Weight of steel sheet, table of sheet weight and thickness according to GOST

Constant improvement of the construction industry brings various new products into our everyday life, with the help of which modern builders have the opportunity to build new structures. Such innovations make it possible to invent more universal elements that find their application in mechanical engineering, the production of specific equipment and in other areas of human activity.

One of these elements is steel sheets, which act as an indispensable part in the construction of various building structures and are used in the development of modern cars and various equipment.

Steel sheets advantageously combine strength, reliability, durability and availability, which makes them very popular design elements among domestic and foreign manufacturing companies.

In more detail, the advantages of steel sheet allow it to be used for:

- construction of welded structures;

- creating hulls for cars or watercraft;

- production of equipment resistant to chemicals and elevated temperatures;

- production of agricultural and industrial machinery.

By the way, the weight of such a sheet is as acceptable as possible, which makes it available for delivery to any facility - customers can place an order for a large batch of steel sheet that will fit even in a not very spacious car.

Due to the specifics of the sheet, including weight, each individual element fits comfortably on top of the other, which ensures the most compact packaging, which has a positive effect on maintaining the integrity of the sheets during transportation.

Variety of steel sheet

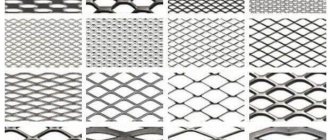

In practice, with the use of modern equipment and a team of experienced professionals, steel products can be manufactured in a wide variety of designs, which allows company clients to implement almost any design solution! Consumers are offered products in the following versions:

- with a corrugated surface (used in the installation of production sites, for the production of high-quality comfortable stairs and other structures where it is necessary to minimize the possibility of sliding on the surface);

- with a corrugated surface (such sheets are mounted as a roofing surface; there is additional treatment with zinc or polyester to increase the original technical characteristics, including reducing the weight of such sheets);

- with a perforated surface (the structural element is produced for the purpose of using it to create unique designer interiors);

- with a cut surface (coated with polymer materials and used for technical purposes);

- stamped sheet (designed for processing external walls of buildings).

As you can see, multifunctional steel sheets can be used for a variety of purposes, the specifics of which are significantly different. Customers only need to indicate their requirements to manufacturers, who are ready to produce high-quality steel elements with specific features.

Weight of steel sheets

Do not forget that the less mass a component has, the easier and more profitable it is to use it to implement your projects. The weight of the steel sheet makes it stand out among other similar products. Detailed data on the mass of products (sheet weight and thickness) can be found in the table below:

| Rolled sheet metal according to GOST | |||||||

| thickness of steel sheet, mm | sheet weight, kg/m2 | thickness, mm | sheet weight, kg/m2 | thickness, mm | sheet weight, kg/m2 | thickness, mm | sheet weight, kg/m2 |

| 0,5 | 3,925 | 1,4 | 10,99 | 6 | 47,1 | 18 | 141,3 |

| 0,55 | 4,32 | 1,5 | 11,77 | 7 | 54,95 | 20 | 157 |

| 0,6 | 4,71 | 1,8 | 14,13 | 8 | 62,8 | 22 | 172,7 |

| 0,7 | 5,5 | 2 | 15,7 | 9 | 70,65 | 25 | 196,25 |

| 0,8 | 6,28 | 2,5 | 19,62 | 10 | 78,5 | 30 | 235,5 |

| 0,9 | 7,06 | 3 | 23,55 | 12 | 94,2 | 40 | 314 |

| 1 | 7,85 | 4 | 31,4 | 14 | 109,9 | 50 | 392,5 |

| 1,2 | 9,42 | 5 | 39,25 | 16 | 125,6 | 60 | 471 |

Of course, for a more detailed calculation of the quantity of required products and the dimensions of each individual unit, including the weight of the steel sheet, the process will require the involvement of qualified construction specialists who can analyze the specifics of the project and advise customers how much material is required to implement the plan, taking into account the weight of the sheet.

Competent assistance from our company employees

specializes in construction and renovation work, so with us you can always get professional assistance in implementing the most daring decisions for the construction of original buildings and the creation of exclusive products.

Competent craftsmen are ready to complete work of any complexity in the shortest possible time or provide you with any quantity of high-quality sheet, the weight of which will allow it to be easily transported throughout the country, so you don’t have to worry about the reliability and speed of completing the task - taking care of the interests of clients is our priority.

