What a “grinder” is nowadays, even a schoolchild knows, is an angle grinder designed for working with metal workpieces using special cutting and grinding wheels. Not everyone, but only professionals, know that such an electric tool can be used for processing wood, so this article is intended to fill this gap in the information available to ordinary users. Disc for an angle grinder for wood - types, general characteristics and standard sizes, as well as safety measures for use and a review of prices for popular models - this is the topic of this article by the editors of HomeMyHome.ru

Depending on the type of discs used, the “grinder” in skillful hands can be used at various stages of working with wooden workpieces: from sawing to grinding

Is the angle grinder designed for working with wood?

The “grinder” was not originally intended for sawing wood, especially for workpieces of considerable thickness and hardwood. This is due to the design features of this type of tool and the associated dangers of use:

- when the saw blade jams, it is difficult to hold the angle grinder in your hands, which can lead to injury;

Important! Jamming of the saw blade when using an angle grinder to cut wooden workpieces is the most common problem with this type of work, which is due to the softness and viscosity of the wood.

- Inhomogeneity of the wood structure due to the presence of knots can lead to damage to the saw blade being used and injury to the user.

Using special circles and following safety rules, the likelihood of injury can be reduced to zero, even when sawing lumber products.

Despite the potential danger of using angle grinders as a tool for sawing wooden products, manufacturers of consumables, which include grinder discs, produce similar products .

Expert's point of view

Victor Isakin

Tool selection specialist for the 220 Volt retail chain

Ask a Question

“For processing workpieces of considerable thickness and for professional use, it is most correct to use a tool originally intended for sawing wood, such as a circular saw and a circular saw.”

The main and most common uses of grinders when working with wood are: stripping, grinding and polishing, for which manufacturers produce special types of discs.

The best wheels with a diameter of 260-310 mm

Large-diameter equipment is suitable for sawing large boards, panels and timber. Recommended for use with powerful professional tools with reliable protection.

Makita Standard B-29234 260x30 mm

High-quality equipment for the Makita Standart B-29234 grinder will provide a clean and accurate cut when sawing hard and soft wood, as well as derivatives of this material.

The model is equipped with 40 teeth made of hardened steel, the seat size of the disc is 3 cm, the outer diameter is 26 cm.

The presented saw blade is recommended for use with professional angle grinders.

The device allows you to perform work at speeds up to 5870 rpm.

The equipment is supplied in high-quality and ergonomic packaging.

Specifications:

- outer diameter - 26 cm;

- landing size - 30 mm;

- number of teeth - 40;

- speed - 5870 rpm;

- disc type - carbide;

- processing material - wood.

Advantages

- affordable price;

- holds the angle well;

- clean cut;

- no beats.

Flaws

- does not work well with hard materials;

- the paint wears off quickly.

Makita Standard B-29290 305x30 mm

The Makita Standart B-29290 model, made of carbide materials, will allow you to produce precise and clean cuts when working with boards, planks, baseboards and other elements during finishing and construction.

The equipment is characterized by a long service life, a special ATB tooth shape, and a hardened blade with 80 teeth.

The disc, with its own thickness of 1.8 mm, allows cutting up to 2.3 mm.

Recommended for use with corded and cordless angle grinders with a 3 cm diameter mounting hole.

Specifications:

- outer diameter - 30.5 cm;

- landing size - 30 mm;

- number of teeth - 80;

- speed - 5000 rpm;

- disc type - carbide;

- processing material - wood.

Advantages

- high-quality cut;

- large diameter;

- no beats;

- convenient packaging.

Flaws

- high price;

- not suitable for high speeds;

- noisy model.

BISON Expert 36907-305-30-100 305x30 mm

Saw blade BISON Expert 36907-305-30-100 with trapezoidal teeth and a negative angle of inclination is suitable for precise longitudinal and transverse cutting of wood, aluminum, laminate and plastic.

The teeth in this model are reinforced with plates made of hard-alloy tungsten carbide materials (VK8), provided with automatic three-sided sharpening with grinding of each element for ideal geometry.

The equipment, with its own thickness of 2 mm, makes it possible to make cuts with a width of 2.8 mm.

The maximum speed of the model is 5000 rpm.

Specifications:

- outer diameter - 30.5 cm;

- landing size - 30 mm;

- number of teeth - 100;

- speed - 5000 rpm;

- disc type - carbide;

- processing material - wood, plastic, metal.

