About bolts. In the photo there are two types of bolts: “short” and “long”.

“Short” ones are intended for fastening wheels on stamped-welded disks, and “long” ones are for fastening cast and forged disks. Bolts for “stampings” have a shorter threaded part and a smaller bolt head compared to long ones.

Wheel bolts are used by European car manufacturers. Nuts are used in the Japanese and Korean automotive industries. When choosing mounting elements, you should have an idea of their technical features.

Types of fasteners

Here are the types of fasteners needed for alloy wheels:

- Bolts are metal rods with a screw thread at the end. Used to connect detachable elements.

- Nuts are round-shaped parts designed to fasten elements by screwing a metal die onto threaded rods.

Steel, aluminum or titanium alloys are used to produce products.

Titanium bolts are distinguished by high quality indicators. Black bolts for alloy wheels are made from steel with the addition of molybdenum or steel with a chrome or nickel coating.

What is important when choosing

When choosing, you need to decide on the following parameters:

- Dimensions. External characteristics are not decisive in selection. It is important to determine the diameter, length, depth and width of the well, and revolutions.

- Material. This is an equally important point when selecting fasteners. The main requirements in this case are aesthetic appearance and high strength. Budget products are made from metal, the rest are made from high-quality steel.

- Appearance. The ferrous metal rod negates the effect of the cast hubcaps. The modern Russian tuning market offers a wide range of decorative coatings. All that remains is to make a choice.

Characteristics of bolts and nuts

Bolts and nuts differ in design features, so the choice is determined by the type of disk. The stamped disc is made from a durable type of steel. Moreover, it has a small thickness at the point of attachment to the central part of the rotating part. For an optimal connection, the bolt and nut must have a flat surface. The composition of cast wheels includes relatively light alloys. They have reduced reliability characteristics. The fastening system of the products is made in the form of a cone.

Thread

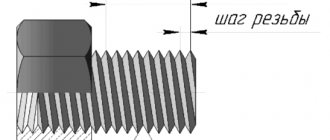

When purchasing bolts, you should pay attention to the threaded part. Not all elements have the same thread pitch. More often there are hardware with a thread pitch of 1.25 and 1.5 mm with a diameter of 12 or 14 mm. It is recommended to purchase new wheel bolts complete with rims or take into account the requirements of the car manufacturer's instructions.

Thread length

To select a bolt of the required length, the easiest way is to try it on site. This technique does not work if the bolt is coated with a coating that is difficult to scratch. Then another option will do; you will need to count the number of revolutions when unscrewing the old bolt. Next, the length of the threaded pin is divided by the resulting figure. The result will be the required length of the fastener.

By size, fasteners are divided into:

- short - used for fixing stamped disk products;

- long - used for tire mounting of alloy wheels.

Pressing surface

In accordance with the classification by landing zone, fasteners are distinguished:

- with a spherical connecting part;

- with a cone-shaped clamping part. Models are produced with and without gaps in the pressure zone. The size of the headrests is 1.3 millimeters.

Many motorists wonder what would be most suitable - a cone or a sphere. In each individual case, in order to select bolts for alloy wheels, it is recommended to seek help from a professional. He will advise what will be better.

Rules for selecting fasteners

When choosing, you should be guided by the make and model of the vehicle. This is the only way to properly secure and center the wheel. Each motorist selects the color and appearance according to his taste preferences. As for the technical characteristics, you should select them according to the rules.

Basic selection rules:

- The optimal speed is from 7 to 9. If it is less, there is a risk of losing a wheel along the way.

- The number of holes on the rod and disks must match each other.

- The thread stroke should be from 1.5 mm.

- The diameter of the threaded part should be chosen at least 12.

Bolt parameters for Renault cars in millimeters:

- The distance of the ribbed platform is 24.

- The distance between the ribbed strips is 1.5.

- Angle - 60 degrees.

- Key 17.

- Diameter - M12.

Mounting parameters for Skoda in millimeters:

- The rib lobe index is 26.

