Pyrometallurgical methods for obtaining zinc

Historically, the first method was pyrometallurgical.

The technology of the method and the hardware design of the process are associated with the peculiarities of the recovery of zinc from oxide. The reduction of zinc oxide to metal by carbon and CO occurs at a temperature of 1,000–1,100 °C, and the boiling point of the resulting zinc is 906 °C. Recovery reactions

ZnO + C ⇄ Zng + CO

ZnO + CO ⇄ Zng + CO2

are accompanied by the release of gaseous zinc and its sublimation (distillation). The waste rock components remain solid. By condensation of pores, liquid metallic zinc can be obtained.

The advantages of the pyrometallurgical zinc production scheme are its low-stage nature, relatively high direct extraction of zinc into the metal (93%), the use of high-performance continuous equipment and the ability to process low-quality raw materials with a high content of iron, arsenic, antimony and silica.

The disadvantages of the pyrometallurgical scheme are the high consumption of coke (up to 25% of the mass of the sinter), high energy consumption when using electric furnaces, low complexity of the use of raw materials and the production of low-grade zinc that requires refining.

Currently, in world practice, no more than 15% of zinc is obtained using the pyrometallurgical method. This technology is usually used for processing poor zinc concentrates with a high content of impurities of iron, arsenic, antimony, silica and with a low content of rare metals (cadmium, indium, thallium and others), as well as with a small production volume and when there is a need for lower grade zinc.

Zinc in medicine

Biological role and functions of zinc in the body

According to scientific research, the adult body contains zinc in the amount of:

- for women - 1.5 grams

- for men - 2.5-3 grams

Percentage of zinc in the body:

- in the skin - 20%

- in the musculoskeletal system - 60%

The main function of the element for the human body is the formation of carbonic anhydrase in red blood cells to maintain acid-base balance. This protein ensures the conversion of carbon dioxide and its return to the lungs for subsequent exhalation. Zinc, being part of 400 digestive enzymes, affects the complete absorption of microelements from food.

In addition to its main properties, zinc performs the following functions:

- Affects the synthesis of hormones. Zinc influences: the activity of triple pituitary hormones; lipid and cholesterol metabolism; action of insulin in the blood.

- There is evidence of the participation of the metal in hematopoiesis and the formation of new cells. These are important functions during growth and for tissue regeneration.

- This microelement is especially important for men, as it actively promotes the production of testosterone. Zinc stimulates the production of seminal fluid and has a positive effect on prostate health.

- It is an antioxidant, neutralizes the effects of toxins and free radicals, preventing the development of cancer.

- Zinc controls the reproduction of DNA and RNA.

- Participates in collagen synthesis. This fibrillar protein forms the basis of connective tissue: joints, tendons, skin, bones, cartilage. Provides their strength and elasticity.

- Zinc “calms” the nervous system, improves mental activity, and has a positive effect on sleep.

- Zinc is the key to immunity. Participates in the metabolism of vitamins A, C, E, helps in the fight against allergies.

Foods rich in zinc

Zinc from food and vitamins is absorbed in the upper intestine through protein compounds from gastric juice. This microelement must be included in the diet of men, pregnant and lactating women and children during the period of their active growth.

TOP 10 food products by zinc content in mcg per 100 grams:

| 1. | Wheat germ | 17.000 |

| 2. | Sesame seeds | 7.800 |

| 3. | Oatmeal | 6.200 |

| 4. | Egg yolk | 5.600 |

| 5. | Beef liver | 5.000 |

| 6. | Peanut | 4.800 |

| 7. | Peas | 2.440 |

| 8. | Rabbit meat | 2.300 |

| 9. | Whole grain wheat bread | 2.130 |

| 10. | Buckwheat | 2.000 |

Daily intake of zinc

With proper nutrition, hypozincosis (zinc deficiency) is not dangerous for humans. Only if problems arise with the absorption of zinc salts from the intestine and its removal from the body, metabolic disorders may occur.

Zinc deficiency often occurs in children during active growth and in breastfed infants. Milk, unfortunately, contains a small amount of the element necessary for development.

In patients with diabetes, there is an increased excretion of zinc in the urine and, accordingly, lower levels of zinc in the body.

To increase the level of zinc in the body, it is recommended not only to add foods rich in this element to the diet, but also to take zinc-containing medications.

Recommended daily doses of zinc depending on gender and age:

- Newborns - 2 mg

- Babies from 6 months. up to 5 years - 3 mg

- Delhi up to 8 years - 5 mg

- Adolescents 8-14 years old - 8 mg

- Men - 15 mg

- Women - 10 mg

- Pregnant women - 15 mg

- Nursing mothers - up to 20 mg

Zinc is an essential nutrient with antioxidant and anti-inflammatory properties that is involved in a variety of biological processes in the human body.

Hydrometallurgical methods for obtaining zinc

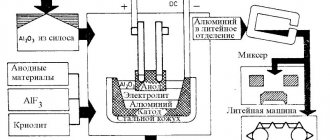

Currently, much attention is paid to a more complete use of the components of zinc-containing raw materials, the introduction of dump-free technology, and the production of high-grade zinc. To solve these problems in the production of zinc, a hydrometallurgical method is used for processing zinc concentrates according to a technological scheme.

The hydrometallurgical method is based on the leaching of zinc oxide with dilute sulfuric acid from a pre-burnt concentrate (cinder):

ZnO + H2SO4 = ZnSO4 + H2O

Zinc is separated from solution by electrolytic reduction at the cathode. At this time, sulfuric acid is regenerated at the anode, which makes it possible to use the spent electrolyte as a solvent when leaching cinder.

