Steel 60S2A is a high-quality structural spring steel used for the manufacture of elastic products. Elasticity and endurance are the main characteristics of the alloy. Due to the carbon and silicon content, alloy 60C2A has high strength values that do not affect elasticity, which makes the steel suitable for the manufacture of rigid structures, with the exception of welded ones. Steel is practically impossible to weld; this feature makes it more in demand for the production of parts in mechanical engineering, aircraft manufacturing, agricultural heavy equipment, etc. The alloy is relatively easy to produce and affordable.

Explanation and chemical composition of grade 60С2А

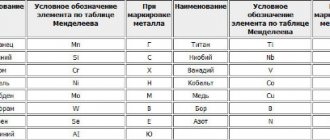

Decoding the marking of 60C2A steel indicates its chemical composition and the quality of the alloy in terms of the content of harmful impurities - sulfur and phosphorus, as well as the degree of deoxidation.

- The number 60 is an indicator of the approximate carbon content in hundredths of a percent, that is, 60C2A steel contains approximately 0.60% carbon. The increased carbon content gives the metal strength and hardness, but makes it vulnerable to impact loads. High carbon steels are more difficult to process - cutting, forging and welding of these alloys are usually limited, requiring special equipment or associated procedures, such as heat treatment before and after welding. The low carbon content makes the steel soft and easy to work with. This steel is excellent at welding, cutting, and can be forged and subjected to various types of machining with virtually no restrictions. This steel is resistant to impact loads, but is characterized by a lack of rigidity.

- C2 - indicates the fact (letter C) and the amount (number 2) of silicon content in the alloy, which in 60C2A steel is approximately 2%. The influence of silicon, as an alloying additive, on the properties of steel starts from 1% content. Without reducing viscosity, silicon increases the strength and elasticity of the material. Thanks to silicon, steel becomes scale-resistant and better resists the effects of acidic environments. Indicators such as magnetic permeability and electrical resistance increase.

- The letter A means that steel 60C2A is a high-quality alloy. The quality of the alloy is determined by its chemical composition, namely the concentration of harmful impurities of sulfur and phosphorus. According to the quality of steel, they are divided into ordinary (st), high-quality (steel), high-quality (A) and especially high-quality (SH). Each category has its own standards for the level of phosphorus and sulfur content. Phosphorus and sulfur form undesirable compounds with iron, which negatively affect the structure of steel, increasing its fragility, especially when heated (red brittleness) and cooled (cold brittleness). The high content of these impurities significantly limits heat treatment, leads to deterioration of weldability and generally has a negative effect on the properties of the metal.

All other elements included in the composition of steel 60S2A are not included in the marking, because do not have a noticeable effect on the properties of steel.

Chemical composition, % (GOST 14959-79)

| C | Mn | Si | Cr | Cu | Ni | S | P |

| no more | |||||||

| 0,58-0,63 | 0,60-0,90 | 1,6-2,0 | 0,30 | 0,20 | 0,25 | 0,025 | 0,025 |

Chemical composition, % (GOST 14959-2016)

| steel grade | Mass fraction of elements, % | ||||||||

| WITH | Si | Mn | Sk | V | W | Ni | B | Cu, no more | |

| 60С2А | 0,58-0,63 | 1,60-2,00 | 0,60-0,90 | No more than 0.30 | — | — | No more than 0.25 | — | 0,20 |

Release Types

There are several main types of metal production marked 60С2А. Let's take a look at the list of the most common and popular options:

- rolled section type (this also includes shaped type);

- calibrated rods;

- steel tape;

- wire products;

- polished rods and silver;

- circle;

- sheet.

Each of the specified types of rolled products in which steel products are produced corresponds to and is regulated by a number of GOSTs.

Substitutes and analogues of steel 60С2А

Analogs are alloys that are identical in chemical composition, produced in other countries and labeled in accordance with foreign standards. Substitutes are any alloys that have similar properties to a sufficient extent that they can replace the main grade. Domestic substitutes for 60S2A steel are grades 60S2N2A, 60S2G, 50HFA.

Foreign analogues:

| Germany DIN (EN) | 60Si7 (1.5027) [1] |

| USA (AISI, ASTM) | 9260 |

| UK (BS) | 251A60 |

| Japan JIS | SUP 6 |

| Poland PN/H | 60S2A |

Product range

Steel 40x - characteristics and application

There is a large range of products made from 60С2А, as well as similar steels, such as: 60С2, С60, 65 g, 60С2ХА, 60СА2.