- Thread stroke - 1.5.

- Diameter - M14.

- Turnkey dimensions 17.

On a note!

To be sure of quality, you should purchase original factory models from trusted places.

What is a bolt pattern

Bolt pattern - indicators indicating the correspondence of the sizes of bolts and disks. The information is useful for searching for disk products. Based on the data, identical holes are found on new disks. The number of recesses is between three and six pieces, but the diameter and distance indicators differ for each manufacturer.

How to measure yourself

Measurements must be as accurate as possible, since the indicators differ in close values with a distance of a couple of millimeters, for example, 98 and 100 or 110 and 112, and they are not interchangeable. To eliminate errors, it is recommended to use a caliper or ruler.

Adjacent holes

Here's how to determine the distance between bolt holes. The dimensions of the circle on which the holes are located are taken. The diameter is determined using compatibility tables or by measuring using a ruler. The resulting distance between adjacent fasteners should be multiplied by a factor that depends on the number of holes. The circumference of a VAZ is 9.8 cm, and that of passenger cars is 139.7 millimeters.

Far holes

A simple measurement method is carried out on models with an even number of recesses - for 4, 6, 8 fasteners. Parallel Hole Distance – PCD.

And here’s how the far holes of disks with five bolts are measured: the calculation is made between non-adjacent recesses, the resulting figure should be multiplied by 1.051.

Hub window diameter

Indicative data for the central hub window are indicated in the table and in the complete bolt pattern formula. In the absence of information, readings are measured with a ruler or caliper. The diameter of the hub area on the VAZ 2110 = 58.6 mm.

The bolt pattern is carried out taking into account the relative size of the vertical axis of symmetry of the disk to the area adjacent to the hub.

Full and abbreviated bolt pattern formula

Manufacturers provide detailed wording that reflects all important meanings. Motorists use abbreviations that do not fully describe the product.

Abbreviated

PCD (Pitch Circle Diameter) is a short formulation that includes two parameters. It is indicated: 4×98 – wheel bolt pattern on a VAZ-2110. The number of four indicates the number of bolt recesses. The number 98 was obtained as a result of the transverse method of measuring their circumference.

Full

Let's look at an example: the full bolt pattern formula is indicated on the rim: 7.5 J×15 H2 5×100 ET 40 D 54.1.

Decoding of alphanumeric groups means:

- 5 JX 15 – rim width 7.5 inches and diameter 15 inches;

- X – indicates that the disc is made by casting or forging;

- J – it is recommended to use the product on single-wheel drive vehicles;

- JJ – marking of all-wheel drive models;

- H2 – the number of protrusions that secure the tires. Models with one protrusion - H1. Absence of protrusions - marking AN;

- Hump - indicates high-quality rubber retention; this feature eliminates depressurization.

Secrets

For car owners, the issue of protecting their car from theft or theft of parts has become no less pressing. Along with alarms and anti-theft devices, security bolts are popular. They have a special head for a key, which is included in the kit. Only the owner can open it. Vandals may try to forcefully remove the wheels, but nothing will work. It is no secret that in car services there are similar keys that are easy to pick up.

You may be interested in this About the characteristics of the bolt pattern of wheels on Renault

For maximum protection, it is advisable to choose the least common product

Types of secrets:

- With a curly profile. Lines of varying curvature are applied to the object. An intricate design is stamped onto the head, the imprint of which is repeated on the hollow key.

- With holes. Asymmetric holes of various sizes are drilled into the rod. The key, in turn, has correspondingly shaped protrusions. Options are possible when the convex parts are located on a metal rod, and the holes are on keys.

Note!

The downside is the likelihood of losing the key. In this case, neither the thief nor the owner himself will be able to remove the secrets. If there is a strong impact, there is a possibility of breaking the knob.

Consequences from another bolt pattern

Using inappropriate bolts is a safety hazard. When a bolt pattern occurs, an axial displacement of the entire wheel relative to the hub occurs. At high speeds, the wheel spins unevenly, the car will shake, which is accompanied by a beating in the steering wheel.

