Decoding

The marking of steel 45 contains information about the active chemical composition, the quality of the material in terms of the content of harmful impurities and the degree of deoxidation.

The word “steel” means that the alloy is of high quality. The quality of the alloy is determined by the level of sulfur and phosphorus in the composition. Sulfur and phosphorus are harmful impurities; they form undesirable compounds with iron, which adversely affect the integrity of the metal structure, lead to increased brittleness at high and low temperatures (red brittleness and cold brittleness), and negatively affect the general properties of the metal. The less phosphorus and sulfur in the steel composition, the higher the quality. Alloys are distinguished by quality:

- ordinary quality (st);

- high-quality (steel);

- high quality (A);

- especially high quality (Ш).

The number 45 indicates the percentage of carbon content in hundredths (0.45%). Carbon is the main structure-forming element in unalloyed carbon steels. By adjusting the carbon content, a significant difference in the properties of the alloy can be achieved. High carbon content gives steel strength and hardness, but reduces ductility and toughness. High-carbon steels withstand static loads well, are not prone to deformation, exhibit high strength indicators and are best suited for the manufacture of rigid building structures, such as load-bearing trusses. Low carbon steels are more suitable for structures subject to impact loads because... they are not prone to brittleness and exhibit high rates of fluidity, impact strength and elasticity. Steels with a low carbon content perform best in processing; they are better at welding, cutting and bending, and are less prone to brittleness, brittleness, and cracking.

Sp (not indicated in this case) means the calm state of steel as a result of a high degree of deoxidation. Deoxidation is the process of removing gases (mainly oxygen and nitrogen) during the solidification stage of the alloy. The higher the level of deoxidation, the fewer bubbles and gas pockets are formed on the surface and in the structure of the metal during its production. Quiet alloys (sp or without an index) have the least porous structure, semi-quiet alloys have an average porosity (ps), and boiling alloys (kp) have the largest number of bubbles. Deoxidation is ensured by introducing a deoxidizer additive into the composition, which binds undesirable elements, preventing gas formation. The most commonly used are manganese and silicon.

The composition of alloy 45 includes chemical elements not indicated in the marking; their quantity is insignificant and does not in any way affect the properties of the metal.

Temperature of critical points of steel 45

As previously noted, to improve the performance properties of the metal, heat treatment is carried out. It involves exerting a certain influence on the structure, after which the crystal lattice is rearranged and the qualities change. When carrying out heat treatment, critical points are often taken into account. Processing of steel St 45 is carried out taking into account the following factors:

- Temperature conditions. It is important to choose the right temperature, since too low will cause incomplete heating of the structure and complete restructuring of the structure will not occur. Too high an indicator causes overheating of the metal, as well as the appearance of scale. A variety of settings can be used to ensure that the required temperature is applied. An example would be blast furnaces or electrical installations. Melting temperatures that are too high determine that it is quite difficult to harden the steel in question at home.

- Rate of temperature increase. The heating rate can also determine which qualities will be transferred to the processed product. Modern equipment allows you to control the heating rate with high precision. For example, HDTVs have an electronic control unit; electrical energy is converted into magnetic energy, which causes heating of the structure.

- The length of time between exposure to different temperatures. When heat treating all metals, the presence of three critical points is taken into account and taken into account. The holding time may depend not only on the chemical composition of the material, but also on the size and shape of the workpiece.

- Features of the cooling process. The quality of the resulting product largely depends on the conditions under which the cooling process took place. For example, it is possible to use oil or water, as well as various powders as a cooling medium.

Quite often, HDTV is used to change the qualities of a metal. It is characterized by high efficiency in application, as well as ease of use. Today there are models that, if desired, can be installed in a home workshop.

Critical points are considered to be temperatures at which restructuring of the structure occurs. There are three main temperature points that are displayed on the plotted diagram.

Attention is also paid to choosing a more suitable cooling medium. For example, it is possible to carry out cooling in water. However, such an environment leads to uneven cooling, which leads to scale and other problems. For higher quality, oil is used. Large workpieces can be cooled in the open air, since it takes a long time to reduce the temperature.

Application

The range of products made from steel grade 45 is very wide, this is due to the properties of the metal, ease of production and prevalence in the domestic market. High-strength parts are produced from this steel, such as:

- cylinders;

- spindles;

- cams;

- bandages;

- trunnions;

- pump rolling pins;

- pins;

- clamps and keys of drilling rigs;

- thrust screw;

- sprocket wheels for drilling drawworks;

- bevel and ordinary gears;

- preventer rollers;

- subs for drilling and working pipes;

- core bit bodies;

- barrels and swivel subs;

- compressors;

- rotors;

- mud pump crosshead pins;

- centrifugal pump shafts;

- mud pump rods;

- sucker rod couplings;

- gear shafts.

The main consumers of steel 45 are the oil production, mining, and engineering industries.

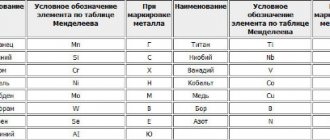

Alloy marking

Structural high-quality carbon steels are marked according to the standard with a two-digit number: steel 05, 08...80, 85, which indicates the average value of carbon content expressed in hundredths of a percent. Three digits of the marking indicate that the alloy contains more than 1% carbon, the letter L indicates the absence of alloying - 45l, the letter St indicates its ordinary quality - St5.

The metallurgical industry produces standard steel grades from 05kp to 60, the average carbon index of which is 0.05-0.60 percent, according to the marking. Decoding steel grade 45 (French analogue of C45) shows a content of 0.45% C.

Advantages and disadvantages

Each alloy has individual characteristics that are most in demand in its main area of application. Universal alloys are quite rare, while universality is usually called a good price-quality ratio compared to analogues, and not the breadth of material properties. The advantages and disadvantages of steel 45 determine its position on the market, the specifics of its application and outline the range of problems solved with its help.

