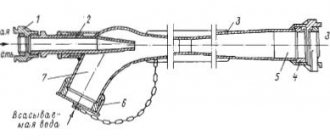

The design elements of the remote ejector for the pump are:

- a chamber into which the pumped medium is sucked;

- mixing unit;

- diffuser;

- a nozzle whose cross-section tapers.

Remote ejector device

How does any ejector work? As mentioned above, such a device operates according to the Bernoulli principle: if the speed of the flow of a liquid or gaseous medium increases, then an area characterized by low pressure is formed around it, which contributes to the rarefaction effect.

If you choose the right pipe shape and flow rate, then air or liquid will be sucked into the outlet located in the narrowed part

So, the operating principle of a pumping station equipped with an ejector device is as follows:

- The liquid medium pumped by the ejector unit enters the latter through a nozzle, the cross-section of which is smaller than the diameter of the inlet line.

- Passing into the mixer chamber through a nozzle with a decreasing diameter, the flow of the liquid medium acquires a noticeable acceleration, which contributes to the formation of an area with reduced pressure in such a chamber.

- Due to the occurrence of a vacuum effect in the ejector mixer, a liquid medium under higher pressure is sucked into the chamber.

If you decide to equip a pumping station with a device such as an ejector, keep in mind that the pumped liquid medium does not enter it from a well or well, but from the pump. The ejector itself is positioned in such a way that part of the liquid that was pumped out of the well or well by means of a pump is returned to the mixer chamber through a tapering nozzle. The kinetic energy of the liquid flow entering the ejector mixer chamber through its nozzle is transferred to the mass of the liquid medium sucked by the pump from the well or well, thereby ensuring constant acceleration of its movement along the inlet line. Part of the liquid flow, which is pumped out by a pumping station with an ejector, enters the recirculation pipe, and the rest goes into the water supply system served by such a station.

Connecting a pump with an external ejector

Once you understand how a pumping station equipped with an ejector works, you will understand that it requires less energy to raise water to the surface and transport it through a pipeline. Thus, not only does the efficiency of using pumping equipment increase, but also the depth from which the liquid medium can be pumped out increases. In addition, when using an ejector that sucks up liquid on its own, the pump is protected from running dry.

The design of a pumping station with an ejector includes a tap installed on the recirculation pipe. Using such a valve, which regulates the flow of liquid flowing to the ejector nozzle, you can control the operation of this device.

Pumping station with remote ejector

Manufacturing

It is quite possible to produce a fairly simple device-unit independently. This will require some parts, such as a tee of a specialized diameter and a fitting that will be located inside it. The correct length ratio must be observed, which should not be more or less, which will not allow such a device to function normally. For fastening you will need a special adapter equipped with corners, which will allow you to create the desired rotation.

The creation process involves several specific points, which includes the process of preparing the required fitting itself. Part of a special 6-sided sample should be ground, which will allow it to be made into a special cone, having a base smaller than the external thread in diameter. After which the deformed part should be corrected with a specialized thread-cutting tool.

The fitting must be screwed all the way into the tee piece. When connecting, be very careful about the length ratio, which is a fairly important factor. Be sure to seal the connection with any available sealant.

Check the ratio of the parts being manufactured, and then from pre-prepared samples you should organize a specialized adapter, which is designed for installation on the pipe.

A well-assembled station will ensure fairly long and trouble-free operation due to its simple design, but, naturally, you must be extremely precise in manufacturing. If you don’t really want to engage in such production, then you can simply purchase it in specialized stores, where a pumping station is always available for free sale.

DIY making

It is quite possible to make ejectors with your own hands. Of course, such work requires a certain responsibility and care, but it is still quite doable.

The vacuum pump is especially popular. The drawings and diagram of such a device are extremely clear.

The ejector, of course, can be easily purchased ready-made. However, if you want to save a lot, it is better to do it yourself.

Making an ejector with your own hands:

- It is necessary to take the tee and attach the fitting to it so that the fitting pipe fits inside the tee and does not protrude from it. If the pipe is too long or short, this can be corrected. In the first case, it can be ground off, and in the second, a polymer tube can be extended.

- Now you need to work with the part that will be connected to the pump. To do this, an adapter is screwed at the top of the tee.

- At the bottom of the tee, in the part where the fitting is located, a bend in the shape of an angle is screwed on. It will connect to the recirculation part of the ejector.

- An angle-type adapter is also screwed into the side of the tee. It is attached to the pipe using a collet clamp.

