Crumb rubber tiles are a facing material that can be made from rubber waste, such as old tires. But the material is durable and flexible; it is suitable for cladding surfaces in administrative buildings, non-residential premises, as well as for external work.

Our article will be devoted to the production of tiles from rubber crumbs with your own hands. The option of producing tiles as a small business is being considered.

What are rubber tiles made of?

Rubber tiles are made from old rubber, such as old car tires and other things. But before starting work, the rubber must be specially crushed into small fractions.

The composition of the future paving stones includes:

- fine rubber fraction;

- polymer glue, which acts as an astringent;

- dyes that are designed to give the finished product the light that you need;

- Modifying additives: will help make paving stones strong and durable.

How to make rubber tiles yourself?

Crumb rubber is not concrete that you can make yourself. Therefore, in order to make rubber tiles, you need to purchase special equipment, including a grinder or crusher, a large mixing mold, and a vacuum press for hot pressing. This equipment is quite expensive. If, in addition to using tiles on your own site, you plan to sell these products, then the purchase of equipment will be justified. If you need tiles only for personal use, it is better to purchase finished products. Moreover, you can choose from the variety of offered assortment what you need.

Using rubber tiles to arrange your personal plot will bring a lot of pleasure during operation.

You just need to lay it out correctly, and then it will be strong, durable and aesthetically pleasing for a long time. After all, she is not afraid of any external influences or natural disasters.

Pros and cons of rubber tiles

Rubber paving stones have undeniable advantages:

- plasticity;

- strength;

- resistance to moisture and temperature changes from -45 to +60C;

- resistance to alkalis and acids;

- ease of installation;

- a rough surface will be injury-free.

Advantages of rubber tiles - video

Minuses

- rubber may not fit into the landscape design, because it is a more functional and economical option rather than one with high aesthetics;

- Installation of rubber tiles requires skill and preparation of the base.

Where is it used?

Application of rubber tiles:

- Playgrounds;

- Treadmills and more;

- Parking;

- Flooring of administrative buildings;

- As part of landscape design.

Raw material: rubber

Where can you find enough raw materials to produce paving stones?

Rubber tiles made from tires are a common practice. The cost of old tires depends on the quality of the rubber, tire dimensions, and manufacturer. The average price for black chips is 17-20 thousand rubles, and for colored chips - 10 thousand more.

You can buy old tires from auto repair shops, individuals, and small businesses. But it’s easier to buy crumb rubber right away. It is sold by factories that process tires into crumbs or by factories that restore tires by treating the tread. In this case, crumb rubber is a production waste.

Necessary equipment

All manufacturing stages must be carried out using special equipment for the production of tiles from crumb rubber. Therefore, the equipment comes first. What will you need to purchase?

- Volcanic press (cold or hot).

- Molds (at least three or four pieces).

- A special construction mixer that allows you to prepare the component raw materials used to produce tiles from crumb rubber.

- Thermal ovens (if the cold processing method is selected).

In addition to special equipment, you will definitely need auxiliary accessories. Such as molding tables, racks for fixing workpieces, platforms on which construction mixers are mounted.

Note! At the initial stage of organizing your own business, you can refuse to purchase auxiliary accessories. But if you are starting a program that should make a profit, it is important to purchase a whole range of special equipment.

Crushing methods

There are two main methods used in production:

- mechanical crushing;

- shock wave crushing.

Mechanical crushing involves grinding the material using special cutters. The low cost of equipment and simple technological process make this method popular and often used.

- The metal seating ring is removed;

- The rubber tire is cut into strips 5-7 cm wide;

- The remaining seat rings are removed;

- The rubber is crushed to obtain crumbs with a fraction of 5 mm;

- Finally, the resulting crumbs are sorted into fractions.

Shock wave crushing and grinding requires the use of special equipment. In a specially equipped chamber, the rubber is subjected to shock wave treatment. The entire process is automated and requires the participation of one operator.

