The POLIPLASTIC group is a modern production and sale of polyethylene pipes throughout Russia, as well as in Belarus and Kazakhstan. The Group's enterprises are equipped with new equipment, its own research and development center allows for continuous improvement of product quality, and a strict control system ensures that products comply with standards. Our clients include government organizations, commercial enterprises and private customers.

The Group's facilities produce polyethylene pipes for water and heat supply, gas supply, sewerage and drainage. The range also includes fittings, components and welding equipment. Products undergo voluntary certification and meet industrial and environmental safety requirements.

Modulus of elasticity of copper

All solids, both crystalline and amorphous, have the property of changing their shape under the influence of force applied to them.

In other words, they are subject to deformation. If a body returns to its original size and shape after the external force ceases its influence, then it is called elastic, and its deformation is considered elastic. For any body, there is a limit to the applied force, after which the deformation ceases to be elastic, the body does not return to its original shape and original dimensions, but remains in a deformed state or collapses. The theory of elastic deformations of bodies was created at the end of the 17th century by the British scientist R. Hooke and developed in the works of his compatriot Thomas Young.

Hooke's and Young's law and coefficient, which determine the degree of elasticity of bodies, were named in their honor, respectively. It is actively used in engineering during calculations of the strength of structures and products.

Young's modulus

Elastic modulus - what is it? Determination of elastic modulus for materials

The modulus of elasticity is a physical quantity that characterizes the elastic behavior of a material when an external force is applied to it in a specific direction. The elastic behavior of a material means its deformation in the elastic region.

History of research into the elasticity of materials

The physical theory of elastic bodies and their behavior under the action of external forces was examined and studied in detail by the 19th century English scientist Thomas Young.

However, the concept of elasticity itself was developed back in 1727 by the Swiss mathematician, physicist and philosopher Leonhard Euler, and the first experiments related to the modulus of elasticity were carried out in 1782, that is, 25 years before the work of Thomas Young, by the Venetian mathematician and philosopher Jacopo Ricatti.

The merit of Thomas Young lies in the fact that he gave the theory of elasticity a harmonious modern look, which was subsequently formalized in the form of a simple and then a generalized Hooke's law.

Physical nature of elasticity

Any body consists of atoms, between which forces of attraction and repulsion act. The balance of these forces determines the state and parameters of a substance under given conditions.

Atoms of a solid body, when insignificant external forces of tension or compression are applied to them, begin to shift, creating a force opposite in direction and equal in magnitude, which tends to return the atoms to their initial state.

In the process of such displacement of atoms, the energy of the entire system increases. Experiments show that for small deformations the energy is proportional to the square of the magnitude of these deformations.

This means that the force, being a derivative with respect to energy, turns out to be proportional to the first power of the magnitude of the deformation, that is, it depends linearly on it.

Answering the question of what is the modulus of elasticity, we can say that it is a coefficient of proportionality between the force acting on an atom and the deformation that this force causes. The dimension of Young's modulus coincides with the dimension of pressure (Pascal).

Modern polyethylene pipes from the POLIPLASTIC Group

Pipelines made of polyethylene pipes are popular not only in Russia, they have been widely used in Europe since the 80s of the last century, which indicates the reliability and prospects of this type of product. On the basis of the POLIPLASTIC Group of Companies’ own research center, developments are underway aimed at creating polymer compositions that make it possible to impart special consumer properties to products and improve the quality of products.

You can buy polyethylene pipes in Moscow and other regions in any quantities in the shortest possible time. Warehouse stocks of finished products and high production capacities of factories allow us to work with large customers without delays. Our coverage area is not only Russia. Some of the enterprises are located in the countries of the Customs Union, thanks to which the products are presented in Kazakhstan and Belarus.

The price of polyethylene pipes from the POLIPLASTIC Group is presented in price lists for each type of product. You can find out more details and get information about the terms and conditions of purchase from our specialists.

Physical meaning of Young's modulus

During a forced change in the shape of objects, forces are generated inside them that resist such a change and strive to restore the original shape and size of elastic bodies.

If the body does not resist changing shape and remains in a deformed form after the end of the impact, then such a body is called absolutely inelastic, or plastic. A typical example of a plastic body is a block of plasticine.