Jet Pump Maintenance

To activate the jet pump, you just need to prepare the system pipelines and supply the working fluid to the nozzle. Multistage steam-air ejectors are put into operation sequentially, starting with the last stage operating into the atmosphere. The normal operation of the stage and the entire ejector is judged by the readings of the vacuum gauges. A failure in the operation of one of the compression stages leads to a failure in the operation of the entire ejector. A breakdown in operation can occur due to a violation of the cooling mode of the condensers, and more often due to clogging of the nozzles with scale, dirt, and salt deposits.

Water jet ejectors of the dehumidification system pump water overboard through non-return controlled valves. When the ejector is put into operation together with the working water in the first period, air is removed from the suction line overboard, and at low tide an intermittent stream of milky color is observed. In the future, the normal operation of the ejector is judged by the position of the drain valve lever, which should be in the open position and vibrate slightly. A decrease in ejector flow can occur when the receiving filters (grids) on the suction pipeline are clogged. For all jet pumps, a decrease in flow and unstable operation (up to failure) are observed when the pressure of the working fluid decreases or when the tightness of the suction pipeline is broken (due to air leaks).

During routine preventive inspections of jet pumps, special attention must be paid to the cleanliness of the internal surface, the condition and dimensions of the flow part of the nozzle, as well as its installation in place, i.e., to alignment and compliance with the distance specified in the form from the nozzle end to the diffuser neck .

In preparation for launching a steam jet ejector, cooling water is supplied to the ejector cooler, the secant valve is opened and the working steam steam line is blown through the ejector. After this, the steam pressure in front of the nozzle rises to normal and, as soon as the vacuum gauge shows a normal vacuum value, the air suction valve to the ejector slowly opens. The ejector of the last stage is put into operation first, the remaining stages are introduced as needed.

During operation of the steam jet ejector, the normal supply and temperature of water in front of the ejector cooler, the pressure of the working steam and the magnitude of the vacuum are monitored.

When the steam jet ejector stops, the intake air valve and the working steam valve are closed, and after the refrigerator has cooled sufficiently, the water supply to it is stopped.

The water jet ejector is started by opening the working water supply valve and the suction valve.

The water jet ejector is stopped by closing the suction and working water valves.

When preparing the injector for start-up, the water inlet valve and the feed valve on the boiler open. Then the secant steam valve opens and the starting valve handle is slowly moved. As soon as all the air comes out of the pilot pipe and water appears, the start valve opens to the required amount.

You should start the injector carefully so as not to get burned by the steam coming out of the pilot pipe.

Recommendations

- Goldfinch and Semmens (2000). How steam locomotives actually work

. Oxford University Press. pp. 94–98. ISBN 978-0-19-860782-3. - Strickland L. Kness (1894). Practice and theory of the injector

. John Wiley & Sons (reprinted by Kessinger Publications, 2007). ISBN 978-0-548-47587-4. - ^ a b

Strickland Landis Kness (1910).

Practice and theory of the injector

. John Wiley & Sons (reprinted by Wentworth Press, 2019). ISBN 978-0469047891. - "STEAM INJECTOR". By: Mr. F. T. BURWELL, GWR MECHANICAL INSTITUTE. SWINDON ENGINEERING SOCIETY. TRANSACTIONS 1929-30 REGULAR MEETING. — JANUARY 21, 1930

- ^ a b

Goldfinch and Semmens (2000).

How steam locomotives actually work

. Oxford University Press. pp. 92–97. ISBN 978-0-19-860782-3. - Perry, R. H., & Green, D. W. (eds.) (2007). Perry Chemical Engineers Handbook

(8th ed.). McGraw Hill. ISBN 978-0-07-142294-9 .CS1 maint: multiple names: list of authors (link) CS1 maint: additional text: list of authors (link) - Power, Robert B. (1993). Steam jet ejectors for the manufacturing industry

(First ed.). McGraw-Hill. ISBN 978-0-07-050618-3. - Pullen, William Wade Fitzherbert (1900). Injectors: Their Theory, Design and Operation

(Second ed.). London: Technical Publishing Company Limited. paragraph 51. - Anderson, David N.; O'Day, Russell M. H. (July 17, 2013). Cab-Forward celebrates Southern Pacific Railroad's signature locomotive

(Revision 1st ed.). Sacramento, CA: Gerald Rood. paragraph 66. - Injector Model, Ted Crawford, Tee Publishing

- "Steam jet pump". General Electric. Received March 17, 2011. US Patent 4847043 ... coolant recirculation in a nuclear reactor.

