SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

When performing construction or repair work, it often becomes necessary to cut a metal workpiece. To do this, you should use special equipment in the form of a milling cutter, grinder or hand-held metal shears. However, it is not always at hand. You can cope with this task using a drill attachment for cutting metal, which will cut a product of small thickness.

Thanks to a large selection of different drill attachments, this universal device can replace many other tools

Sheet metal cutting tools

One of the most popular roofing materials is corrugated sheeting or metal tiles. The use of these materials requires high precision and accuracy, so during installation you must use a specialized cutting tool. Installation of sheet roofing material requires cutting it to appropriate sizes, which depends on the technological task. The following types of cutting tools are used for cutting sheet metal:

- Hand scissors for cutting metal are the cheapest tool, which is inconvenient to use when cutting long sheets. The cutting line is uneven, intermittent, and with burrs

- Hand saw for cutting metal - this tool is also not the best for processing sheet material. If you use a hacksaw for metal, then the work should be done only with a blade without a frame, and the cutting process will take a lot of time, so when performing large volumes of work this method is not relevant

- Jigsaw - to cut sheet metal, you will need a special cutting tool, in the spindle of which you need to install a special blade with fine teeth. The disadvantage of this tool is that when cutting, warping of the walls of the sawn product will occur.

- Circular electric saw - when using a circular saw, you will need to install a special disk or circle for metal processing. A circular saw is expensive, so buying one specifically for cutting sheet material is not at all rational

- A grinder or angle grinder is one of the most popular tools that every craftsman has in his arsenal. Using a grinder is convenient, but to cut sheet material, you will also need a special abrasive disc. Moreover, if a grinder is used for cutting sheet metal, then the circle should be as thin as possible. An angle grinder has its drawbacks - overheating of the metal, which entails a violation of the integrity of the paintwork. The result of using a grinder for cutting metal is damage to the material, as it begins to rust, and after a short period of time it may need to be recoated

In addition to the above tools, manufacturers produce special attachments for cutting sheet metal. These attachments are used directly for cutting sheet material; they are also called attachments, since they work in tandem with electric drills or screwdrivers. It is rational to purchase an attachment for an electric drill when large volumes of roofing work are performed.

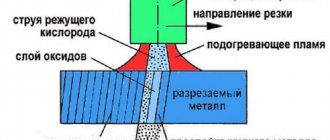

The drill attachment for cutting metal tiles operates due to a special design, which is implemented through the use of a matrix. The repetition of the movement of the knives contributes to cutting sheet metal with high precision and accuracy. Using an attachment for cutting metal on a drill makes it possible to perform work with high precision and accuracy, which is why it is recommended to buy such a device.

This is interesting!

The attachment under consideration for an electric drill is called nibblers. Structurally, it is similar to hand scissors (depending on the model), but the operating principle is significantly different.

Why not Bulgarian?

If you carefully read the instructions for metal tiles and their installation, then, of course, you found a point where it is stated that cutting with a grinder is prohibited . In this case, the product warranty is simply voided. Why is that?

The metal tiles are protected on top by a special polymer that does not tolerate high temperatures. And when using an angle grinder, the metal will heat up just to those critical temperatures, so that both the zinc coating and the polymer layer will melt in certain places. The result is deformation of the protective layers; such tiles will be damaged by rust and may even leak.

In addition, sparks from the contact of the abrasive disc and the tiles will fly in different directions, causing damage . These points will become small, and in the future more dangerous islands of corrosion.

Advice: if you decide to cut with a grinder, then try to protect the tile sheets from sparks. And cover the cut areas with facade paint. Although this is not the best, it is a tolerable option.

Why is it better to choose metal scissors for a drill?