Types of deformation

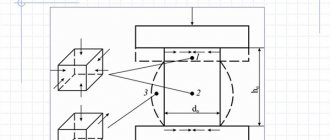

R. Hooke studied the elongation of rods made of various substances under the influence of weights suspended from the free end. The quantitative expression of the degree of change in shape is considered relative elongation, equal to the ratio of absolute elongation and original length.

As a result of a series of experiments, it was found that absolute elongation is proportional with the elasticity coefficient to the original length of the rod and the deforming force F and inversely proportional to the cross-sectional area of this rod S:

Δl = α * (lF) / S

The inverse of α is called Young’s modulus:

1/α = E

Relative deformation:

ε = (Δl) / l = α * (F/S)

The ratio of tensile force F to S is called elastic stress σ:

ε=α σ

Hooke's law, written using Young's modulus, looks like this:

σ = ε/α = E ε

Now we can formulate the physical meaning of Young’s modulus: it corresponds to the stress caused by stretching a rod-shaped sample twice, provided its integrity is maintained.

In reality, the vast majority of samples fail before they have stretched to twice their original length. The value of E is calculated using the indirect method for small deformations.

Stiffness coefficient for elastic deformation of the rod along its axis k = (ES) / l

Young's modulus determines the magnitude of the potential energy of bodies or media subjected to elastic deformation.

Basic information

Young's modulus (also called the longitudinal modulus of elasticity and the modulus of elasticity of the first kind) is an important mechanical characteristic of a substance. It is a measure of resistance to longitudinal deformation and determines the degree of rigidity. It is designated as E; measured in n/m 2 or in Pa.

This important coefficient is used when calculating the rigidity of workpieces, assemblies and structures, and in determining their resistance to longitudinal deformations. Substances used for the manufacture of industrial and building structures, as a rule, have very large E values. And therefore, in practice, E values for them are given in gigaPascals (10 12 Pa)

The value of E for rods can be calculated; for more complex structures it is measured during experiments.

Approximate values of E can be obtained from the graph constructed during tensile tests.

Tensile test schedule

E is the quotient of normal stress σ divided by relative elongation ε.

Hooke's law can also be formulated using Young's modulus.

Modulus of elasticity of various materials

Elastic moduli for different materials have completely different values, which depend on:

- the nature of the substances that form the composition of the material;

- mono- or multicomponent composition (pure substance, alloy, etc.);

- structures (metallic or other type of crystal lattice, molecular structure, etc.);

- density of the material (distribution of particles in its volume);

- the processing to which it was subjected (firing, etching, pressing, etc.).

For example, in the reference data you can find that the elastic modulus for aluminum is in the range from 61.8 to 73.6 GPa. Apparently, this depends on the state of the metal and the type of processing, because for annealed aluminum the Young’s modulus is 68.5 GPa.

Its significance for bronze materials depends not only on the processing, but also on the chemical composition:

- bronze – 10.4 GPa;

- aluminum bronze during casting – 10.3 GPa;

- rolled phosphor bronze – 11.3 GPa.

Young's modulus of brass is much lower - 78.5-98.1. Rolled brass has the maximum value.

Copper itself in its pure form is characterized by a resistance to external influences that is much greater than its alloys - 128.7 GPa. Processing it also reduces the indicator, including rolling:

- cast – 82 GPa;

- rolled – 108 GPa;

- deformed – 112 GPa;

- cold drawn – 127 GPa.

Titanium (108 GPa), which is considered one of the strongest metals, has a value close to copper. But heavy but brittle lead shows only 15.7-16.2 GPa, which is comparable to the strength of wood.

For iron, the stress-to-strain ratio also depends on the method of its processing: cast - 100-130 or forged - 196.2-215.8 GPa.

Cast iron is known for its brittleness and has a stress-to-strain ratio of 73.6 to 150 GPa, which is consistent with its type. Whereas for steel, the elastic modulus can reach 235 GPa.

The values of strength parameters are also influenced by the shape of the products. For example, for a steel rope, calculations are carried out, which take into account:

Interestingly, this figure for a rope will be significantly lower than for a wire of the same diameter.

It is worth noting the strength and non-metallic materials. For example, among the Young's moduli of wood, pine has the lowest - 8.8 GPa, but the group of hardwoods, which are united under the name "iron wood", has the highest - 32.5 GPa, oak and beech have equal indicators - 16.3 GPa.

Among building materials, the resistance to external forces of seemingly durable granite is only 35-50 GPa, while even glass is 78 GPa. Concrete is inferior to glass - up to 40 GPa, limestone and marble, with values of 35 and 50 GPa, respectively.