Prices for rolled steel elements, depending on the specifics of the sheet, including weight, are presented in this table:

Hot rolled steel sheet

| Sheet thickness | Sheet sizes | Unit | Cost in rubles |

| 1.5 mm | 1.5*1250*2500 | PC. | 2011 |

| 2 mm | 2*1250x*2500 | PC. | 2441 |

| 2.5 mm | 2.5*1250*2500 | PC. | 3038 |

| 3 mm | 3*1250*2500 | PC. | 3625 |

| 4 mm | 4*1500*3000 | PC. | 6700 |

| 4 mm | 4*1500*6000 | PC. | 12943 |

| 5 mm | 5*1500*3000 | PC. | 8196 |

| 5 mm | 5*1500*6000 | PC. | 16420 |

| 6 mm | 6*1500*3000 | PC. | 10228 |

| 6 mm | 6*1500*6000 | PC. | 20048 |

| 8 mm | 8*1500*6000 | PC. | 26005 |

| 10 mm | 10*1500*6000 | PC. | 32460 |

| 12 mm | 12*1500*6000 | PC. | 40416 |

Hot rolled steel sheet

| Sheet thickness | Sheet sizes | Unit | Cost in rubles |

| 1.5 mm | 1.5*1250*2500 | m2 | 643 |

| 2 mm | 2*1250x*2500 | m2 | 780 |

| 2.5 mm | 2.5*1250*2500 | m2 | 970 |

| 3 mm | 3*1250*2500 | m2 | 1160 |

| 4 mm | 4*1500*3000 | m2 | 1500 |

| 4 mm | 4*1500*6000 | m2 | 1430 |

| 5 mm | 5*1500*3000 | m2 | 1820 |

| 5 mm | 5*1500*6000 | m2 | 1830 |

| 6 mm | 6*1500*3000 | m2 | 2270 |

| 6 mm | 6*1500*6000 | m2 | 2230 |

| 8 mm | 8*1500*6000 | m2 | 2900 |

| 10 mm | 10*1500*6000 | m2 | 3600 |

| 12 mm | 12*1500*6000 | m2 | 4500 |

You can obtain all other information on the weight of the sheets and other features of the products during a telephone consultation with the managers of our organization.

Source: https://moskomplekt.ru/ves-lista-stalnogo/

Cold rolled sheet GOST 19904-90, GOST 19904-74 (Cold rolled sheet and coil steel)

View price - Cold rolled sheet

Cold-rolled steel sheets with a width of 500 mm or more are produced with a thickness of 0.35 - 5 mm in sheets, and with a thickness of 0.35 - 3.5 mm in rolls. Sheets less than 3mm have a cutting size of 1250*2500, more than 4mm inclusive - 1500*6000.

Application of cold-rolled sheet It is used for cold stamping and the manufacture of products with high surface quality, as well as in construction, mechanical engineering, instrument making, shipbuilding, aircraft manufacturing, electric power, and for the manufacture of agricultural machinery. In construction, cold-rolled sheets are used to tighten structures of special strength. It is often used in the processing industry - sheets polymer-coated metal sheets , perforated metal sheets are made from cold-rolled sheets. Cold-rolled sheets also used as raw materials for profile metal wall sheets and metal tiles.

Cold Rolled Sheet Production: Hot rolling is used to produce a coil, followed by the pickling process of the hot rolled steel sheet where special chemicals are applied to the metal. The metal is later rolled under high pressure in a cold rolling mill and either left as a sheet or formed into a coil. If it is necessary to impart certain physical properties to the sheet, it is also subjected to compression. This technology for manufacturing cold-rolled metal sheets makes it possible to obtain a thinner layer with greater performance properties, because of this, cold-rolled sheets are more expensive than hot-rolled sheets, they are distinguished by ductility and a smoother surface.

Suppliers of cold-rolled sheets: OJSC Novolipetsk Metallurgical Plant (NLMK), OJSC Severstal.

Cold-rolled steel sheets (CC) are made from high-quality steel and ordinary quality steel:

- carbon steel - 08ps, 08kp, 10, 15ps, 15, 20ps, St 1ps, St2ps, St2sp, St3ps, St3sp according to GOST 16523-97 for general purpose;

- low-carbon steel - 08ps, 08kp, 08yu according to GOST 9045-93 - for cold stamping.

