Cold welding is nothing more than glue. Recently it has become very popular, this is due to its affordable price, easy use and the absence of the need to use additional tools. Also, a person does not need to have any additional knowledge in order to use this substance.

High temperature cold welding is one of the varieties of this substance. In addition to domestic use, its services are often used in industrial settings. Its main distinguishing property from other varieties is what can be understood from its name. Connections made with this substance can withstand temperatures in excess of one thousand degrees. Most often, this subtype of cold welding is used for gluing and repairing metal products or parts. With its power, automobile components, furnaces, boilers, etc. are repaired.

In general, everywhere where classical welding and ordinary cold welding cannot help. This product can be used both at home and in various industrial enterprises without any problems. The connections can withstand flame without problems. The composition of the mixture is designed in such a way that exposure to high temperature only increases the strength of the connection.

What kind of glue can it be?

- One-component , which hardens when exposed to air moisture when the package is opened;

- Two-component , consisting of epoxy resin components with fillers. Hardens after thorough mixing of the components. Two-component adhesive can be thick or liquid. The liquid composition is best suited for sealing and gluing pipes and sealing cracks. Plastic compound is best for repairing and joining broken parts of a part. There are known cases where high-temperature cold welding for metal was used to restore broken threads of fastening studs and broken parts of the collars of metal bushings.

You can buy cold welding either by going to the Yandex Market website, or you can immediately in the VSEINSTRUMENTS.Ru store

Temperature characteristics

The composition of the adhesive mass determines what temperature cold welding can withstand. The user manual always states this value. If you carefully follow all the requirements of the manual, the seam will withstand this temperature without loss of strength.

Budget brands are usually developed for a maximum temperature of around 260 C. Special types of mixtures have a maximum operating temperature of over 1300 C. They cost significantly more, but they allow you to repair parts and products operating at high temperatures. This is an excellent help if the use of hot technology is difficult for reasons of fire safety or accessibility of the repair site.

Types of cold welding glue

- Liquid . This adhesive consists of two epoxy resin components. The packaging is in separate packages. The glue is prepared by mixing these components immediately before work. The liquid structure has better wettability of product surfaces and joint strength.

- Plastic - this composition has the viscosity of children's plasticine. It is made in the form of a rod of round or rectangular cross-section. The rod consists of two parts combined from the middle part and the shell. The core is the hardener, the shell is the base. To prepare the mixture, just cut off the required amount of the rod and mix thoroughly. To restore and glue parts, apply a well-crushed component to the surfaces to be glued and tightly connect the parts.

- Universal . In this welding, the components are selected in such a way that they can connect with each other almost any materials that cannot be joined with conventional glue: non-ferrous metals, wood, plastic, glass, iron, concrete and ceramics. But, it is worth considering that the bond strength is lower than that of specialized adhesives.

- Automotive . The components are selected for use in the repair and maintenance of mechanisms and machines; its composition is ideally selected for gluing plastic, polymers, metal, glass and rubber in stationary and field conditions.

- Special - Components are added to the composition to impart special properties to the compound: water resistance or resistance to high operating temperatures in water. Cold welding for metal, high-temperature, waterproof, the price is very low considering the capabilities and scope of its application.

Application area

The heat resistance of the adhesive determines the scope of application:

- Household. Repair of heating radiators, gas boilers, water heaters, stoves, pots, kettles.

- Automotive . Repair of all vehicle components that are exposed to high temperatures: cooling systems, exhaust gases and engine.

Important! A modern engine is a high-tech unit. Without professional skills, you should not carry out repairs. Before using cold welding to repair an engine, we recommend consulting with specialists

Preparing the surface for joining

General requirements. Before gluing, do:

- Thoroughly degrease the surfaces; to do this, moisten a lint-free cloth with denatured alcohol, a special degreasing liquid, or at least acetone, and wipe the gluing area. Then treat the same areas with two grades of sandpaper, first coarse, then No. 10-12;

- Apply glue and press the parts as tightly as possible;

- After 5-10 minutes. the parts will set and the part can be left for a day for the final hardening of the seam;

- You can use the item in at least a day.

Warning! Cold welding is not a replacement for traditional welded joints, especially in areas that bear the brunt of service loads.

The domestic market will be represented by numerous companies producing cold welding. Consumers who need a high-quality product for repairing mechanisms use products from foreign manufacturers, since they are of higher quality than domestic brands. According to consumer reviews, the highest quality of domestic manufacturers is the Astrohim brand, and Polymet, which has a quality certificate. Foreign brands include Hi-Gear, Abro, Poxipol. High-temperature cold welding for metal has different prices depending on the manufacturer and characteristics.