Operating principle of the ejector

The deeper the well, the more difficult it is to draw water from it. Therefore, a pump is used to move fluid through the pipeline. However, with a well depth of more than 7 meters, a conventional such device will not be enough. In this case, you can purchase a more powerful submersible device or supplement the system with an ejector, which will completely solve this problem.

The principle of operation of the ejector can be understood by studying the illustration presented.

An ejector pump is a device that moves the energy of one medium to another. Its operating principle is based on increasing the water pressure in the pipeline due to the rapid movement of liquid along a special branch.

This operating principle allows you to increase the capacity of an existing surface pumping station. Thanks to this, it is possible to extract water from a well up to 40 meters deep. To better understand how this device works, it is necessary to monitor its operation.

Operating principle of the ejector pump:

- Water flows through the nozzle into the ejector. In this case, the cross-sectional diameter of the nozzle is less than the diameter of the entrance to the ejector system.

- By passing through a narrow nozzle into a chamber with a larger diameter, the liquid is significantly accelerated. Thus, its pressure increases. An area of lower pressure is formed in the mixer chamber.

- Thanks to the rarefied atmosphere, liquid, which is under higher pressure, begins to be sucked into the chamber at tremendous speed.

This device is very useful for deep wells. After all, it allows you to quickly pump out water from the deepest holes.

Using cooling towers to cool water

The type of cooling tower is selected depending on the total volume of the circulation cycle, the required temperature difference, and operating features.

For large volumes of cooled water, reaching several tens of thousands of cubic meters per hour, tower cooling towers are most often used. These structures can be seen at most thermal power plants and nuclear power plants.

In industrial enterprises they are used much less frequently - the total volume of water in the system is divided into smaller local cycles with their own operating parameters, different from others. Therefore, in such circulating systems, fan or ejection cooling towers are more often used.

An ejection cooling system differs from a classic fan cooling system in that the excess air flow is created due to the ejection effect, which is where the corresponding name comes from. Ejection is the process of mixing two media (steam and water, water and sand, etc.), in which one medium, under pressure, affects the other and, dragging it along with it, pushes it in the required direction. Using special nozzles, water is broken into very small droplets and sprayed under high pressure inside the installation. The flow of droplets carries with it an air mass with lower pressure. The remaining processes are similar to any other evaporative cooling tower.

Ejection systems have their obvious pros and cons. The positive aspects include the simplicity of the design: there are no fan units and no irrigation device is required. Such cooling towers are easier to maintain. However, from the advantages, there are also disadvantages: lower cooling capacity, high requirements for water quality, a significant decrease in efficiency when the nozzles become clogged or the pressure in the system decreases, and additional costs for powerful pumps.

Ejector: description of design and principle of operation

The ejector consists of the following structural elements: housing, high-pressure (ejecting) gas nozzle, low-pressure (ejecting) gas nozzle, mixing chamber and diffuser.

A gas ejector is a device in which the excess pressure of high-pressure gases is used to compress low-pressure gases.

The basis of the operation of a gas ejector is that low-pressure gas rushes into the mixing chamber due to the fact that a vacuum region is created in it (pressure below the pressure of the low-pressure gas). The vacuum region is created when high-pressure gas passes at high speed and pressure through a supersonic nozzle (tapered cross-section). In the mixing chamber, the two streams are combined and a mixed stream is formed. Having passed the mixing chamber, the flow rushes into the diffuser, in which it slows down and pressure increases. At the ejector outlet, the mixed flow has a pressure higher than the pressure of the low-pressure gas. It is important to note that the increase in pressure of low-pressure gas occurs without the expenditure of external energy. The operation of ejector equipment is based on the use of elementary physical laws, which makes it possible to obtain effective and reliable technical solutions using ejector technology (in comparison with mechanical superchargers - compressors, pumps, fans, etc.)

The gas ejector is simple in design, reliable in operation, has a short payback period, is mounted in an open area, operates in a wide range of gas parameters, and easily switches from one operating mode to another.

The design of the ejectors is flanged, welded.

