molybdenum powder mp47

Molybdenum alloys

NIMO 28

Molybdenum alloys

NIMO 20Avh

Molybdenum alloys

Tungsten-Molybdenum alloys

Molybdenum alloys

Any molybdenum alloys are classified as heavy, given the presence of a refractory metal as a base. Pure molybdenum with additives or a compound alloyed with other metals has high strength characteristics and is resistant to external environmental factors, corrosion, and extreme high temperatures.

Chemical properties and characteristics

Molybdenum occupies a special place among metals. With its help, it is possible to obtain alloys that are used in precision measuring instruments, counterweights, jet engines, melting furnace screens, in a wide variety of mechanisms and critical installations.

Mo is located in the 5th group and 5th period in the periodic table of chemical elements. The density at normal room temperature is 10,200 kg/m3, and the melting point reaches 2620±10°C. It imparts amazing properties to alloys: heat resistance, strength, reliability, low coefficient. expansion when exposed to high temperatures, insignificant neuronal capture cross section. At the same time, in terms of thermal conductivity, it is inferior to copper, but ahead of iron. In terms of processing, it is simpler compared to tungsten. But the latter refractory metal exhibits better mechanical strength.

In terms of their properties and characteristics, molybdenum alloys are as close as possible to pure metal, especially if the base occupies a large percentage of the total mass. Tungsten-molybdenum alloys are endowed with the best properties of both elements. By varying the ratios of refractory metals in one compound, it is possible to obtain a semi-finished product or a finished product with the required parameters.

Technologists point out that one of the significant disadvantages of Mo is its susceptibility to oxidation at temperatures above 500°C. At the same time, although alloying does not completely solve this problem, it helps to increase heat resistance and reduce fragility (for example, by introducing lanthanum oxide), and increase the time the part is exposed to increased load. When certain components are added, the recrystallization time increases.

Types and features of alloys

This category of the production catalog presents various compounds in the form of powder and finished rolled products. Let's reveal some of them:

• Tungsten-molybdenum. From compounds based on refractory metals, crucibles and extruded blanks, hot-rolled sheets, plates, rings, parts for equipping high-temperature and hydrogen furnaces, and sputtering targets are obtained. With certain processing, it is possible to obtain products of complex shapes. • Nickel-molybdenum alloys. The most common combination, available in various brands. Applicable for alloying steels, they are common in the manufacture of containers/vessels for radioactive elements, having a greater absorption coefficient of gamma rays than lead. Alloying in this case is more economical when compared to using pure Mo. At the same time, the characteristics of the finished products are almost identical. Collimators, dosimetric equipment and protective blocks/screens are also made from such alloys. • Chromium-molybdenum compounds. Chromium increases the strength of the joint, making it heat-resistant and acid-resistant. Alloys with the addition of cobalt are used in the production of artificial teeth, crowns, and bridges. Solid, but at the same time moderately elastic compounds do not corrode and do not react with biological fluids, food and drinks.

In addition to purchasing molybdenum alloys with nickel, tungsten and other metals, it is possible to order additional services - processing semi-finished and finished parts by various mechanical and chemical methods to give them certain qualities.

What properties does steel acquire as a result of alloying?

Each chemical element introduced into an alloy changes it. The proportions of impurities matter. In addition, one alloy is usually alloyed not with one metal additive, but with several.

Nickel alloying

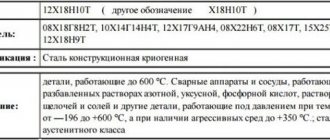

In steel alloys, the metal nickel as an impurity helps ensure that austenite is formed and preserved in the alloy. This increases the strength of the alloy. If chromium and molybdenum are added to nickel, then nickel becomes even more effective for thermally strengthening steel, increasing its toughness, as well as fatigue strength. Ferritic steels are alloyed with nickel - they become more tough. Chromium-nickel austenitic steels are better resistant to corrosion.

Chromium alloying

Chromium is an element that, when added, improves the resistance of a metal alloy to the phenomena of oxidation and corrosion, makes the steel more durable even when heated to high temperatures, and also improves the ability of a high-carbon alloy to resist wear due to friction. In the process of alloying with chromium, chromium carbides are formed - thanks to them, the steel becomes harder and stronger: knives and other piercing and cutting tools can be made from it. If the steel also contains impurities of tin, arsenic, phosphorus or antimony, then they segregate to the boundaries of the “grains” of the alloy, which causes an increase in the temper brittleness of the steel alloy.

Alloying with molybdenum

Molybdenum creates greater thermal hardening during steel tempering (after hardening). Steels containing molybdenum at high temperatures are characterized by less creep.

Also, when molybdenum is included, the grain size of the alloy decreases and the steel becomes stronger. The indicator of resistance to corrosion processes (including pitting corrosion) improves.

By combining metal additives using alloying technology, chromium-nickel-molybdenum, chromium and chromium-nickel alloys are obtained, which have optimal sets of parameters for certain operating conditions and processing methods.

How to buy molybdenum alloy profitably?

At ]LLC "New Technologies"[/anchor] you can order the production of heavy alloys based on refractory metals. You can buy molybdenum alloy of both common and rare brands. Before ordering, we recommend that you contact the company’s specialists. Many years of experience as a technologist and a well-functioning production line make it possible to strictly comply with GOST regulations in the production of powder, blanks in the form of ingots and bars, as well as any complex products made of chromium-molybdenum alloys, compounds containing nickel, tungsten, etc. metals in the composition. Call right now and find out about the possibility of placing an order for a batch of the required volume or for the production of parts according to individual drawings.

