Brass LO70-1 Brass LMtsA57-3-1 Brass LMtsAZhKS70-7-5-2-2-1 Brass LMtsZh57-1.5-0.75 Brass LMtsKA58-2-1-1 Brass LMtsKNS58-3-1.5-1 ,5-1 Brass LMtsKNSA58-3-1.5-1.5-1 Brass LMtsSKa58-2-2-1-1 Brass LMsh68-0.05 Brass LN65-5 Brass LNKMts49-10-0.3-0.2 Brass LNKoMts49-9-0.2-0.2 Brass LNMts60-9-5 Brass LO60-1 Brass LO62-1 Brass LKS65-1.5-3 Brass LO90-1 Brass LOK59-1-0.3 Brass LOMNA49-0 ,5-10-0.4-0.4 Brass LOMsh70-1-0.04 Brass LOMsh70-1-0.05 Brass LS58-2 Brass LS58-3 Brass LS59-1 Brass LS59-1V Brass LS59-2 Brass LS60 -1 Brass LS63-3 Brass LS64-2 Brass LS74-3 Brass LA85-0.5 Brass L59 Brass L60 Brass L63 Brass L66 Brass L68 Brass L70 Brass L72 Brass L75mk Brass L80 Brass L85 Brass L90 Brass L96 Brass LA77-2 La Tun LA77 -2u Brass LMts58-2 Brass LAZ60-1-1 (LAZH60-1-1L) Brass LAZHMtsS52-2-1-1.5-1 Brass LAMsh77-2-0.04 Brass LAMsh77-2-0.05 Brass LAN59- 3-2 Brass LANKMts 75-2-2.5-0.5-0.5 (alloy 156) Brass LAF94-0.5-0.15 Brass LZhMts59-1-1 Brass LZhS58-1-1 Brass LK62-0 .5 Brass LK75V Brass LKAN80-1-1.9-5.8 Brass LKANMTs75-2-2.5-0.5-0.5 Brass LKBO62-0.2-0.04-0.5

Standards

| Name | Code | Standards |

| Wire made of non-ferrous metals and their alloys | B74 | GOST 1066-90, GOST 1066-2015, OST 4.021.105-92, OST 4.021.112-92, OST 4.021.116-92, TU 48-21-409-79, TU 48-21-493-75 |

| Ribbons | B54 | GOST 15527-2004, GOST 2208-2007, OST 4.021.078-92, TU 48-21-541-76 |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 28873-90, OST 4.021.009-92, TU 48-21-642-79 |

| Pipes made of non-ferrous metals and alloys | B64 | GOST 494-90, GOST 494-2014, OST 4.021.123-92, OOP 5.9243-87, TU 48-21-667-79, TU 48-21-77-72, TU 48-21-798-86 |

| Rods | B55 | GOST 6688-91, GOST 2060-2006, GOST R 52597-2006, GOST 31366-2008, OST 4.021.020-92, OST 4.021.037-92, OST 4.021.041-92, TU 48-21-381-74 , TU 48-21-559-76, TU 48-21-603-78, TU 48-21-93-77, TU 48-0810-119-86 |

| Sheets and strips | B53 | GOST 931-90, OST 4.021.050-92, OST 4.021.067-92, TU 84-320-78, TU 1845-069-07515308-98 |

| Long and shaped rolled products | B52 | TU 48-21-434-84 |

Areas of use

The wide range of applications of products made from LS59-1 brass is explained by such characteristics as:

- low cost;

- high hardness and strength;

- good machinability;

- wear resistance and corrosion resistance.

All this allows this alloy to be successfully used for manufacturing:

- elements of gear and worm connections;

- bushings and liners for various purposes;

- fastening elements;

- pipe products.

Chemical composition

| Standard | P | Fe | Cu | Zn | Sn | Sb | Pb | Bi |

| GOST 2208-2007 | ≤0.02 | ≤0.5 | 57-60 | Remainder | ≤0.3 | ≤0.01 | 0.8-1.9 | ≤0.003 |

Cu is the base. According to GOST 15527-2004, GOST 2060-2006, GOST 2208-2007, the sum of other elements must be ≤ 0.750%. The total mass fraction of tin and silicon should be no more than 0.50%. In brass, a mass fraction of nickel of up to 1.0% is allowed due to the mass fraction of copper, which is not taken into account in the sum of other impurities.