Flexible materials such as rubber can withstand axial loads ranging from 0.0015 to 0.0079 GPa.

Saint-Venant's formula for solid sections

For parts with high torsional inertia, the torsion is a pure or dominant Saint-Venant type. In addition, since the torsional modulus does not need to depend on the chosen axis system, it can be constructed as a function of algebraic invariants, which can be formed from the area and moments of the cross-sectional region of the part. In 1855, Saint-Venant proposed a formula that met this requirement and gave good results for most solid sections:

J = K 4 κ ( i and i z ) {displaystyle J = {frac {A^{4}}{kappa(I_{y}I_{z})}}}

Where the value κ {displaystyle kappa} is often taken to be between 35 and 40, the only limitation usually placed on the use of this formula is the convexity of the cross-section. This formula is based on the approximation of unity to an ellipse.

Elastic limit

According to the definition, the modulus of elasticity shows how much stress must be applied to a solid body so that its deformation is 100%. However, all solids have an elastic limit, which is equal to 1% deformation. This means that if an appropriate force is applied and the body is deformed by an amount less than 1%, then after the cessation of this force the body exactly restores its original shape and size. If too much force is applied, at which the deformation value exceeds 1%, after the cessation of the external force, the body will no longer restore its original dimensions. In the latter case, they speak of the existence of residual deformation, which is evidence of exceeding the elastic limit of a given material.

Index

- 1 Torsional modulus of elasticity of a circular section

- 2 Torsional modulus of elasticity of a rectangular section

- 3 Torsional modulus of elasticity of a triangular section

- 4 Torsional modulus of elasticity of an elliptical section

- 5 Torsional modulus of elasticity for any section

- 6 Torsional modulus of elasticity in thin-walled profiles 6.1 Open thin-walled section

- 6.2Single thin-walled closed section

- 6.3 Thin-walled composite closed profile

What is copper

Cuprum

One of the most common non-ferrous metals used in industry is copper, its Latin name is Cuprum, after the island of Cyprus, where it was mined by the Greeks many thousands of years ago. This is one of the seven metals that were known in ancient times; jewelry, dishes, money, and tools were made from it.

Historians even called the period (from the 4th to the 3rd millennium BC) the Copper Age. D.I. Mendeleev put this metal in 29th place in his table, after hydrogen, since copper does not displace it from an acidic environment. Copper is a non-ferrous metal that has unique physical, mechanical, and chemical properties.

The density of copper in kg m³ is one of the most important characteristics; it is used to determine the weight of the future product.

How is density determined?

The density of any substance is an indicator of the ratio of mass to total volume. The most common system for measuring density is kilogram per cubic meter. For copper this figure is 8.93 kg/m³. Since there are different grades of metal, which differ depending on the impurities of other substances, the overall density may vary. In this case, it is more appropriate to use another characteristic - specific gravity. In measuring systems, this indicator is expressed in different quantities:

Formula for determining the density of a substance

- SGS system - dyn/cm³;

- SI system - n/m³;

- MKSS system - kg/m³

In this case, the following formula can be used to convert values:

1 n/m³ = 1 dyne/cm³ = 0.102 kg/m³.

Specific gravity is an important indicator in the production of various materials containing copper, especially when it comes to its alloys. This is the ratio of the mass of copper to the total volume of the alloy.

You can consider how this indicator is used in practice using the example of calculating the weight of 25 copper sheets, 2000*1000 mm in size, 5 mm thick. First, let's determine the volume of the sheet - 5 mm * 2000 mm * 1000 mm = 10000000 mm3 or 10,000 cm³.

Specific gravity of copper 8.94 g/cm³

We calculate the weight of copper in one sheet - 10,000 * 8.94 = 89,400 g or 89.40 kg.

The mass of rolled copper in the total amount of material is 89.40 * 25 = 2,235 kg.

This calculation scheme is also used when processing scrap metal.

Basic properties

Smelting copper from ore

Copper, as a metal, is obtained by smelting ore; in nature it is difficult to find pure nuggets; mainly enrichment and extraction is carried out from:

- chalcocite ore, in which the copper content is about 80%, this type is often called copper luster;

- Bronite ore, here the metal content is up to 65%

- covellite ore - up to 64%.

In terms of its physical properties, copper is a red-colored metal; a pink tint may be present in the section; it is classified as a heavy metal because it has a high density.