There are the following types of rolled products according to GOST: strip, rolled products, calibrated rods, strip, forged blanks, forgings.

Foreign analogues of steel 60S2A include:

- Poland-60S2A;

- Germany-60MnSiCr4;

- Japan-SUP 6, SUP 7;

- Bulgaria-60S2A;

- China-60Si2Mn;

- USA-9260,G92600;

- France-61 SiCr7;

- England-251 H60.

Currently, new structural grades with similar properties are being developed, new methods are being introduced to obtain quality and mechanical characteristics while reducing energy costs for production.

Characteristics and Application

Steel 60S2A is not prone to temper brittleness and is insensitive to flakes. This steel is called spring-spring, which indicates its preferred application - the manufacture of heavily loaded springs, rings, friction discs, shafts, washers. The maximum heating temperature for steel 60S2A is 250C. The alloy can be used at high humidity due to the presence of silicon in the composition, but this does not make it stainless. 60S2A is an upgradeable alloy. Indicators of elasticity, strength, and resistance to dynamic variable loads increase after heat treatment. To improve properties, steel is subjected to three types of heat treatment - annealing, hardening and tempering. Recommended heat treatment:

- low annealing at 650-700 °C;

- hardening at 870±10 °C in oil;

- tempering at 430-490 °C (HRC 44-48, σв = 155-180 kgf/mm2).

Steel 60S2A is not used for the manufacture of welded structures, because It is not possible to create a strong welded joint.

Heat treatment

Hardening is carried out at 870 degrees, the product cools in an oil bath. Tempering is carried out at 470 degrees, which makes it possible to obtain troostite (ferrite-cementite structure). It maintains a hardness of 35-45 HRC.

Temperature treatment is:

- initial – annealing;

- final – hardening;

- middle - vacation.

Tempering increases the hardness of 60S2A steel to 365-445 HB. If the coiling of the spring is carried out with a single heating, then the next stage is heat treatment.

Conditions of use

Conditions for using steel 60S2A for disc springs (GOST 33260-2015)

| ND for supply | Spring standard | Application temperature, °C | Additional instructions for use |

| Assortment GOST 2283, GOST 7419. Technical requirements GOST 14959 | GOST 3057 | -60 to 120 | Used for work in conditions of atmospheric corrosion with anti-corrosion coatings* |

*After electrochemical coatings, heat treatment (tempering) is required to remove hydrogen embrittlement, as indicated in the design documentation.

Conditions for using steel 60S2A for helical coil springs (GOST 33260-2015)

| ND for supply | Application temperature, °C | Additional instructions for use |

| Wire GOST 14963. Rolled products GOST 2590 | -60 to 250 | Safety and pressure relief valves, bypass and shut-off valves, etc. |

NOTE. For class II springs, it is allowed to replace rolled grade 60C2A with grade 60C2.

Hand over alloy 60S2HFA (GOST 14959 - 79) in St. Petersburg

Steel, structural leaf spring

60S2KhFA is a metal alloy based on iron (Fe), its content in 60S2KhFA must be at least 95%. The alloy 60S2KhFA necessarily contains silicon, chromium, carbon, manganese, and vanadium. The permissible amount of impurities is determined in the chemical composition table.

Urgent demand

- Urgently! Alloys AMS5537 (L-605), AMS5536 (Hastelloy X)

- Urgently! Nickel N-1 (cathode sheets)

- Urgently! Railway rails - scrap, liquid scraps

Private advertisements

- sell ferrous metals, steels and alloys

- purchase non-ferrous metals and alloys

- purchase non-ferrous metals and alloys

- purchase non-ferrous metals and alloys

- purchase non-ferrous metals and alloys

- purchase ferrous metals, steels and alloys

- purchase non-ferrous metals and alloys

- purchase ferrous metals, steels and alloys

- sell ferrous metals, steels and alloys

- sell ferrous metals, steels and alloys

- purchase ferrous metals, steels and alloys

- purchase ferrous metals, steels and alloys

- sell non-ferrous metals and alloys

- sell non-ferrous metals and alloys

- sell petroleum products and their waste

All ads + Add yours Useful tools

- Determine the brand Determine the alloy by composition

- Pipe or angle weight Metal calculator

- For scrap acceptors Calculation of the profitability of the transaction

Determine the alloy by chemical composition Determine the mass by the shape of the product Calculate the profitability of the transaction