If you have to cut sheet material, then for such purposes it is better to refuse to use an angle grinder. Scissor-style metal cutting drill attachments provide the following benefits:

- High quality cutting line. Using scissors on a drill or screwdriver allows you to get the highest quality cut when cutting sheet material

- The attachment is suitable not only for electric drills, but also for cordless screwdrivers, as well as pneumatic tools

- It is convenient to carry out work even on the roof if you use a cordless drill or screwdriver

- There is no need to use high-power electric tools

- The ability to perform not only straight, but also curved cuts

- Versatility, which allows you to use the device for cutting any type of sheet material, not just metal

- High productivity - cutting thin sheet steel with a drill using special scissors allows you not only to get a neat cut, but also to achieve results in a short time

- Easy to use - no additional training is required to learn how to use the attachment

- Easy to maintain - the console does not require special care, as it has a simple design. To start using the tool, just attach the attachment to the power tool chuck.

Knowing the advantages of using an attachment for cutting metal, you can make an appropriate decision about the need to purchase it. Many people are interested in the question of how thick sheet material can be pierced by drill scissors.

Manufacturers do not recommend using attachments for cutting sheet material whose thickness exceeds 3 mm. However, it is also worth understanding that cutting such thick metal reduces the service life of the attachment and also requires the use of special powerful power tools.

Drill scissors can be used to cut materials with the maximum permissible thickness (it all depends on the manufacturer of the attachment):

- Aluminum - up to 2 mm

- Stainless steel - up to 1.2 mm

- Regular steel - up to 1.8 mm

- Copper and brass - up to 1.5 mm

To make a curved cut with nibblers, you will need to get the hang of it. Before you start cutting, you need to practice. The operating principle of nibblers is based on converting the rotational movements of the chuck into reciprocating ones. These movements activate the knife, which is responsible for cutting the sheet material.

Although scissors for drills and screwdrivers have many advantages, they are also affordable, so everyone can afford such a useful device. If you plan to cover a house or an extension using metal profiles or tiles, then using a special attachment will not only make the work easier and faster, but will also allow you to carry out manipulations with high precision and accuracy.

This is interesting!

Using a grinder to cut material requires the craftsman to lower it from the roof to the ground, while special attachments on the screwdriver allow cutting directly from above.

Main disadvantages

Like any other device for carrying out repair and finishing work, this attachment has disadvantages. First of all, this is rapid wear.

When grinding rough surfaces, friction occurs and the paint stripper is deformed. Over time, the teeth fly off, reducing the effectiveness of processing. The average life of the nozzle is enough to remove paint in 1-2 rooms.

In contrast to this disadvantage, it is worth noting the low price of the paint remover, which is lower than that of modern power tools and solvents. This allows you to stock up on several attachments for repairs throughout the entire apartment.

Distinctive features of the Cricket drill attachment

The attachment for drill and screwdriver called “Cricket” is presented in the form of cutting scissors used to create an even cut. They can be used to cut not only steel materials, but also plastic. The manufacturer indicates that scissors can be used not only for cutting sheet material, but also for profiled products.

The Cricket device is used for cutting materials of thickness:

- For aluminum up to 2 mm

- For steel up to 1.5 mm

- For stainless steel up to 1.2 mm

- For plastic up to 2.5 mm

The effectiveness of the attachment also depends on the power tool used. High performance of the nozzle is ensured when using a power tool with the following parameters:

- Electric motor power of at least 400 W

- Chuck rotation speed 3000 rpm

- Key or quick-release collet chuck

The peculiarities of working with a cricket attachment are that the tool has two cutting surfaces. When one surface becomes dull, you need to twist the handle to the other side and continue working. The Cricket set also includes an additional replaceable cutting surface. Manipulating the console is simple. To do this, the attachment shaft is fixed in the tool chuck. Work must be carried out with both hands, holding the power tool with one hand and the attachment with the other.

This is interesting!

If we compare the speed of operation of a drill attachment and a grinder when cutting corrugated sheets, then the latter option is inferior. Even if you manage to cut through sheet metal faster with an angle grinder, compare the quality of the resulting cut to make sure that it is rational to purchase an attachment for an angle grinder for cutting profiled material.