How the described material is made

Typically, the production of rubber tiles begins with the processing of recyclable materials. Old tires can be shredded in two ways:

- Using mechanical crushing. To implement this, cutting machines are used. They are inexpensive, anyone can work with them, so the cost of producing raw materials is quite low.

- Using shock wave crushing. To carry it out, old car tires are placed in special chambers, then they are subjected to a certain effect, as a result of which crumbs are obtained. This process is fully automated and can be controlled by one person. Due to the high cost of installation, the cost of raw materials increases.

Note! Before sending the tires to the crusher, all metal parts are removed from the car tires, then they are cut into strips 5 cm wide. And only then the blanks are sent to the crusher, where they are cut into the sizes of the specified fractions.

What fractions of crumb rubber are required?

Crumb fractions vary from 0.1 to 10 mm. Small fractions (0.1-4 mm) are used to make single-layer tiles, both black and other colors.

Fractions of 2-10mm are used for the lower layers of rubber paving stones.

If the thickness of the tile is more than 1.5 cm, you can make the tile two-layer. So the bottom layer will be made of coarse fraction, and the top will be made of fine and more expensive crumbs.

Two-layer paving stones created according to this principle have its advantages:

- cost savings: fine fractions are more expensive;

- Saving dye: you can paint only the top part of the tile, and the bottom remains black;

- Less binder will be required for a large fraction.

Polymer glue consumption

Polyurethane glue costs 140 rubles per kg. Consumption directly depends on the following factors:

- The amount of glue depends on the fraction. The finer the fraction, the more glue will be required.

- No dyes are needed to make colorless tiles. Dyes dry out the glue, so the consumption will be higher.

- To produce dense products, more binder is required.

Glue consumption varies from 4 to 12% depending on the conditions listed above.

Let's illustrate with an example:

- Colorless paving stones, 4-10 mm chips need 4% glue;

- Black tiles, chips 1.2-1.8 mm will require 6%;

- Colored tiles with identical chips - 7-9% glue.

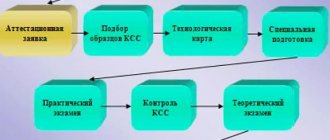

Technological process

- Crushing rubber, obtaining crumbs.

- Rubber fraction, polymer glue, dyes and modifying additives are added to the mixer.

- The mixture is mixed and loaded into special molds.

- Pressing raw material into tiles of the desired thickness and shape.

- Baking is the finishing process. There are two ways: “when cold,” the molds are sent to thermal cabinets. There, the raw materials are processed at low temperatures. “Hot” vulcanization requires high temperatures.

During hot processing, pressure is applied to the tile at a temperature of 140C. The procedure takes 15 minutes. Cold processing lasts 4 hours or more, and the temperature is only 80 C.

Manufacturing technology

To produce tiles, 2 pressing methods are used:

- hot;

- cold.

The first option is cheaper and faster. But at the end you will get a toxic product of low quality. Domestic manufacturers prefer cold pressing. This method allows you to obtain durable tiles, but it is not very productive.

The energy costs for both methods are the same. Only the nature of electricity consumption differs. With the hot method, electrical energy is consumed cyclically, only during operation of the press. During cold pressing, it is necessary to constantly consume electricity to maintain the desired temperature in the drying chambers.

Let's consider the main stages of production:

- Preparatory. At this stage, the main raw materials are prepared. To do this, old car tires are freed from metal rings and textile threads, and then crushed in a crusher to the desired fraction.

- Preparation of the mixture. Rubber crumbs, glue, pigments and modifying fillers are loaded into the mixer in the required proportion.

- Molding. The finished mixture is filled into special molds and sent to the press.

- Pressing. The raw material is compressed to a specified density and thickness.

- Baking. In the hot production method, the material is baked under pressure at +130°C. The cold method involves placing molds with raw materials in ovens for processing at lower temperatures (+60°C).

It is necessary to strictly adhere to the production technology of rubber tiles. Pay special attention to the following important nuances:

- Rubber crumb size. The quality of the coating and its physical and mechanical characteristics depend on this parameter.

- Availability of lubricant in the molds before loading the mixture.

