Perhaps the most interesting, based on the variety of qualities, brands, characteristics and applications, is a brass alloy. And, despite the fact that its price is lower than, say, copper, it is used even in the manufacture of jewelry. The composition of brass is simple, but different proportions give such diverse qualities that it needs to be discussed in detail.

Composition and classification of brasses

The classic composition assumes the presence of copper and zinc in the alloy in a ratio of 2:1, respectively. The Ancient Romans knew such brass. Skeptics will remember that zinc in its pure form was discovered in the 16th century. But in the case of Ancient Rome, we are talking about zinc-containing rock, which at that time was already being processed.

At that time, it was believed that it was the presence of zinc that determined the color, and only later did it become known that the sunny shade of the brass alloy is obtained due to the fact that the presence of zinc dilutes the copper redness.

- Brass is divided into two-component (simple) and multi-component (special).

One of the markings for products made from brass indicates the percentage of components. So the letter L indicates the type of alloy - brass. and the adjacent numerical index indicates the copper content in the composition. For example, “L80” stands for “brass consisting of 80% copper and 20% zinc.”

Two components are not a mandatory requirement. If there are more of them, then each component introduced into the brass composition is displayed in the marking using the corresponding letter symbol following the letter L. Tin, nickel or lead can be used as additives. At the same time, brass changes its properties.

Additives are introduced into the alloy to achieve certain purposes. For example, brass in classical proportions cannot be used in shipbuilding. All thanks to the instability of brass to the effects of saline solutions (sea water). Additives introduced into the alloy solve this problem while maintaining the basic characteristics.

- According to the degree of processing, alloys are divided into: wrought (brass strip, wire, pipe, brass sheet) and cast (fittings, bearings, instrument parts).

Wrought two-component brass

Deformable multi-component brasses

Foundry brasses

Application

Scope of application of copper-zinc (brass) alloys processed by pressure (GOST 15527-2004):

- L60; L63; L68; L80; L90; L96 - Pipelines, gaskets, washers, rivets, meshes, spindles, valve bushings, nuts, parts subject to corrosion.

- LA77-2; L062-1; L070-1; LS59-1 — Condenser and manometric tubes; parts processed by stamping; bushings; disks; housings; fasteners; brackets; accessories.

- LMts58-2 - Bearings, bushings, antifriction parts.

Scope of application of copper-zinc alloys (brass), foundry (GOST 17711-93):

- LC40S; LTs40Mts1.5; LTs37Mts2S2K - Fittings, valve bodies, bushings and bearing cages, tees, adapters operating in air or fresh water.

- LCZ0AZ; LTs25S2 - Anti-friction parts of simple configuration: bushings, liners, sliders, car bearing fittings.

Up

Additives in alloys

Alloying elements are used in brasses. These are substances introduced into the alloy in order to change the structure, and as a result, the characteristics. These elements include:

- Aluminum. The presence of aluminum in the alloy reduces the volatility index. As a result of interaction with oxygen, a layer of aluminum oxide is formed on the surface of the product, which eliminates the volatility of the material.

- Magnesium. This additive is most often introduced in combination with iron and aluminum. Thus, the structure changes, and the alloy becomes stronger, wear-resistant, and corrosion-resistant.

- Nickel. This type of additive is introduced to neutralize the effects of oxidative processes.

- Lead. The presence of this alloying element provides plasticity to the material. It becomes more malleable, easier to mechanically influence, including cutting. Used for products that do not have a load-bearing function during operation.

- Silicon. The additive is introduced to increase the strength of the metal and its rigidity. If lead is added in parallel, the anti-friction properties will improve. Again, alloys of copper, zinc, silicon with lead and bronze with tin are becoming competing. The cost of the latter is higher.

- Tin. This metal is added to eliminate the risk of corrosion pockets. This is especially important in shipbuilding. With the addition of tin, salt water is not harmful to the metal.

