For watering household plots or organizing water supply in a country house, storage tanks are mainly used, the filling of which requires feasible automation. This simplifies the use of irrigation and water supply systems and eliminates the need for visual monitoring of the filling and emptying of the hydraulic accumulator. Considering that the container is usually located quite high, it is very inconvenient to keep an eye on the state of the liquid in the tank. Special sensors for monitoring the filling of the container will cope with this task perfectly.

Types of fill level monitoring products

Liquid level monitoring devices are divided into two main types: contact and non-contact.

Proximity sensors: description

They are used mainly in industrial processes and are divided into ultrasonic devices, capacitive, electrode, operating on the hydrostatic principle, and so on.

Such devices are used not only in water, but also in other environments, including aggressive ones. The circuit includes, in addition to the sensor itself, which is immersed or installed on the walls of the tank, a control controller, which is installed in a separate control unit outside the tank. Such systems are complex and expensive, and, therefore, unprofitable for use in domestic conditions. To control the filling level of the tank with water necessary for irrigation or plumbing, it is more advisable to use simpler and cheaper devices.

Characteristics of contact devices

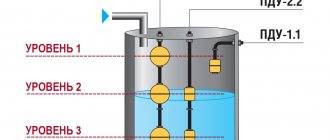

The most common devices for monitoring the filling of tanks in this type are float-type contact sensors assembled on the basis of reed switches. The devices are simple, reliable and cheap. They are divided according to their location in a container with liquid:

- Vertical arrangement. A rod with a float and a magnet moves along a vertical tube on which the reed switches for turning the pump on and off are located.

- Horizontal placement. Installed in the upper or lower part of the tank wall. As the tank is filled, the float with a magnet attached to it rises on a transverse rod to the reed switch, which switches off the power supply to the pump.

Float sensors for filling control with various design features can be purchased in stores. The choice depends on the specific installation location of the device and operating conditions.

AUTOMATION: PUMPING WATER INTO THE TANK

You have a dacha, for example, like this:

At the dacha there is a well, for example, like this:

There is electricity (of course!) and a 220V, single-phase submersible pump:

There is also a 200 liter tank:

And you want the tank to fill AUTOMATICALLY!

Then, you need to take two more identical compact FineTek float sensors, like these:

and install these sensors on the tank.

so that the pump turns on when there is no or little water in the tank:

But this is not enough for the pump to turn on and off; you also need a PA10-U sensor controller from Autonics. Here he is:

And if your pump is powerful enough, more than 400W, then you will also need a contactor, for example, this one:

Well, perhaps that's all. Now comes the fun part - connecting! Here's the diagram:

In general, nothing complicated. Considering that you have a summer house, a well, a pump and a tank, and you have the wisdom to purchase everything else, you will probably have the ingenuity to make the correct connection.

The position of the switches on the front panel of the controller should be as follows:

Order technical manuals for sensors and devices from us, as well as the sensors and devices themselves.

Connect and enjoy the automated tank filling process. And enjoy your holiday!

We simply give you the opportunity to know more so that you become the best among professionals!

Review of other news releases:

Selection and supply of automation equipment

Source

Recommendations for making the right choice

The selection of a container fill control sensor depends on a large number of factors:

- Composition of the liquid. It is important to know the amount of foreign impurities in the water. Impurities can change the density and electrical conductivity of the liquid, which will lead to inaccurate readings from a conventional sensor.

- Capacity and material for making the tank.

- Functional purpose of the vessel for generating liquid.

- Type of control. It is important to monitor the maximum and minimum filling levels of the container.

- Possibility of connecting the device to an automated general control system of the “Smart Home” type.

- Switching characteristics of the device.

There are many more criteria for selecting this sensor. But they are most likely not useful for domestic use. Selection parameters can be significantly reduced by focusing on the following parameters:

- Tank capacity.

- Trigger method.

- Control circuit.

A significant reduction in selection criteria allows you to select a sensor in a store at a fairly low price. It also makes it possible to make the device with your own hands without loss in response quality and safety of use.