Corrosion resistance

Due to the presence of lead in the chemical composition of brass of the brand in question, a separate phase is formed in its internal structure, which has a positive effect not only on its workability, but also on its resistance to corrosion. Compared to other brass alloys, LS59-1 is more resistant to corrosion. Products made from such brass are not subject to cracking and oxidation when used in conditions of high humidity and temperature changes.

However, there is no need to talk about the exceptionally high corrosion resistance of LS59-1: in this parameter, this alloy is similar to brasses of other brands. In particular, it is not recommended to use it in cases where it will come into contact with products made of iron, aluminum and zinc. In addition, the corrosion resistance of LS59-1 will be poor when:

- simultaneous exposure to high humidity and high pressure;

- contact with fatty acids;

- operation in hydrogen sulfide environment;

- contact with ore waters and mineral acids;

- constant interaction with oxidized solutions and chlorides.

The characteristics of brass allow the metal to be used for the production of shut-off and connecting valves operated at temperatures above 100 degrees

LS59-1 demonstrates its corrosion resistance well under the following operating conditions:

- atmospheric air, including that saturated with sea salt vapor;

- dry steam;

- liquid medium characterized by a very low content of salts and acids;

- freon, alcohol solutions and antifreeze;

- salty sea water in a sedentary state.

It should be borne in mind that the interaction of LS59-1 brass with a gaseous or liquid medium characterized by a high content of ammonia, oxygen and carbon dioxide has a very negative effect on the corrosion resistance of the alloy.

Mechanical characteristics

| Section, mm | σB, MPa | d5, % | d10 | d10 | Brinell hardness, MPa | HV, MPa |

| Cold rolled strip as delivered according to OST 4.021.078-92 (transverse samples) | ||||||

| 0.14-2 | 340-490 | — | ≥25 | — | — | — |

| 0.1-2 | 460-640 | — | ≥5 | — | — | — |

| Cold-rolled strips and sheets in delivery condition according to GOST 2208-2007 (samples) | ||||||

| — | 340-470 | — | ≥25 | — | ≥100 | ≥105 |

| — | ≥590 | — | ≥3 | — | — | — |

| — | 400-500 | — | ≥10 | — | — | — |

| — | 460-610 | — | ≥5 | — | ≥200 | — |

| Hot-rolled sheets in delivery condition in accordance with GOST 931-90, OST 4.021.050-92 sheets and strips in accordance with GOST 2208-2007 (samples) | ||||||

| 2-25 | 360-490 | — | ≥18 | — | — | — |

| Cold-rolled sheets and strips in delivery condition according to GOST 931-90, OST 4.021.050-92, OST 4.021.067-92 (transverse samples) | ||||||

| 3-12 | 340-470 | — | ≥25 | — | ≥100 | — |

| 3-10 | 460-610 | — | ≥5 | — | ≥200 | — |

| Cold-deformed square wire as delivered according to OST 4.021.112-92 (longitudinal samples) | ||||||

| 3.9-7 | ≥340 | — | ≥30 | — | — | — |

| 3.9-5 | 400-640 | — | ≥5 | — | — | — |

| 5-7 | 440-640 | — | ≥8 | — | — | — |

| Cold-deformed round wire for general purpose as delivered in accordance with OST 4.021.105-92 (samples) | ||||||

| 0.7-1 | ≥340 | — | ≥25 | — | — | — |

| 1.1-1.8 | ≥340 | — | ≥27 | — | — | — |

| 2-12 | ≥340 | — | ≥30 | — | — | — |

| 2-5 | ≥390 | — | ≥10 | — | — | — |

| 5.6-12 | ≥390 | — | ≥12 | — | — | — |

| 0.7-1 | ≥490 | — | ≥1 | — | — | — |

| 1.1-1.8 | ≥470 | — | ≥3 | — | — | — |

| 2-5 | 490-640 | — | ≥5 | — | — | — |

| 5.6-12 | 440-640 | — | ≥8 | — | — | — |

| Hexagonal cold-deformed wire as delivered according to OST 4.021.116-92 (longitudinal samples) | ||||||