Since many accompanying impurity elements (copper, cadmium, nickel, cobalt and others) pass into the solution during leaching, the solution is thoroughly cleaned before electrolysis. The purer the solution supplied for electrolysis, the higher quality commercial zinc is obtained.

During electrolysis the following reaction occurs:

ZnSO4 + H2O = Zn + H2SO4 + 0.5O2

Despite the multi-stage nature, the hydrometallurgical method has many advantages: high complexity of the use of raw materials, production of high-grade zinc that does not require refining, high overall recovery of zinc and other valuable components into the corresponding products, elimination or significant reduction in coke consumption. In world practice, up to 85% of zinc-containing raw materials are currently processed using this method.

Metal production

Necessary equipment

Zinc does not exist in its pure form. It is extracted from other natural rocks. These include polymetallic sulfide ores and some minerals: sphalerite, smithsonite, zincite, smithsonite, hemimorphite, cleiophane, calamine, wurtzite, willemite and others. The most common mineral is sphalerite.

If zinc is found in mixed ores, then its companions most often are thallium, cadmium, germanium, gallium, and indium.

Zinc is processed in industrial plants. Each plant has its own technological production features. Therefore, the production line and equipment may vary. The following equipment can be observed at zinc plants:

- Vertical mechanized rotors.

- Shaft and arc electric furnaces.

- Electrolytic rotors.

- Transporters.

- Kilns.

- Electrolysis baths or entire electrolysis complexes.

Calculation of raw materials

Pure zinc is obtained by processing sulfide, zinc and polymetallic ores. The amount of processed zinc-containing raw materials depends on the ability and capacity of the plant. It is individual for everyone. Therefore, an accurate calculation of the required raw materials must be made within the framework of a specific production.

Next, we will consider technologies, processes and methods for the production of zinc, as well as products made from it.

Methods of obtaining

To isolate zinc, the ore is enriched by flotation or gravity. The result of such enrichment is the production of zinc concentrate. In addition, by-products are copper, pyrite and lead concentrates.

The separated zinc concentrate is fired in a furnace. As a result, zinc oxide is formed. Here the production process is divided into two stages. The resulting sulfur dioxide is used for processing sulfurous acid, and zinc goes to the next stage of processing.

Pure zinc can be acquired in the following ways:

- The first method: pyrometallurgical (distillation) . The essence of this production method is as follows: the resulting concentrate is roasted, sintered and reduced with coal or coke. The resulting metal vapors are condensed and poured into molds.

- Second method: electrolytic (hydrometallurgical) . The essence of the second method is that after firing the concentrate is treated with sulfuric acid. The resulting solution is purified from foreign impurities and subjected to the electrolysis process.

You will learn about the pyrometallurgical method of obtaining zinc from the video below:

Stages

Zinc goes through the following production stages:

- Preparation of raw materials for processing.

- Refining of prepared raw materials.

- Preparation for the leaching stage.

- Carrying out leaching.

- Cleaning the solution from impurities.

- Electrolytic deposition.

- Melting cathode zinc.

As an example, let us consider in more detail the sequence of zinc production at a Russian enterprise - the Chelyabinsk Zinc Plant.

- Receiving raw materials. The company is supplied with raw materials (zinc concentrate) in railway cars. Raw materials from various suppliers are mixed (to average the total impurity values) and sent along a conveyor for firing.

- Concentrate roasting. The plant uses five furnaces for heat treatment. At very high temperatures, the concentrate oxidizes (880-950ºС). The result is two products: sulfur dioxide and zinc cinder. The sulfur dioxide is purified and sent to process sulfurous acid. Exothermic reactions take place in the furnace, with the help of which the generated heat is stored and remains for melting.

- Obtaining sulfur. The sulfuric acid obtained during the roasting process is utilized.

- Leaching. Zinc is extracted into a special solution. However, not only zinc, but also various impurities get into the liquid. When the required concentration of the solution is obtained, the mixture is sent for purification. However, it is not possible to isolate all the zinc. Some part still remains in solution. Therefore, the solution is subjected to additional filtration. After this, the zinc is sent to the Waelz workshop. These are ovens whose shape is similar to a cylinder. They carry out rotational movements. Two combustion products go through this stage: cinder and sulfur dioxide.

- Electrolysis of zinc. The procedure takes place in an electrolysis complex. Cleaning solutions is carried out using zinc dust. After cleaning, products are formed that are called cakes. The cake is subsequently used for cadmium production.

- Cake rolling. In order to maximize the yield of zinc from the cake, the said substance is mixed with coke breeze and heated to a high temperature (1200 C). The entire process takes place in a rotary tube furnace. The final products at this stage are Waelz oxide and cuprous clinker. The oxide is sublimated in the process, cooled and captured by special filters. Subsequently, the Waelz oxide is used for leaching, and the clinker is sent as raw material to copper plants.

- Hydrometallurgical process. Here the processing takes place in a sulfuric acid solution. The process is necessary to obtain several valuable elements: zinc sulfate solution, commercial zinc and lead cake, which includes indium alloys, lead and indium. Water from processing is treated with soda ash, filtered using a filter press and re-entered into the technological process.

- Foundry. The resulting zinc metal cathode is melted in induction furnaces.

- Bottling shop. Then the zinc is cast into blocks of 0.5-1.0 tons and ingots of 25 kg. The process is carried out using a centrifugal casting machine. The plant also has an installation for the production of zinc dust, which costs many times more than zinc itself.

Next, zinc producers in Russia and the world will be considered.