- Maintain proportions when preparing the mixture.

- To increase the water resistance of the tiles, you need to use a smaller fraction of crumbs and increase the press pressure.

- The larger the fraction of crumb rubber, the faster the color of the material is lost during operation.

- It is better to make tiles more than 2 cm thick in two layers. The top layer is made of small crumbs, the bottom layer is made of coarse crumbs. If you want to make a two-layer rubber tile, you will need an additional mixer to prepare different layers.

- One pressing machine must produce tiles of the same thickness, regardless of its configuration. The thinner the coating, the faster its formation occurs.

Many manufacturers produce two-layer rubber tiles. This approach allows them to significantly reduce the cost of the finished product, since the mixture includes a cheap large fraction of the feedstock.

Proportions

To prepare a mixture of crumb rubber, all the necessary components are taken in the following proportions:

- crumb rubber - 80%;

- polymer glue - 10%;

- pigment - 3.5%;

- modified fillers - 0.5%.

The smaller the crumb fraction, the more glue will be needed. Pigment substances dry out the binder, so there may be less of it in black tiles. Before pouring ingredients into the mixer, they must be accurately dosed using a scale. Failure to comply with the technology may negatively affect the quality characteristics of the finished product.

Hot way

For the hot method of producing tiles, you will need a vulcanization press, under which the vulcanization process occurs at a temperature of +130°C. The molds with the mixture are kept under pressure for 30 minutes. After this, you can remove the finished tiles.

Hot pressing significantly increases volumes because it speeds up the process of making tiles. However, fast is not always good.

When using the hot method, the characteristics of the product deteriorate, which negatively affects its quality. These tiles have a stronger burnt rubber smell. In addition, it quickly deteriorates under the influence of various environmental factors.

The glue should be well absorbed into the structure of the mixture components. With the hot method, it does not have time to firmly bind all the components, so the tile becomes fragile and not strong enough. Under the influence of high temperatures, the connecting links do not dry, but are baked, which negatively affects the elasticity of the tile and its strength.

Cold way

The finished rubber mixture is loaded into molds and placed under a press. After pressing, the carts with the molds are loaded into special chambers for drying. They are kept for 4-6 hours at +60°C. After this time, the carts can be removed from the chamber.

The productivity of the cold method depends on the volume of the drying chamber. The larger the chamber, the more carts it will fit. Thanks to this, you can regulate the quantity of products produced.

At first glance, it may seem that making tiles this way is less productive. During cold pressing, chemical reactions slow down, the glue has time to reliably bind all components, and as a result you get durable, high-quality material with excellent performance characteristics. Production volumes can be increased by purchasing additional equipment.

Tile production equipment

For established tile production, you will need special equipment, devices, such as molds for pouring, as well as the required number of components for making tiles from crumb rubber.

What equipment is needed?

- To avoid crushing the rubber yourself, it is better to buy crumb rubber right away.

- Crumbs, polymer glue and all additives are loaded into the raw mixer. To obtain a homogeneous mixture, construction mixers with a centrifuge are needed. The cost of a raw mixer is 100-200 thousand rubles. To avoid downtime due to untimely supply of raw materials, purchase two mixers.

- Volcanic press: it is in them that paving slabs are baked. There are two baking methods: “cold” and “hot” method. The cost of a volcanic press is 350 thousand rubles, provided that the productivity is 100 m2 per day.

Technological process for the production of crumb rubber with demonstration of equipment - video

Auxiliary devices and accessories

- Forms for pressing. The mixture will be in such molds when it enters the oven. Cost – 30 thousand rubles per piece.

- Carts for transporting raw materials: crumbs and glue around the construction site.

- Measuring scoops, mugs and other containers.

- Scales for weighing the components of rubber paving stones.

As a result, you can produce a wide range of products:

- thin and thick rubber tiles;

- waterproof and drainage, allowing water to pass through;

- black, colored and interspersed with other colors;

- with or without a picture;

- with or without locking connections;

- different hardness;

- with a rough surface.

Below are possible products, their names and parameters.

What else should you consider before starting production?