Recommended processing modes for springs made of steel 60С2А

| Temperature, °C | Hardness HB of finished springs | |

| oil hardening | vacations | |

| 850-870* | 460-480 | 418-387 |

*When bending sheets and hardening with one heating, the temperature rises to 900-950 °C. Hardness of metal products made from steel 60S2A as delivered (GOST 14595-2016)

| Hardness of metal products, HB, no more | |

| without heat treatment (categories 1 B, 2B, ZB, 4B, ZG, ZD and ZE) | heat-treated (categories 1A, 2A, ZA, ZB and 4A) |

| 302 | 269 |

Astromech of 60 gates in 2 lines

Egocentric interpretation

When we get to the second line, we get an outward projection. These people project outwardly that they can accept limitation. Many of them may suffer from pressure in their lives. Remember that this is just a projection of the nature of this hexagram coming out. This does not necessarily mean that they accept restrictions. What they project outward is that they accept the limitation. This line is called Adaptation.

Situations:

Nine second. You will not leave the outer courtyard. Misfortune.

Give up your usual way of thinking and acting. Reconsider your views on what is happening, otherwise the path will be closed. Adapt and fit into your environment.

Exaltation

A. Limitations are Saturn's favorite theme and he exalts the line. Saturn provides energy that can adapt to limitation. An understanding of the nature of constraint is developed in order to accept those constraints when necessary and thus take advantage of opportunities when they arise.

Energy that can adapt to restraint. Basically, these people project outwardly that they are limited. They don't know that there is something on the other end of the MS. So every time someone breaks through this, they have a door to this limitation. Generally speaking, these people will always be reserved, and in this restraint, accepting this limitation as a projection, there cannot be a deep melancholy within: Why am I accepting this limitation? Is this limitation really valuable? Is this constraint the right constraint? Is this limitation a mutation that I need?

A fall

B. Pragmatism and down-to-earth views, characteristic of the Earth, lead the line of opportunism to decline. Under the influence of the Earth, adaptation to limitation is strengthened, which becomes habitual and maintains the nature of the limitation even when it no longer exists. Energy appears for adaptation, which can get stuck without mutation occurring.

The second line will accept the limitation and will have the reserved, exalted side always open to the possibility that the limitation will end and then it will seem that: "Accepting the limitation was the right thing to do."

On the decline side of this energy: energy for adaptation, which can get stuck without possible mutation. The restriction suddenly goes away. For example, you have someone who walked every day in West Berlin. When he got to a place where there was a wall, he would turn around and go home. When the wall was removed, he could not cross this line. The limitation is gone, but there is no mutation, no change in path or method. This is the other side of the second line.

There is a deep dependence on second line limitation: people who are addicted to their medicine even when they are healthy.

You may also be interested in: karmic purpose here, compatibility in love relationships, psychosomatic reasons here, keys of the matrix of fate https://matix.fractalhd.ru/, human design human design, fortune telling with tarot cards is the most accurate

Technological properties

- Forging temperature, °C: beginning 1200, end 800. Sections up to 250 mm are cooled in air, sections 251-350 mm are cooled in a pit.

- Weldability - not applicable to welded structures.

- Cutting machinability - Kvtv.spl = 0.70 and Kvb.st = 0.27 in the hot-rolled state at HB 270-320 σв = 1080 MPa.

- Flock sensitivity - not sensitive.

- Tendency to temper brittleness - not prone.

Hardenability (GOST 14959-2016)

| Hardness HRCe at a distance from the end, mm (hardening from 850 °C) | |||||||||

| 1,5 | 3 | 4,5 | 6 | 9 | 12 | 15 | 18 | 27 | 39 |

| 60-67 | 59-67 | 57-66 | 54-65 | 44,5-63 | 38,5-60 | 35,5-56 | 34-52,5 | 30-43,5 | 27-39,5 |