Casting brass alloys

There are two main types of brass alloys for mass consumption: casting and wrought (jewelry is also included in a separate group). The characteristics and processing technologies of casting brasses are described in GOST 17711. Materials of this type are characterized by increased density, reduced gas content and good corrosion resistance. Due to the partial evaporation of zinc during the casting process, the metal is well deoxidized, but it is important to control this process so that the characteristics of the finished product correspond to the calculated values.

Cast brasses are characterized by reduced segregation (heterogeneity that occurs during the casting and crystallization process), increased melt fluidity and a low shrinkage coefficient. In terms of mechanical characteristics, finished parts made from this metal are similar to products made from aluminum and tin bronze, while their cost is significantly lower due to a simpler production technology.

Of course, cast brass alloys also have certain disadvantages. Thus, during crystallization, quite large cavities can form on the surface of products, leading to a significant percentage of defects. It is also important to consider that due to the evaporation of zinc, smelting must be carried out using special fluxes.

Household uses of brass

Brass is characterized by softness and pliability during machining. At the same time, alloys are characterized by strength. Its external resemblance to gold determined its popularity in jewelry production. Brass is used to give a golden hue to orders and medals, as well as to apply ornaments to dishes. Decorations and accessories made from it have an attractive appearance at a minimal price.

Brass shades have come to the service of jewelers:

- M 67/33 yellow;

- M 60/40 green;

- M 75/25 golden;

- M 90 bright yellow.

L62 and L68 are needed as simulators for students of jewelry art. This choice is due to the similarity in characteristics. But for the manufacture of insignia, brass is used, which contains 15% zinc and 5% aluminum. Such products are wear-resistant.

Brass is characterized by durability. Jewelry made from this alloy does not suffer from old age or wear and tear. Knowing this quality and selecting the optimal composition, Zippo manufactures most lighter models from brass. The steel façade is created through a galvanic process (chrome plating). The presence of a brass alloy in the base distinguishes original products, where brass is the main material, from fakes, where there are no brass parts.

The main application of products made from a two-component alloy is found in fasteners and shut-off valves. These are bolts and screws, coils and adapters, taps and valves. We use brass, the composition of which includes the maximum percentage of copper. The purpose of this brass alloy composition is to minimize cost.

The use of multicomponent alloys (the composition includes more than two ingredients) is wider. This:

- aviation;

- shipbuilding;

- refrigeration equipment (brass heat exchanger tubes);

- production of watch movements, etc.

All thanks to the fact that brass alloys are malleable, soft, but at the same time they are durable materials.

Care instructions

Brass is cleaned and polished with oxalic acid. It is sold in hardware and building materials stores. Before processing the alloy, the concentrated acid composition must be diluted at the rate of 200 ml per 10 liters of water. Only after this the product can be treated with an acid composition.

Physico-chemical properties of brass alloys

In appearance, brass resembles bronze, which is why they are confused or even identified. But in bronze the main alloying component is tin, not zinc, so these are two completely different copper-containing metals with significantly different physicochemical properties.

Zinc (Zn, Zincum) is in position 30 in the periodic table. He is included in the secondary subgroup of the second group of the fourth period. Under normal conditions, pure zinc is a brittle metal with a characteristic bluish tint. In air it quickly oxidizes, and if a zinc stick is bent, a characteristic cracking sound is heard (in this way zinc resembles tin). Pure zinc does not occur in nature.

Copper (Cu, Cuprum) is located right in front of zinc in the periodic table - in 29th position. It belongs to the elements of the eleventh group of the fourth period. In its pure form, it is a soft, ductile metal of rose-gold color. Under natural conditions, the surface of purified copper quickly oxidizes, combining with atmospheric oxygen. Despite this, it is found in its native form, thanks to which it became one of the first metals known to man. The most ancient copper products found during excavations in the village of Catal Huyuk (Turkey) date back to 7500 BC.

Brass manufacturing technology

To obtain a brass alloy, you need to follow a number of steps:

- Place the copper raw material in a clay bowl, after weighing it.

- Place the bowl in a special oven.

- Lump zinc and the necessary additives are added to the molten copper.

- The resulting alloy is melted until the composition is homogeneous.