- A constant voltage of 380V is required.

- To install the necessary equipment, a room with an area of 100 m2 is required. Room height from 3 m.

- Special equipment is automated, but to keep the process going, a full-fledged working team is required.

The process of processing tires into rubber crumbs. Summary The production of rubber paving stones as a mini-business is a great idea. It is worth deciding in advance on the sales market, component suppliers and purchasing the necessary equipment.

Rubber tiles are used for garden paths, children's playgrounds, gyms, and administrative buildings. Crumb paving stones have a wide range of applications, so a quality product will always be in price.

Making your own rubber coating

A troubling thought often haunts the heads of savvy craftsmen: “Is it possible to make a safety coating from crumb rubber yourself?” Yes, let's look at interesting Internet offers together. The first interesting question: “How to make crumb rubber at home?” Let's start with the fact that there are really original tips on the Internet for making crumb rubber:

“At the initial stage, it is necessary to prepare a sufficient amount of raw materials, i.e. old car inner tubes and corresponding cutting tools. To make a coating with an area of one square meter and a thickness of 10 mm, about 8 kg of crumb rubber is needed. When producing crumbs from old chambers, the loss of material by weight is minimal. Thus, it is necessary to prepare the starting material at the rate of 8 kg of old cameras per 1 square meter of coating. To grind rubber, you can use ordinary scissors or an ax. If desired, you can build special guillotine shears. As a last resort, you can organize cutting of the cameras with a fairly sharp knife. Making crumbs should be done according to the following algorithm:

- Remove all metal elements from the old camera

- Cut the camera into thin strips

- Grind the thin strips obtained in step 2"

Factory tire recycling

Hot press for making rubber tiles

It is clear that only the most purposeful will survive such a test, and only as an experiment. Having obtained crumb rubber in one way or another, we proceed to the manufacture of a safety coating.

It is impossible to make rubber tiles at home, since special equipment is required and the entire production technology must be followed. All that remains is a seamless coating. Here we should remember the restrictions on the use of seamless coating, which we previously discussed here. Next, we will consider a specific case of using expensive EPDM crumb rubber at home, taken from the Internet.

“So the object is a country house, a concrete platform in front of the garage of 8 m2. Photo "before", with the necessary materials and tools. True, a metal spatula, specially purchased, turned out to be unnecessary; a plastic one was used.

I bought a dark beige crumb. With a thickness of 10 mm of crumbs you need 7-8 kg per 1 square meter. m., the consumption depends on the evenness of the base and the hands of the paver, it took us 8. There is also a black secondary crumb, it is made from old tires, it costs 10 times less and, in principle, would also be suitable for covering the front of a garage, but the beige color is ideal approached the tiles on the terrace near the house, so we chose it. Add 15% of the binder to the crumbs, proportion 1*7, and mix with a drill. It's better to have a scale handy to weigh the parts, we added the binder with a jar, and it flows like honey, so it was very inconvenient.

Before applying the mixture, the base must be primed with a solution of 50% binder 50% solvent. The solvent is ordinary white spirit. We primed it in parts so as not to run on the glue. Then they simply poured the mixture with a trowel, leveled it and leveled it with a plastic spatula. It was periodically sprinkled with a bucket to prevent the glue from sticking.The mixture is very convenient and manageable to work with, and is flexible for about 30 minutes after application, so all imperfections can be corrected in time.

It turned out very similar to cork coating. It dried, however, longer than expected, almost a day.

Checking the car's coverage, demonstration run.

It turned out there was a trail of sand. Access to the yard is from a dirt road. But on beige crumbs it is almost invisible. Now I have my doubts about the black color on the ramp. The beige turned out to be very not easily soiled.Karcher can withstand it, the same nozzle as for the car is not brought closer than 20 cm, and sand and dirt are washed off from a regular garden hose.

You can use fine crumbs, then the surface will be smoother. But one of the advantages of the coating is that the dirt will remain on the coating and will not fall into the house or garage; it can then be washed off with water from a hose, and if there is no canopy, then the rain will wash it away. By the way, dry garbage, leaves, and grass can be easily swept away with a broom.