Pros:

- resistance to intense loads, impacts and friction;

- possibility of operation in severe weather conditions;

- high endurance limit;

- good tolerance to temperature changes;

- low production cost;

- ease of machining;

- low sensitivity to flakes;

- not subject to temper brittleness;

- retains properties at temperatures up to 600C.

Minuses:

- loses strength when heated above 200C;

- weldability is limited;

- the material is susceptible to corrosion.

Steel 45

A huge number of different steels are supplied to production lines, which are characterized by their specific properties. An example is the material steel 45, which is widely used. This steel is characterized by certain performance qualities that are worth considering. GOST for steel 45 determines the concentration of all chemicals. The grade is characterized by a relatively low cost, and the decoding of the steel grade determines its wide distribution. Let's take a closer look at the features of this offer.

Why harden

The purpose of the hardening procedure is to improve the characteristics of the outer layer of metal and thus extend the service life of the product. Thanks to hardening, steel acquires the following qualities:

- Increased hardness and strength. Allows loaded parts, such as springs and springs, to withstand heavy loads.

- Increased wear resistance. Allows you to extend the life of parts by reducing abrasion or fatigue.

- No brittleness after heat treatment. Because Only the surface of the product is subjected to hardening, the middle remains soft.

About steel processing 45

In mechanical engineering, grade 45 steel is first heat treated. After normalization, any mechanical “decor” (milling, turning) is simpler and easier. This is how various shafts, gears, cylinders, spindles, and cams are obtained.

After finishing heat treatment or hardening, the completed parts can “boast” greater resistance to wear. At the exit, they are cooled in water and subjected to low-temperature tempering (200-300 o C), the hardness indicators are about 50 HRC.

Types of delivery

| GOST 51245-99; | |

| B03 - Metal forming. Forgings | GOST 8479-70; |

| B22 – Long and shaped rolled products | GOST 5422-73; GOST 2591-2006; GOST 2879-2006; GOST 9234-74; GOST 8319.0-75; GOST 11474-76; GOST 1133-71; GOST 8320.0-83; GOST 2590-2006; |

| B23 - Sheets and strips | GOST 82-70; GOST 14918-80; GOST 19903-74; GOST 16523-97; GOST 103-2006; |

| B24 - Tapes | GOST 3560-73; |

| B32 – Long and shaped rolled products | GOST 8560-78; GOST 1050-88; GOST 14955-77; GOST 10702-78; GOST 1051-73; GOST 8559-75; GOST 7417-75; |

| B33 - Sheets and strips | GOST 4405-75; GOST 1577-93; |

| B34 - Tapes | GOST 2284-79; |

| B62 — Steel pipes and connecting parts for them | GOST 8645-68; GOST 8642-68; GOST 20295-85; GOST 8644-68; GOST 12132-66; GOST 23270-89; GOST 9567-75; GOST 8646-68; GOST 13663-86; GOST 24950-81; GOST 8638-57; GOST 21729-76; GOST 53383-2009; GOST 3262-75; GOST 8734-75; GOST 8639-82; GOST 8731-87; GOST 8732-78; GOST 8733-74; |

| B71 – Low carbon steel wire | GOST 1526-81; GOST 5663-79; GOST 792-67; |

| B72 – Medium and high carbon steel wire | GOST 9389-75; GOST 9850-72; GOST 3920-70; GOST 3110-74; GOST 7372-79; GOST 9161-85; GOST 26366-84; |

| B76 – Metal mesh | GOST 3306-88; GOST 51568-99; |

Melting point of steel 45

Steel 45 in stock. Shipment of rental products on the day of payment in batches of any size.

Description

Steel 45 GOST stands out among similar products by a number of the following characteristics: purpose and functionality, chemical composition of elements, possible substitutes, suppliers, maximum operating temperature, foundry and technical set of characteristics. In terms of basic properties, its main substitutes are distinguished: steels 40Х, 50 and 50Г2. In terms of their characteristics, they are the closest with a similar set of functions.

Mechanical properties at T=20oC

| Assortment | sв | sT | d5 | y | KCU | Thermal change |

| — | MPa | MPa | % | % | kJ/m2 | — |

| Pipes, GOST 8731-87 | 588 | 323 | 14 | |||

| The rod is calibrated, GOST 10702-78 | 590 | 40 | Annealing | |||

| Rolled products, GOST 1050-88 | 600 | 355 | 16 | 40 | Normalization | |

| Rolled products cold-hardened, GOST 1050-88 | 640 | 6 | 30 | |||

| Rolled products annealed, GOST 1050-88 | 540 | 13 | 40 | |||

| Annealed tape, GOST 2284-79 | 440-690 | 14 | ||||

| Cold-worked tape, GOST 2284-79 | 690-1030 | |||||

| Strip, GOST 1577-93 | 600 | 355 | 16 | 40 | Normalization |

Characteristics and application of steel 45: high strength indicator and technical characteristics

Steel is a wrought alloy of iron (forgeable) with carbon and other elements. It is obtained from a composition in which there is room for cast iron and steel scrap, and is processed in open-hearth furnaces, oxygen converters and electric furnaces. If the iron alloy contains more than 2.14% carbon, then it is already cast iron.

Steel classification

On the market, 99% of all steel is a structural material in the broad sense. This group includes steels for the construction of building structures , the manufacture of machine parts, elastic elements, tools, as well as for special working conditions, having certain indicators, for example, heat-resistant, stainless and others.

The main qualities of the material are:

- Strength, which is characterized by the ability to withstand sufficient stress.

- Plasticity, this characteristic allows it to withstand deformation without damage to destruction both during the production of structures and at overload points during their operation.

- Viscosity helps absorb the work of external forces and prevents the propagation of cracks.

- Heat resistance and cold resistance.

- Elasticity and hardness.

Steel and alloys are classified:

- In terms of chemical and structural composition.

- By quality. This indicator is influenced by the production method and the content of harmful impurities.

- According to the degree of deoxidation and hardening of the metal in the mold.

- By application.