Critical diameter d

| Critical hardness, HRCе | Amount of martensite, % | d, mm, after hardening at 850 °C | |

| in water | In oil | ||

| 51-53 | 50 | 47-82 | 24-53 |

| 58-60 | 90 | 60 | 36 |

Density ρп kg/cm3 at test temperature, °С

| Steel | 20° | 100° | 200° | 300° | 400° | 500° |

| 60С2А | 7680 | 7660 | 7630 | 7590 | 7570 | 7520 |

Linear expansion coefficient α*106, K-1

| steel grade | α*106, K-1 at test temperature, °C | |||||||

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | |

| 60С2А | 11,8 | 12,7 | 13,3 | 13,7 | 14,1 | 14,5 | 14,4 | 12,2 |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | ||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

| 60С2А | 28 | 29 | 29 | 30 | 30 | 30 | 29 | 29 | 28 |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature, °C | ||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

| 60С2А | 212 | 206 | 198 | 192 | 181 | 178 | 158 | 144 | 134 |

Modulus of elasticity in torsional shear G, GPa

| steel grade | At test temperature, °C | |||||||

| 20 | 100 | 200 | 300 | 400 | 600 | 700 | 800 | |

| 60С2 | 82 | 80 | 77 | 74 | 69 | 54 | 54 | 50 |

Specific heat capacity c, J/(kg*K)

| steel grade | s, J/(kg*K), at test temperature, °C | |||||||

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | |

| 60С2А | 510 | 510 | 520 | 535 | 565 | 585 | 620 | 700 |

Hardening

Hardening is carried out in a shot blasting machine, in which each point is exposed to shot for 20-30 seconds. Feeding is carried out at a speed of 70-100 kg/minute, the diameter of the elements is 0.8-1.2 mm. This treatment creates an even silver color.

The second treatment option is captivity. The spring is kept in a compressed state for 20-40 hours. The procedure is carried out after heat treatment of steel 60C2A. Repeated compression (5-10 times) and shot peening are also used.

Ra Uru Hu o 60.2 Adaptability, Determination

60.2 Determination▲ Saturn. From understanding the nature of limitations and accepting constraints when necessary comes the ability to take advantage of opportunities that arise. Energy that can adapt to constraints or influences. Earth. Adaptation to a limiting principle or influence that becomes a habit, maintaining the nature of the limitation even when it no longer exists. Energy to adapt, which can get stuck before reaching the final mutation.

Second line people project outwardly that they can accept limitations. Most of them suffer greatly due to the pressure they endure in their lives. Do not forget that this is only the nature of the hexagram projected into the outer world. This does not mean that they actually accept these restrictions. The line is called Determination. Saturn is exalted. From understanding the nature of constraints and accepting constraints when necessary comes the ability to take advantage of opportunities that arise. In the white book: energy that can adapt to a restraining principle or influence. Basically, these people project outward that they are limited by some principle or influence (that something is holding them back). They don't know that there is something on the other end of the channel. Therefore, only from time to time, when someone breaks through this barrier (destroys the barrier), the path to these restrictions is opened for them. Generally speaking, these people will always be under a limiting principle or influence, and in this state, accepting their limitations as a projection, they may experience deep melancholy within. Why do I accept these restrictions? Do they have real value? Are these restrictions going in the right direction? Are they the mutation I need?

On the other hand, we have an adaptation to a limiting principle or influence, which becomes a habit, preserving the nature of the limitations even when they no longer exist, the Earth is damaged. This is the essence of this second line. By projecting outwardly that it will accept the limitations and be at their mercy, exaltation is always open to the possibility that the limitation may end and then there is a feeling: “Aha, it was right to accept these limitations.” The damage is the energy to adapt, which can get stuck before reaching the final mutation. The restriction can suddenly be lifted, it suddenly goes away. These are the people who go for a walk every day in West Berlin. Having approached the place where the wall stood, they turn around and go home. The wall has been removed, but they cannot cross the line. The limitation disappeared, but the mutation did not occur, the path did not change.

The second line is deeply attached to its limitations (narcotically dependent on them). These are people who continue to take medications even when they are healthy.

Cons of steel 65g

Like any alloy, this one has a number of disadvantages that prevent this material from being used for certain purposes:

- Due to the fact that this material belongs to the group of carbon-containing compounds, it is extremely susceptible to corrosion.

- Although this steel is easy to sharpen, it loses its edge quite quickly. That is why you need to watch the cutting edge and its alignment, and constantly sharpen the knife.

- Quite significant restrictions on use.

Advantages and disadvantages are more relative; they cannot always be applied to all knives made from a given alloy. This is due to the fact that each manufacturer’s production technology is either slightly or seriously different from each other.