If you regularly turn the wheels on the surface, I think it won’t last long, again the question is which car, if the SUV is 2 t+ and the tires are studded, then the pavement will get damaged quickly.

Quote:

Message from Offroad TS, since the winter has finally passed (without incidents - I already read)? How was the snow/ice removed, how does the surface feel on a car track? If possible, with a photo

I give you a photo.

It seems like the snow has never been cleared away this winter. When turning the wheels in place, individual granules are torn out from the coating, but this is not critical, wear is not visible, and particles that were not initially incorporated are torn out. To be honest, this section is not heavily used, so there are definitely no ruts. There are no problems with cleaning, the sloping open area is washed off by rain. Which, considering entering the yard from the ground, is very good. And the sand is not particularly visible on the beige; the coating has not yet been cleaned after winter.

In this example, a seamless coating was laid at the entrance to the garage. The coating work was carried out by an enthusiast who had experience working with crumbs. The basis was taken from one of the expensive EPDM rubber crumbs. It should be noted that such crumb rubber is not sold in stores, and manufacturers do not sell it in small quantities. For this installation process, it is very important to thoroughly mix the chips and binder, and this is difficult to achieve under these conditions. The coating was not strong enough for its purpose. The rubber coating will be used under heavy load. Therefore, there is a fear that it will soon become unusable. In any case, such an experiment is an expensive pleasure. This means that before starting work, everything must be taken into account and weighed - literally and figuratively.

Another example of “home” work is decorating the porch with rubber crumbs. This work can also be done independently. We also attach an online report from the same craftsman:

This weekend I started making a porch at my dacha. I did it myself, so I didn’t get a detailed photo report, but the overall result is visible. And so traditionally there is a “before” photo, the remarkable configuration of the porch is a consequence of repeated reconstructions of the veranda. For the coating I chose two colors of crumb rubber. I decided to make the design simple - a dark frame with a bright middle, and decided to make the middle part a mix of 20% dark, 80% bright. Marking with chalk using a 10mm OSB ruler, which later became the rule. The total area of the porch is 5.5 sq.m., the frame took about three hours, it was necessary to sculpt the beautiful transitions and especially the vertical parts of the steps very carefully. But I did the whole middle in about 40 minutes. I didn’t use a stick this time so that the crumbs don’t stick to the spatula; you can lubricate it with a 50/50 solution of glue, binder and solvent. But I didn’t guess with the spatula, I bought a new one 40 cm, it turned out to be too big for a small frame. As a result, the corners turned out a little uneven, and I couldn’t stretch them properly. Here's a view of the almost finished porch. I left one corner for a passage, I'll finish it next weekend. "Semi-final" photo. Overall it looks good. A neighbor saw and thought that we had laid a rug on the porch. I'll make it beautiful and post a photo of it in finished form.

In principle, everyone can try to “conjure” a small fragment of rubber crumbs. However, as we have already said, you cannot buy such a volume of raw materials, dyes and polymer binders in a store.

BUT, now the ELITPLIT company is holding a promotion! If you have a great desire to work with an innovative material yourself, we will give you the opportunity to visit our production of rubber plates, and to get acquainted with the new rubber material for safety coatings, you can purchase at the ELITPLIT factory the necessary necessary set of components for experiments in the independent production of rubber coatings from yourself on the site. To visit the plant, you must contact the company's managers in advance by calling the ELITPLIT hotline . In addition, professional technologists will advise you on how to properly work with crumb rubber.

See also:

Rubber tile. GOST or TU? New certificates for rubber tiles Technical regulations for playgrounds EAEU TR 042/2017 Polyurethane adhesive for crumb rubber Trauma-proof coating. Question - answer Advantages of rubber tile coating Rubber tiles and curbs - safety coating Polymer drainage module 300x300x11 mm Rubber tiles or seamless coating? How to check the quality? Winter and summer in one color or reliable dyes for rubber tiles Hot or cold pressing of rubber tiles. Objective reality.