Chemical composition

Depending on the carbon content, they are divided into groups:

- carbon less than 0.3% C - low-carbon.

- Medium carbon, when it is from 0.3 to 0.7% C.

- More than 07% C is high carbon.

To improve the technological properties of the material, steel is alloyed. What does it mean? , alloying elements are added to its composition . Typically, better properties appear when alloying is complex.

In alloy steels, classification occurs due to the total percentage of impurities contained in it:

- Low alloyed, in which less than 2.5%.

- Medium alloyed - from 2.5% to 10%.

- Highly alloyed - above 10%.

Structural composition

Alloy steels are divided into types according to structural analysis:

- In annealed form - ledeburite, ferritic, hypoeutectoid, hypereutectoid, austenitic.

- In normalized form - autenitic, martensitic, pearlitic.

The pearlite class is characterized by a low content of alloying elements. This includes alloy and carbon steels. Martensitic includes steels with a higher percentage of alloying substances. The authenite class includes materials with a high content of alloying elements.

impurities

Based on the production method and impurity content, this material is divided into 4 groups:

- Ordinary quality . Their chemical composition is carbonaceous. They are smelted using oxygen or in open-hearth furnaces. These steels are inexpensive and inferior in properties to other classes.

- High quality . According to their chemical properties, they are carbon or alloyed. Just like the previous type, they are smelted in converters or in open-hearth furnaces, while more stringent requirements for the composition of the charge, melting and casting work are observed.

- High quality . This type is usually smelted in electric furnaces. Very high quality steel is produced using electric furnaces with electroslag remelting. Other advanced methods are also used aimed at increasing the purity of non-metallic inclusions (sulfur and phosphorus).

- Thanks to electroslag remelting , which effectively removes sulfides and oxides, especially high-quality steels are created. Such steels are only alloyed. They are processed in electric furnaces, and special electrometallurgy methods are applied to them.

Steel 45

This steel alloy differs from others in a set of special characteristics that are unique to this brand. It is distinguished by its application and high functionality , unique composition of chemical compounds, and a set of foundry and other production parameters.

Analogues and substitutes

domestic analogues:

| Rolled metal grade | Substitute | ||||

| 45 | 40X | ||||

| 50 | |||||

| 50G2 | |||||

| Foreign analogues of steel grade 45 | |||||

| USA | 1044, 1045, 1045H, G10420, G10430, G10440, G10450, M1044 | ||||

| Germany | 1.0503, 1.1191, 1.1193, C45, C45E, C45R, Cf45, Ck45, Cm45, Cq45 | ||||

| Japan | S45C, S48C, SWRCH45K, SWRCH48K | ||||

| France | 1C45, 2C45, AF65, C40E, C45, C45E, C45RR, CC45, XC42H1, XC42H1TS, XC45, XC45H1, XC48, XC48H1 | ||||

| England | 060A47, 080M, 080M46, 1449-50CS, 1449-50HS, 50HS, C45, C45E | ||||

| European Union | 1.1191, 2C45, C45, C45E, C45EC, C46 | ||||

| Italy | 1C45, C43, C45, C45E, C45R, C46 | ||||

| Belgium | C45-1, C45-2, C46 | ||||

| Spain | C45, C45E, C45k, C48k, F.114, F.1140, F.1142 | ||||

| China | 45, 45H, ML45, SM45, ZG310-570, ZGD345-570 | ||||

| Sweden | 1650, 1672 | ||||

| Bulgaria | 45, C45, C45E | ||||

| Hungary | A3, C45E | ||||

| Poland | 45 | ||||

| Romania | OLC45, OLC45q, OLC45X | ||||

| Czech | 12050, 12056 | ||||

| Austria | C45SW | ||||

| Australia | 1045, HK1042, K1042 | ||||

| Switzerland | C45, Ck45 | ||||

| South Korea | SM45C, SM48C | ||||

Weldability and substitutes for structural and tool steels

A table is provided of the main grades of structural and tool steels, including stainless and heat-resistant, and recommendations for welding parts made from them.

STEEL GRADES

| GOST | Steel grades | Substitutes | Weldability |

| 380-94 | St0 | welds without restrictions | |

| St2kp St2ps St2sp | St2sp St2ps | welds without restrictions. for thicknesses greater than 36 mm, heating and subsequent heat treatment are recommended | |

| St3kp | St3ps | welds without restrictions. for thicknesses greater than 36 mm, heating and subsequent heat treatment are recommended | |

| St3ps St3sp | St3sp St3ps | welds without restrictions. for thicknesses greater than 36 mm, heating and subsequent heat treatment are recommended | |

| St3Gps | St3ps Steel 18Gps | welds without restrictions. for thicknesses greater than 36 mm, heating and subsequent heat treatment are recommended | |

| St4kp | limited weldability | ||

| St4ps | St4sp | limited weldability | |

| St5ps St5sp | St6sp St4sp | limited welding. Preheating and subsequent heat treatment are recommended | |

| St6ps | limited welding. Preheating and subsequent heat treatment are recommended | ||

| St6sp | St5sp | limited welding. Preheating and subsequent heat treatment are recommended | |

| 801-78 | ШХ15 | ShKh9, ShKh12, ShKh15SG | welding method KTS |

| SHH15SG | HVG, ShH15, 9HS, HVSG | welding method KTS | |

| ШХ4 | welding method KTS | ||

| 1050-2013 | 08 | Steel 10 | welded without restrictions, except for parts after chemical-thermal treatment |

| 08kp 08ps | Steel 08 | welded without restrictions, except for parts after chemical-thermal treatment | |

| 10 | 08, 15, 08kp | welded without restrictions, except for parts after chemical-thermal treatment | |

| 10kp 10ps | 08kp, 15kp, 10 | welded without restrictions, except for parts after chemical-thermal treatment | |

| 15 | 10, 20 | welded without restrictions, except for parts after chemical-thermal treatment | |