Top 3. "DIAMAZ" METAL

Rating (2021): 4.39

39 reviews from resources taken into account: Reviewer

Best price Universal adhesive “Diamond” has the most affordable price among cold welding products.

The most popular cold welding Low price and high performance characteristics of the joints make ALMAZ cold welding the most popular in the domestic market.

- Characteristics

Average price: 90 rub.

- Country Russia

- Weight: 20 g

- Curing time: 30 min.

- Temperature resistance: +5…+150˚C

- Number of components: 2

The top participant in our rating, ALMAZ METAL, has gained great popularity among consumers due to its high efficiency and ease of use. The two-component adhesive composition based on epoxy resin demonstrates the best adhesive characteristics in relation to ferrous and non-ferrous metals. The presented cold welding reliably holds parts together, eliminates a small leak in a radiator or water supply system, and restores the integrity of the item. Among the advantages is the ability to work with a wet surface. Not everyone likes the pre-glue preparation stage - the top layer is very sticky and gets your hands dirty.

Advantages and disadvantages

- Moisture resistance

- Durable seam

- Black color

- Component mixing process

See also:

- 5 best welding machines for polypropylene pipes

Adhesive composition "Abro"

Cold weld epoxy for metal, high temperature, water resistant, viscous consistency, applied like putty. Contains steel powder, which gives the components strength and heat resistance, moisture resistance and strength. The homeland of the brand is the USA.

Characteristics:

- Seam color is black;

- Packaging round plastic container;

- Operates up to + 260°C;

- Package size, 110x30x30 mm.

- Package weight, 60 g.

Due to its high-quality characteristics, it is used for temporary repairs of critical car parts, such as:

- sealing crankcase cracks,

- battery leak repair,

- various types of damage to body parts,

- cracks in the cylinder head and block

In addition to its good thermal properties, “Abro” is moisture resistant and is suitable for repairing cracks in plumbing fixtures, leaking pipes, sealing cracks in ceramic slabs, earthenware toilets, and tank bodies at home. Cold welding for metal, high-temperature, oil-resistant, is used for repairing exhaust manifolds and exhaust pipes.

After the components have completely hardened, mechanical processing with a file, sandpaper or any cutting tool is allowed. It can be used to restore part of a lost part of a vase, or a metal fragment.

Adhesive ABRO thermal steel 85

The properties that make “ABRO thermosteel” unique are its high heat resistance, the seam remains operational at a temperature of 1400°C, which allows the product to be used for repairing mufflers, car exhaust manifolds, boilers, steam pipes and pipes for hot water supply, various mechanisms, where for what -For some reason, conventional welding cannot be used. When using high-temperature waterproof cold welding glue for metal, you must use the instructions for use.

Characteristics:

- A one-component mixture, hardens upon contact with air moisture, requires thorough mixing;

- Reaches 95% hardness within 3 hours, the product after applying a well mixed component can be used after 24 hours. If the glue is heated to 45°C, the hardening time is reduced to several hours;

- It has a viscous consistency and can be applied with a spatula, knife, manually or using a special gun;

- Surface preparation is standard for all adhesives;

- Weight: 85 gr.

Due to its unique properties, welding can be used to seal large holes or cracks. If the thickness of the connector is more than 8 mm, it is necessary to use an additional metal mesh, which is used as reinforcement and placed inside the crack. In this case, the thickness of the seam must be at least 6 mm. If a second coat is necessary, ensure that the first coat is completely cured.

The Russian company presents a line of high-quality and fast welding of metal, ceramics, stone and polymer materials. All products are certified.

Instructions for use

Before use, carefully read the instructions for use. It contains technical specifications. You can also find the necessary information regarding the safe use of glue and recommended areas of application.

Below are general rules when using cold welding.

Safety rules when working with cold welding Cold welding is a non-toxic material. Its use does not require the use of safety glasses or respiratory protection. The main safety requirement for some products is to protect the skin and mucous membrane from direct contact with the glue.

In case of contact with eyes, rinse the contact area thoroughly with plenty of water and consult a doctor. This applies to the finished mixture - contact with the dried product will not cause harm to health. The containers for preparing the mixture must be clean and free of foreign elements. Further use of the utensils for eating is undesirable.

Astrohim glue, for metal, 55

specializes in gluing metals, including stainless steel, and contains special additives from iron oxides to give the gluing strength. Retains its properties at temperatures from -60 to +150°C.

Characteristics:

- Anti-corrosion.

- Moisture resistant;

- Heat resistant;

- Weight 55 gr.