Electrical part

The station motor is powered directly from the electric meter through a circuit breaker.

To protect the pump, quickly de-energize the engine in cases of unstable power supply or rotor overload, it is advisable to select a machine 10% more than the rated power. For the station motor used in the example, the rated power is 0.77 kW, taking into account the requirements, you need to use a 3.85 A circuit breaker ((770 W + 77 W) / 220 V), but the closest parameter is 5 A. You can use a circuit breaker with differential control.

As practice shows, conventional circuit breakers with similar current parameters cope with their functions quite well.

Self-manufacturing of the sensor

Suppose the task is to automate the use of a “Malysh” type pump to provide water to a summer house or country house. As a rule, water is pumped into a storage tank, and it is necessary to ensure timely, automatic shutdown of the pump when the tank is sufficiently filled. There is no need to install complex and expensive sensors for this. You can make a device based on a reed switch that will perfectly perform the task with your own hands. Let's call this device: an electric float valve for the water level in a tank based on a reed switch.

Reed switch

A reed switch is a switch that is the main performing part in the device of a reed switch water level sensor for controlling a pump. It looks like a small sealed glass container with a vacuum or inert gas inside. Inside there is a closed or open contact group, in other words, two closed or open contacts made of ferromagnetic material with a gold or silver top coating. When exposed to a magnetic field, the contacts of the part are magnetized and repel each other, opening the circuit in which they are connected, stopping its operation, or, conversely, they close and turn on the circuit. Reed switches are divided into two types:

- Reed switch with normally closed contacts.

- Reed switch with normally open contacts.

The environment inside the glass bulb prevents oxidation of contacts and the formation of sparks when shorted.

Sensor device based on a reed switch

To manufacture the device, you will need a 220-volt magnetic coil starter and a pair of reed switches, one of which is closed in the normal state, and the second is open. And you will also need a float for the water tank, which is made of foam plastic, a rod, a tube and three wires of small cross-section and thickness.

The operation of the device is simple and, most importantly, safe. The operating principle is as follows:

- In the process of collecting liquid, the float with a magnet, having reached the maximum level of the reed switch, which is in a closed state, opens under the influence of the magnetic field, commutating the power triggering coil, which turns off the pump.

- As the water from the reservoir decreases, the float lowers and when it reaches the lower reed switch, which is triggered by a short circuit under the influence of a magnetic field, the starting coil is switched to start the pump.

- A sensor made according to this principle can operate for many years without complaints, unlike electronic control systems for monitoring the filling of containers. Making a float water level sensor with your own hands is not difficult, and it does not require any special knowledge in the field of electrical engineering.

Scheme for controlling water pumping by a drainage pump

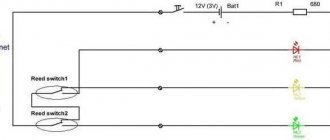

Based on the principle of vertical operation of the float mechanism, it is possible to propose a sensor connection diagram for switching the drain pump start relay with an additional 12 volt power supply.

It is worth noting that reed switches are not capable of handling high currents and cannot turn the pump on or off directly. Therefore, they are used in low voltage circuits to switch high-power relays to start or stop a pump. When the level is high, liquid is pumped out until the minimum set level is reached. The operating principle is as follows:

- When the liquid in the container rises to the upper level, the float with a magnet closes the upper reed switch SV 1, and current begins to flow to the relay coil P1. The contacts close in parallel with the connected reed switch, which puts the relay into a self-capturing state. This function does not allow the coil supply voltage to be switched off when the reed switch SV 1 is opened. This is achieved by connecting the relay load and its coil in one circuit.

- The power coil of relay P2 in the electric pump power circuit is switched on and liquid pumping begins.

- When the liquid level decreases, the float with a magnet reaches the lower reed switch SV 2, closing its contacts. A positive voltage potential begins to be supplied to the relay coil P1 from the other side as well. This leads to the removal of the self-capture function and the relay being turned off, which switches off the power coil P2, which provides power to the electric pump.