- The undeniable advantages of jet pumps :

- There are no moving parts in the design

- They have small overall dimensions and weight;

- Ejectors are easy to maintain;

- Low maintenance requirements;

- They have high reliability;

- Installation is carried out in a matter of hours;

- Short payback period with low initial price;

If the operating conditions of the facility change, replacement of internal elements (nozzles, diffuser) occurs within 3-4 hours;

Content

There are low and high pressure ejectors

Low pressure ejectors

Low-pressure ejectors, driven by fans with a capacity of 1000-12000 m 3 /h, with hydraulic losses in the suction networks of 49-294 Pa and coefficient β = 1, are typed and centrifugal fans are selected for them, produced by industry complete with an electric motor and a vibration-isolating base.

High pressure ejectors

High-pressure ejection devices are classified according to the degree of compression (the ratio of the final pressure of the mixture p to the initial ejected pH) and the degree of expansion of the working flow (the ratio of the initial pressure in front of the nozzle pp to the final pressure behind the nozzle pH and are divided into three groups:

- gas jet compressors with a high expansion ratio and a moderate compression ratio;

- gas (steam) jet ejectors having a high degree of compression with a high degree of expansion;

- gas (steam) jet injectors with a high degree of expansion and a low degree of compression.

The second group of devices is used to maintain a deep vacuum; with a compression ratio pс/pн>2.5, they are used in condensing units of steam turbines and in steam ejector refrigeration units. Optimal for them is a conical mixing chamber.

Features and principle of operation of the installation

At factories producing wastewater disposal equipment, 2 types of pumping equipment are manufactured - with an internal and external ejector pump.

Devices with an internal ejection device pump out water from shallow (8 m or less) wells, reservoirs and wells.

A feature of such equipment is the presence of a “self-priming” function, as a result of which the water level is regulated, which is below the level of the inlet pipe. In this regard, before turning on the device, it is necessary to fill it with water.

After the device is filled with water and turned on, the impeller of the installation with an internal ejector pump sends water to the inlet of the ejector, thereby forming the necessary jet. It moves through a thin tube and the water pressure becomes faster.

When a pipe is connected to the inlet pipe, water begins to flow into the station.

The water then enters a chamber which sucks up the liquid. At the same time, the water pressure becomes less and the liquid flows through the diffuser to the outlet, slightly increasing the flow speed.

A device that uses an external ejector for a pumping station differs from an internal ejection pump in that it is used only at a depth of 10 m or more.

It is also difficult to install external ejector pumps on these devices. The pipes that connect the pumping devices to each other are installed only in a vertical position. Otherwise, a lot of air will enter the inlet line and it will stop working normally.

The optimal option for using devices with a remote ejector is to install the device at a depth of 20 m. As the lifting height increases, its performance decreases.

As a result, the external pumping device has less efficiency than the internal one.

Advantages, principle of operation and installation details

A surface pump with an external ejector has the following advantages:

- work with great depths up to 50 meters;

- small dimensions and weight of the station;

- convenience of supplying water to the object;

- ability to work in extreme conditions – at temperatures from -20 to + 130 degrees.

Of course, not every steam ejector pump can boast all of the above advantages. So, some models can work in severe frost conditions, others cannot.

Design features and principle of operation

The design elements of the remote ejector for the pump are:

- a chamber into which the pumped medium is sucked;

- mixing unit;

- diffuser;

- a nozzle whose cross-section tapers.

Remote ejector device

How does any ejector work? As mentioned above, such a device operates according to the Bernoulli principle: if the speed of the flow of a liquid or gaseous medium increases, then an area characterized by low pressure is formed around it, which contributes to the rarefaction effect.

If you choose the right pipe shape and flow rate, then air or liquid will be sucked into the outlet located in the narrowed part

So, the operating principle of a pumping station equipped with an ejector device is as follows:

- The liquid medium pumped by the ejector unit enters the latter through a nozzle, the cross-section of which is smaller than the diameter of the inlet line.

- Passing into the mixer chamber through a nozzle with a decreasing diameter, the flow of the liquid medium acquires a noticeable acceleration, which contributes to the formation of an area with reduced pressure in such a chamber.

- Due to the occurrence of a vacuum effect in the ejector mixer, a liquid medium under higher pressure is sucked into the chamber.

If you decide to equip a pumping station with a device such as an ejector, keep in mind that the pumped liquid medium does not enter it from a well or well, but from the pump. The ejector itself is positioned in such a way that part of the liquid that was pumped out of the well or well by means of a pump is returned to the mixer chamber through a tapering nozzle. The kinetic energy of the liquid flow entering the ejector mixer chamber through its nozzle is transferred to the mass of the liquid medium sucked by the pump from the well or well, thereby ensuring constant acceleration of its movement along the inlet line. Part of the liquid flow, which is pumped out by a pumping station with an ejector, enters the recirculation pipe, and the rest goes into the water supply system served by such a station.

