Many gold buyers wonder why this precious metal is so expensive? But apart from gold's appearance, attractive color and beauty, it has many benefits from a chemical and physical point of view. For example, density, malleability, and the melting point of gold—these are the characteristics of the metal that are used in jewelry, industry, and medicine.

How gold is melted

Why is gold melted and mixed with less precious metals?

Gold is a hard, refractory metal that is often mixed with other metals such as copper, silver, iron, aluminum, and platinum. At the same time, it often changes color (it becomes white, brown, red). Purposes of alloys:

- Increased strength. Pure gold is easily deformed. Therefore, it is fused with stronger elements - this way you can get a harder material.

- Saving money. Pure gold is an extremely expensive metal. To save money, it can be fused with cheaper components - the price of the final product will be lower.

- Giving gold a unique color (pink, white, green, blue, purple and other alloys). Ligatures of various metals are responsible for the corresponding shade.

To mix metals, they need to be heated to a certain temperature at which it turns from solid to liquid (melting phenomenon). This indicator is called the melting point. If necessary, the material can be heated even after it has melted.

Once a certain temperature is reached, gold may begin to evaporate (this point is called the boiling point).

Gold bullion production process

PHYSICAL PROPERTIES

| Mineral color | rich yellow, fading to white-yellow with a predominance of silver |

| Stroke color | brilliant yellow |

| Transparency | opaque |

| Shine | metal |

| Cleavage | No |

| Hardness (Mohs scale) | 2,5-3 |

| Strength | malleable |

| Kink | jagged |

| Density (measured) | 15 – 19.3 g/cm3 |

| Radioactivity (GRapi) | 0 |

| Magnetism | diamagnetic |

Maximum melting temperature of gold: the higher the purity, the higher the degree

Fineness is the specific concentration of gold in the alloy. The most popular hallmarks are 999, 585 and 375. The number reflects the ratio of gold content per 1000 units of material. 1 kg of 999 fine contains 999 grams of gold, and the remaining 1 gram is impurities. The rule applies: the higher the sample, the higher the melting point.

- 375 gold melts and becomes liquid at a temperature of approximately 600-750 degrees.

- 585 gold product - at a temperature of about 700-850 degrees Celsius.

- The melting point of 999 gold is 1064 degrees Celsius. The boiling point of high-grade gold (999) is about 2700 degrees.

Important! If you are interested in the melting point in Kelvin, then add 273 to the numbers.

The melting point of gold depends on its purity

What is the heating device made of?

If it is not possible to get professional equipment, you can melt gold using a gasoline burner. Before you start making it, you need to acquire the following:

- Airbrush spray. An air injector or garden equipment that sprays chemicals is quite suitable for this purpose.

- A jar. It is important that it has an airtight lid.

- Automotive air pump. A machine compressor is also suitable.

- With a hose.

- Sealant.

Comparative analysis of melting temperatures of gold of various samples

| Gold | Silver | Copper | Zinc | Cadmium | Melting temperature |

| 999 | Trace amount | Trace amount | Trace amount | Trace amount | 1064 |

| 585 | 138 | 229 | 36 | 12 | 850 |

| 585 | 163 | 207 | 46 | 850 | |

| 585 | 125 | 205 | 85 | 830 | |

| 585 | 160 | 205 | 30 | 20 | 820 |

| 585 | 150 | 205 | 30 | 30 | 800 |

| 585 | 193 | 133 | 33 | 56 | 790 |

| 585 | 100 | 225 | 90 | 770 | |

| 585 | 104 | 176 | 20 | 115 | 710 |

Main advantage

If you think that gold is valued for its beauty, you are a little mistaken. It turns out that the gold metal is valued for its unique flexibility. When gold is exposed to high temperatures, it takes on small forms, and at low temperatures, metal particles form a massive vein. The resulting veins can be seen with the naked eye.

Jeweler's work

Plus, gold is resistant to corrosion. There are cases where gold jewelry lay in the ground for decades, and after removal it remained in its original form, without changing color or shape. The precious yellow metal is resistant to chemicals and belongs to the noble category.

Stages of preparing gold for factory smelting

To produce gold bars, natural ore or nuggets are used, which undergo a procedure of mining, beneficiation and smelting. Most often, ore is smelted at factories using special furnaces after three-stage preparation:

- Mechanical cleaning of material. Strong water pressure is used to separate particles from soil and stones. Water may contain additional additives that improve the quality of cleaning.

- Refining-chemical cleaning (from impurities). Cleaned metal still contains particles of dust or other elements. To reduce their number, the material is washed with aqua regia.