When installing wheels, car enthusiasts often encounter such a problem as a discrepancy in the diameter of the fasteners. In this case, eccentric bolts with a movable conical part are suitable, which will eliminate discrepancies in size.

Eccentrics

Standard fasteners have a hexagon shape, a threaded part and a conical clamping part. A unique characteristic of disc eccentric bolts is their floating cone with an offset center of gravity.

The degree of displacement can range up to 1 mm

The axial distance between holes may vary. The standards for this PCD indicator are varied and not always fully thought out. The result is vibration while driving. This makes it more likely that bearings, levers and rubber bands will fail faster. For such cases, the ideal solution would be to use eccentrics. Thanks to the movable cone, a gap is formed between the inner and outer diameters.

Tightening fasteners on alloy wheels

Before installing the bolts into the mounting recesses, it is recommended to treat the hardware with graphite lubricant. As a result, when it comes into contact with the disk, the head of the bolt or nut will rotate and make full contact. This will prevent blocking during starting power due to friction between the disc and the mounting system. Bolts are produced that compensate for minimal deviations in fastener dimensions. A loose connection will lead to cyclical failures in the fastening system; the bolts and nuts will begin to unscrew themselves.

Locking bolts for alloy wheels

Secret bolts for alloy wheels are another subtype. If you install locks, car tires will be protected from theft. You won't be able to remove the wheel with a regular wrench. To unwind the secrets, you will need a key that comes with them in one set.

When selecting fasteners for wheels, you should remember that cast products are relatively thick. Accordingly, longer bolts are selected for them than for stamped discs.

Many, especially novice, car enthusiasts, when certain situations arise, are interested in questions - where to buy bolts for wheels or where to buy bolts for wheels? However, despite all the apparent simplicity, the answers to these questions are not so clear.

The fact is that the modern automotive industry is very diverse. Accordingly, there are a large number of manufacturers and brands of cars. And almost every manufacturer produces wheel bolts that are suitable specifically for the vehicles they produce.

Therefore, before purchasing, you definitely need to read the information from the car’s registration certificate, which indicates which wheel bolts are used in your car. Well, you need to buy bolts for disks in accordance with this information.

The second important question is where to buy wheel bolts? The answer to this question is much easier. The Sekretki-spacers.rf store offers its customers wheel bolts, nuts, locks and other products. We draw your attention to the fact that the catalog contains only premium products. This means that when purchasing a product from us, you are purchasing excellent quality spare parts that are guaranteed to serve you for many years. You will find detailed information in the product catalogue.

Hello dear Drivers, it’s time to change the car’s shoes from casting to stamps. And the first thing every car owner thinks about is whether the bolts will fit. Everything is very simple. For casting we have long bolts from 28, 30, 33 mm.

But on stamped wheels these bolts will be larger and will touch the brake system elements in the drums of the rear wheels. So what kind of bolts exist? and how to choose them?

The first thing you can start with is which bolts are suitable for VAZ cars. Depending on the type of wheel, two types of bolts are used in VAZ 2110,2114,2115,1118,2170,2190 cars, short and long, where: 1) Wheel bolt for stamped wheels 21080-3101040-10 M12×1.25×23 wrench 17mm.

2) Wheel bolt for casting 21120-3101040-10 M12×1.25×27 wrench 19mm.

How to choose bolts that are suitable for disks?

And so the standard bolts that come from the factory with stamped disks have dimensions: 12 * 1.25, total bolt length 44 mm, threaded part length 24 mm. And the bolts for alloy wheels have a size of 12*1.25, the total length of the bolt is 51 mm, the length of the threaded part is 28 mm.

Thickness of the stamped disk at the attachment point. L=4 mm, Thickness of the cast disc at the mounting location. L=7 mm.

Conclusion: It is impossible to make a mistake in choosing the bolts for mounting the wheels, you just need to know the thickness at the place where the disk is attached and, taking into account the measurements, choose either a short or long bot. Good luck to everyone on the roads!