Connecting a pump with an external ejector

Once you understand how a pumping station equipped with an ejector works, you will understand that it requires less energy to raise water to the surface and transport it through a pipeline. Thus, not only does the efficiency of using pumping equipment increase, but also the depth from which the liquid medium can be pumped out increases. In addition, when using an ejector that sucks up liquid on its own, the pump is protected from running dry.

The design of a pumping station with an ejector includes a tap installed on the recirculation pipe. Using such a valve, which regulates the flow of liquid flowing to the ejector nozzle, you can control the operation of this device.

How does the device work?

The steam ejector pump has a fairly simple principle of operation - a small amount of water, which is located in a special tank of the device, is used to assist in drawing in liquid. The operating principle is simple but very effective.

Although, such a system does not have serious performance. But so far no one has invented a new pumping system that can draw liquid from greater depths. That's why a water ejector pump is so popular today.

The ejector for the pump is always lowered to the required depth for water intake, and the pumping system is mounted on the surface for ease of use and adjustment of the water intake system.

Contacts

Chistocom online store - chistocom.ru Phones: 8 495-592-33-40, 8 966-096-00-66 Address: Vidnoye, Belokamenny highway, 1A Office hours: Mon-Thu from 09:00 to 18:00; Fri from 09:00 to 17:00; Sat and Sun - closed e-mail:

- Review

- Characteristics

Ejectors are used to supply chemicals. Installed after the pressure regulator. The ejector is used in self-service car washes to apply chemicals.

The operation of the injector is determined by:

1 Select a model (nozzle) depending on the performance of the high-pressure apparatus.

2 The difference in water pressure allows you to mix chemicals thanks to the “Venturi” nozzle effect. This effect occurs when water passes through the diameter of a larger low pressure nozzle that is mounted on the lance (for example when using a double lance)

3 HP hose length. This hose should not be longer than 20 m.

4 Inner diameter of the high pressure hose. The longer the hose, the larger its diameter should be. Lengthening the hose affects the performance of the injector.

Types of ejectors

Having decided what an ejector is, you need to understand its varieties. Two types of devices are usually used to equip pumping stations. The first option involves incorporating the device into the design of the pumping device. In the second case, we are talking about separate placement. Each of these solutions has its own advantages and disadvantages that must be taken into account when organizing the system.

Built-in models

In this embodiment, the ejector is installed under the pump housing or next to it. This allows you not to look for additional space for it. All that is required is to implement the usual procedure for installing a pumping station. The closed housing provides the ejector with reliable protection from dirt and dust.

Such a pumping station with an ejector can draw water from a depth of up to 8 meters. It is capable of serving the territory of dacha farms, where the need for watering is especially acute. The weaknesses of indoor ejectors usually include noise during operation. For this reason, they try to install them away from living quarters (most often a separate room is allocated for this). The station's electric motor must have sufficient power to create recirculation.

Remote models

External installation of the ejector involves the use of an additional tank for pumping water. It creates the necessary working pressure and additional pressure difference, which reduces the load on the equipment. The ejector switching in such a scheme is carried out to the immersed section of the pipeline. This will require laying an additional pipe, which means the well will have to be made wider. As a result of this design solution, the system efficiency decreases by almost 35%.

On the other hand, this makes it possible to service wells up to 50 meters deep, significantly reducing the noise level during station operation. The place where it is located is often the house itself (its basement). The distance to the water intake point can be up to 40 meters, this does not affect the efficiency of the equipment. Such advantages make the external type ejection pump especially popular. All equipment is located in one prepared place, which increases its service life and ensures ease of maintenance and system setup.

Choice: built-in or external

Depending on the type of installation, the ejectors used in the set of a water supply pumping station can be built into the pump or external, while the difference in their design lies in the mounting details.

The advantages of the built-in type of ejector are the compactness and protection of the installation from contamination, the absence of additional mechanical filters for cleaning from suspended and insoluble impurities. At the same time, pumps with a built-in ejector are characterized by higher electrical power and increased noise during operation, which should be taken into account when installing the power supply network and site layout.

Remote-type ejectors (external) are installed either directly into the well or next to it. The energy efficiency of such devices is somewhat lower compared to built-in ones, but they allow you to work with deeper wells.