- By swapping the reed switches SV 1 and SV 2, the sensor will turn off the pump when the container is filled to the set level and turn it on when the liquid level drops.

Scheme of water supply for a house with a storage tank

The presented scheme can be easily integrated into existing piping, both in water supply with one central pipeline and with several. Its compactness is due to the use of free space above the tank, in which the pumping station is suspended on brackets.

Picture 1.

Figure 1 shows a water supply diagram for a private house with two central pipelines consisting of:

- 1 - tank 500 liters;

- 2 - pump;

- 3 — receiver (membrane tank);

- 4 - pressure switch;

- 5 — bronze five-point adapter;

- 6, 17 — pressure gauge;

- 7 — hose with reinforcing braid;

- 8 - check valve;

- 9 — float valve;

- 10 - American with external thread;

- 11 — American with internal thread;

- 12 - bronze transition from the container to the external thread;

- 13, 14 — MRN (male thread coupling);

- 15 — МРВ (internal thread coupling);

- 16 - bronze transition from external thread to internal thread;

- 18 — flow meter;

- 19 — mesh filter;

- 20 - 26 shut-off valves.

The suction discharge and distribution line is made of polypropylene pipeline and transitions with diameters of 32 mm (suction) and 20 mm.

Inexpensive industrial devices

There are also inexpensive models of liquid level control sensors, which can be purchased in stores for about 2 thousand rubles

Various modifications of ARS

Such float sensors are usually used in reservoirs. The measuring head in devices of this type is small, which makes the device compact. The load capacity, according to the operating instructions, can reach 1 ampere. The wire entry into the devices is sealed. The body is made of plastic. The operating differential is 45 degrees. The maximum pressure for correct operation of devices is 3 bar. The cost is about 2 thousand rubles, depending on the modification.

“Crystal” container filling control devices

These float type sensors can be used in harsh environments. Very compact. The measuring head is 2.3 centimeters in diameter. The maximum pressure for correct operation reaches 3.3 bar. The wire input is made in the form of a plastic seal. The devices are equipped with a spark protection barrier. Can work in hot environments. The price is slightly higher than 2 thousand rubles, depending on the modification.

Burkle devices

These devices are designed for contaminated environments, but can also be used in clean ponds and clean water tanks. The maximum pressure for correct operation is 4.1 bar. The maximum possible load is 1A. It is possible to work in environments heated to 170 degrees, in liquids with a density of up to 3 kg per square meter. cm. The average price of the device is 2,200 rubles and depends on minor modifications made by the manufacturer.

Fine Tek and Wilo sensors

These float type devices can be used in harsh environments. They are used for drainage purposes and can also be installed in wells. The sensors can withstand loads up to 2 amperes. The measuring heads are compact and measure 2.5 cm. The wire inputs are made in a specialized seal. The cases are made of heat-resistant plastic. The devices are equipped with fuel probes, which allows their use in flammable environments. The price ranges from 2 thousand to 2500 rubles and also depends on the modification.

Wilo float-type devices are the cheapest, but are not functionally designed for aggressive environments and can only be used in clean water. The sensors have small measuring heads and are compact in appearance. The maximum temperature of use is 140 degrees. The operating differential is only 30 degrees. The maximum operating pressure does not exceed 2 bar. The price of such sensors fluctuates around 1900 rubles.

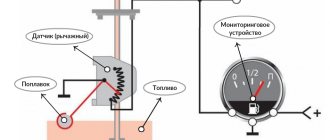

Design and principle of operation

The design of measuring devices of this type is determined by the following parameters:

- Functionality, depending on this device, is usually divided into alarms and level meters. The former monitor a specific tank filling point (minimum or maximum), while the latter continuously monitor the level.

- The operating principle can be based on: hydrostatics, electrical conductivity, magnetism, optics, acoustics, etc. Actually, this is the main parameter that determines the scope of application.

- Measuring method (contact or non-contact).