Replacing nuts on my car

Let's get back to the situation with my car. To the question that made me study this subject. Let me remind you that when replacing wheels, the tire service workers asked their wife for special nuts for alloy wheels, and when they didn’t find any, they insistently advised changing the existing ones to special ones.

Of course, I listened to their recommendations, after all, experts advise. Moreover, the story was as follows. The car was purchased from a dealership with a standard set of stamped wheels. Later, the stamped wheels were replaced with cast ones from the Russian manufacturer SKAD. The stamped discs were fastened with five conical nuts and of course no one changed these nuts. They also attached the casting. This made me wonder if I did everything right.

As it turned out, the purchased alloy wheels have a similar conical seat. When installing alloy wheels, the nut is completely screwed onto the stud, which has a small protrusion above the nut. That is, there are no deviations from the rules and regulations, as can be seen from the picture below.

The question arises: why did tire workers ask for special nuts for alloy wheels? Incompetence? They do not sell them themselves; there is no commercial benefit for them from such a replacement.

I was interested in this topic in other places. I didn’t go around the city specifically asking about the need to replace the nuts, but I did contact some tire shops that I came across along the way. No one answered me specifically or tried to understand the situation, even if there were no clients and the master was clearly idle. They spoke mostly in general phrases. “If your nuts are from stamping, then you definitely need to change them, otherwise it will be bad...”

Characteristic differences

Wheel bolts for stamped wheels differ in length and material. Usually good steel is used, which has several types of coating:

It must be said that any type of coating is only a top protective layer. Therefore, it cannot provide reliable protection against corrosion.

To give the stamped disc a more aesthetic appearance, chrome-plated bolts are ideal. If you properly care for your car and operate it normally, the bolts will never rust.

Appearance and service life

When choosing, most motorists tend to choose chrome-plated wheel bolts. However, no type of topcoat provides guaranteed protection against corrosion. It all depends on the operating conditions and quality of care. Molybdenum and nickel-plated screws are not inferior in performance.

The only objective advantage is the spectacular and aesthetic appearance of the chrome coating

The service life depends on the strength class, which is recognized as a quality mark. The higher this indicator, the longer the product can be used before corrosion occurs. The existing fittings are produced at Russian, European and Chinese factories. Russian-made mounts are suitable for domestic cars. For Volkswagen and other auto industry giants, you should choose Italian models created specifically for European cars. There are special catalogs for them with a number and article number.

Purchasing bolts for caps can sometimes be the only solution to the problem. For example, deficiencies in PCD readings between holes can be corrected using eccentrics. In addition to the main function, this part plays the role of an accessory that transforms the appearance of the car. To confidently move on the roads, you should determine what type of accessories will suit a particular vehicle.

What bolts are needed for stamped wheels?

If we are talking about VAZ wheels, then they are secured to the hub with fasteners, the length of which allows you to make 7-9 turns when screwing in. The most suitable length is considered to be sufficient to screw into the entire thickness of the hub on one side, with a small protrusion of 2-3 mm on the other.

To determine the exact length, you can use verification methods:

- Unscrew the used bolt from the wheel and count how many threads there are on it. Then divide the resulting number by the available bolt length. As a result, a result will be obtained showing the working length of the part.

- Buy the desired element in the store and screw it into a stamping disc. If the parameters match the rim, you can be sure that it will easily screw into the hub.

When purchasing a bolt, you should consider the following basic parameters:

It is necessary to select fasteners so that they do not unscrew spontaneously. If you make a mistake with the diameter, it may happen that only one or two fasteners are tightened, the rest will be loose.

As a result, the wheel will not take the desired position, the tires will begin to wear out quickly, the car will be unstable and may lose control.

The industry also produces bolts for stamped disks, called “secrets”. It must be said that this design is not very effective in terms of fastening, but it performs its protective function successfully. To screw it in and out you need to have a special “secret key”.