Advantages

- works with a wide range of materials;

- gives a clean and even cut;

- perfect workmanship;

- high performance.

- Advantage;

Flaws

- not an affordable price tag;

- there are vibrations;

- heavy weight.

- Flaw;

DeWALT Extreme DT4260-QZ 305x30 mm

The high-quality carbide saw blade DeWALT Extreme DT4260-QZ will provide accurate cuts when working with plywood, veneer, soft and hard wood.

The presented equipment is also suitable for cutting soft non-ferrous metals.

The model can be used with corded and cordless angle grinders with a 3 cm mounting hole.

With its own thickness of 1.8 mm, the element provides a cut of 2.6 mm.

The equipment has improved balancing, which prevents bending and vibration and provides increased cutting accuracy.

Specifications:

- outer diameter - 30.5 cm;

- landing size - 30 mm;

- number of teeth - 60;

- speed - 5800 rpm;

- disc type - carbide;

- processing material - wood.

Advantages

- high-quality execution;

- renowned manufacturer;

- clean and even cut;

- excellent tooth sharpening.

Flaws

- non-critical beats;

- heavy weight;

- high price.

CMT 294.060.11M 260x30 mm

Saw blade CMT 294.060.11M, suitable for use with angle grinders, is an ideal solution for cutting soft and hard wood, plywood, veneer, and various panel materials.

The model guarantees clean and precise longitudinal and cross cutting.

The equipment is compatible with corded and cordless angle grinders with a 3 cm mounting hole.

The thickness of the disc is 1.8 mm, the cutting width is 2.5 mm.

The model maintains a maximum speed of 7300 rpm, weighs 1900 g, and has slots that reduce vibration and noise.

Specifications:

- outer diameter - 26 cm;

- landing size - 30 mm;

- number of teeth - 60;

- speed - 7300 rpm;

- disc type - carbide;

- processing material - wood, plate.

Advantages

- workmanship;

- absence of beats and vibrations;

- large disc diameter;

- quality cut.

Flaws

- high price;

- the equipment is heavy;

- noisy at high speed.

General characteristics of discs for grinders, depending on the type

Discs designed for different types of use vary in their design and the materials used in their manufacture. In this regard, different types of similar products have different general characteristics, which requires their separate consideration.

Circular disc for angle grinders for wood, 125 mm

Cut-off models

There are several types in this product category:

- circular saw blades – considered “dangerous” saw blades;

- chain - made using links intended for chain saws;

- with a small number of teeth - they are the safest compared to compass analogues;

- made of tungsten carbide - the safest type of such equipment.

The chain disk can be used for both sawing and roughing

For your information! Circular discs come in two modifications: a “dangerous” and a “less dangerous” option. A distinctive feature of models of the “less dangerous” type is the presence of protection against jamming, provided by the spread of the teeth.

Chain modifications are less dangerous when used, because Their design provides for a non-fixed fit of the saw chain on the surface of the disc.

Expert's point of view

Victor Isakin

Tool selection specialist for the 220 Volt retail chain

Ask a Question

“If the saw chain jams during use, the disk mounted on the angle grinder continues to rotate, the tool does not break out of the hands, allowing it to be stopped in an emergency.”

A disc with a small number of teeth cuts wood well both along and across the grain

Discs with a small number of teeth come in two types:

- with 3 teeth – used with small “grinders” with a diameter of up to 150 mm;

- with 4 teeth - used on large grinders with a diameter of 230 mm.

A distinctive feature of models made from tungsten carbide is the absence of teeth on the cutting surface of the product. The cutting element is the segments located around the circumference of the disk.

Important! Tungsten carbide models are capable of sawing various metal products (nails, screws, etc.) that may end up in the workpiece without damaging the cutting elements or their integrity.

Appearance of a tungsten carbide disc mounted on an angle grinder

Discs for roughing work

For stripping wooden products, manufacturers produce several types of attachments that differ in design and types of materials used in their manufacture.

A grinding disc with crumbs applied to its surface

By design, such nozzles can be made in the form of:

- a disk with spikes or crumbs applied to its surface;

- glasses with cutting elements made of twisted wire inserted around its circumference;

- disk with wire turns mounted on its surface.