- Deposition of a metal alloy. After cleaning with aqua regia, the material is placed in clean water, where the final purification of the material occurs. The particles sink to the bottom (due to their high density) - after settling, they are taken out and dried.

Melting gold in special melting furnaces

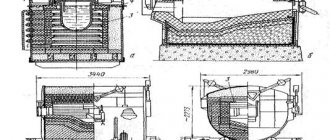

The gold particles are placed in a furnace where they are heated to the melting point. After reaching it, they take a liquid form and merge into the corresponding forms of an ingot or product (depending on the shape of the crucible) until they cool completely. Various furnaces can be used to melt material in factories:

- Gas. The crucible is placed inside the furnace, and a gas burner is supplied. During startup, the burner heats the crucible, which transfers heat to the gold particles.

- Induction. The crucible is supplied with electrical wires connected to a current source. When the circuit is completed, the electricity heats the mold and melts the material inside.

- Muffle. Electric heating elements are connected to the crucible from below and on the sides. They begin to heat up when the circuit is closed, which also leads to the melting of the material.

Gold smelting - technology

TOP 3 effective ways to melt gold at home

The main methods of melting gold products in factories were discussed above. However, there are craftsmen who have learned to transform this material at home. Practice shows that such smelting is “blacker” than factory smelting. If you follow the basic rules of remelting, you can obtain a completely pure alloy that will contain a minimum of impurities. Instructions on how to melt gold yourself:

STRUCTURE

Crystal structure of gold

Crystallizes in the cubic system, in the form of octahedra, rhombic dodecahedrons, cubes and more complex crystals; They are often distorted, strongly elongated, forming “wires”, “hairs”, or flattened parallel to the octahedron face. Native gold, especially low-grade gold, is characterized by a variety of growth forms; it is usually in the form of skeletal crystals, dendrites, thread-like and twisted-filamentary crystals. Streak-like and irregular lump-like, “hooked” discharges are widespread; Their surfaces often contain imprints of crystals of other minerals, the aggregates of which included accumulations of native gold. Etching reveals the crystalline granular structure of the gold particles.

Equipment and materials for home metal smelting

The list of necessary equipment depends on the method of metal remelting:

- Melt using a burner. To carry out the work you will need a gas cylinder and a burner (autogen). It is recommended to melt gold on a refractory brick, which will not begin to crumble when heated. The crucible can be made from refractory clay. It is also recommended to use refractory tongs to place the material into the crucible.

- Melt using a melting furnace. Most melting furnaces sold in online stores are in the jewelry category. They are completely autonomous (the design contains its own crucible). Therefore, you will only need gold particles.

- Melt using a microwave. For melting, use a microwave oven with a power of 1200 watts or more. You will also need two bricks - two recesses should be made in them (the bricks are placed in the oven with the recesses facing each other to create free space). It is recommended to make the crucible from graphite (microwave radiation can melt the clay).

How to clean castings

After the borax has served its purpose and cleansed the molten gold of excess compounds, you will have to rid the ingot of the remnants of the borax itself. For final cleaning you will need:

- hydrochloric acid - 20 ml;

- nitric acid - 10 ml;

- distilled water - 0.5 l;

- fireproof flask;

- electric stove.

The casting must be boiled in an acid solution for 5 minutes and rinsed with clean water. This part of the experiment is best carried out outdoors, for example in a summer cottage: acid fumes are toxic.

Section question - answer

Melting point of 585 gold in degrees Celsius?

Expert opinion

Pribrezhny Gennady Valentinovich

Jeweler 6th category

It all depends on what alloying additives and in what quantities are included in the alloy in addition to gold. Typically, the melt temperature of 585 sample is in the range from 700 to 850 degrees.

Melting temperature of gold at home

Expert opinion

Grishanov Mikhail Petrovich

Jeweler, director of the Grishanov and Co. workshop

Everything depends primarily on the sample + you need to make a small addition on top, since higher heat losses are usually observed outside. 585 sample is recommended to be heated to 900 degrees, 999 to 1200 degrees, 375 to 800 degrees.

Does gold melt in a fire?

Expert opinion

Pribrezhny Gennady Valentinovich

Jeweler 6th category

It all depends on how exactly the building burns and what type of product is inside it. Typically, in a serious fire, the fire can heat the room to 900-1100 degrees. Samples 585 and 375 melt at this temperature, but, if you're lucky, the product 999 samples will remain unharmed.

Melting gold at home

Does gold melt in a fire?