Finally

And yet, if you are not a professional roofer, then you won’t find a better option than a drill attachment . It can be an excellent help both on the roof and in everyday life. If you need to cut metal without squealing and fiery splashes, like from an angle grinder, please do so. In addition to the convenience of operation, the fact that you do not need to buy an expensive device is captivating. The attachments themselves are not that expensive and fit on any drill. For professional work with metal tiles, such attachments are rather weak, but for home use they are the best option.

Whatever you use to cut, it is better to treat the cut edges with paint , such as façade paint.

Cutting sheet metal with a steel beaver attachment

Another type of attachment for power tools is also used for cutting sheet metal - this is the Steel Beaver attachment. Many craftsmen call such attachments adapters, but they are not such. After all, this is the final mechanism by which useful work is performed.

The steel beaver also works on the principle of cutting shears, thereby eliminating the occurrence of sparks and overheating of the metal. If the sheet material is processed incorrectly, the manufacturer does not guarantee the quality of the overlap or service life. The Steel Beaver set also includes a replaceable die and a punch. The use of the attachment is recommended in conjunction with a power tool that has the following technical parameters:

- The rotation speed of the chuck must be at least 1500 rpm

- Power not less than 350 W

- Collet

Compared to a grinder, special attachments for drills make it possible to change the cutting angle up to 360 degrees. This is convenient when you need to make a shaped cutout in corrugated sheets or metal tiles. The minimum cutting radius when using attachments is 12 mm. The use of a special device is achieved by high cutting productivity of sheet material.

Characteristics of nozzles

Thanks to the impressive number of varieties of drill accessories described, the latter can be called one of the most versatile tools. In particular, with the help of attachments, high-quality grinding of various surface areas is carried out - even those that are very difficult to reach. In addition, using such products it is very convenient to clean miniature parts that require extreme care from the performer.

Another reason explaining the popularity of woodworking attachments is the significant cost savings. Practice shows that these devices allow you to solve the vast majority of tasks, effectively replacing a specialized and very expensive tool. Another remarkable feature of drill attachments is the ability to make them yourself (provided that the master pays due attention to the balance of the attachments and the quality of the materials used).

As for the reasons that may prevent the use of the described products, these include low productivity in comparison with a professional tool and the need for the performer to have certain skills. In addition, many craftsmen consider attachments less convenient than specialized equipment for woodworking.

In order for the purchased attachment to meet the expectations of its owner, the latter should familiarize himself in detail with the classification of such products - both by the type of work carried out with their help and by the specifics of the design.

By purpose

Depending on the characteristics of the operations performed, the following types of products described are distinguished.

For grinding

This type of device allows you to give the desired appearance to the surfaces being treated and involves the use of highly effective abrasive materials. The latter are most often silicon carbide, aluminum oxide and synthetic diamond. The material responsible for processing wood can be glued to the working surface of the nozzle and applied to a base made of paper or fabric.

For milling

Such devices are designed to solve a wide range of problems - in particular, high-quality alignment of grooves and work with the end edges of workpieces. If the master has auxiliary supports and attachments, he can turn the drill into full-fledged equipment for milling wood.

For polishing

The type of attachments under consideration is in many ways reminiscent of a grinding attachment, differing from it in the specifics of the filler used. The material of the latter is soft (as a rule, it is foam rubber or thin dense felt), due to which such devices are successfully used for fine processing of wooden surfaces.

For stripping

The solution to this problem involves the use of attachments called brushes. Such products are most often made of rigid wire and are used to remove paint residues and in other situations that require bringing the surface into proper condition. They are suitable for roughing, which is carried out before grinding and other “fine” operations.