Features: when preparing the mixture in a warm room, it can be used for gluing parts at a temperature of -10 ° C. Available in a sealed blister pack. High-temperature, water-resistant cold welding for metal can be purchased in specialized stores or ordered on online resources.

Peculiarities

The composition can be used in any area where conventional metal welding is effective, but a number of objective reasons prevent the latter from working. This method of joining metal surfaces consists of combining elements using the plasticity of the welding mixture, which penetrates into the material.

A special feature of cold welding is also the fact that to ensure productive work there is no need to purchase specialized expensive equipment. This method can be classified as pressure welding, but the soldering is obtained due to deep plastic deformation, which destroys the oxide layer of the material, which makes the distance between the elements similar to the parameters of the crystal lattice. It is the increase in the energy level of substances that favors the creation of a strong chemical bond.

The properties of this material make it possible to work with surfaces and structures made of non-ferrous and ferrous metals. The main feature of this method of fastening is the fact that cold welding is an ideal option for repairing metal products that are sensitive to heat and provides a reliable connection between different metals.

The method has a number of advantages.

- The products are available to consumers and sold in many supermarkets.

- In most cases, it is possible to connect elements without first dismantling them.

- The work does not take much time.

- The bonded surfaces do not deform because they are not exposed to high temperatures.

- The weld seam meets the requirements of aesthetic appeal.

- Often this method is the only way to connect parts. This applies to welding elements made of copper and aluminum, as well as containers that contain explosive substances.

- The technology eliminates the generation of waste.

- There is no need to make maximum efforts to carry out the process of joining parts.

- The material is absolutely harmless.

- The work does not require special skills or special tools.

- There are heat-resistant varieties of the composition that can be worked with at temperatures above +1000 C.

The disadvantages of the material include several features.

- The strength of the welding seam is still lower compared to conventional welding, so the products are not always suitable for use on an industrial scale.

- Cold welding is not positioned as a material for sealing large defects.

- Surfaces to be joined need to be thoroughly cleaned before applying the compound. Otherwise, the quality of adhesion decreases sharply.

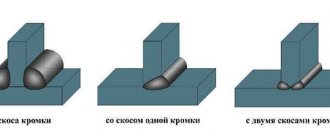

Based on the location of the connecting seam and the type of working surfaces, several types of cold welding can be distinguished.

- Point – recommended for tires and kitchen utensils made of aluminum and copper, attaching nozzles to aluminum wires, thereby increasing the quality of connection of electrical contacts;

- Suture - designed for the production of housings for various devices and equipment, as well as volumetric sealed containers;

- Butt - used for making rings and connecting wires;

- T-bar – used for gluing brass studs, busbars of electric locomotives;

- Shear welding is intended for pipes providing water supply, including heating systems, as well as for transmission lines on railways.

Depending on the adhesive composition and its thickness, welding is classified as follows:

- Plasticine-like, resembling a bar, having one or two layers (the technology for using such material requires preliminary mixing and softening of the product);

- Liquid, consisting of glue and hardener, which must be mixed before application (that's why it is called two-component).

Read also: DIY belt wrench

Regarding the target orientation, several types of cold welding are distinguished.

- Waterproof composition designed for work in water.

- A vehicle repair product containing metal filler. This welding is produced specifically for working with automotive parts.

- A product designed for working with metals, containing a certain filler, thanks to which almost all types of surfaces are connected to each other.

- Universal welding. It provides reliable connection of different materials (wood, various polymers, etc.). This product is the most popular on the market.

- High temperature cold welding. It can be used at temperatures from +1500 to -60 C.

Astrohim glue, for aluminum, 55

One of the reasons for “incompatibility” when gluing together parts made of non-ferrous metals, including aluminum, is the formation of an oxide film upon contact with oxygen. Special adhesive for aluminum “astrohim” contains components that prevent the formation of oxide during gluing, the connection is strong and durable.

Characteristics:

- Specialization for gluing parts made of aluminum and its alloys, joining aluminum parts with other materials in any combination - (wood, ceramics, plastic)

- Operation of parts after welding from - 60 +150°C.

- Available in a plastic shell, weight 55 g.

Before operation, it is necessary to carefully exchange components among themselves. It sets in three hours, the product can be used after a day.

Top 5. Linocol Bostik

Rating (2021): 4.07

Best hardening speed Cold welding for PVC Linocol Bostik hardens within a minute after application - this is the best indicator in the rating.

- Characteristics

Average price: 290 rub.

- Country: France

- Weight: 60 g

- Curing time: 1 min.