| 15kp 15ps | 10kp, 20kp | welds without restrictions | |

| 18kp | welds without restrictions | ||

| 20 | 15, 20 | welded without restrictions, except for parts after chemical-thermal treatment | |

| 20kp 20ps | 15kp | welded without restrictions, except for parts after chemical-thermal treatment | |

| 25 | 20, 30 | welded without restrictions, except for parts after chemical-thermal treatment | |

| 30 | 25, 35 | limited welding. Preheating and subsequent heat treatment are recommended | |

| 35 | 30, 40, 35G | limited welding. Preheating and subsequent heat treatment are recommended | |

| 40 | 35, 45, 40G | limited welding. Preheating and subsequent heat treatment are recommended | |

| 45 | 40Х, 50, 50Г2 | difficult - weldable. heating and subsequent heat treatment are required | |

| 50 | 45, 50G, 50G2, 55 | difficult - weldable. heating and subsequent heat treatment are required | |

| 55 | 50, 60, 50G | not applicable for welded structures | |

| 58 | 30ХГТ, 20ХГНТР, 20ХН2М, 12ХНЗА, 18ХГТ | not applicable for welded structures | |

| 1414-75 | A20 | Steel A12 | not applicable for welded structures |

| A30 A40G | A40G | not applicable for welded structures | |

| 1435-90 | U7, U7A | U8 | not applicable for welded structures |

| U8, U8A | U7, U7A U10, U10A | not applicable for welded structures | |

| U9, U9A | U7, U7A, U8, U8A | not applicable for welded structures | |

| U10, U10A | U10, U10A | not applicable for welded structures | |

| 4543-71 | 15X | 20X | welded without restrictions, except for parts after chemical-thermal treatment |

| 20X | 15Х, 20ХН, 18ХГТ | welded without restrictions, except for parts after chemical-thermal treatment | |

| 30X | 35X | limited weldability | |

| 35X | 40X | limited weldability | |

| 38ХА | 40Х, 35Х | difficult to weld | |

| 40X | 45Х, 35ХА, 40ХС | difficult to weld, requires heating and subsequent heat treatment | |

| 45X | 40Х, 45Х, 50ХН | difficult to weld, requires heating and subsequent heat treatment | |

| 50X | 40Х, 45Х, 50ХН | difficult to weld, requires heating and subsequent heat treatment | |

| 15G 20G | 20G, 20, 30G | well weldable | |

| 30G | 35, 40G | limited weldability. Preheating and subsequent heat treatment are recommended | |

| 35G | limited weldability. Preheating and subsequent heat treatment are recommended | ||

| 40G | 45, 40Х | limited weldability. Preheating and subsequent heat treatment are recommended | |

| 45G | 40G, 50G | difficult to weld. Preheating and subsequent heat treatment are recommended. | |

| 50G | 40G, 50 | difficult to weld. Preheating and subsequent heat treatment are recommended. | |

| 10G2 | 09G2 | welds without restrictions. | |

| 35G2 | 40X | difficult to weld. heating and subsequent heat treatment are required. | |

| 40G2 | 45G2, 60G | difficult to weld. heating and subsequent heat treatment are required. | |

| 45G2 | 50G2 | difficult to weld. heating and subsequent heat treatment are required. | |

| 50G2 | 45G2, 60G | not applicable for welded structures | |

| 47GT | 40HGRT | not applicable for welded structures | |

| 18ХГТ | 30ХГТ, 25ХГТ, 12ХН3А, 12Х2Н4А, 20ХН2М, 20ХГР | welded without restrictions, except for parts after chemical-thermal treatment | |

| 20ХГР | 20ХН3А, 20ХН24, 18Х1Т, 12ХН2, 12ХН3А | welded without restrictions, except for parts after chemical-thermal treatment | |

| 25ХГТ | 18ХГТ, 30ХГТ, 25ХГМ | subsequent heat treatment is required | |

| 30ХГТ | 18ХГТ, 20ХН2М, 25ХГТ, 12Х2Н4А | limited weldability. Preheating and subsequent heat treatment are recommended | |

| 33ХС | difficult to weld | ||

| 38ХС 40ХС | 40ХС, 38ХС, 35ХГТ | difficult to weld | |

| 15HF | 20HF | welded without restrictions (KTS method) | |

| 40HFA | 40Х, 65Г, 50ХФА, 30Х3МФ | difficult to weld. heating and subsequent heat treatment are required. | |

| 15ХМ | welds without restrictions. Preheating and subsequent heat treatment are recommended | ||

| 30ХМ 30ХМА | 35ХМ, 35ХРА | limited weldability. Preheating and subsequent heat treatment are recommended | |

| 35ХМ | 40Х, 40ХН, 30ХН, 35ХГСА | limited weldability. Preheating and subsequent heat treatment are recommended | |

| 38ХН | limited weldability. Preheating and subsequent heat treatment are recommended | ||

| 20ХН | 15ХГ, 20ХНР, 18ХГТ | limited weldability. | |

| 40ХН | 45ХН, 50ХН, 38ХГН, 40Х, 35ХГФ, 40ХНР, 40ХНМ, 30ХГВТ | difficult to weld. Preheating and subsequent heat treatment are recommended | |

| 45ХН | 40ХН | difficult to weld. Preheating and subsequent heat treatment are recommended | |

| 50ХН | 40ХН, 60ХГ | not applicable for welded structures | |

| 20ХНР | 20ХН | limited weldability. heating and subsequent heat treatment are required. | |

| 12ХН2 | 20ХНР, 20ХГНР, 12ХН3А, 18ХГТ, 20ХГР | limited weldability. heating and subsequent heat treatment are required. | |

| 12ХН3А | 12ХН2, 20ХН3А, 25ХГТ, 12Х2НР, 20ХНР | limited weldability. heating and subsequent heat treatment are required. | |

| 20ХН3А | 20ХГНР, 20ХНГ, 38ХА, 20ХГР | limited weldability. heating and subsequent heat treatment are required. | |