Liquid hot brass is poured into molds. Furnaces for the production of alloys usually operate on solid fuel - coal.

A problem with melted brass alloys is zinc evaporation. Therefore, smelting plants are equipped with absorbent systems to capture it, after which it is reintroduced into the brass alloy. The next feature of the alloy manufacturing technology is the need for re-melting. During primary brass shrinks, and deflections form in the products.

The temperature required for melting brass cannot be lower than +8000 C. The exact indicator is calculated for each brand of brass separately. The amount of zinc in alloys is inversely related to the melting point of brass. That's all the technology is.

Receiving technology

Brass does not occur in nature.

The source material for its production is three types of raw materials:

- Primary. Copper, zinc and other ores are mined from natural deposits.

- Copper, zinc, and other metal scrap suitable for recycling (recyclables). Accumulated at collection points.

- Waste from the metallurgical plants' own production cycle.

Traditional production methods involve the use of furnaces for smelting copper and its alloys. Typically these are electro-induction units equipped with a magnetic core and operating at low frequencies.

Microstructure of ground and etched brass alloy under 400x magnification

Alloy production process:

- Hot copper is placed in a furnace.

- Next, lump zinc is loaded.

- Melting takes place at 875-945°C.

- Alloying additives are added to special brasses.

- The mass is mixed until smooth and poured into molds.

The output is flat or round brass ingots. The smelted products have different hardness, degree of hardening and aging.

Advanced technologies include the installation of ventilation for exhaust during melting of vapors that are dangerous to humans.

The special role of brass composition

Brass can look like bronze if the compositions and proportions are chosen correctly and the surface of the brass is treated. Today, due to their lower cost, copper-zinc alloys have begun to gain positions in the market. Once popular bronze chandeliers, sconces, decorative items and faucets are now increasingly made of brass.

And so that external differences in the alloys cannot be discerned, the surface of the brass is subjected to a special chemical composition. This is how they make plumbing brass.

The conquest of the decorative metals market does not end there. Now brass is a material for headboards, candlesticks, kitchen hoods and utensils, and other interior elements. It is not for nothing that alloys received the status of the most important metals in the world. And even typographic fonts are brass.

Manufacturability of brass

Copper- and zinc-based metals lend themselves well to machining, making it possible to turn any parts from blanks and preliminary castings. In addition, they lend themselves well to soldering.

The main disadvantage is the tendency for brass with a high zinc content (more than 20%) to crack, especially when used in a humid environment and in the presence of ammonia vapor. The first sign of a decrease in the strength of rolled brass metal is the loss of natural color; other properties gradually deteriorate.

Melt brass technology

To obtain the melt, two main technologies are used:

- melting in crucibles made of refractory clay by heating in a flame or shaft furnace;

- melting in a reverberatory furnace without the use of crucibles.

Molten metal is poured into sand molds to produce blanks and ingots. It is important to consider that part of the zinc evaporates during the process, so it is necessary to choose an alloy in which its proportion will be slightly higher. The correction for evaporation is calculated individually for a specific technology so that the proportions of metals in the finished product correspond as much as possible to the design values.

Let's analyze the chemical properties of brass and the influence of all its components.

The designation of all varieties of brass according to GOST is the capital L. For a 2-component alloy, it is followed by the percentage of copper, and the remainder is zinc. An example is L63. For multi-component brass, the first letters of alloying elements are added to L, and their percentage in the composition is added to the number separated by a dash (LS59-1). The amount of zinc is calculated by subtracting the sum of these numbers from 100.

Zinc improves the mechanical properties of brass, increasing its ductility and strength. Its maximum ductility is achieved at 30 percent zinc content. If Zn is more than 39%, the ductility deteriorates, and the strength of the alloy, on the contrary, increases sharply.

Arsenic prevents dezincification of brass when it is in aggressive fresh water at room or elevated temperatures.