Expert's point of view

Dmitry Kholodok

Technical director of repair and construction

Ask a Question

“Sanding attachments are used to remove paint and other coatings applied to a wood surface, as well as to rough the wood surface being leveled.”

Attachments for the “grinder”, which have twisted wire elements in their design

Grinding and polishing models

To perform grinding and polishing, there are special attachments used for both wood and other materials (metal, plastic, glass, etc.).

Set of polishing attachments for angle grinders (125mm) Bison model “3591-125-H7”

Nozzles used for such purposes are of two types:

- the basis of the design is a metal base fixed to the angle grinder shaft, and circles made from sandpaper of different grain sizes or polishing materials (felt, fabric, etc.), which, in turn, are attached to the base using Velcro;

- flap sanding wheel.

Flap sanding wheels are available in different grits, which allows you to choose the one you need for a specific type of processing.

What types of cutting wheels are there?

Parameters used to classify cutting discs for wood:

- Disc diameter;

- Depth of wood cut;

- Characteristics of teeth: shape, frequency, number.

What should you consider when planning to use a cutting disc for a modern grinder?

- If cutting saw blades for an angle grinder on wood will be rarely used, and the type of wood being processed will be different, it is best to choose a model with variable beveled teeth.

- Models with straight teeth are suitable for cutting coniferous and soft wood. Such saw blades successfully process even the softest wood, guaranteeing a decent work result.

- The trapezoidal tooth allows for universal use. When choosing such equipment, it is best to cut medium-density chipboards. If desired, you can use other types of products.

What parameters are desirable to take into account for successful work with wood when choosing sawing consumables?

- Rounded cutouts are required, which will be made towards the shaft.

- The optimal disc thickness is 2 mm.

- The depth of the cuts made can reach 20 mm.

- The cutouts may be empty, but in some cases they are filled with copper.

Equipment for grinding and roughing work

In most cases, working with materials involves the need not only for polishing, but also for grinding and roughing activities.

Cutting wood is a dangerous activity . At the same time, anyone with the necessary equipment can grind the array. The most important thing is to understand the principles of performing technological operations.

Most often, petal discs on an angle grinder are used for peeling. By carefully studying the specifics of the product, you can understand how functional and effective it is.

The name gives an initial idea about the design features of the consumable tool. Its working surface has several sandpaper petals. This structure is comparable to fish scales. At the same time, such low-roughness paper allows you to guarantee a soft sanding of natural wood. The quality and degree of processing depend on the grain size of the material, so polishing and grinding can be carried out in accordance with the requirements.

The flap disc for an angle grinder is quite popular, but if desired, you can use another consumable tool.

For example, the sticky universal disc deserves attention. Modern attachments for grinders provide the ability to quickly change Velcro. The price of the adhesive discs used for basic operations is lower than that of a solid blade disc, but the service life is also shorter. If, however, you choose a universal adhesive wheel for an angle grinder, then it can be used for processing and grinding various materials, which confirms the demand for this product.

Polishing and grinding tools may be of high quality, but they cannot guarantee successful completion of the job. What is the reason for this? It's very simple: the wood used must be thoroughly dried. Moreover, raw wood should not be used. Otherwise the result will be unpredictable. When choosing a blade for wood, you need to be sure that the material being processed has the appropriate properties.

Sometimes stripping work is required to remove the old layer of paint or varnish, or fungal infections. Polishing and grinding tools always perform at a decent level only if the wood is prepared according to technological requirements. Taking into account that polishing and grinding discs for grinders are not provided for initial processing, roughing attachments are required.

When choosing similar attachments for an angle grinder, you can feel the maximum benefit from them when cleaning old surfaces that have been painted many times. This is explained by the following factor: the nozzles are made in the form of a metal plate, which is densely studded with wire bristles located closer to the outer circumference, radially or perpendicular to the disk.

Tips for work

Finishing work begins only after the workpiece has been successfully given preliminary outlines. The results largely depend on what types of attachments are used to perform the assigned tasks.

Angle grinders are used as a cutter, as well as polishing and grinding devices. Attachments for an angle grinder increase the functionality of the device used.

So, how to carry out the polishing and sanding process when processing wood? What tools are needed for successful work?

- Brush cord. These tools are ideal for rough sanding of wood. It is assumed that it is possible to successfully level the wood, giving the optimal shape to the product.