Expert opinion

Grishanov Mikhail Petrovich

Jeweler, director of the Grishanov and Co. workshop

This is possible, although in practice it is rarely used due to high heat loss, as well as the risk of contamination of the product. A good fire is on coal. If heated with wood from the forest, melting will not occur.

At what temperature does gold melt at home, how to melt it?

Expert opinion

Pribrezhny Gennady Valentinovich

Jeweler 6th category

Heating should be carried out with a small margin. The optimal temperature for casting 585 is 900 degrees, 375 is 800 degrees, 999 is 1200 degrees. Use a stove or gas burner to heat. You can also melt using a microwave.

What determines the color of gold jewelry?

What color the jewelry produced will acquire depends on the type of components in the alloy and their percentage. A product in which gold and silver make up 25% respectively, and copper 50% will have a red tint. White color - if the alloy includes palladium, nickel, silver. Green - silver and copper. Pink - silver, palladium and copper.

Sources

- https://jgems.ru/metally/zoloto

- https://DedPodaril.com/zoloto/imform/temperatura-plavleniya-zolota.html

- https://k-tree.ru/tools/chemistry/periodic.php?element=Au

- https://tokar.guru/metally/temperatura-plavleniya/temperatura-plavleniya-i-kipeniya-zolota.html

- https://goldomania.ru/articles-3/temperatura_plavleniya_zolota.html

- https://golden-inform.ru/proby/temperatura-plavlenija-zolota/

- https://www.vseznaika.org/chemiks/chto-takoe-zoloto-i-za-chto-cenyat-etot-metall/

- https://vplate.ru/zoloto/plavleniye/

- https://TheMineral.ru/metally/zoloto

- https://zhazhdazolota.ru/interesnoe/temperatura-plavleniya-zolota

- https://zolotoigid.ru/temperatura-plavleniya

Level of international reserves

International reserves of the world's countries in 2006

| States with the largest international reserves. | $1953 (March 2009) | |

| 2 | Japan | $1042.34 (August 2009) |

| — | Eurozone | $531 (February 2009) |

| 3 | Russia | $413 (July 2009) |

| 4 | Republic of China | $305 (April 2009) |

| 5 | India | $256 (May 2009) |

| 6 | The Republic of Korea | $212 (April 2009) |

| 7 | Brazil | $203 (March 2009) |

| 8 | Hong Kong | $186 (March 2009) |

| 9 | Singapore | $166 (March 2009) |

| 10 | Germany | $144 (February 2009) |

These ten countries contain more than 50 percent of the world's total international reserves.

Counterfeits, fakes...

We have to disappoint you: more than 70% of gold imported into Russia is counterfeit. A lot of gold jewelry is imported without the hassle of customs and assay inspections, so be careful when purchasing jewelry.

Sometimes it is simply impossible to distinguish a fake, despite checking with a detector. Especially if the jewelry is imported.

It is better to buy jewelry in reputable stores and let it be produced by well-known Russian or foreign companies. The cost of the product will be higher than at sales and in dubious places, but the likelihood of running into a fake is less.

When purchasing, pay attention to the presence of a brand (falsifying it is a crime; most scammers try not to mess with this).

Carefully examine the “underside” of the product - the neater it is, the more carefully the stones are fixed, the higher the guarantee of authenticity.

A little history

Because gold could be found almost anywhere in the world, it became an essential element in almost all human cultures.

Starting with Ancient Egypt, where decorative gold objects dating back over 5,000 years have been found. Advertising - Continued below

The beauty of gold was associated by ancient people with immortality and the wealth of the gods, so jewelry and decorative elements were made from it. Gold was also one of the first currencies to replace traditional barter exchange.

Children's gold bracelet. Egypt. Approximately 2650 BC Photo: www.metmuseum.org

The very first gold coins were minted in the kingdom of Lydia in 550 BC, and since then this metal has remained the main element of the monetary system. Even after modern paper money was adopted, currencies remained linked through the Gold Standard, a system introduced in the 1870s that fixed the value of these currencies in a certain amount of gold.

Precautions for smelting operations

Foundry processes require increased safety precautions. There should be no flammable substances near the isolated work area. You should not skimp on protective equipment; you should definitely purchase glasses with protective glass on a garter, an apron, gloves, and work clothes.

Clothing must cover the entire body, since even a drop of hot precious metal can burn a section of skin to the bone.

You can also purchase a fire extinguisher to prevent a fire.

Homemade silver smelting

Price

Noble metal is always dear. Today its value is determined on the stock exchange. There, the units of measurement for elite goods are the troy ounce (denoted as oz) and gram (g).

