4. TOOLING HIGH-SPEED STEEL

High-speed steels are characterized by increased red resistance (600–650 °C) and are the most common tool material. Approximately 70% of all metal-cutting tools are made from high-speed steels.

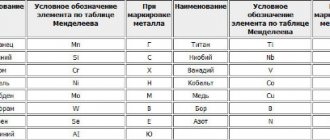

The grades, chemical composition and technical requirements for high-speed steels are regulated by GOST 19265–73. The chemical composition of the main grades of high-speed steels is given in table. I.3.

Decoding the brand

Brand designations indicate the chemical composition of the steel. Each element that significantly affects the properties and characteristics of the metal is included in the marking. Impurities contained in the alloy in small concentrations are not indicated in the labeling.

- 15 – the number indicates the carbon content in hundredths (0.15%). Steels with a high carbon content are the strongest and hardest, but are inferior in terms of ductility and toughness. If there is little carbon in the alloy, such an alloy is considered “soft” - it is suitable for use under high dynamic (shock) loads, but lags behind in hardness. Varying the carbon content allows you to select the steel for the task, depending on the purpose of the product.

- X – chromium (up to 0.9%). Chromium steels resist corrosion well, and with a chromium content of about 18% they become stainless. Chromium makes steel even harder, with virtually no effect on ductility. High-alloy steels are generally difficult to machine, have limited weldability and are difficult to cut.

- C – silicon (up to 0.7%). Silicon is used in the production of steel as a deoxidizing agent - an additive that prevents gas formation during the solidification of the alloy. It protects the metal from acid attack and binds sulfur, which improves the quality of the alloy.

- N – nickel (up to 0.6%). Thanks to nickel, steel heats up better, resists corrosion better, becomes stronger and more ductile. This is an expensive alloying additive; chromium is often used to reduce the cost of the alloy.

- D – copper (up to 0.4%). Added to construction steel, it increases the strength and corrosion resistance of the material.

In addition to those listed, 15HSND steel also contains manganese, phosphorus, sulfur, vanadium and other elements in small quantities. The content of harmful impurities - sulfur and phosphorus - according to GOST 5058-65 should not exceed 0.04% for each element.

A little history

For a long time in the history of mankind, iron has firmly entered the life and everyday life of people. Then, as now, metal was processed by metal. Although it was just a blacksmith's sledgehammer. After the invention of metalworking machines, the possibility of cold processing of metal products became possible.

In the beginning, the processing speed was not significant. But in 1858, the Scot Mushet added manganese and tungsten to the crucible. Steel containing these elements made it possible to increase processing speed. This material was the prototype of modern high-speed steels, including P9.

Characteristics and Application

The main purpose of steel 15HSND is welded metal structures and their elements. High-strength parts are produced from steel 15HSND for operation under conditions of corrosion risk, ultra-low (up to -70C) or ultra-high (up to +450C) temperatures. The alloy is successfully used in bridge building, mechanical engineering, construction, carriage building, metalworking industry and other industries. Due to the properties of 15HSND steel, the use of rolled metal leads to material savings of up to 20% compared to sheet steel of other grades. Its use in prefabricated structures and large-scale engineering projects significantly reduces the final cost of construction. Thin and thick sheets of 15HSND steel are most in demand on the market. The alloy is valued for its resistance to impact loads, ease of processing, lack of tendency to crack, and relative availability.

Steel 15HSND is insensitive to flakes, has little tendency to temper brittleness, and is not limited in weldability. Welding is carried out in the following ways: ADS (flux and gas protection), ESW, RDS.

Methods and methods of sharpening

Even high-speed steel P12 is subject to wear and dullness, despite its impressive strength properties. If we take into account the information about the use and properties of this alloy, then we can safely say that it will not be possible to sharpen them using grinding wheels from electrocorundum: the surface after such treatment still remains rough, and the cutting qualities do not improve.

The most correct option would be to take the knife to a specialized workshop for sharpening, which has CBN wheels at its disposal. Having such cars in your garage is an unaffordable luxury and simply not advisable.

You can, of course, try sharpening at home, but it’s worth considering: at a minimum, this will require diamond stones, the prices of which have been very high lately. In this case, processing will be carried out in 2 stages:

- First, use a stone with a large grain - the so-called coarse sharpening.

- Then use a fine-grain abrasive for final sanding.

It is better not to try to sharpen it in a garage, as there is a chance of damaging the tool beyond its original state.