- End discs make it easy to grind workpieces. In most cases, such work is required for miter cuts. The operation of the end disk resembles the interaction of the workpiece with the saw.

- Flap sanding attachments are the most popular type of consumables used. The characteristics of the tool determine the ability to process various workpieces, including natural wood. It is important to note that cleaning of complex wooden objects is carried out only using radial strips.

- Felt wheel - allows you to achieve minimal roughness in processed products. The basis is compressed wool, fine-haired, semi-coarse-haired and coarse-haired. A felt working tool allows you not only to carry out high-quality processing of wood or other material, but also to give a perfectly smooth surface comparable to a mirror.

- A grinder wheel intended for grinding is often compared to a disc of the same name. It is important to note that the Velcro circle is a universal tool with a wide range of applications. Various woodworking tools perform specific tasks, but the sanding wheel sometimes surprises with its versatility and high level of efficiency.

- A chain disk for wood is one of the most productive, but crude methods of processing natural material.

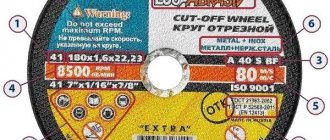

When choosing equipment, it is advisable to take into account not only the diameter, but also each accompanying informative designation. The inscriptions will allow you to determine the purpose of the tool and follow the recommendations during operation. Marking discs, circles and attachments for an angle grinder is a guarantee of a successful result.

A modern grinder is a convenient and effective tool. For high-quality work, special attachments and discs are required that allow you to effectively process wood, metal and any other material of interest.

Standard wheel sizes for grinders

When producing discs for angle grinders, the company's manufacturers operating in our country produce their products in accordance with the following regulatory documents:

- GOST 21963-2002 (ISO 603-15-99, ISO 603-16-99) “Cutting wheels. Technical conditions".

- GOST R 53410-2009 (ISO 603-12:1999-ISO 603-14:1999, ISO 15635:2001, ISO 13942:2000) “Grinding wheels for hand-held grinding machines. Technical conditions".

In accordance with these documents, the standard sizes of disks used on angle grinders are: 115, 125, 150, 180 and 230 mm.

For your information! The seat size for all standard sizes is 22.2 mm.

The use of angle grinders for grinding wooden products is quite widespread among users of different categories.

Types of discs for working with wood

The rotation of the spindle on which the disk is mounted is used for various jobs: sawing, planing, milling and many others. Special wheels significantly expand the functionality of the angle grinder.

Circular (toothed)

circular saw blade

The oldest of all wood cutting discs. Their distinctive feature is the presence of triangular teeth with which wood is cut.

Often they come with win solder (tungsten carbide). This allows the discs to maintain excellent sharpness and hardness even under intense wear and heat.

Such discs cannot be installed on an angle grinder. They are designed for circular saws.

Chain

The design is simple: the thick-walled disk has an end groove in which the saw chain is located. At rest, it moves freely in the groove, but as soon as the speed increases, the centrifugal force jams the chain with special cams and begins to rotate along with the disk under the influence of friction.

chain disc for grinder

This arrangement provides unsurpassed security. When the chain bites, it simply rotates along the cam groove, giving the operator the ability to turn off the rotation. This does not affect her performance, but may save her from injury. Unfortunately, such disks have a significant drawback - their high price, since such equipment is much more difficult to manufacture.

Universal

universal disc for wood

It gets its name from the fact that it can work with a wide range of materials. This is not only solid wood, boards and timber, but also chipboard, fiberboard, MDF, and polymer products.

The universal disk is made of steel. It has a straight and even edge, with grooves in three places, on one side of which there are carbide cutters.

With only three cutting elements around the circumference, the high rotation speed is compensated for and the blade is much safer to handle than a traditional serrated blade.

For the first time such discs were produced under the Graff Speedcutter brand. Until now, they are considered the standard of quality, although many companies specializing in angle grinders have begun to produce them.

With cutting edge made of tungsten carbide chips

Externally, this disk is similar to a segmented metal disk - approximately the same thickness.

But there are also differences: the circle on the tree consists of a strong steel base, on the side of which a special abrasive is applied around the circumference - tungsten carbide chips. Due to this, the edge of the disk is rough.

tungsten carbide disc for wood

The tungsten carbide blade can be used on all types of wood and wood products, as well as hard plastics.

Tungsten carbide is heat resistant, so there is no need to worry about overheating during normal operation.