A troy ounce is 31.1 g. About the same as a gold cube with an edge of just under 1.5 cm.

The price of the gold metal is constantly changing, depending on the state of the economy. If it is “stormy”, it goes up in price. In calm times, business people prefer other financial instruments.

However, noble aurum is a profitable long-term investment. In 20 years, since the beginning of the millennium, it has risen in price sevenfold - from $300 to $2000 per ounce.

Where is it used?

For centuries, the gold metal has been used as a material for coins and jewelry. This is a status material from which royal and imperial crowns, crowns, and other attributes of power were made. History knows golden thrones.

Today, extracted raw materials are distributed in the following areas (%):

- jewelry – 40;

- reserves of national central banks and international financial organizations – 25;

- investment accounts – 25;

- industry, medicine - 5 each.

Gold coins were in use as a means of payment until the First World War (1914). They exchanged any paper bill for them.

Jewelry

Gold is the number one material for the upper price segment in jewelry. In jewelry, it is magnificent on its own and as a setting for precious stones.

Investment

Precious metal is a proven object for preserving and increasing capital.

Every country has a gold reserve. In Russia it is measured in thousands of tons.

Ordinary citizens are trying to create a family “pot”:

- Traditionally, people invest in bank bullion or bullion coins.

- In the jewelry segment, items with an unusual provenance (history) or authorship of famous brands are recognized as investment objects.

If we are talking about a mass-produced ring, necklace, or brooch, products of simple shapes are considered reasonable investments. When taking it to a pawnshop or selling it, the loss in value will be minimal. In such situations, even the most intricate gold jewelry is assessed as scrap for recycling. Accepted by weight at the so-called “technical” price.

Gold bars

The largest gold reserves in the world (as of 2018).

| № | Country/organization | Gold (tons) | Share of gold in the total volume of foreign exchange reserves of the state (%) |

| 1 | USA | 8133,5 | 74,5 % |

| 2 | Germany | 3369,9 | 69,6 % |

| 3 | International Monetary Fund | 2814,0 | — |

| 4 | Italy | 2451,8 | 66,6 % |

| 5 | France | 2436,0 | 62,4 % |

| 6 | Russia | 2170,0 | 18 % |

| 7 | China | 1842,6 | 2,3 % |

| 8 | Switzerland | 1040,0 | 5,2 % |

| 9 | Japan | 765,2 | 2,5 % |

| 10 | Netherlands | 612,5 | 67,3 % |

Medicine

Pharmacologically, aurum compounds are used in the manufacture of medications for the treatment of rheumatoid arthritis, tuberculosis, and other ailments. The radioactive isotope of the metal is used by oncologists.

Priorities have changed when using noble metals in dentistry. Until the mid-twentieth century, it was considered prestigious to have gold teeth (crowns). But today the precious metal is being replaced by metal-ceramics and other new materials. But those who want to look young “sew” gold threads under the skin.

Industry

Gold raw materials are indispensable in industry. So, for radio electronics it is a soldering material. It covers the mirrors of telescopes to ensure long-distance communications and is used in advanced industries, including nanotechnology.

The noble metal has even found use in cooking. Confectioners decorate finished products with it.

Food additive E175 is edible gold.

Scientists managed to obtain aurum from mercury by knocking out “extra” atoms. The alchemists' dream came true, but the cost of the final product exceeded the market price by orders of magnitude.

Cleaning silver from impurities yourself

The procedure for removing impurities is called refining. Using refining you can clean:

- Scrap of high-grade precious metal products;

- Technical silver;

- Waste from electrical cleaning;

The refining process should take place in a room with a powerful hood or outside. Substances harmful to humans will be released into the air.

To clean silver from impurities, you can place the material inside a liter jar and fill it halfway with nitric acid. The reaction will be manifested by heat and a pronounced bitter odor.

You will need to wait until the essence has cooled completely. Next, a saline solution is added to the container. As the reaction progresses, the precious metal chloride will settle to the bottom.

Now you need to pour running water into the jar. When the sediment sinks to the bottom again, the surface water layer is drained. The action is repeated several times until the essence becomes completely transparent.

Important! For 100 g of processed material, 250-350 ml of each reagent are needed.

A fairly common cleaning method is electrolysis. This refining is based on the characteristics of a smooth electric current. Silver parts act as the anode, and a silver plate acts as the cathode.

For the electrolysis method you will need:

- DC transformer;

- Clamps;

- Vessel with electrolyte (silver dissolved in nitric acid);