A distinctive characteristic is electrical conductivity. Due to this, the metal is widely used in the manufacture of cables and electrical wires. In this indicator, copper is second only to silver; in addition, there are a number of other physical characteristics:

- hardness - on the Brindel scale equals 35 kgf/mm²;

- elasticity - 132000 MN/m²;

- linear thermal expansion - 0.00000017 units;

- relative elongation - 60%;

- melting point - 1083 ºС;

- boiling point - 2600 ºС;

- thermal conductivity coefficient - 335 kcal/m*h*deg.

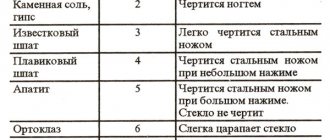

Allowable tensile stress in some materials

From life experience we know that different materials resist changes in shape in different ways. The strength characteristics of crystalline and other solids are determined by the forces of interatomic interaction. As interatomic distances increase, the forces that attract atoms to each other also increase. These forces reach a maximum at a certain amount of stress, equal to approximately one tenth of Young's modulus.

Tensile test

This value is called theoretical strength; when it is exceeded, the destruction of the material begins. In reality, destruction begins at lower values, since the structure of real samples is heterogeneous. This causes an uneven distribution of stresses, and destruction begins from those areas where the stresses are maximum.

Values of σrast in MPa:

| Materials | σrast | |

| Bor | 5700 | 0,083 |

| Graphite | 2390 | 0,023 |

| Sapphire | 1495 | 0,030 |

| Steel wire | 415 | 0,01 |

| Fiberglass | 350 | 0,034 |

| Structural steel | 60 | 0,003 |

| Nylon | 48 | 0,0025 |

These numbers are taken into account by designers when choosing the material for parts of a future product. Strength calculations are also carried out using them. For example, cables used for lifting and transport operations must have a tenfold safety margin. They are periodically checked by hanging a load ten times greater than the cable's rated load capacity.

The safety margins built into critical structures are also multiple.

Methods for determining and monitoring strength indicators of metals

The development of metallurgy and other related areas for the production of metal objects is due to the creation of weapons. At first they learned to smelt non-ferrous metals, but the strength of the products was relatively low. Only with the advent of iron and its alloys did the study of their properties begin.

The first swords were made quite heavy to give them hardness and strength. Warriors had to take them in both hands to control them.

Over time, new alloys appeared and production technologies were developed. Light sabers and swords came to replace heavy weapons. At the same time, tools were created.

With the increase in strength characteristics, tools and production methods were improved.

Types of loads

When using metals, different static and dynamic loads are applied. In the theory of strength, it is customary to define the following types of loads.

Compression - an acting force compresses an object, causing a decrease in length along the direction of application of the load. This deformation is felt by frames, supporting surfaces, racks and a number of other structures that can withstand a certain weight. Bridges and crossings, car and tractor frames, foundations and reinforcement - all these structural elements are under constant compression.

Tension - the load tends to lengthen the body in a certain direction. Lifting and transport machines and mechanisms experience similar loads when lifting and carrying loads.

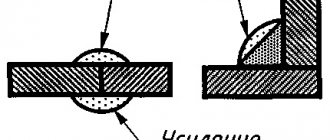

Shear and shear - such loading is observed in the case of forces directed along the same axis towards each other. Connecting elements (bolts, screws, rivets and other hardware) experience this type of load. The design of housings, metal frames, gearboxes and other components of mechanisms and machines necessarily contains connecting parts. The performance of devices depends on their strength.

Torsion - if a pair of forces acting on an object are located at a certain distance from each other, then a torque occurs. These forces tend to produce torsional deformation. Similar loads are observed in gearboxes; the shafts experience just such a load. It is most often inconsistent in meaning. Over time, the magnitude of the acting forces changes.

Bending – a load that changes the curvature of objects is considered bending. Bridges, crossbars, consoles, lifting and transport mechanisms and other parts experience similar loading.

In the middle of the 17th century, materials research began simultaneously in several countries. A variety of methods have been proposed for determining strength characteristics. The English researcher Robert Hooke (1660) formulated the main provisions of the law on the elongation of elastic bodies as a result of the application of a load (Hooke's law). The following concepts were also introduced:

- Stress σ, which in mechanics is measured in the form of a load applied to a certain area (kgf/cm², N/m², Pa).