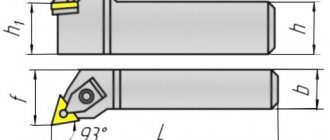

Lead enhances the antifriction properties of brass and promotes better machinability of workpieces by cutting. This element acts as a lubricant and reduces wear on cutting tools. The chips become brittle, brittle and do not stick to the cutters or cutters. The surface of the parts is smooth, with the required roughness parameters.

Iron reduces the grain size of brass, increases the hardness of the alloy and increases its recrystallization temperature.

Tin, aluminum and nickel make brass more resistant to corrosion in seawater and air while increasing its strength.

Brass is a copper-zinc alloy. Its components in the presence of an electrolyte solution (water, etc.) form a galvanic couple. Moreover, the more active metal, zinc, is destroyed. The brass dezincification process starts. This is corrosive destruction, accompanied by darkening of the surface of the material and the release of white zinc oxides on it.

Because of this, the use of brass fasteners with mating elements made of steel, bronze or aluminum alloys is not allowed. Those. brass parts can only be connected to each other or using chemically inert plastics (polyamide, etc.). In addition, brass must be stored in warehouses at positive temperatures without significant changes. High air humidity and condensation are not allowed.

| Conformity table of domestic and foreign brands of brass | |||

| ASTM | DIN | GOST | |

| C21000 | CuZn5 | 2.0220 | L96 |

| C22000 | CuZn10 | 2.0230 | L90 |

| C23000 | CuZn15 | 2.0240 | L85 |

| C24000 | CuZn20 | 2.0250 | L80 |

| C26000 | CuZn30 | 2.0265 | L70 |

| C26200 | CuZn33 | 2.0280 | L68 |

| C26800 | CuZn37 | 2.0323 | L63 |

| C27200 | |||

| CuZn40 | L60 | ||

| C35000 | CuZn38Pb5 | 2.0371 | LS59-1 |

| C37100 | |||

| C35600 | CuZn36Pb3 | 2.0375 | LS63-3 |

| C36000 | |||

| C68700 | CuZn20A12 | 2.0460 | LAMsh 77-2-0.05 |

| C37700 | CuZn39Pb2 | 2.0380 | LS59-2 |

| C38500 | CuZn39Pb3 | 2.0401 | LS59-3 |

| C37800 | CuZn30Pb2 | 2.0402 | LS58-2 |

| CuZn20Al2 | LA77-2 | ||

| CuZn38AlIMn2Al1 | LAZ60-1-1 | ||

| CuZn40Mn1 | LMts58-2 | ||

| CuZn40Al1Mn | LMtsA57-3-1 | ||

| CuZn28Sn1 | LO701 | ||

| CuZn38Sn1 | LO62-1 | ||

| CuZn35Pb2 | LS63-2 | ||

| CuZn38Pb2 | LS60-2 | ||

The density of brass, as one of its physical properties, differs little from copper. If the permissible amount of silicon in the alloy is exceeded, the brass will have less density and strength.

Additives to the alloy of manganese, tin and aluminum contribute to an increase in the tensile strength of brass parts. To increase the elongation factor, alloying with iron is necessary.

Due to the significant copper content and the presence of zinc, the electrical properties of brass are excellent. Electrodes for erosion machines are made from it.

The melting points of brass are in the range of 855 – 965 for lead alloys and 885 – 1070 °C for two-component alloys. This value decreases with increasing zinc content.

| Technical comparison of Copper and brass grades L63 and LS59-1 | |||

| Fur. show | Copper | L63 | LS59-1 |

| Electrical resistivity | 0,018 | 0,065 | 0,065 |

| Thermal conductivity | 0,925 | 0,25 | 0,25 |

| Impact strength | 17.0 | 14.0 | 5.0 |

| Tensile strength, shear in MPA | 210 | 240 | 260 |

| Machinability | 18% | 40% | 80% |

Brasses subjected to processing by plastic deformation (rolling, bending, pressing, forging, embossing) are single-phase (L63, up to 30% zinc) or two-phase (40 - 45% Zn). The last category (for example, LS59-1) is excellently processed only in a hot state, and 1-phase - in a cold or heated state. In order to relieve residual stresses inside the part and increase its hardness and strength, products after stamping and similar processing are subjected to heat treatment (hardening) at a temperature of 240 - 260 oC.