| 12Х2Н4А | 20ХГНР, 12ХН2, 20ХГР, 12ХН3А, 20Х2Н4А | limited weldability. heating and subsequent heat treatment are required. | |

| 20Х2Н4А | 20HGNR, 20HGNTR | limited weldability. heating and subsequent heat treatment are required. | |

| 30ХН3А | 30Х2ГН2, 34ХН2М | limited weldability. heating and subsequent heat treatment are required. | |

| 20ХГСА | 30ХГСА | welds without restrictions | |

| 25ХГСА | 20ХГСА | welds without restrictions | |

| 30ХГС, 30ХН2МА | 40HFA, 35ХМ, 40ХН, 35ХГСА | limited weldability. heating and subsequent heat treatment are required. | |

| 38Х2Н2МА | not applicable for welding work | ||

| 40ХН2МА | 40HGT, 40HGR, 30H3MF, 45HN2MFA | difficult to weld. heating and subsequent heat treatment are required | |

| 40Х2Н2МА | 38Х2Н2МА | difficult to weld. heating and subsequent heat treatment are required | |

| 38ХН3МА | 38ХН3ВА | not applicable for welded structures | |

| 18Х2Н4МА | 20Х2Н4А | difficult to weld. heating and subsequent heat treatment are required | |

| 30ХГСА | 40HFA, 35ХМ, 40ХН, 25ХГСА, 35ХГСА | difficult to weld. heating and subsequent heat treatment are required | |

| 35ХГСА | 30ХГС, 30ХГСА, 30ХГТ, 35ХМ | difficult to weld. heating and subsequent heat treatment are required | |

| 30ХГСН2А | difficult to weld. heating and subsequent heat treatment are required | ||

| 38ХГН | 38ХГНМ | difficult to weld. heating and subsequent heat treatment are required | |

| 20ХГНР | 20ХН3А | difficult to weld. heating and subsequent heat treatment are required | |

| 20ХН2М | 20ХГР, 15ХР, 20ХНР, 20ХГНР | difficult to weld. heating and subsequent heat treatment are required | |

| 30ХН2МФА | 30HN2VFA | difficult to weld. heating and subsequent heat treatment are required | |

| 36Х2Н2МФА | difficult to weld. | ||

| 38ХН3МФА | not applicable for welded structures | ||

| 45ХН2МФА | difficult to weld. heating and subsequent heat treatment are required | ||

| 20ХН4FA | 18Х2Н4МА | not applicable for welded structures | |

| 38Х2МУА | 38Х2УА, 38ХВФУ, 38Х2У, 20Х3МВФ | not applicable for welded structures | |

| 5520-79 | 16K 18K | welds without restrictions | |

| 20K | welds without restrictions | ||

| 22K | limited weldability. Preheating and subsequent heat treatment are recommended | ||

| 5632-72 | 40Х9С2 | not applicable for welded structures | |

| 40Х10С2М | difficult to weld. heating and subsequent heat treatment are required | ||

| 08Х13 12Х13 20Х13 25Х13Н2 | 12Х13, 12Х18Н9Т 20Х13 12Х13, 14Х17Н2 | limited weldability. Heating and heat treatment are used depending on the welding method, type and purpose of structures | |

| 30Х13 40Х13 | not applicable for welded structures | ||

| 10X14AG16 | 12Х18Н9, 08Х18Н10, 12Х18Н9Т, 12Х18Н10Т | welds without restrictions | |

| 12Х17 | 12Х18Н9Т | not recommended for welded structures. difficult to weld | |

| 08Х17Т, 08Х18Т1 | 12Х17, 08Х18Т1, 08Х17Т | limited weldability | |

| 95Х18 | not applicable for welded structures | ||

| 15Х25Т | 12Х18Н10Т | difficult to weld. heating and subsequent heat treatment are required | |

| 15Х28 | 15Х25Т, 20Х23Н18 | difficult to weld. heating and subsequent heat treatment are required | |

| 20Х23Н13 | limited weldability | ||

| 20Х23Н18 | 10Х25Т, 20Х23Н13 | limited weldability | |

| 10Х23Н10 | limited weldability | ||

| 20Х25Н20С | limited weldability | ||

| 15Х12ВНМФ | difficult to weld | ||

| 20Х12ВНМФ | 15Х12ВНМФ, 18Х11МНФБ | difficult to weld | |

| 37Х12Н8Г2МФБ | limited weldability | ||

| 13Х11Н2В2МФ | limited weldability | ||

| 45Х14Н14В2М | difficult to weld | ||

| 40X15N7G7F2MS | difficult to weld | ||

| 08Х17Н13М21 | 10Х17Н13М21 | well weldable | |

| 10Х17Н3М2Т | well weldable | ||

| 31Х19Н9МВБТ | difficult to weld | ||

| 10Х14Г14Н4Т | 20Х13Н4Г9, 12Х18Н9Т, 12Х18Н10Т, 08Х18Н10Т | welds satisfactorily | |

| 14Х17Н2 | 20Х17Н2 | well weldable | |

| 12Х18Н9 17Х18Н9 | 20Х13Н4Г9, 10Х14Г14Н4Т, 20Х13Н4Г9 | welds without restrictions | |

| 08Х18Н10 08Х18Н10Т 12Х18Н9Т 12Х18Н10Т | 12Х18Н10Т, 15Х25Т, 08Х18Г8Н2Т, 10Х14Г14Н4Т, 08Х17Т | welds without restrictions | |