For cutting

The described type of device is complex and high cost, and working with it is reminiscent of using an electric jigsaw. Such attachments cope well with cutting wood up to 2 cm thick, as well as chipboard and plywood. The versatility of the products under consideration deserves special attention, allowing them to be used for cutting other materials - primarily artificial polymer compounds and some alloys.

For working with self-tapping screws

For working with self-tapping screws This simplest type of attachment is used with drills that can operate at low speeds. Manufacturers often offer kits that include attachments with different diameters, which allows them to be used to work with most self-tapping screws.

You can also purchase attachments used to create large holes, and flexible drills that allow you to reach any hard-to-reach place. Such devices are used relatively rarely, and therefore not every specialized store sells them.

By design

Today, there are many known attachments for wood processing, which differ markedly in shape and other features of their structure. The most popular ones can be found below.

Plate

Presented in several variations, made using various abrasive materials. For sanding wood, rubber and plastic attachments are most suitable, and for polishing it is justified to use products with a surface made of fine-grained sandpaper. There are also devices that allow you to change the angle of the abrasive attachment rod.

Drums

In most situations, they are used for high-quality processing of holes and end sections of workpieces. Such attachments look like barrels of regular cylindrical shape, to the surface of which sanding tape is attached. Drum-type products allow you to sand wood without any difficulty, which is especially important for round or oval holes.

Cup

Such devices are well suited for removing old paint and other procedures that involve rough processing of a wooden surface. The attachments in question are a bowl with a tightly fixed brush made of wire or abrasive nylon. To choose the appropriate option, the master should take into account the degree of surface treatment that needs to be achieved.

Disk

They are a variety of products discussed in the previous paragraph. The key difference between disc nozzles and cup nozzles is the diametric arrangement of the bristles, which allows you to process wood in the most inaccessible places.

Petalaceae

The design of these attachments, also called fan attachments, involves a rod to which many sanding sheets are attached. Such devices are ideal for radius grinding and finishing polishing. In addition, flap devices can be used for accurate processing of workpieces with complex surfaces.

Read also: What is a servo drive in a machine

End

Products belonging to this variety may have significant external differences and are made from different materials. Most often they are used to perform the initial or final stage of processing holes and the internal surface of workpieces of complex shape.

Soft

These attachments have minimal wear resistance and are therefore only suitable for polishing surfaces. The most popular devices are made of foam rubber, felt and leather, which have a round shape and are securely fixed to the axis.

As for milling with a drill, it is carried out through the use of cutters - special attachments made of hard alloys. The choice of a specific type of these devices is determined by the specifics of the task for which they are used. Thus, to obtain neat grooves in the workpiece, it is rational to use disc cutters, and it is advisable to “entrust” the execution of complex cuts to shaped cutters. It is also worth considering the shape of the teeth of the purchased product, based on which it can be backed or pointed. Experience shows that both varieties cope well with their duties, however, the former allow a greater number of resharpenings than the latter.

It is also worth mentioning the nozzles designed for cutting large diameter holes. These include feather drills, which have a flat cutting part and are optimally suited for solving the above-mentioned problem. Using these devices you can work with wood, plywood, chipboard and oriented strand boards, cutting round holes with a diameter of 35, 50 and even 60 mm. In addition, Forstner drills, which have a centering tip, and drill bits, equipped with many cutting teeth and allowing holes up to 100 mm in diameter, are suitable for solving this problem.

Turboshear drill attachment for metal cutting

In addition to the “Cricket” and “Steel Beaver”, manufacturers produce a scissors attachment for drills and screwdrivers called Turboshear. This attachment is more like ordinary hand-held metal scissors. Structurally, the nozzle is based on two cutting edges. One edge is movable and the other is fixed. Due to the reciprocating movements of the movable edge of the attachment, the material is cut. Among the advantages of the Turboshear nozzle it should be noted:

- High speed of work completion

- Ability to cut while holding the tool with one hand

- Ease of use

The disadvantage of the Turboshear attachment is that the slightest dulling of the cutting edges reduces the performance of the tool, and the cut results in burrs and chips. To restore the functionality of the device, you will need to replace the knives.