- Elastic modulus E, which determines the ability of a solid body to deform under loading (applying force in a given direction). Units of measurement are also defined in kgf/cm² (N/m², Pa).

The formula according to Hooke's law is written as ε = σz/E, where:

- ε – relative elongation;

- σz – normal stress.

Demonstration of Hooke's law for elastic bodies:

From the above dependence, the value of E for a certain material is derived experimentally, E = σz/ε.

The modulus of elasticity is a constant value that characterizes the resistance of a body and its structural material under normal tensile or compressive load.

In the theory of strength, the concept of Young's modulus of elasticity is adopted. This English researcher gave a more specific description of the methods of changing strength indicators under normal loads.

The elastic modulus values for some materials are given in Table 1.

Table 1: Modulus of elasticity for metals and alloys

| Name of material | Elastic modulus value, 10¹² Pa |

| Aluminum | 65…72 |

| Duralumin | 69…76 |

| Iron, carbon content less than 0.08% | 165…186 |

| Brass | 88…99 |

| Copper (Cu, 99%) | 107…110 |

| Nickel | 200…210 |

| Tin | 32…38 |

| Lead | 14…19 |

| Silver | 78…84 |

| Gray cast iron | 110…130 |

| Steel | 190…210 |

| Glass | 65…72 |

| Titanium | 112…120 |

| Chromium | 300…310 |

What does the modulus of elasticity of concrete depend on?

The elastic properties of concrete depend on factors:

- quality and volume content of aggregates;

- material class;

- air temperature and intensity of radioactive radiation;

- environmental humidity;

- load exposure time;

- mixture hardening conditions;

- age of concrete;

- reinforcement

Fillers

Concrete is a conglomerate of two components - cement stone and aggregates. In a heterogeneous structure, a complex stress state arises. Stiffer particles absorb the bulk of the load, and areas with transverse tensile forces are formed around pores and voids.

Coarse aggregate, having a high Young's modulus, increases the elastic properties of concrete. Small dust particles, pores and voids reduce them.

Concrete class

The higher the class of the material, i.e. The greater its compressive strength and density, the better it resists deforming loads. Concrete B60 has the highest modulus of elasticity - 39.5 MPa * 10-3, the minimum indicator for a composite of class B10 is 19 MPa * 10-3.

Temperature and radiation

An increase in ambient temperature and solar radiation intensity lead to a decrease in elastic properties and an increase in deformations. This is due to an increase in the internal energy of concrete, a change in the trajectories of movement of molecules in a solid, linear expansion of the material, and, as a consequence, increased plasticity.

The difference is not taken into account for fluctuations within 20°C. Large temperature changes significantly affect the deformation of concrete structures. Table SP 63.13330.2012 shows the values of elastic moduli depending on temperature.

Humidity

Fluctuations in air humidity lead to changes in the elastic properties of the material. The creep coefficient φ is used in the calculations. The higher the content of water vapor in the environment, the lower the indicator and, accordingly, the less plastic deformation of the structure.

Load application time

The modulus of elasticity depends on the duration of the load. When the structure is instantly loaded, the deformations are proportional to the magnitude of the external forces. Under long-term stresses, the value of E decreases, the changes develop according to a nonlinear dependence and are summed up from elastic and plastic deformations.

Strengthening conditions

During testing, it was noticed that naturally hardening concrete has a higher modulus of elasticity than when the material is processed by steaming at atmospheric pressure or in autoclave units.

This is explained by the fact that a change in the conditions for developing strength leads to the formation of a larger number of pores and voids due to uneven temperature expansion of the volume and deterioration in the quality of hydration of cement grains. Such concrete has lower elastic properties compared to concrete hardened under normal conditions.

Age of concrete

Freshly laid concrete gains strength within 28 days. But even after this time, the material under load has both elastic and plastic properties. It reaches its greatest hardness after about 200-250 days. The E indicator at this age is maximum, corresponding to brand strength.

Reinforcement of structures

To absorb tensile and compressive forces, frames or meshes from reinforcement of classes AI, AIII, A500C, At800, as well as from composites or wood are placed in reinforced concrete.

The use of reinforcement increases the elasticity, compressive and tensile strength of the structure during bending, and prevents the formation of shrinkage and deformation cracks.

Safety factor

To quantify the safety factor during design, a safety factor is used. It characterizes the product’s ability to withstand overloads above rated loads. For household products it is small, but for critical components and parts that, if destroyed, can pose a danger to human life and health, it is made multiple times.