When working with such a disk, quite a lot of fine dust is produced, this is a kind of disadvantage.

Many companies produce such discs, but Bosch discs are considered one of the most reliable and high-quality.

Petalaceae

Abrasive flap disc

These are circles designed for processing wooden surfaces. They have a combined structure: pieces of sandpaper are attached to the base, which overlap each other, like in a flower. The record got its name from this similarity.

Using it on wood gives the effect of sandpaper. It works no worse than a belt sander, so for one-time rough jobs, it’s a smart decision not to buy a separate tool.

Petal radial

Another type of circle that uses sandpaper fragments. Only now they are attached to the end of the base, spreading radially to the sides.

flap discs for grinding on an angle grinder

The disc touches the workpiece with its edge, providing grinding in hard-to-reach and critical places: grooves, channels, recesses. The radial petals wear out.

Polishing

polishing disc for grinder

If sanding involves removing a significant layer of wood to level it, polishing is the final step. Polishing wheels are used to give the product a smooth finish.

Most often they consist of two parts: a hard base with a soft pad and a removable nozzle with a sticky layer.

The accessory consists of many fine-grained abrasive cubes. Due to their softness, they wear out quite quickly, after which the nozzle is changed, but the base remains - a significant plus for savings.

Brush (wire)

Brush (wire) discs for eyelash machines

The disc consists of metal wires that are tightly intertwined and collected into bundles (for rough processing) or secured at only one end, maintaining their shape due to internal elastic forces.

There are two types: corner and end. These attachments are often used to remove old paint or varnish. This is significantly faster and more efficient than sanding because the ends of the wire brushes not only remove the paint layer, but also grab the edges and remove, exposing the wood. After treatment with a rough brush-disc, the surface must be sanded and polished.

Milling

Milling disc for grinder

An original design that allows you to mill wood surfaces. In this case, there is a hollow toroid with several slots along the edge of the circle into which carbide blades are placed.

They can be combined into one with the base, or they can be removable. In the second case, the wear problem can be solved by replacing the cutting parts.

One of the most famous companies producing milling accessories for grinding machines is the Australian company Arbotech. Its products are expensive, but at the same time they are of high quality and excellent cutting characteristics.

The range includes not only round flat disks, but also cylindrical end disks, with which you can mill grooves, slots, and holes.

woodworking

On the domestic market of hand-held electric tools, discs for angle grinders from Russian and foreign companies are presented. Among them, the most popular are:

- "GRAFF" (Belarus);

- "GREATFLEX" (China);

- "Bosch" and "Klingspor" (Germany);

- “Ziflex”, “PRACTIKA”, “LUGA” and “ZUBR” (Russia);

- "Makita" and "Hitachi" (Japan);

- "FIT" (Canada).

In addition to the brands listed above, other manufacturing companies are also popular in different regions of our country, which is due to the location of the region and the presence of dealers of these companies in a particular territory.

Saw blade brand “Zubr” with outer diameter 235 mm

Technique for sanding wood with an angle grinder

When starting to process wood with an angle grinder, you need to keep two main points in mind:

- You should not process the surface of the workpiece with the entire area of the grinding disc, as marks from the wheel may remain. Only the upper part of the nozzle is used.

- During sanding, the grinder is guided along the grain of the wood: this way there will be no marks left. At the same time, it is important to find a support point so that your hands do not get tired.

The general process of sanding wooden surfaces with a grinder is divided into several separate stages:

- Preliminary preparation of the coating. All remnants of the previous paint and varnish are removed with rough grinding wheels. It is also worth making sure that there are no nails or screws sticking out from the floor or wall, if they are the ones being sanded. Protruding fasteners must be removed, and if this is not possible, immersed as deeply as possible into the surface so that they do not in any way affect the operation of the angle grinder.

Pre-processing of the part

When sanding floors, there are two more mandatory rules. Even if only a small area of the floor is being processed with a grinder, it is recommended to remove all furniture from the room and cover doorways and windows with thick film or oilcloth to protect from dust. Any cracks or gaps in the working surface are unacceptable. Only after filling the holes with a special wood putty and drying can you start sanding.