There are many other models of scissors for drills and screwdrivers. Which nozzle is better to buy, it all depends on the amount of work and the technological tasks set. Steel Beaver and Cricket are not expensive compared to Turboshear. The Turboshear nozzle is made in the USA and has high performance and long service life.

Tips for use

When processing wood with attachments using a drill, the performer must adhere to the following requirements.

- The device used must be securely fastened in the chuck. If there is any, even minimal, play, work cannot begin.

- One of the key conditions, taking into account which allows you to avoid injuries and other troubles, is the mandatory fixation of the workpiece being processed.

- While working, it is advisable to hold the drill with both hands, which is especially important for powerful equipment.

- If the performer wants to turn on reverse, he needs to wait until the instrument he is using comes to a complete stop.

- When processing wood, special attention should be paid to pressure. It should be quite strong, but not excessive.

Upon completion of work, you must wait for the nozzle to cool for several minutes. You should not touch it during the specified period of time (you can burn your fingers).

In addition, the performer should not experience discomfort from small particles filling the space of the room when working with wood. Inhaling them is strongly discouraged, which makes it justifiable to use a respirator - an inexpensive and very effective personal protective equipment. Also, do not neglect glasses, which reduce the likelihood of foreign objects getting into your eyes. This advice is especially relevant in situations where processing is performed using wire brushes.

In conclusion, we can confidently state that anyone who values their time and energy should use drill attachments for working with wood. Such products have many obvious advantages with a minimum number of disadvantages, and therefore are suitable for the vast majority of performers.

For information on one of the attachments for working with wood, see the following video.

A drill is a tool whose main function is to impart rotational movement to the drill.

The drill is indispensable for repairs and construction of any complexity. And all this, thanks to various attachments, adapters, attachments, adapters and other devices that make the drill a truly universal hand tool.

Drill attachments - the ancient ancestor of drilling

According to the degree of mechanization, drills can be divided into two types - manual and electric. But, regardless of the type, any of them can be used to perform such work as: drilling holes, stirring solutions, grinding, cutting and tightening/unscrewing screws. The drill can be used as a pump for pumping water and even for plucking chickens. According to its characteristics, an impact drill can replace a hammer drill in everyday life.

It is unlikely that you can find another tool on the market that would perform as many functions. Of course, the quality of work performed using drill attachments is somewhat different from what could be obtained using a special tool. But, in particular cases, in households and everyday life, this is quite enough.

What is a drill attachment, what types of adapters are there, what they are intended for and how to choose the right one - that’s what our article is about.

An attachment is an additional device that allows you to expand the functions of the drill.

From the many types of them, we will select the most popular ones and consider them in detail.

Differences between using an attachment on a drill and a screwdriver

An electric drill and a screwdriver differ not only in purpose, but also in design. The attachment for cutting thin sheet metal can be attached to both drills and screwdrivers. It is important to consider the following factors:

- A screwdriver has a lower chuck rotation speed compared to a drill. The screwdriver also has low power, so when cutting sheet steel you need to choose the right tool

- Ease of use. Unlike a drill, a screwdriver has less weight, and it is not tied to a power cord. This makes it easier to use as a drive mechanism for metal snips

- Lack of inertia - after the power supply is cut off, the screwdriver chuck stops immediately, but on a drill it continues to rotate for some time. When performing high-precision work, the quick stop of the power tool chuck is even better, as it responds more accurately to the press of a button

A screwdriver, like a drill, can be used for cutting sheet materials, but it is necessary to choose a power tool wisely.

Key Benefits

The paint remover does not crush the old layer into dust, but carefully removes it in large fragments. This speeds up the work significantly, and in just an hour you can clean from 1 to 4 square meters of surface. This method greatly simplifies cleaning after dismantling the old coating (there is no need to carefully collect dust with a wet cloth or vacuum cleaner).