Cold rolled sheets are produced:

1. rolling accuracy:

a) by thickness:

- high - VT

- increased - AT

- normal accuracy - BT

b) in width:

- high - VSH

- increased - AS

- normal - BS

- high - VD

- increased - blood pressure

- normal - DB

c) along the length:

2. flatness:

- especially high - PO

- high - PV

- improved - PU

- normal - mon

3. by the nature of the edge:

- unedged - BUT

- edged - O

4. according to the ability to draw:

- normal - N (not used)

- deep - G (not used)

- very deep - VG (steel 08yu)

- difficult - SV

- especially difficult - OSV

5. according to the quality of surface finishing:

- especially high

- high

- increased

- regular

6. on the surface: matte and glossy

Example of cold-rolled sheet marking:

Sheet BT - PV - O - 0.8x1250x2500 GOST 19904-74 II - VG-08YU GOST 9045-93

This is a cold-rolled sheet of normal rolling accuracy in thickness (BT), high flatness (FL), cut edge, thickness 0.8 mm, width 1250 mm, length 2500 mm, according to GOST for assortment 19904-74, high surface finish (II), very deep drawing (VD), made of steel 08yu, according to GOST 9045-93 (thin-sheet cold-rolled for cold stamping).

Cold rolled steel sheet GOST 19904-90 , GOST 19904-74. Main dimensions, weight of cold rolled sheet

| Metal sheet thickness , mm | Sheet width, mm | Weight of 1 m of metal sheet , kg |

| 0,50 | 1250 | 4,91 |

| 0,70 | 1250 | 6,87 |

| 0,80 | 1250 | 7,85 |

| 1,00 | 1250 | 9,81 |

| 1,20 | 1250 | 11,78 |

| 1,50 | 1250 | 14,72 |

| 2,00 | 1250 | 19,63 |

| 2,50 | 1250 | 24,53 |

| 3,00 | 1250 | 29,44 |

Buy cold rolled sheet

From us you can purchase cold-rolled sheets of all types produced from the warehouses of branches, warehouses in the Moscow region or directly from the plant. We provide services for cutting, delivery and assembly of sheets. You can see the availability, assortment of cold-rolled sheets and the price list of metal sheets For more detailed information on the price of cold-rolled steel sheets , to clarify the weight of the sheet and make a quantity calculation, to issue an invoice and fill out an application, to clarify payment options and request a certificate for the metal already taken, please contact the manager by contacting him by phone

(8452) 57-00-18, e-mail: [email protected]

Weight of sheets, rolled steel sheets GOST 16523-89, GOST 14637-89

All rolled products, depending on their shape, can be divided into four main groups:

a) grade steel;

b) sheet steel;

c) pipes;

d) special types of rental.

Rolled sheets of steel and non-ferrous metals are used in various industries and construction. In this regard, sheet steel, for example, is divided into automotive, transformer, roofing tin, etc. The production of sheet steel with tin, zinc, aluminum and plastic coatings, polymer coating, as well as flat, smooth and profiled: corrugated sheets, expanded metal, perforated.

Weight of steel sheet: types of metal and forms of execution, product brands and calculation of mass of 1 m2

Of all the rolled products of metallurgy, it is easiest to determine the weight of a steel sheet: the formula for finding the volume of a rectangular parallelepiped, which is a plate, is known from a primary school course: length, width, height. It remains to multiply the resulting product by the density of the metal, and the calculated weight will be obtained. But in some cases this calculation scheme does not work.

When purchasing sheet metal, you have to deal with the weight of individual plates, whether they are purchased by quantity or by the total weight of the steel surface that needs to be built. This need is associated not only with setting prices, but also with hiring lifting equipment when performing loading and unloading operations. Usually calculations are done with a calculator in the following sequence:

- establish the specific gravity of the sheet material - if it is steel, then the density is 7.85 t/m3;

- determine the volume of a single plate and multiply by their number, or the total area of the metal - by the thickness;

- the final result - the calculated weight of steel is obtained according to the formula P = V * 7.85 with dimensions in tons, if the values were taken in meters.

Example: sheet steel, the weight of 1 m² of a 10 mm thick plate will be 1 * 0.01 * 7.85 = 0.0785 t, or 78.5 kg. When manufacturing rolled sheets, tolerances are established for maximum deviations of dimensions from the nominal parameters. As a result, errors are obtained between the calculated values of the metal mass and the actual values obtained as a result of weighing. The wider the tolerance field, the greater the difference.

Another factor influencing the weight of sheet steel is the presence of coating on galvanized rolled metal or corrugations and perforations on certain brands of products. To help customers, manufacturers and suppliers place an automatic calculator on their websites that greatly simplifies calculations.

If the weight of a sheet of metal is known, it is easy to calculate the number of plates in a ton or pack indicating the mass.

Sheet Metal Materials

Flat products are used in many industries - both in load-bearing structures and for decorative and finishing purposes. In addition to steel, the following raw materials are used for its production:

- aluminum;

- copper;

- zinc;

- alloys.