Use in its pure form

Nickel is a silver-colored metal. It has high strength and ductility. It has ferromagnetic properties, is well welded, forged and stamped. Resistant to acids and alkalis. Will not oxidize in open air due to the oxide film.

Areas of application of the material in its pure form:

- Used as a protective coating for other metal surfaces. In this case, the protective layer is applied using cladding or galvanoplasty methods. Protects other metals from corrosive processes.

- Containers for storing and transporting chemicals, acids, and alkalis are made of metal.

- It is often used as a catalyst. This is due to the catalytic properties of the material, which are similar to palladium. However, this metal is much cheaper.

- Manufacturing of neutron beam choppers. Thanks to this, the metal became widespread in nuclear physics.

In addition to its use in the food and chemical industries, the pure material is used in the manufacture of alkaline batteries.

Peculiarities

Nickel and alloys based on it have certain features and characteristics. It is important to consider them before using them in industry.

Structure and composition

The structure of nickel-based alloys varies depending on what components are included in their composition. The characteristics of the finished material also depend on this. This material is a silver-colored metal found in the earth's crust, water and air. In nature you can find not only a homogeneous metal, but also mixtures based on it. This is due to the fact that it combines well with other materials. Common components in mixtures are iron, molybdenum, copper, chromium.

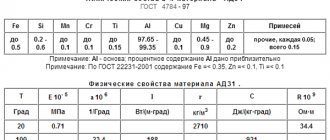

Properties and characteristics

The physical and chemical properties of a material help determine where it can be used and how it will change during certain processing steps. Characteristics:

- Density - 8800 kg/m3.

- Melting point - 1455 degrees Celsius.

- Boiling point is about 2900 degrees.

- Maximum tensile strength - 9000 MPa.

- Thermal conductivity - 90.9 W/(m*K).

- Electrical resistance - 0.0684 μOhm*m.

Due to their characteristics, nickel and mixtures based on it are used in various areas of industry. They lend themselves well to processing on industrial equipment, which expands their scope of application.

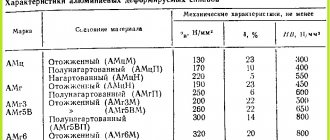

Stamps

According to the state document GOST 849-2008, 7 grades of nickel are designated. These include H0, H1,2,3,4, H1Ay and H1y. The composition of the brands is the content of the main substance up to 99.9%, a small amount of cobalt and third-party impurities.

Application area

Pure metal is not used as often as nickel alloys. Application areas of alloys:

- They are used in mechanical engineering, construction, and pipeline manufacturing. Massive structures are made from this metal and are protected from rust.

- Parts for equipment that operates in aggressive environments. The alloys are resistant to acids, corrosive processes, and alkalis.

- Alloys are used to make gas turbines.

- In everyday life, products made from nickel alloys can be found in the form of furniture fittings, taps and mixers.

- Nickel is part of the alloys that are used to make white gold.

Nickel-cadmium batteries are made from this material. Metal compounds are diverse and due to this they are used in various areas of industry.

Alloys

Nickel is the basis of many alloys. It is worth taking a closer look at the most popular compounds based on this metal.

Nickel based alloy

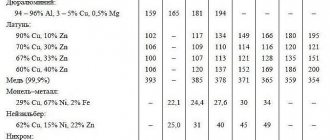

With copper

The most popular compounds are nickel and copper. The result is a material that is not similar in its characteristics to the original metal. In the manufacture of metal mixtures, 3 popular compounds can be distinguished:

- Monel is a material that contains approximately 67% nickel. Has a high strength index. It can be compared with different types of steels. Used in aircraft manufacturing, shipbuilding, and in the manufacture of power tools. You can find monel parts in musical instruments.

- Cupronickel is a well-known alloy whose main component is copper. Nickel in the composition can contain up to 30%. Used in the manufacture of jewelry, figurines, cutlery.

- Copel is a mixture of 44% nickel. The wire from which compensation wires are made is made from it.

There are other mixtures with the addition of zinc, which have their own characteristics and characteristics.

With chrome

Compounds of chromium and nickel are known to many as nichrome. The peculiarity of this alloy is its high electrical resistance and high melting point. Nichrome also has good strength and heat capacity. Applications:

- Manufacturing of parts for devices operating in aggressive environmental conditions.

- Production of heating elements and equipment for heat treatment.

- Nichrome wire is used in the manufacture of electric furnaces.

- This alloy is used to make evaporation filaments used in electronic cigarettes.

If nichrome is coated with a silicon-based alloying layer, it can be used in the chemical industry. The additional coating makes the material resistant to acids.

With molybdenum and other metals

When combining nickel with molybdenum, chromium is added to the composition. The percentage of base metal reaches 77%. In this case, molybdenum in the composition can contain up to 9%. The rest is occupied by chromium. The peculiarity of the connection is its high strength and rigidity.

An alloy with molybdenum is used in medicine. Bridges are made from it. Difficult to process. It is almost impossible to make castings from such material. However, due to their characteristics and low cost, alloys with molybdenum are highly popular.

With iron

This mixture is called invar. It is a compound of iron and nickel. They use ready-made material in the manufacture of parts for mechanical watches.

Compound of iron and nickel