Margin of safety

Accurate calculation of strength characteristics makes it possible to create a sufficient safety margin and at the same time not to overweight the structure, worsening its performance characteristics. For such calculations, complex mathematical methods and sophisticated software are used. The most important designs are calculated on supercomputers.

Characteristics of polyethylene pipes

The maximum pressure that a HDPE pipe can withstand during its service life is calculated by the formula:

MOP=

2MRS

(SDR - 1) k

, Where

MRS – minimum long-term strength specified in the material labeling;

SDR is the ratio of the outer diameter of the pipe to the wall thickness. The indicator has an inverse relationship with wall thickness, therefore, the lower its value, the thicker the pipe will be. With a lower SDR, the resistance of products to mechanical stress will be higher, but with a constant outer diameter, the throughput will be reduced.

Young's modulus of elasticity and shear, Poisson's ratio values (Table)

Elastic properties of bodies

Below are reference tables for commonly used constants; if two of them are known, then this is quite sufficient to determine the elastic properties of a homogeneous isotropic solid.

Young's modulus or modulus of longitudinal elasticity in dyn/cm2.

Shear modulus or torsional modulus G in dyn/cm2.

Compressive modulus or bulk modulus K in dynes/cm2.

Compressibility volume k=1/K/.

Poisson's ratio µ is equal to the ratio of transverse relative compression to longitudinal relative tension.

For a homogeneous isotropic solid material, the following relationships between these constants hold:

G = E / 2(1 + μ) - (α)

μ = (E / 2G) - 1 - (b)

K = E / 3(1 - 2μ) - (c)

Poisson's ratio has a positive sign and its value is usually between 0.25 and 0.5, but in some cases it can go beyond these limits. The degree of agreement between the observed values of µ and those calculated using formula (b) is an indicator of the isotropy of the material.

Tables of Young's Modulus of Elasticity, Shear Modulus and Poisson's Ratio

Values calculated from relations (a), (b), (c) are given in italics.

| Material at 18°C | Young's modulus E, 1011 dynes/cm2. | Shear modulus G, 1011 dynes/cm2. | Poisson's ratio µ | Modulus of bulk elasticity K, 1011 dynes/cm2. |

| Aluminum | 7,05 | 2,62 | 0,345 | 7,58 |

| Bismuth | 3,19 | 1,20 | 0,330 | 3,13 |

| Iron | 21,2 | 8,2 | 0,29 | 16,9 |

| Gold | 7,8 | 2,7 | 0,44 | 21,7 |

| Cadmium | 4,99 | 1,92 | 0,300 | 4,16 |

| Copper | 12,98 | 4,833 | 0,343 | 13,76 |

| Nickel | 20,4 | 7,9 | 0,280 | 16,1 |

| Platinum | 16,8 | 6,1 | 0,377 | 22,8 |

| Lead | 1,62 | 0,562 | 0,441 | 4,6 |

| Silver | 8,27 | 3,03 | 0,367 | 10,4 |

| Titanium | 11,6 | 4,38 | 0,32 | 10,7 |

| Zinc | 9,0 | 3,6 | 0,25 | 6,0 |

| Steel (1% C) 1) | 21,0 | 8,10 | 0,293 | 16,88 |

| (soft) | 21,0 | 8,12 | 0,291 | 16,78 |

| Constantan 2) | 16,3 | 6,11 | 0,327 | 15,7 |

| Manganin | 12,4 | 4,65 | 0,334 | 12,4 |

| 1) For steel containing about 1% C, elastic constants are known to change during heat treatment. 2) 60% Cu, 40% Ni. |

The experimental results given below are for common laboratory materials, mainly wires.