Designations

| Name | Meaning |

| Designation GOST Cyrillic | 60С2Х |

| Designation GOST Latin | 60C2X |

| Translit | 60S2H |

| By chemical elements | 60С2Cr |

| Name | Meaning |

| Designation GOST Cyrillic | 60С2ХА |

| Designation GOST Latin | 60C2XA |

| Translit | 60S2HA |

| By chemical elements | 60С2Cr |

| Name | Meaning |

| Designation GOST Cyrillic | 60С2ХАА |

| Designation GOST Latin | 60C2XAA |

| Translit | 60S2HAA |

| By chemical elements | 60С2CrN |

Briefly about the 60 gates in the 2 lines of Human Design (60.2 Adaptability, Determination)

60.2 Determination / People with the potential to bring lasting change to the world / Gate of Acceptance (challenge?) / Broken Chalice / Sidhi-Dar-Shadow: Justice-Realism-Limitation

There is always something in your life that you feel is limiting you and preventing you from developing. By your behavior, you demonstrate that you accept the restrictions, although inside you may feel depressed because of this.

Determination. Saturn is exalted. Understanding the nature of limitation in order to accept its restraint when necessary and thus be able to take advantage of opportunities when they arise. Energy that can adapt to restraint. The earth is in decline. Adaptation to containment that becomes habitual and maintains the nature of the constraint even though it no longer exists. Energy for adaptation that can become stuck without the possibility of mutation.

Results

To summarize, it is worth noting that such steel is often used for sporting edged weapons, as well as weapons for tournaments. After all, it is precisely in this scenario of use that shock resistance and low cost of the product are required.

Knives will be made from this steel for a long time, but still in more specialized industries. Although knives made from such steel are almost never used in the kitchen, especially recently, there are plenty of people who like to make blades from the remains of such an alloy.

Source

Commentary on Article 60.2 of the Labor Code of the Russian Federation

1. Article 60.2 establishes the rules for engaging an employee, along with the work specified in the employment contract, to perform additional work in a different or the same profession (position) during the established duration of the working day (shift).

2. According to Part 1 of the commented article, the employer can entrust an employee to perform such additional work only with his written consent and for an additional fee. The amount of additional payment in accordance with Art. 151 of the Labor Code is established by agreement of the parties to the employment contract, taking into account the content and (or) volume of additional work (see commentary to Article 151).

3. In accordance with Part 2 of Art. 60.2 additional work assigned to an employee along with the work specified in the employment contract can be performed by him in the order of combining professions (positions), by expanding service areas, increasing the volume of work, or in connection with the assignment of duties of a temporarily absent employee.

Combination of professions (positions) is the performance by an employee, along with his main work in the profession (position) determined by the employment contract, of additional work in another profession (position) for the same employer during the duration of the working day (shift) established for him. As a rule, the employee is entrusted with combining a vacant position or profession.

In contrast to combining professions (positions), when expanding service areas or increasing the volume of work, the employee performs work in the same profession or position, which is stipulated by the employment contract, but to a greater extent compared to what he performed in accordance with the employment contract.

The performance by an employee of the duties of a temporarily absent employee without releasing him from work in the profession (position) stipulated by the employment contract is permitted both in the same profession (position) that the employee performs in accordance with the employment contract, and in another profession (position).

It should be borne in mind that in cases where, in order to fulfill the duties of a temporarily absent employee, an employee is released from work stipulated by the employment contract, then in this case there is a temporary transfer to another job to replace the temporarily absent employee. Such a transfer is carried out in the manner prescribed by Art. 72.2 (see commentary to it).

4. The law does not establish either a minimum or maximum period for which an employer can entrust an employee to perform additional work along with his main job. In each specific case, the period during which the employee will perform additional work in the order of combining professions (positions), expanding service areas, increasing the volume of work, or in connection with the assignment of duties to a temporarily absent employee, is determined by the employer with the written consent of the employee (Part. 3 Article 60.2). If the employee does not agree with the period determined by the employer, this period may be determined by agreement of the parties. If the parties cannot agree on the period during which additional work must be performed, the employee has the right to refuse to perform it.

The period during which an employee, without release from work specified in the employment contract, will perform the duties of a temporarily absent employee is limited by the period of absence of this employee.

5. According to part 4 of the commented article, the deadline for completing additional work determined by the parties is not binding on them. The employee has the right to refuse to perform additional work ahead of schedule, and the employer has the right to cancel the order to perform it ahead of schedule, warning the other party about this in writing no later than three working days in advance.

At the same time, as follows from the content of this norm, neither the employee nor the employer is obliged to indicate the reason why they early refuse the agreement to perform additional work.