Processing steel 15HSND

Steel 15HSND is well processed in all ways; this is one of the main advantages of the material, ensuring its continued wide popularity throughout the world. Forging begins at a temperature of 1180C and ends at 840C. Cutting is carried out after normalization and tempering procedures, using machine tools, preferably plasma machines for maximum accuracy. Cold-rolled thin sheets are made from steel 15ХСНД; bending and cold stamping are allowed. The metal can be welded without restrictions; heat treatment is not required either before or after welding. Steel can be hardened at a temperature of 900C in water and then tempered.

Description

Steel 15 is used : for the production of rolled sheets 4−14 mm of category 1−2, intended for cold stamping; bolts, screws, hooks and other parts that require high ductility and operate at temperatures from -40 °C to +450 °C; after CHT (chemical-thermal treatment) - levers, cams, fasteners and other parts that are subject to the requirements of high surface hardness and low core strength; electric welded pipes; electric-welded cold-deformed pipes intended for driveshafts of cars, tractors and machines; reed wire intended for weaving reeds.

Note

Degree of deoxidation - sp.

Substitutes of domestic and foreign production

Steel 15HSND is popular on the market and has many analogues, both in Russia and abroad. If replacement is necessary, steel is selected that exactly or approximately matches the original in terms of performance characteristics. In Russia there are at least five brands suitable as a substitute for the 15HSND alloy. For detailed information on exact and approximate analogues, see the tables below.

| Rolled metal grade | Substitute |

| 15HSND | 14ХГС |

| 14SND | |

| 15GF | |

| 16G2AF | |

| 16GS |

Foreign analogues

| Europe (EN) | 1.0562, 1.0565, 1.0566, 1.1106 |

| Germany (DIN) | StE 355, WStE 355, TStE 355, EStE 355 |

| USA (ASTM) | A 633 Gr.C, A 588 |

| France (AFNOR) | E 355 R/FP |

| Sweden (SIS) | 2132 |

| Japan (JIS) | QLA 37 |

| Italy (UNI) | Fe E 355 KG, Fe E 355 KW, Fe E 355 KT |

| Spain (UNE) | A 355 KG; DD AE 355 KW, AE 355 KT |

Marking

In stamp books valid in Russia, quick-cutters are designated in a special way. They start with the letter P from the English word rapid, that is, fast. The numbers that come after this letter indicate the tungsten content as a percentage.

Thus, the interpretation of the P9 steel marking means: high-speed steel with a tungsten content of the total mass, on average 9%.

Scope and analogues

Grade P9 is used mainly in the manufacture of tools for metal processing. Drills, various cutters, countersinks, turning tools. Among the analogues, we can mention P18 steel, which is very similar in characteristics. There are also foreign analogues.

Source

Type of delivery

Types of supply of material 15HSND

| B22 – Long and shaped rolled products | GOST 8239-89; GOST 26020-83; GOST 9234-74; GOST 8509-93; GOST 8510-86; GOST 8240-97; GOST 8278-83; GOST 8281-80; GOST 8282-83; GOST 2591-2006; GOST 2590-2006; GOST 11474-76; GOST 25577-83; GOST 14635-93; GOST 19425-74; GOST 19771-93; GOST 19772-93; GOST 13229-78; GOST 21026-75; GOST 8283-93; |

| B23 - Sheets and strips | GOST 103-2006; GOST 82-70; GOST 6713-91; GOST 19903-74; GOST 17066-94; |

| B33 - Sheets and strips | GOST 19282-73; |

| B62 — Steel pipes and connecting parts for them | GOST 20295-85; GOST 24950-81; |

Temperature of critical points, °C

| Ac1 | Ac3 | Ar3 | Ar1 |

| 730 | 885 | 803 | 650 |

Characteristics of high-speed steels

The category of high-speed steels includes alloys whose chemical composition is supplemented with a number of alloying additives. Thanks to such additives, steels are given properties that allow them to be used for the manufacture of cutting tools that can operate efficiently at high speeds. What distinguishes high-speed tool steels from conventional carbon alloys is that the tools made from them can be successfully used for processing hard materials at high speeds.