In addition, the design features are determined by the nature of the technological environment. It is one thing to measure the height of drinking water in a tank, another to check the filling of industrial wastewater tanks. In the latter case, appropriate protection is necessary.

What is well automation?

The automation unit for submersible or surface pumps is a modern electronics unit that includes a hydraulic accumulator, modules and a pressure gauge. All of them guarantee the correct operation of the highway.

Automation functions for water pumps:

- Control. All processes are carried out automatically, without control or supervision.

- Protection against water hammer. A water reserve is created in the main line in case of equipment malfunction or breakdown.

- Electronic devices are triggered in the absence of a liquid medium and turn off the electric current.

Automation for a water supply pump without a hydraulic accumulator helps prevent equipment breakdown and premature failure.

Automation device for a well.

Installation of a surface electric pump

To install a surface electric pump and external stations, it is necessary to make and equip a well. In private and country houses, on summer cottages, it is recommended to make a caisson. It can be metal, plastic, concrete. Such designs differ in shape - round, square or rectangular.

Plastic caissons are considered economical options. They are light in weight and easy to set up and install. But groundwater can lift the material outward, causing the structure to collapse. For a country house, you can buy concrete caissons, which are made of individual rings. This material allows water to pass through, so there will be moisture inside the structure.

The best option is to use metal, but it is expensive and requires costs for arrangement and installation. Inside the caisson there is water intake equipment, a hydraulic accumulator, and a pump. In surface pumps, the intake depth is no more than 9 m. To connect surface equipment, a deep and large hole is needed.

Installation diagram of a surface electric pump.

The suction pipe can increase the level of water pressure in the system and protect the components. It is lowered 1 m. After installation, connections are made, the functionality of the equipment is checked and errors are eliminated.

Pumping equipment control options

The following types of devices are used to control a submersible pump:

- control panel consisting of a block of necessary mechanisms;

- press control;

- automatic control device that maintains a certain pressure in the water supply system.

The control panel is a fairly simple unit that allows you to protect the pumping product from voltage surges and short circuits. Automatic operating mode can be obtained by connecting the control unit to the pressure and liquid level switch. In some cases, the control panel is connected to a float sensor. The price of such a control unit is low, but its effectiveness without the use of pump protection against dry operation and a pressure switch is questionable.

Advice: for self-installation, it is better to use a unit with a built-in system.

The control unit in the form of a press control has built-in passive protection against dry operation, as well as equipment for automated pump operation. To control the system, it is necessary to monitor a number of parameters, namely fluid pressure and flow level. For example, if the water flow exceeds 50 liters per minute, then the pumping equipment under press control operates without stopping. The machine operates and turns off the pump if the water flow decreases and the pressure in the system increases. If the fluid flow is less than 50 liters per minute, then the pumping product starts when the pressure in the system drops to 1.5 bar. This operation of the machine is especially important during sudden pressure surges, when it is necessary to reduce the number of starts and stops of the pump at a minimum flow rate.

An automatic control device that allows you to maintain constant pressure in the system must be used where any pressure surges are extremely undesirable.

Attention: if the pressure readings are constantly overestimated, then the energy consumption will increase, and the efficiency of the pump, on the contrary, will decrease.

Preparatory work

A polymer mesh and a check valve are attached to the end of the pipe

Before implementing one of the connection schemes, appropriate preparation of the area is necessary. To achieve this, the following work is carried out:

- Digging trenches to lay a pipeline below the freezing point of the soil. Typically a slight slope is made towards the source to allow the equipment to operate more efficiently.

- After the preparation of the trench is completed, a polyethylene pipe with a diameter of 3.2 cm is laid from the well or well and connected to the pumping equipment. A polymer mesh and a check valve are attached to the end of the pipe. If you do the installation yourself, then in order to do everything correctly, it is better to buy a pipe with a valve and filter mesh already installed.

Advice: if the pipeline is installed above the freezing point, then it is necessary to insulate it. An electric heating cable laid nearby will help to additionally heat the pipes.