Metal sheets are often used as roofing, fastening the plates together with folds manually or using tools. All listed materials are suitable for this purpose. In addition to zinc, which is not used in its pure form: it is sprayed onto steel, or alloyed with copper and titanium - the so-called titanozinc is obtained. '

Naturally, the weight of the products of each metal will differ significantly, because the density of aluminum is 2.72, copper 8.3–8.9, zinc - 7.13, titanium 4.51 t/m3.

Weight of sheet steel - calculation methods depending on thickness and grade (95 photos)

Steel is an alloy of iron and carbon; the raw material for steel production is pig iron. In addition, production waste is used in the form of steel and cast iron scrap. The main methods used are converter, open-hearth and electric furnace steelmaking processes.

Steel is classified according to purpose, chemical composition, structure:

- by purpose - structural, spring-spring, instrumental, heat-resistant boiler, stainless, heat-resistant, acid-resistant;

- by chemical composition - carbon and alloyed;

- The structure of steel is austenitic, ferritic, martensitic, bainite and pearlitic.

Metal forming

A technological process as a result of which plastic deformation of the material occurs and the shape, size and properties of the metal change. It is divided into forging, rolling, stamping, pressing and drawing.

Rolling

Compression of a metal ingot between the rolls of a rolling mill. 90% of all steels are rolled.

The range of rolled steel is extensive: sections, profiles, sheets, pipes. A significant volume of the rolled products market is occupied by rolled steel sheets.

Sheet steel

Divided into groups depending on the thickness of the section. Sheets from 4 mm and above are thick sheet steel, up to 3.9 mm are thin sheet steel. Sheets are produced on rolling mills using hot and cold rolling.

Hot rolled sheets

Hot rolled sheet is a steel plate with a smooth surface, produced through the process of heat treatment and rolling of various grades of steel, including alloy and high-carbon steel.

The resulting products have high strength, reliability, and resistance to aggressive environments. The weight of hot-rolled sheets can be determined in three ways as follows.

Limit deviations:

- with cut edge, in rolls from +2 to +7 mm depending on the width of the rolled product;

- with cut edge in sheets from +6 to +10 depending on the width of the rolled product;

- with uncut edge +20 mm.

- rolled sheet by sheet from +10 to +15 mm depending on the length of the sheet;

- rolled on continuous mills and cut into sheets from +15 to +25 depending on the length of the sheet, +10 at the request of the consumer;

Cold rolled sheets

Cold rolling is used to produce high-precision thin sheets and strips of steel. Cold rolled products provide high parameters of physical and chemical characteristics and surface quality of the product. The weight of cold-rolled sheets is also determined by the methods indicated below.

Limit deviations:

- with a cut edge of rolled sheets from +6 to +15 mm depending on the width of the rolled product;

- rolled sheet by sheet from +10 to +15 mm depending on the length of the sheet;

Sheet weight

When producing rolled products, due to equipment errors, the thickness of the sheet changes, and accordingly, the actual weight of a square meter of steel changes.

The theoretical weight of rolled products can be calculated in 3 ways.

The first one, from the reference book, according to the sheet steel weight table.

Second, using an online rolled metal calculator:

- Open the calculator page for the desired metal product;

- Select the type of rolled metal;

- Fill in the data - length, width, thickness;

- Click the calculation button.

Third, calculate the theoretical weight using the formula:

Рт = Н * В * L * 7850; where, Рт — theoretical weight, kg; H – sheet thickness, m; B—sheet width, m; L – sheet length, m; 7850 - specific gravity of sheet steel, kg/m3.

With bilateral tolerances, the weight is calculated based on the nominal dimensions. If one-sided, plus - according to the nominal size with the addition of 50% of the tolerance value. At minus, on one side - minus 50% of the tolerance value.

Weight of galvanized steel

Determined by the corresponding table, or by the formula:

P = P1 + P2, where P is the weight of galvanized sheet (kg), P1 is the weight of iron, kg; P2 - zinc weight, kg.

P1 = H1 * B1 * L1 * 7.85, where H1 is the thickness of the steel, mm (the thickness of the steel is 0.05 mm less than the finished sheet for the first class of galvanizing and 0.03 mm less for the second class); B1 - width of steel sheet, m; L1 - length of steel sheet, m; 7.85 – specific gravity of steel, t/m3.

P2 = H2 * B2 * H2 * 7.13, where, H2 is the thickness of galvanizing (depends on the class, where the 1st class has a thickness of 0.0381 mm, and the 2nd class - 0.0216 mm); B2 - galvanizing width, m; L2 - galvanizing length, m; 7.13—zinc density, t/m3.