- Primary grinding. It is carried out with coarse-grained discs in the range P20-P40. If you don’t have such a circle at hand, you can cut out and glue a piece of sandpaper to the angle grinder attachment. Perform 2-3 passes with a grinder over the entire working area. At this stage, it is especially important to control the force of pressing on the nozzle: weakly - the processing will not be good enough, too much - a large load on the angle grinder motor.

Primary grinding

- Fine stripping. Replaceable petal attachments of varying degrees of granularity are used - from P60 to P80. The master makes 1-2 full passes over the wooden workpiece being processed.

Fine grinding is done using a flap attachment.

- Putty gaps. After sanding, all gaps must be eliminated. First, they are passed over with a nozzle with a minimum grain size, and then the treated areas are puttied. Two points are worth highlighting here. In places that are difficult to access, you will have to process them manually. Plus, during grinding a lot of dust is generated, and we must not forget to remove it in a timely manner.

Wood putty

Final grinding steps

Final polishing of the wooden surface is carried out using sanding discs made of felt and soft cloth marked P100 or P120. A wax-based polishing paste is first applied to the wood, and then 1-2 passes are made along the surface area to be treated. After polishing, all that remains is to prime the surface. By priming, not only the remaining small roughnesses are smoothed out, but the service life of the wood is also extended. Oil paints or alkyd enamels are best suited as a primer for wood.

The procedure is done manually with brushes in the following sequence:

- Dip the brush well in the primer, apply to the workpiece, spread over the entire area.

- Wait until the paint is completely absorbed and the wood dries - at least 2 days.

- Apply 2 more layers of primer, and the second can be coated only after the first has dried.

- After this, the priming will be completed. You can apply a top coat of varnish to the wood.

Priming wood

Safety precautions when working with a grinder on wood

When performing work on wood processing using an angle grinder, the safety measures are the same as when using metal and other materials. However, in connection with the physical properties of wood, which have already been written about above (softness and viscosity), it is necessary to take them into account, and in this regard:

- You cannot fix the “Start” button, because in this case, it will not be possible to quickly turn off the tool.

- Sawing workpieces must be performed at a strictly specified angle, without creating distortions that can cause the saw blade to jam.

- All work must be carried out with the protective cover installed and the use of personal protective equipment (gloves).

When performing grinding work, the use of respiratory protection is also necessary. - It is better not to use “dangerous” saw blades equipped with large teeth on large-sized “grinders”, because In the event of an emergency, it will be impossible to hold the tool in your hands.

- The presence of a speed controller on the tool is not a prerequisite for its use for such work, but it is desirable, because This will reduce the likelihood of injury if the saw blade jams.

What to look for when choosing a saw blade for wood?

The key features that you should pay attention to when choosing a saw blade for an angle grinder are the following:

- External diameter of the equipment. The size of the wheel largely depends on the power of the angle grinder and the type of work being carried out. 12.5 cm discs are considered the most suitable for wood. A larger diameter increases productivity, but requires professionalism and increased safety measures.

- Internal (landing) diameter. For angle grinders it is standard - 22 mm. Otherwise, the disks can be installed through special adapter rings. Some equipment models may be equipped with this accessory.

- Disk type. Monolithic equipment is characterized by low cost, but requires periodic setting of teeth and sharpening. More durable carbide blades require little maintenance and provide clean cuts at any speed.

- Number of teeth. Cross cutting requires the use of discs with a large number of cutters - 60-90. Accordingly, longitudinal cuts are obtained better when using models with a small number of teeth.

- Rotational speed. High speed blades are suitable for working with dense and hard wood. The low-speed attachment is ideal for soft and sticky wood.

Review of prices for popular models

The cost of products depends on the place of their sale, technical characteristics and brand of the manufacturer. This section of the article presents several models, on the basis of which one can get an idea of the order of the numbers that determine the cost of one or another type of similar product.

"GRAFF Speedcutter"

The “GRAFF Speedcutter” disc is a model with a small number of teeth.

The disc is designed for sawing wood and plywood, laminate and board materials (fibreboard, chipboard). The model is equipped with three teeth.

| Disk type | Outer diameter, mm | Thickness, mm | Weight, kg |

| Cut-off | 115 | 3,8 | 0,12 |

Review of the “GRAFF Speedcutter” model:

More details on Otzovik: https://otzovik.com/review_6165824.html

GRAFF Speedcutter

"GREATFLEX 71-125120"

This petal-type model is made on a fabric basis using abrasive materials

GREATFLEX 71-125120 and consists of 72 petals located at an angle of 10˚ to the working plane of the disk, which allows to increase the efficiency of use of the product.

| Disk type | Outer diameter, mm | Grain | Weight, kg |

| Grinding (flap) | 125 | 120 | 0,08 |

Review of the GREATFLEX 71-125120 model:

More details on Otzovik: https://otzovik.com/review_4655934.html

GREATFLEX 71-125120

"Bosch 2608623013"

“Bosch 2608623013” can cut wood and nails, plastic and drywall.