| 12Х18Н12Т | 12Х18Н9, 12Х18Н9Т, 12Х18Н10Т | limited weldability | |

| 08Х18Г8Н2Т | 12Х18Н9 | welds without restrictions | |

| 20Х20Н14С2 | welds without restrictions | ||

| 12X25N16G7AR | welds without restrictions | ||

| 08Х22Н6Т | 12Х18Н9Т, 12Х18Н10Т, 08Х18Н10Т | welds without restrictions | |

| 06ХН28МДТ | Alloy: 03ХН28МДТ | welds without restrictions | |

| ХН35ВТ | difficult to weld | ||

| ХН35ВТУ | difficult to weld | ||

| ХН70У | limited weldability | ||

| ХН70ВМУТ | difficult to weld | ||

| KhN70VMTUF | difficult to weld | ||

| ХН77TYUR | difficult to weld | ||

| ХН78Т | Alloy: KhN38T, 12Kh25N16G7AR, 20Kh23N18 | difficult to weld | |

| ХН80ТБУ | difficult to weld | ||

| 5781-82 | 20ХГ2Ц | — | welds without restrictions |

| 35GS 25G2S | St5sp, St6, St5ps | welds without restrictions | |

| 5950-73 | ХВ4Ф | SKS11 JIS G4404 | not applicable for welded structures |

| 9Х1 | 9x2 | not applicable for welded structures | |

| 9ХС | HVG | not applicable for welded structures | |

| HVG | 9ХС, 9ХВГ, ШХ15СГ | not applicable for welded structures | |

| 9ХВГ | HVG | not applicable for welded structures | |

| Х6ВФ | Х12Ф1, Х12М, 9Х5Ф | not applicable for welded structures | |

| X12, X12VMF | X12MF | not applicable for welded structures | |

| Х12МФ Х12Ф1 | Kh6VF, Kh12F1, Kh12VMF Kh6VF, Kh6VFM | not applicable for welded structures | |

| 7ХГ2ВМФ | not applicable for welded structures | ||

| 7Х3 8Х3 | 8Х3 7Х3 | not applicable for welded structures | |

| 5ХНМ | 5ХНВ, 5ХГМ, 4ХМФС, 5ХНВС, 4Х5В2ФС | not applicable for welded structures | |

| 5ХГМ | 5ХНМ, 5ХНВ, 6ХВС, 5ХНС, 5ХНСВ | not applicable for welded structures | |

| 4ZMFS | not applicable for welded structures | ||

| 4Х5МФС | not applicable for welded structures | ||

| 4ХМФ1С | not applicable for welded structures | ||

| 3Х3МХФ | not applicable for welded structures | ||

| 6ХС | not applicable for welded structures | ||

| 4ХВ2С | 4Х5В2ФС, 4Х3В2М2 | not applicable for welded structures | |

| 5ХВ2СФ 6ХВ2С | 6ХВ2С 6ХЗФС | not applicable for welded structures | |

| 6ХВГ | not applicable for welded structures | ||

| 9045-93 | 08YU | 11305 standard CSN411305 | welds without restrictions |

| 14959-79 | 65 70 | 60, 70 65G | not applicable for welded structures |

| 75 | 70, 80, 85 | not applicable for welded structures | |

| 85 | 70, 75, 80 | not applicable for welded structures | |

| 60G | 65G | not applicable for welded structures | |

| 65G | 70, U8A, 70G, 60S2A, 9HS, 50HFA, 60S2, 55S2 | not applicable for welded structures | |

| 55С2 | 50S2, 60S2, 35Х2AF | not applicable for welded structures | |

| 60С2 60С2А | 55S2, 50HFA, 60S2N2A, 60S2G, 50HFA | not applicable for welded structures | |

| 70С3А | 70S3A standard BDS6742 | not applicable for welded structures | |

| 55ХГР | 55ChGR standard BDS6742 | not applicable for welded structures | |

| 50HFA | 60С2А, 50ХГФА, 9ХС | not applicable for welded structures | |

| 60С2ХА | 60S2HFA, 60S2N2A | not applicable for welded structures | |

| 60S2HFA | 60С2А, 60С2ХА, 9ХС, 60С2ВА | not applicable for welded structures | |

| 65S2VA | 60С2А, 60С2ХА | not applicable for welded structures | |

| 60С2Н2А | 60С2А, 60С2ХА | not applicable for welded structures | |

| 19265-73 | P18 | P12 | when butt welding with steel 45 and 40X, weldability is good |

| R6M5K5 | HS6-5-2-5 standard DIN17350 | when butt welding with steel 45 and 40X, weldability is good | |

| R9M4K8 | HS10-4-3-10 standard DIN17350 | when butt welding with steel 45 and 40X, weldability is good | |

| 19281-2014 | 09G2 | 09G2S, 10G2 | welds without restrictions |

| 14G2 | 15HSND | limited weldability | |

| 12GS | 15GS | welds without restrictions | |

| 16GS | 17GS | welds without restrictions | |

| 17GS | 16GS | welds without restrictions | |

| 17G1S | 17GS | welds without restrictions | |

| 09G2S | 10G2S, 09G2 | welds without restrictions | |

| 10G2S1 | 10G2S1D | welds without restrictions | |

| 10G2BD | 10G2B | welds without restrictions | |

| 15G2SFD | welds without restrictions | ||

| 14G2AF | 16G2AF | welds without restrictions | |

| 16G2AF | 14G2AF | welds without restrictions | |

| 18G2FAps | 15G2FADps, 16G2AF, 10HSND, 15HSND | welds without restrictions | |

| 14ХГС | 15HSND, 16GS | welds without restrictions | |

| 15G2AFDps | 16G2AF, 18G2AFps, 10HSND | welds without restrictions | |

| 10HSND | 16G2AF | welds without restrictions | |

| 10KhNDP | 10XHAP standard PN/H84017 | welds without restrictions | |

| 15HSND | 16G2AF, 14HGS, 16GS | welds without restrictions | |

| 20072-72 | 12MH | 12CrMo standard GB3077-88 | welds without restrictions. Preheating and subsequent heat treatment are recommended |

| 12Х1МФ | 12Cr1MoV standard GB3077-88 | welds without restrictions. Preheating and subsequent heat treatment are recommended | |

| 25Х1МФ | 25Cr2MoVA standard GB3077-88 | welds without restrictions. Preheating and subsequent heat treatment are recommended | |

| 20Х3МВФ | welds without restrictions. heating and subsequent thermal treatment are recommended | ||

| 15Х5М | 12CrMo205 standard MSZ2295 | welds without restrictions. Preheating and subsequent heat treatment are recommended |

If, in any case, you need to weld steel for slightly different purposes, you can use the following recommendations.