Chemical composition

Chemical composition, % (GOST 19281-2014)

| C, no more | Si | Mn | P | S | Cr | Ni | Cu | V | other elements |

| no more | |||||||||

| 0,12-0,18 | 0,40-0,70 | 0,40-0,70 | 0,030 | 0,035 | 0,60-0,90 | 0,30-0,60 | 0,20-0,40 | no more than 0.12 | — |

Designations

| Name | Meaning |

| Designation GOST Cyrillic | 15 |

| Designation GOST Latin | 15 |

| Translit | 15 |

| By chemical elements | 15 |

| Name | Meaning |

| Designation GOST Cyrillic | 15A |

| Designation GOST Latin | 15A |

| Translit | 15A |

| By chemical elements | 15 |

Mechanical properties

| GOST | Delivery status | Section, mm | σ0.2, MPa | σв, MPa | δ5(δ4), % |

| no less | |||||

| GOST 19281-89 | Long and shaped rolled products | From 5 to 10 | 345 | 490 | 21 |

| From 10 to 32 incl. | 325 | 470 | 21 | ||

| Sheet and strip as delivered (transverse samples) | Up to 32 incl. | 345 | 490 | 21 | |

| GOST 17066-94 | Hot rolled sheet | From 2 to 3.9 incl. | — | 490 | (17) |

Mechanical properties during tensile testing (GOST 19281-2014)

| Strength class | Rolled cross-section dimensions, mm | steel grade | Mechanical properties, no less | ||

| Yield strength σt, N/mm2, | Tensile strength σв, N/mm2, | Relative elongation δ5, % | |||

| 325 | Up to 60.0 incl. St. 60.0 to 140.0 | 15HSND | 325 | 450 | 21 |

| 345 | Up to 20.2 incl. St. 20.2 to 140.0 | 345 | 480 | ||

| Up to 32.0 incl. St. 32.0 to 50.0 | 490 | ||||

Mechanical properties (GOST 6713-91)

| steel grade | Rolled thickness, mm | Mechanical properties under tension | Impact strength KCU(a1), J/cm2(kgf*m/cm2), for rental categories, at temperature, °C | Cold bending test until the sides are parallel | |||||||

| Tensile strength σв, N/mm2 (kgf/mm2) | Yield strength σt, N/mm2 (kgf/mm2) | Relative elongation δ5, % | 1 | 2 | 3 | 1 and 2 | 3 | ||||

| -40 | -60 | -70 | +20 | -20 | 1 | 2 and 3 | |||||

| after mechanical aging | |||||||||||

| no less | |||||||||||

| 15HSND | 8-32 | 490-685 (50-70) | 345 (35) | 21 | 29 (3,0) | 29 (3,0) | 29 (3,0) | 29 (3,0) | 29 (3,0) | d = 2a | d = 1.5a |

| 33-50 | 470-670 (48-68) | 335 (34) | 19 | — | 29 (3,0) | 29 (3,0) | 29 (3,0) | 29 (3,0) | d = 2a | d = 1.5a | |

Impact strength KC (GOST 19281-89)

| Delivery status | Section, mm | KSU, J/cm2 at temperature, °C | |

| -40 | 70 | ||

| KSV | |||

| Long products | From 5 to 10 | 39 | 34 |

| From 10 to 20 incl. | 29 | 29 | |

| From 20 to 32 incl. | 29 | — | |

| KSU | |||

| Sheet and strip (transverse samples) | From 5 to 10 | 39 | 29 |

| From 10 to 32 incl. | 29 | 29 | |

Mechanical properties at elevated temperatures

| tsp, °С | σ0.2, MPa | σв, MPa | δ5, % |

| 20 | 370 | 620 | 20 |

| 200 | 370 | 590 | 610 |

| 300 | 360 | 610 | 11 |

| 400 | 375 | 590 | 14 |

| 500 | 300 | 365 | 17 |

NOTE. The sheet is normalized.

Mechanical properties depending on tempering temperature

| ttp, °С | σ0.2, MPa | σв, MPa | δ10, % | ψ, % | KSU, J/cm2 | Hardness HB |

| 200 | 1220 | 1450 | 10 | 56 | 78 | 425 |

| 300 | 1160 | 1370 | 10 | 57 | — | 410 |

| 400 | 1080 | 1170 | 11 | 58 | 78 | 360 |

| 500 | 840 | 930 | 15 | 62 | 118 | 275 |

| 600 | 640 | 740 | 20 | 68 | 176 | 220 |

NOTE. Quenching at 900°C in water.

Endurance limit (n=107)

| Delivery status | σ-1, MPa | τ-1, MPa |

| Samples without a notch [2], σв=490-560 MPa [1] | 304 | 157 |

High-speed tool steels: grades, characteristics, markings

Materials such as high-speed steels have unique properties, which makes it possible to use them for the manufacture of tools with increased strength. The characteristics of steels classified as high-speed steels allow them to be used to produce tools for a wide variety of purposes.

Mills, taps, reamers are typical products made from high-quality high-speed steel