An important advantage of the “Paint Remover” nozzle is the ability to process almost any surface in multi-story buildings. Initially, the tool was created for removing paint from concrete, but practice has shown that it is also effective when sanding other materials:

- bricks;

- cinder block;

- wood;

- metal;

- sandstone

This attachment can be used to remove the old layer of varnish from floorboards for the purpose of their subsequent restoration, as well as remove paint from walls and floor coverings without any difficulty.

Security for communications

The paint remover carefully removes the polymer layer and does not create a risk of damage to power and low-current cable systems. Its environmental friendliness also plays an important role. The absence of heat treatment does not lead to the decomposition of polymers and the appearance of toxic emissions.

This attachment is also effective in cases where it is necessary to remove old paint in houses built back in the 60s of the last century. Soviet paint is one of the most toxic (contains a large mass fraction of lead), so it must be removed carefully, using a special tool. You can't wash it into dust.

How to cut profiled sheet material with a nozzle

To connect the attachment to a power tool, the design of the attachment has special protrusions - shanks. Typically, shanks are hexagonal in shape and are clamped into the collet chuck of the power tool. After securing the shank in the power tool chuck, you can begin to work. When performing work, it is important to follow these recommendations:

- If the work is being carried out for the first time, it is recommended to first practice on the remains of sheet materials

- Work is carried out by holding the tool with both hands. This is necessary not only to comply with safety regulations, but also to ensure that the cut is smooth and neat. If you perform work while holding only a drill or screwdriver, the attachment will vibrate strongly, and therefore you will not be able to get an even cut. The exception is Turboshear brand consoles

- It is better to carry out work below (not on the roof) from a safety point of view, although in exceptional cases it is possible to use tools above

- To get the highest quality cut, you need to carry out the work with an assistant. One person holds the sheet to be cut, and the second does the actual work of cutting the material.

- Before starting work, you need to use a marker or pencil to make markings along which to cut thin-sheet material.

In order for the cuts to be neat, even and without defects, you need to learn how to use the tool correctly. This will take practice.

To summarize, it should be noted that buying an attachment for cutting sheet material is recommended for specialists who deal with roofing houses and other buildings using steel sheet material. If you plan to cover a shed or other outbuilding yourself, then using a drill attachment for cutting metal, you will be able to complete the work with high precision and accuracy.

Features of choice

Considering the impressive number of attachments for wood processing on the market, special attention should be paid to the basic rules for their selection.

- Depending on their origin, purchased products may differ significantly in quality, which affects the effectiveness and duration of their use. Professionals advise against buying low-quality attachments in favor of products from trusted manufacturers, which are fully worth their cost.

- When choosing a suitable device, the performer must take into account the main characteristics of the drill he is using - power, features of the chuck and the ability to change the rotation speed. If the purchased attachment does not fully correspond to the tool being used, it will be much more difficult to achieve the desired result.

- To choose a suitable device for a drill, it is reasonable for a novice performer to seek help from a competent employee of a specialized store. This step allows you to save time and get at your disposal a product that optimally suits the conditions of the task.

It is also worth considering that separate attachments allow you to work not only with wood, but also with other popular materials - for example, glass or ceramics.

Flexible shaft - extension

The flexible shaft is indispensable for furniture makers. It helps to attach fittings, screw small shelves and assemble components even in hard-to-reach places. The shaft bends at a large angle and transmits movement from the screwdriver to the nozzle located at the end, allowing you to quickly screw in self-tapping screws.

Flexible extension for screwdriver and drill

The device is made of high quality materials. The shaft is resistant to constant use, does not fray or deform. Suitable for most modern drills and compatible with a variety of fasteners.

| Price | 120.66 rub. |

| Rating | 4,8 |

| Reviews | 73 |

| Orders | 145 |

| Delivery to Russia | Free |

Buy on Aliexpress