WELDABILITY OF STEEL

The main characteristics of the weldability of steels are their tendency to crack and the mechanical properties of the weld.

According to weldability, steel is divided into four groups: 1 - good weldability; 2 - satisfactory weldability; 3 - limited weldability; 4 - poor weldability

To group 1

include steels, welding of which can be performed without heating before welding and during the welding process and without subsequent heat treatment. But the use of heat treatment is not excluded to relieve internal stress. Steels St1 - St4 according to GOST 380-94 have good weldability; steel 08; 10:15; 20; 25 according to GOST 1050-2013; steel 15L; 20L according to GOST 977-88, steel 15G; 20G; 15X; 20X; 20ХГСА; 12ХН2 according to GOST 4543-71. Steel 12Х18Н9Т; 08Х18Н10; 20Х23Н18 according to GOST 5632-72

To group 2

mainly include steels, when welded under normal production conditions, cracks do not form, as well as steels that require preheating to prevent cracks, steels that must be subjected to preliminary and subsequent heat treatment. St5ps steels have satisfactory weldability. St5sp according to GOST 380-94. steel 30; 35 according to GOST 1050-2013; steel Z0L; 35L according to GOST 977-88; steel 20ХНЗА; 12Х2Н4А according to GOST 4543-71.

To group 3

include steels prone to cracking under normal welding conditions. They are pre-heated and heated. Most steels in this group are also heat treated after welding. St6ps steels have limited weldability. St6sp according to GOST 380-94; steel 40; 45; 50 according to GOST 1050-2013; steel 30ХМ; 30ХГС; ZZHS; 20Х2Н4А according to GOST 4543-71; steel 17Х18Н9; 12Х18Н9 according to GOST 5632-72.

To group 4

include steels that are most difficult to weld and prone to cracking. They must be welded with preliminary heat treatment, heating during the welding process and subsequent heat treatment. 40G steels have poor weldability; 45G; 50G; 50Х according to GOST 4543-71. steel 55L according to GOST 977-88; U7 steel; U8; U8A; U8G; U9; U10; U11; U12 according to GOST 1435-90; steel 65; 75; 85; 60G; 65G; 70G; 50ХГ; 50HGA; 55С2; 55С2А; 60С2; 60С2А according to GOST 14959-79; steel X12; XI2M; 7X3; 8X3. CHVG; ХВ4; 5ХГМ; 6ХВГ according to GOST 5950-73.

Chemical composition (according to GOST 1050-2013)

| Chemical element | % |

| Carbon (C) | 0.42-0.50 |

| Silicon (Si) | 0.17-0.37 |

| Copper (Cu), no more | 0.25 |

| Arsenic (As), no more | 0.08 |

| Manganese (Mn) | 0.50-0.80 |

| Nickel (Ni), no more | 0.25 |

| Phosphorus (P), no more | 0.035 |

| Chromium (Cr), no more | 0.25 |

| Sulfur (S), no more | 0.04 |

Features of steel grade 45

Steel 45 has increased characteristics of strength, endurance, is well processed, and is affordable. It has found application in almost all areas of industry, where there are constant mechanical loads and difficult temperature conditions. Products made of steel 45, for example, the extremely popular circle and hexagon st45, can withstand differences in the range from 200 to 600 o C.

If we compare some characteristics of raw materials of grade 45 and, for example, grade 35, then the influence of the proportion of carbon in the alloy composition becomes obvious. Thus, 0.42 - 0.5% versus 0.32 - 0.4% (respectively) indicates increased hardness characteristics of steel 45.

If steel 35 is classified as limitedly weldable, then steel 45 (GOST 1050-88) is very difficult to weld. This is perhaps the first of the latter’s “disadvantages”. The second is susceptibility to corrosion due to the presence of nickel and chromium.

Steel 35 is usually used for the manufacture of parts of not too high strength, subjected to light and medium loads during operation: these are axles, cylinders, crankshafts, connecting rods, while grade 45 raw materials are used to make more reliable parts with improved strength characteristics.

Comparative characteristics of raw materials can be found here:

Mechanical properties

Mechanical properties at elevated temperatures

| test t, °C | σ0.2, MPa | σB, MPa | δ5, % | δ, % | ψ, % | KCU, J/m2 |

| Normalization | ||||||

| 200 | 340 | 690 | 10 | 36 | 64 | |

| 300 | 255 | 710 | 22 | 44 | 66 | |

| 400 | 225 | 560 | 21 | 65 | 55 | |

| 500 | 175 | 370 | 23 | 67 | 39 | |

| 600 | 78 | 215 | 33 | 90 | 59 | |

| Specimen with a diameter of 6 mm and a length of 30 mm, forged and normalized. Deformation speed 16 mm/min. Strain rate 0.009 1/s. | ||||||

| 700 | 140 | 170 | 43 | 96 | ||

| 800 | 64 | 110 | 58 | 98 | ||

| 900 | 54 | 76 | 62 | 100 | ||

| 1000 | 34 | 50 | 72 | 100 | ||

| 1100 | 22 | 34 | 81 | 100 | ||

| 1200 | 15 | 27 | 90 | 100 | ||

Mechanical properties of rolled products

| Heat treatment, delivery condition | Section, mm | σB, MPa | δ5, % | δ4, % | ψ, % |

| Hot-rolled, forged, calibrated and silver steel of the 2nd category after normalization | 25 | 600 | 16 | 40 | |

| Calibrated steel of the 5th category after hardening | 640 | 6 | 30 | ||

| Steel, calibrated and calibrated with a special finish after tempering or annealing | <590 | 40 | |||