| Substance | Young's modulus E, 1011 dynes/cm2. | Shear modulus G, 1011 dynes/cm2. | Poisson's ratio µ | Modulus of bulk elasticity K, 1011 dynes/cm2. |

| Bronze (66% Cu) | -9,7-10,2 | 3,3-3,7 | 0,34-0,40 | 11,2 |

| Copper | 10,5-13,0 | 3,5-4,9 | 0,34 | 13,8 |

| Nickel silver1) | 11,6 | 4,3-4,7 | 0,37 | — |

| Glass | 5,1-7,1 | 3,1 | 0,17-0,32 | 3,75 |

| Glass yen crowns | 6,5-7,8 | 2,6-3,2 | 0,20-0,27 | 4,0-5,9 |

| Jena flint glass | 5,0-6,0 | 2,0-2,5 | 0,22-0,26 | 3,6-3,8 |

| Welding iron | 19-20 | 7,7-8,3 | 0,29 | 16,9 |

| Cast iron | 10-13 | 3,5-5,3 | 0,23-0,31 | 9,6 |

| Magnesium | 4,25 | 1,63 | 0,30 | — |

| Phosphor bronze2) | 12,0 | 4,36 | 0,38 | — |

| Platinoid3) | 13,6 | 3,6 | 0,37 | — |

| Quartz threads (floating) | 7,3 | 3,1 | 0,17 | 3,7 |

| Soft vulcanized rubber | 0,00015-0,0005 | 0,00005-0,00015 | 0,46-0,49 | — |

| Steel | 20-21 | 7,9-8,9 | 0,25-0,33 | 16,8 |

| Zinc | 8,7 | 3,8 | 0,21 | — |

| 1) 60% Cu, 15% Ni, 25% Zn 2) 92.5% Cu, 7% Sn, 0.5% P 3) Nickel silver with a small amount of tungsten. |

| Substance | Young's modulus E, 1011 dynes/cm2. | Substance | Young's modulus E, 1011 dynes/cm2. |

| Zinc (pure) | 9,0 | Oak | 1,3 |

| Iridium | 52,0 | Pine | 0,9 |

| Rhodium | 29,0 | Red tree | 0,88 |

| Tantalum | 18,6 | Zirconium | 7,4 |

| Invar | 17,6 | Titanium | 10,5-11,0 |

| Alloy 90% Pt, 10% Ir | 21,0 | Calcium | 2,0-2,5 |

| Duralumin | 7,1 | Lead | 0,7-1,6 |

| Silk threads1 | 0,65 | Teak | 1,66 |

| Web2 | 0,3 | Silver | 7,1-8,3 |

| Catgut | 0,32 | Plastics: | |

| Ice (-20C) | 0,28 | Thermoplastic | 0,14-0,28 |

| Quartz | 7,3 | Thermoset | 0,35-1,1 |

| Marble | 3,0-4,0 | Tungsten | 41,1 |

| 1) Reduces rapidly with increasing load 2) Detects noticeable elastic fatigue |

| Temperature coefficient (at 150C) Et=E11 (1-ɑ (t-15)), Gt=G11 (1-ɑ (t-15)) | Compressibility k, bar-1 (at 7-110C) | |||

| ɑ, for E | ɑ, for G | |||

| Aluminum | 4,8*10-4 | 5,2*10-4 | Aluminum | 1,36*10-6 |

| Brass | 3,7*10-4 | 4,6*10-4 | Copper | 0,73*10-6 |

| Gold | 4,8*10-4 | 3,3*10-4 | Gold | 0,61*10-6 |

| Iron | 2,3*10-4 | 2,8*10-4 | Lead | 2,1*10-6 |

| Steel | 2,4*10-4 | 2,6*10-4 | Magnesium | 2,8*10-6 |

| Platinum | 0,98*10-4 | 1,0*10-4 | Platinum | 0,36*10-6 |

| Silver | 7,5*10-4 | 4,5*10-4 | Flint glass | 3,0*10-6 |

| Tin | — | 5,9*10-4 | German glass | 2,57*10-6 |

| Copper | 3,0*10-4 | 3,1*10-4 | Steel | 0,59*10-6 |

| Nickel silver | — | 6,5*10-4 | ||

| Phosphor bronze | — | 3,0*10-4 | ||

| Quartz threads | -1,5*10-4 | -1,1*10-4 |

Elastic modulus of metals table

Modulus of elasticity for steel as well as for other materials

Before using any material in construction work, you should familiarize yourself with its physical characteristics in order to know how to handle it, what mechanical stress will be acceptable for it, and so on.

One of the important characteristics that is often paid attention to is the elastic modulus.

Below we will consider the concept itself, as well as this value in relation to one of the most popular materials in construction and repair work - steel. These indicators for other materials will also be considered, for the sake of example.

Modulus of elasticity - what is it?

The modulus of elasticity of a material is a set of physical quantities that characterize the ability of a solid body to elastically deform under conditions of application of force to it. It is expressed by the letter E. So it will be mentioned in all the tables that will go further in the article.