- Temperature resistance: +5…+35˚C

- Number of components: 1

One-component cold welding for rubber and polyvinyl chloride products (pipes, linoleum, etc.) reacts with the surface being treated and transforms the joint into a homogeneous area within one minute. Polymerization of the seam eliminates the passage of moisture - this is one of the best compounds for sealing and connecting PVC pipelines. A convenient needle attachment for careful application is very useful - if glue gets on the decorative surface of the linoleum, it will not be possible to remove it. After a quarter of an hour, the treated area is ready for work. Among the shortcomings, the owners indicate only a pungent odor (disappears after hardening) and the high cost of Linokol.

Advantages and disadvantages

- Best setting speed

- Moisture resistance

- Strong odor before drying

Astrohim glue Fast steel

contains components that accelerate the hardening process; it contains finely dispersed iron filings and metal scale.

The product can be used after 3-4 hours. Used to restore unloaded parts, threads of fastening bolts and studs.

Characteristics:

- Available in the Total Bond Series;

- Specialization – restoration of metal parts of car bodies and mechanisms;

- Operating temperature range from -60 to +150°C;

- The tensile strength of 1 cm 2 is 25 MPa;

- Surface preparation before bonding is common to all epoxy welds;

- Available in blister packs of 75 g.

The product can be used after three to four hours. You can buy high-temperature cold welding for metal in specialized stores, distribution centers, or order it on online resources.

Top 5. "CONTACT"

Rating (2021): 4.21

11 reviews taken into account from resources: Otzovik, YandexMarket

Eliminates emergency leaks without drying Thanks to its high adhesive ability, the universal cold welding “Contact” can quickly eliminate a leak in a pipe, oil pan or gas tank without first drying the damaged area.

- Characteristics

Average price: 239 rub.

- Country Russia

- Weight: 50 g

- Curing time: 180 min.

- Temperature resistance: -40…+150˚C

- Number of components: 2

The universal adhesive has proven itself excellent in restoration and gluing of various metals, glass, ceramics, plastic, and wood. Easily takes a given shape and sets quickly. For cold welding, stopping a leak in a water pipe or gas tank is not a problem. At the same time, the glue performs its task by working with a wet surface. Due to its high adhesion, “Contact” perfectly seals the most inaccessible places. The plasticity of the compound prepared for work decreases sharply after 3-5 minutes, so you need to work with it quickly. Treating the base during application (cleaning and degreasing) increases the reliability of the connection, however, during emergency repairs this is not always convenient.

Advantages and disadvantages

- Hardens quickly

- High adhesion

- Solvent resistance

- Foundation preparation required

Chinese Industry Representative Runway - "Cold Welding"

In terms of characteristics and properties, it is in no way inferior to Russian ones, but at a lower price. universal, liquid. Designed for gluing porcelain, ke

frames, wood, any plastic and other non-metallic objects.

Characteristics:

- Color – steel metallic;

- Contents: 2 separate blister packs;

- Weight 29 gr. 2 pieces.

Peculiarities:

It sets in 5 minutes, the product can be used within a day, it is vibration resistant, does not shrink, the seam can be processed with grinding and cutting tools.

Russian composition Zubr

The universal adhesive is intended for joining parts made of ceramics, earthenware, concrete, metal, glass, stone, plastic.

Waterproof and oil and solvent resistant, widely used in repairs in rooms with high humidity. Characteristics: Resistant to aggressive environments, water, oils and solvents.

- The product remains operational according to the stated characteristics from – 40 to 150

- After hardening, it is subjected to mechanical impact with any cutting or grinding tools. Can be painted.

- Packaging tubes 60g. in blister pack

Choosing a universal glue: what to look for?

When choosing cold welding, in addition to the brand and price, the following parameters are important:

Type of bonded surface.

There are universal adhesives for metal, linoleum and rubber, plastic and concrete. Moreover, the composition allows you to combine materials in any combination, combining into one whole, for example, concrete and wood, rubber and plastic, steel and glass.

Vibration resistance.

Cold metal welding withstands vibration loads, is resistant to aggressive environments and temperature changes. Successfully restores the tightness of radiators, tanks and fuel lines, oil pans and other elements.

Tear resistance.

Restoration of components operating under physical load using universal glue allows the connection to withstand forces of up to 200 N*m. Such welding is indispensable for emergency repair of a car suspension, as it will allow you to independently eliminate the malfunction (broken lever, rod, etc.) and get to a service center or garage without the help of a tow truck.

Heat resistance.

A special type of cold welding that can withstand heating up to 150-250˚C. It is successfully used to restore car mufflers, highways and heating system equipment.

Moisture resistance.

Adhesives of this group are impervious to moisture, and in some cases can be applied even to a wet surface, maintaining high adhesion to it.

Hardening time.

Since cold welding is often used for emergency repairs, setting time is important. The smaller it is, the better.