Conversion factor

The ratio of the theoretical Рт to the actual Рф weight is expressed by a value called the “Conversion factor” Кп.

KP is necessary to calculate the actual weight of the rolled product.

Example:

Sheet 20 mm thick with double-sided tolerance; dimensions 1500x6000 mm; Kp=1.02;

RT = 0.02 * 1.5 * 6 * 7850 = 1413 kg;

RF = 1413 / 1.02 = 1385.3 kg

Theoretical weight of sheet metal!

Good afternoon or evening, visitors to our site. I would like to present you with a table of the theoretical weight of rolled sheets. As an employee of a metal trading company, I had to face difficulties when I first started working. Many of my clients asked me to calculate the weight and price of steel metal products. Of course, if every day If you answer questions like this: “How much does a 2mm sheet weigh, cutting 1000\2000mm?”, then useful information will definitely be stored in your memory, but you won’t remember everything, and I often use the calculations from this table. These non-secret materials will be a useful guide for all market participants, both buyers and and sellers of rolled metal. Please note that here are only standard sizes of hot-rolled sheets. If you are purchasing a non-standard size or piece of sheet, be sure to consult with the managers of our company or use the metal calculator on our website.

Another sure way is to independently calculate using the mathematical formula H x L x B x7.85 = P

- H-thickness of steel sheet (unit "mm")

- L-length of steel sheet (unit "m")

- B is the width of the steel sheet (unit "m")

- 7.85 kg/dm3 - coefficient (density of black steel)

- P-theoretical weight of steel sheet

We are always happy to come to the rescue, our Metal Depot on highway number one has in stock a large quantity of rolled sheets of various cuts and thicknesses. The city of Krasnodar and the Krasnodar Territory is the service area of our company, any metal (ferrous and stainless) wholesale and retail, in in stock and on order.

| Sheet thickness, mm | Standard sheet sizes | Sheet weight, kg | Weight sq.m, kg |

| 2 | 1000x2000 | 31.20 | 15.60 |

| 1250x2500 | 49,06 | 15,70 | |

| 2,5 | 1250x2500 | 61,33 | 19,63 |

| 3 | 1250x2500 | 73,59 | 23,55 |

| 3,5 | 1250x2500 | 85,86 | 27,48 |

| 1500x6000 | 282,60 | 31,40 | |

| 5 | 1500x6000 | 353,25 | 39,25 |

| 6 | 1500x6000 | 423,90 | 47,10 |

| 7 | 1500x6000 | 494,55 | 54,95 |

| 8 | 1500x6000 | 565,20 | 62,80 |

| 9 | 1500x6000 | 635,85 | 70,65 |

| 10 | 1500x6000 | 706,50 | 78,50 |

| 12 | 1500x6000 | 847,80 | 94,20 |

| 14 | 1500x6000 | 989,10 | 109,90 |

| 16 | 1500x6000 | 1130,40 | 125,60 |

| 18 | 1500x6000 | 1271,70 | 141,30 |

| 20 | 1500x6000 | 1413,00 | 157,00 |

| 22 | 1500x6000 | 1554,30 | 172,70 |

| 25 | 1500x6000 | 1766,25 | 196,25 |

| 28 | 1500x6000 | 1978,20 | 219,80 |

| 30 | 1500x6000 | 2119,50 | 235,50 |

| 32 | 1500x6000 | 2260,80 | 251,20 |

| 35 | 1500x6000 | 2472,75 | 274,75 |

| 36 | 1500x6000 | 2543,40 | 282,60 |

| 40 | 1500x6000 | 2826,00 | 314,00 |

| 45 | 1500x6000 | 3179,25 | 353,25 |

| 50 | 1500x6000 | 3532,50 | 392,50 |

| 55 | 1500x6000 | 3885,75 | 431,75 |

| 60 | 1500x6000 | 4239,00 | 471,00 |

| 65 | 1500x6000 | 4592,25 | 510,25 |

| 70 | 1500x6000 | 4945,50 | 549,50 |

| 80 | 1500x6000 | 5652,00 | 628,00 |

| 90 | 1500x6000 | 6358,50 | 706,50 |

| 100 | 1500x6000 | 7065,00 | 785,00 |

| 110 | 1500x6000 | 7771,50 | 863,50 |

| 120 | 1500x6000 | 8478,00 | 942,00 |

| 130 | 1500x6000 | 9184,50 | 1020,50 |

| 140 | 1500x6000 | 9891,00 | 1099,00 |

| 150 | 1500x6000 | 10597,50 | 1177,50 |

| 160 | 1500x6000 | 11304,00 | 1256,00 |