It is impossible to say that there is only one way to determine the value of elasticity. Different approaches to the study of this quantity have led to the fact that there are several different approaches at once. Below are three main ways to calculate the indicators of this characteristic for different materials:

- Young's modulus (E) describes the resistance of a material to any tension or compression during elastic deformation. Young's version is determined by the ratio of stress to compressive strain. Usually it is simply called the modulus of elasticity.

- Shear modulus (G), also called stiffness modulus. This method reveals the ability of a material to resist any change in shape, but while maintaining its norm. Shear modulus is expressed as the ratio of shear stress to shear strain, which is defined as the change in the right angle between existing planes subjected to shear stresses. The shear modulus, by the way, is one of the components of such a phenomenon as viscosity.

- Bulk modulus (K), also called bulk modulus. This option denotes the ability of an object made of any material to change its volume if it is exposed to a comprehensive normal stress, which is the same in all its directions. This option is expressed by the ratio of the magnitude of volumetric stress to the magnitude of relative volumetric compression.

- There are also other indicators of elasticity, which are measured in other quantities and expressed in other ratios. Other very well-known and popular options for elasticity indicators are the Lamé parameters or Poisson's ratio.

General concept

The modulus of elasticity (also known as Young's modulus) is one of the indicators of the mechanical properties of a material, which characterizes its resistance to tensile deformation. In other words, its value shows the ductility of the material. The greater the elastic modulus, the less any rod will stretch, all other things being equal (load magnitude, cross-sectional area, etc.).

In the theory of elasticity, Young's modulus is denoted by the letter E. It is an integral part of Hooke's law (the law on the deformation of elastic bodies). Connects the stress arising in the material and its deformation.

According to the international standard system of units, it is measured in MPa. But in practice, engineers prefer to use the dimension kgf/cm2.

The elastic modulus is determined experimentally in scientific laboratories. The essence of this method is to tear dumbbell-shaped samples of material using special equipment. Having found out the stress and elongation at which the sample failed, divide these variables by each other, thereby obtaining Young's modulus.

Let us immediately note that this method is used to determine the elastic moduli of plastic materials: steel, copper, etc. Brittle materials - cast iron, concrete - are compressed until cracks appear.

Additional characteristics of mechanical properties

The modulus of elasticity makes it possible to predict the behavior of a material only when working in compression or tension. In the presence of such types of loads as crushing, shear, bending, etc., additional parameters will need to be introduced:

- Stiffness is the product of the elastic modulus and the cross-sectional area of the profile. By the value of rigidity, one can judge the plasticity not of the material, but of the structure as a whole. Measured in kilograms of force.

- Relative longitudinal elongation shows the ratio of the absolute elongation of the sample to the total length of the sample. For example, a certain force was applied to a rod 100 mm long. As a result, it decreased in size by 5 mm. Dividing its elongation (5 mm) by the original length (100 mm) we obtain a relative elongation of 0.05. A variable is a dimensionless quantity. In some cases, for ease of perception, it is converted to percentages.

- Relative transverse elongation is calculated similarly to the point above, but instead of length, the diameter of the rod is considered here. Experiments show that for most materials, transverse elongation is 3-4 times less than longitudinal elongation.

- The Punch ratio is the ratio of the relative longitudinal strain to the relative transverse strain. This parameter allows you to fully describe the change in shape under the influence of load.

- The shear modulus characterizes the elastic properties when the sample is exposed to tangential stresses, i.e., in the case when the force vector is directed at 90 degrees to the surface of the body. Examples of such loads are the work of rivets in shear, nails in crushing, etc. By and large, the shear modulus is associated with such a concept as the viscosity of the material.

- The bulk modulus of elasticity is characterized by a change in the volume of the material for uniform, versatile application of load. It is the ratio of volumetric pressure to volumetric compressive strain. An example of such work is a sample lowered into water, which is subject to liquid pressure over its entire area.

Read also: Causes of car compressor not working

In addition to the above, it should be mentioned that some types of materials have different mechanical properties depending on the direction of loading. Such materials are characterized as anisotropic. Vivid examples are wood, laminated plastics, some types of stone, fabrics, etc.

Isotropic materials have the same mechanical properties and elastic deformation in any direction. These include metals (steel, cast iron, copper, aluminum, etc.), non-laminated plastics, natural stones, concrete, rubber.