This model is coated with hard metal alloys and is universal in its use.

| Disk type | Outer diameter, mm | Thickness, mm | Weight, kg |

| Cut-off | 125 | 1 | 0,15 |

Review of the Bosch 2608623013 model:

More details on Otzovik: https://otzovik.com/review_3959218.html

Bosch 2608623013

"PRACTICE 773-606"

Appearance of “PRACTICA 773-606”

| Disk type | Outer diameter, mm | Grain | Weight, kg |

| Rough | 125 | 24 | 0,3 |

PRACTICE 773-606

"FITIT 39556"

The FITIT 39556 model is successfully used for grinding materials of varying degrees of hardness

| Disk type | Outer diameter, mm | Grain | Weight, kg |

| Grinding (flap) | 125 | 120 | 0,07 |

The cost of “FIT IT 39556” ranges from 95 to 130 rubles, depending on the company selling the product.

FIT IT 39556

"Luga 3656-125-25"

Appearance "Luga 3656-125-25"

One of the most widespread models among ordinary users. It is characterized by low cost and good performance characteristics.

| Disk type | Outer diameter, mm | Grain | Weight, kg |

| Grinding (flap) | 125 | 60 | 0,09 |

Review of the Luga 3656-125-25 model:

More details on Otzovik: https://otzovik.com/review_3749759.html

Luga 3656-125-25

Precautionary measures

The master in the photo did everything right - he put on gloves, goggles, a respirator and clothes with sleeves.

When processing wood with hand tools, it is important to follow safety precautions and precautions. This is especially true for grinders, because the rotation speed of the circle reaches 13,000 rpm.

There is no such thing as too much protection.

It is imperative to protect your eyes, hands and respiratory tract, for which the following means are used:

- Construction safety glasses or masks;

- Work gloves made of fabric or canvas;

- Respirators or gauze bandages;

- Long sleeve robe;

- Various protective covers for tools, suction and removal systems for chips and dust.

High-quality models of sanders are equipped with vacuum cleaners to remove sawdust.

Important! When working with an angle grinder using rigid attachments, the operator must be in an area that does not intersect with the plane of the scattering of fragments when the wheel is spaced apart during rotation.

Tips and tricks for sanding wood using an angle grinder

Some useful tips about sanding wood with a grinder:

- It is important to choose the right angle grinder for this job. It is recommended to use a tool with a speed of up to 6 thousand per minute or a speed controller. At high speeds, grinding discs are more susceptible to clogging and, accordingly, wear out more quickly.

- To avoid the wire getting in the way while working, it is better to use a cordless angle grinder.

- Sanding wood involves a lot of dust and shavings, so angle grinder models with motor protection are preferable. Another option is to attach a dust collector to the grinder.

- Eye and respiratory protection is necessary when operating an angle grinder. There should be mittens on your hands.

- The protective cover of the grinding disc must not be removed during operation. It also has a protective function: if the circle breaks into small fragments, the casing will protect the master from falling fragments.

- If a cutting wheel is installed on the angle grinder, the wooden surface must be polished strictly at a right angle. Otherwise, the grinding will turn out uneven, and the angle grinder itself may jam in the workpiece.

- It is better to never use grinding discs that do not fit the grinder in at least one of the dimensional parameters.

- It is not allowed to use a wheel with even minor defects.

- Circles for circular saws and other third-party attachments should not be installed on an angle grinder - there is no need to reinvent the wheel, standard grinding and cutting discs are sufficient. In addition, this is impractical: circular saw discs are designed for a much lower speed, which means that the grinding will be of poor quality, and the disc itself may break.

Cleaning wood with a grinder is a simple procedure, but the result will meet expectations only if all stages are performed correctly: surface preparation, primary and fine sanding, filling gaps, polishing, priming. You should only use abrasive wheels of the appropriate size and grit.