| Normalized and hot rolled sheets | 80 | 590 | 18 | ||

| Normalized or hot rolled strips | 6-25 | 600 | 16 | 40 | |

| Hot rolled sheet | <2 | 550-690 | 14 | ||

| Hot rolled sheet | 2-3,9 | 550-690 | 15 | ||

| Cold rolled sheet | <2 | 550-690 | 15 | ||

| Cold rolled sheet | 2-3,9 | 550-690 | 16 |

Mechanical properties of forgings

| Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | HB |

| Normalization | |||||

| 100-300 | 245 | 470 | 19 | 42 | 143-179 |

| 300-500 | 245 | 470 | 17 | 35 | 143-179 |

| 500-800 | 245 | 470 | 15 | 30 | 143-179 |

| <100 | 275 | 530 | 20 | 44 | 156-197 |

| 100-300 | 275 | 530 | 17 | 34 | 156-197 |

| Hardening. Vacation | |||||

| 300-500 | 275 | 530 | 15 | 29 | 156-197 |

| Normalization. Hardening. Vacation. | |||||

| <100 | 315 | 570 | 17 | 39 | 167-207 |

| 100-300 | 315 | 570 | 14 | 34 | 167-207 |

| 300-500 | 315 | 570 | 12 | 29 | 167-207 |

| <100 | 345 | 590 | 18 | 59 | 174-217 |

| 100-300 | 345 | 590 | 17 | 54 | 174-217 |

| <100 | 395 | 620 | 17 | 59 | 187-229 |

Mechanical properties depending on tempering temperature

| holiday t, °С | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HB |

| Quenching 850 °C, water. Samples with a diameter of 15 mm | ||||||

| 450 | 830 | 980 | 10 | 40 | 59 | |

| 500 | 730 | 830 | 12 | 45 | 78 | |

| 550 | 640 | 780 | 16 | 50 | 98 | |

| 600 | 590 | 730 | 25 | 55 | 118 | |

| Quenching 840 °C, water. Workpiece diameter 60 mm | ||||||

| 400 | 520-590 | 730-840 | 12-14 | 46-50 | 50-70 | 202-234 |

| 500 | 470-520 | 680-770 | 14-16 | 52-58 | 60-90 | 185-210 |

| 600 | 410-440 | 610-680 | 18-20 | 61-64 | 90-120 | 168-190 |

Mechanical properties depending on the section

| Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 |

| Quenching 850 °C, tempering 550 °C. Samples were cut from the center of the blanks. | |||||

| 15 | 640 | 780 | 16 | 50 | 98 |

| 30 | 540 | 730 | 15 | 45 | 78 |

| 75 | 440 | 690 | 14 | 40 | 59 |

| 100 | 440 | 690 | 13 | 40 | 49 |

Material properties

The mechanical properties of steel 45 determine the wide distribution of this metal. The carbon concentration is 0.45%, other impurities are extremely minor. This largely determines the following characteristics:

- The density of steel 45 or specific gravity is 7826 kg/m 3. This ensures a low weight of the resulting products, but they cannot be called light. Density may vary slightly depending on the chemical composition.

- The structure is not prone to temper brittleness. Steel 45, whose characteristics can be called a universal offer, is very often subjected to hardening, due to which the surface hardness significantly increases.

- Very often, blanks are delivered after heat treatment. It significantly increases surface hardness. This point also determines that the hardness of steel 45 in the delivered state can vary over a fairly wide range. As a rule, the hardness is maintained at a level of 10 -1 HB, which corresponds to 170 MPa.

- Steel grade 45 is a difficult-to-weld metal, which makes welding difficult. That is why the structure is initially heated and only after this the elements are connected. The hardenability of steel 45 is also at a fairly low level, which complicates the cutting process. Welding can be used with a variety of welding equipment. The use of appropriate electrodes can significantly simplify the welding process. Cutting with a welding machine is also significantly more complicated.

- Forging is carried out quite often. It is carried out at a temperature of 1250 degrees Celsius, at the end the indicator is 700 degrees Celsius.

- The tensile strength and elastic modulus can vary over a fairly wide range. It all depends on the heating temperature of the surface. The yield strength of steel determines how easy it is to cast various workpieces.

Properties of alloy St 45

In general, we can say that the metal is suitable for use in the manufacture of various products. In most cases, heat treatment is carried out, which can significantly increase performance characteristics. It is worth considering that only by maintaining the temperature regime can conditions be provided for the correct restructuring of the crystal lattice.

Technological properties

| Forging temperature |

| Start 1250, end 700. Sections up to 400 mm are cooled in air. |

| Weldability |

| Difficult to weld. Welding methods: RDS and KTS. Heating and subsequent heat treatment are required. |

| Machinability |

| In the hot-rolled state at HB 170-179 and sB = 640 MPa Kutv.spl. = 1, Kub.st. = 1. |

| Tendency to release ability |

| Not inclined. |

| Flock sensitivity |

| Insensitive. |

Specifications

Critical point temperature

| Critical point | °C |

| Ac1 | 730 |

| Ac3 | 755 |

| Ar3 | 690 |

| Ar1 | 780 |

| Mn | 350 |

Physical properties

| T (Grad) | E 10-5 (MPa) | a 10 6 (1/Deg) | l (W/(m deg)) | r (kg/m3) | C (J/(kg deg)) | R 10 9 (Ohm m) |

| 20 | 2 | 7826 | ||||

| 100 | 2.01 | 11.9 | 48 | 7799 | 473 | |

| 200 | 1.93 | 12.7 | 47 | 7769 | 494 | |

| 300 | 1.9 | 13.4 | 44 | 7735 | 515 | |

| 400 | 1.72 | 14.1 | 41 | 7698 | 536 | |

| 500 | 14.6 | 39 | 7662 | 583 | ||

| 600 | 14.9 | 36 | 7625 | 578 | ||

| 700 | 15.2 | 31 | 7587 | 611 | ||

| 800 | 27 | 7595 | 720 | |||

| 900 | 26 | 708 |

cutting

| Initial data | Machinability Ku | |||

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| hot rolled | 170–179 | 650 | 1,0 | 1.0 |