Brass is similar in color to bronze. But the latter is attracted to a magnet, while brass is practically not. In addition, brass has a high density and, accordingly, a workpiece made from it with the same configuration is heavier than bronze. When brass parts are heated to 600 - 650 °C (dark red tint), ashen zinc oxide appears on their surface, which bronze does not have. Brass is more ductile at the expense of wear resistance and strength, which are higher in bronze. And bronze resists corrosion better when in contact with salty sea water. Under these conditions, only tin brass of the LO brand is comparable to it. The brass at the fracture site is light with a fine-grained structure, bronze is painted dark brown and has large grains.

The advantages of brass parts are:

- Resistance to corrosion destruction, which manifests itself when products are exposed to air, sea water, most organic and carbon dioxide. Brass is more resistant to oxidation processes than stainless steel.

- Pliability under pressure is characteristic of alloys that do not contain lead. This facilitates their forging and stamping (with or without heating).

- Low thermal conductivity, so when the temperature drops, the properties of the products do not change.

- There is no residual magnetization at the end of exposure to current or electromagnetic field. Therefore, such parts (for example, made from L63A material) do not create interference and are used in devices with increased sensitivity to interference.

Brasses are resistant in the following environments (at normal temperatures):

- air, incl. nautical

- dry steam at low speeds (oxygen, carbon dioxide and ammonia accelerate corrosion)

- fresh water (ammonia, hydrogen sulfide, chlorides, acids accelerate corrosion)

- in sea water at low water speeds

- dry halogen gases

- antifreezes, alcohols, freons

Relatively stable:

- alkali without stirring

Brasses are unstable in the following environments:

- wet saturated steam at high speeds

- mine waters

- oxidizing solutions, chlorides

- mineral acids

- hydrogen sulfide

- fatty acid

The main areas of application of brass products are the chemical, aviation and shipbuilding industries, refrigeration engineering, electrical engineering and energy (contacts, busbars, power transformers), production of high-precision electronic devices and sensors. Brass is used in everyday life for decorating the interior of premises, installing plumbing fixtures and making furniture, assembling acoustic musical instruments, wooden structures in construction, for making information and advertising signs, and souvenirs.

The main brands of brass that are widely used are:

- Two-component (L63, L68, L70, etc.).

- Multicomponent - aluminum (LA77-2, LA 85-0.5, etc.), silicon (LK80-3), manganese (LMts58-2), tin (LOK59-1-0.3, LO60-1), nickel (LN65-5) and lead (LS59-1, LS63-3).

The brass used for the production of fasteners includes the LS59-1 grade. This multicomponent alloy contains up to 60% copper; 42.2% zinc; 1.9% lead and 0.75% impurities. The melting point is 885...895 oC. This type of brass can be easily processed by pressure, but it is mainly used for making parts by cutting. Lead will facilitate drilling, milling and turning of workpieces.

The range of products made from LS59-1 includes:

- Rods of various sections, wire and rolled profiles.

- Strip, plate, sheet and round pipe.

The delivery state of the blanks is soft, semi-hard and hard.

This brass has excellent wear resistance. Therefore, guides for machine tools and sleeves for sliding bearings are made from it. But due to its increased fragility, such material is not resistant to impacts and cannot be used for load-bearing elements.

For the manufacture of decorative furniture fittings, rivets and other fasteners, two-component brass L63 (Cu – 65%, Zn – 38%) with a melting point of up to 910 °C is used.

It is used to produce sheet metal, wire, round pipes and various rods. Thanks to the single-phase structure of the crystal lattice, this alloy is more ductile than other brasses and is excellently deformable using all known technologies (drawing, drawing, stamping, etc.). To maintain decent corrosion resistance, L63 parts produced by cutting are pre-annealed. Such brass products do not oxidize in the environment of liquid and gaseous refrigerants, other halogen-containing substances, aqueous solutions of antifreeze and alcohol, and dry water vapor.