How to avoid wheel theft

To protect wheels from theft, some use “secrets,” as they are called. This is a bolt that cannot be unscrewed with standard tools, but only with an individual special key, available only to the owner of the car.

Various methods are used to protect such fasteners. For example, the head of a bolt can be made in the shape of an irregular polygon or a completely arbitrary figure; one of the profiles is sometimes shifted to the side. A perforated profile with holes of various diameters and depths is also used. You cannot determine the reliability of secrets by looking at their profile; it is more important to use products from proven and reliable manufacturers.

Usually, in order not to ruin the secret bolt, it is tightened with less force. Because of this, such wheel bolts in the VAZ 2109 are placed one on each wheel. Unfortunately, in our country there are still people who like to “take off” your car’s shoes, so the topic of secret locks remains relevant for now.

All these secrets make it difficult for lovers of easy money to remove the wheels, they make it difficult. Because if you have time, you can unscrew everything, but thieves have little time.

Therefore, in order to most effectively protect your wheels, you should follow several rules.

- It is better to buy expensive secrets, this helps to avoid matching products. Because when producing unique secrets, after some time the cycle repeats, and there is some chance of repetition of parts. But in expensive products such coincidences are excluded.

- If you buy alloy wheels, it is better to choose ones in which the secrets would be “recessed” inside the disk rather than on the surface. They are more difficult to unscrew.

- It is worth purchasing bolts with a flat pattern at the top of the head, which is not sharpened to a key. (For example, an asterisk or a heptagon). That is, the drawing should be as unusual and flat as possible.

The price on the Internet for regular wheel bolts is from 14, and for “secret” ones from 160 rubles.

Sometimes car enthusiasts use bolts for VAZ 2109 wheels with an offset center. They are easy to find in online stores. Such bolts are used if there are no original disks and others have been installed with slight differences. The eccentric bolts allow you to align all the holes and securely fasten the wheel.

Bolts are made from different materials. This can be steel with an admixture of molybdenum or steel coated with nickel, chromium, etc., sometimes even titanium. Coated bolts have a nice appearance. But don’t think that this is the best choice. The problem is that any bolts are susceptible to corrosion. And the technology of nickel or chromium coating with sufficient stability has not yet been created. After a year, coated bolts will inevitably lose their beauty. Therefore, the appearance of the bolts is practically unrelated to their operational data. The most important factors are strength, thread pitch, length and type of bolt head.

To change wheels yourself, you need to know how to properly unscrew and tighten the wheel bolts. To do this, you should look at the photos and videos. There are a lot of such materials on the Internet. There are also instructions online for tightening bolts using a torque wrench. It is especially important when installing new bolts after approximately 50 km to check the tightness of all bolts. Most likely, some of them will have to be tightened up!

What nuts are needed for stamped wheels?

Today, on some domestic cars, as well as foreign cars made in the USA and Japan, disks are secured with several types of nuts:

- Open,

- Closed,

- With or without collar.

Closed wheel nuts protect the hub from dirt. They are made, similar to bolts, from different materials.

The most commonly used are stainless steel or titanium. When choosing a wheel nut, you need to take into account the most important parameter - thread matching.

Nuts are also made of aluminum. They are designed for mounting wheels on sports cars.

The parts are distinguished by their low weight and increased softness of the metal. Such nuts must be constantly monitored and tightened.

Open type cone nuts are also used to fasten stampings. For wheel tuning, titanium nuts are installed. Their main difference is considered to be high strength and low weight.

However, titanium is a noble and not cheap metal, so not everyone can afford them - their cost is an order of magnitude higher than similar fasteners.

Centering rings

Another wheel fastening element that can only be used for alloy wheels is the centering ring. Rings will be needed if the diameter of the central hole of the disk is larger than what the car manufacturer recommends. The rings form a tight connection between the wheel rim and the seat on the hub. They are also designed to center the wheel on the hub and evenly clamp it with fasteners.

Centering rings must be plastic, and you should buy them in stores. Metal homemade products turned on a lathe cannot be used, as they cause an imbalance and become tightly stuck.