| 3-12 | ≥340 | — | ≥30 | — | — | — |

| 3-5 | 490-640 | — | ≥5 | — | — | — |

| 5-12 | 440-640 | — | ≥8 | — | — | — |

| Rods in delivery condition according to OST 4.021.020-92, GOST 2060-2006 (longitudinal samples) | ||||||

| 10-50 | ≥360 | ≥22 | — | ≥18 | — | 80-140 |

| 55-160 | ≥360 | ≥22 | — | ≥18 | — | 70-140 |

| 3-50 | ≥330 | ≥25 | — | ≥22 | ≥80 | 80-140 |

| 13-20 | ≥390 | ≥15 | — | ≥12 | ≥100 | 121-170 |

| 21-40 | ≥390 | ≥18 | — | ≥15 | ≥100 | 121-170 |

| 3-12 | ≥410 | ≥10 | — | ≥8 | ≥100 | 121-170 |

| 3-12 | ≥490 | ≥7 | — | ≥5 | ≥130 | ≥171 |

| Square rods according to OST 4.021.037-92 in delivery condition (longitudinal samples, the diameter of the inscribed circle is indicated in the cross-section) | ||||||

| 41-80 | ≥360 | ≥22 | — | ≥18 | — | 70-140 |

| 3-36 | ≥330 | ≥25 | — | ≥22 | — | 80-140 |

| 12-30 | ≥390 | ≥15 | — | ≥12 | — | 121-170 |

| 30-36 | ≥390 | ≥18 | — | ≥15 | — | 121-170 |

| 5-12 | ≥410 | ≥10 | — | ≥8 | — | 121-170 |

| 5-12 | ≥490 | ≥7 | — | ≥5 | — | ≥171 |

| Rods of increased ductility as delivered in accordance with GOST 2060-2006 (longitudinal samples) | ||||||

| 10-180 | ≥360 | ≥23 | — | ≥20 | — | — |

| 3-50 | ≥340 | ≥32 | — | ≥30 | — | — |

| 13-20 | ≥430 | ≥16 | — | ≥14 | — | — |

| 21-40 | ≥410 | ≥20 | — | ≥17 | — | — |

| 3-12 | ≥430 | ≥14 | — | ≥12 | — | — |

| 3-12 | ≥490 | ≥12 | — | ≥9 | — | — |

| Pressed rods of rectangular cross-section in delivery condition according to GOST 6688-91 (longitudinal samples) | ||||||

| — | ≥370 | — | — | ≥21 | — | — |

| Hexagonal bars according to OST 4.021.041-92 in delivery condition (longitudinal samples) | ||||||

| 41-80 | ≥360 | ≥22 | — | ≥18 | — | 70-140 |

| 5-50 | ≥330 | ≥25 | — | ≥22 | — | 80-140 |

| 12-20 | ≥390 | ≥15 | — | ≥12 | — | 121-170 |

| 20-36 | ≥390 | ≥18 | — | ≥15 | — | 121-170 |

| 5-12 | ≥410 | ≥10 | — | ≥8 | — | 121-170 |

| 5-12 | ≥490 | ≥7 | — | ≥5 | — | ≥171 |

| Pressed pipes in delivery condition according to GOST 494-90 | ||||||

| ≥390 | — | — | ≥20 | — | — | |

Physical properties

The phase state of the LS59-1 alloy is determined by a small amount of substance in the b-phase, while lead is present as an independent phase, which explains its good machinability. This is the main property of lead brasses. High-speed processing of alloy workpieces occurs with little tool wear. During the process, small loose chips are formed, which ensures the cleanliness of the surface being processed and a slight hardening during cutting. Due to its good machinability, alloy LS59-1 is used for the production of small-sized parts for ultra-precision mechanics.

LS59-1 has low impact strength and low bending strength with an existing notch. The alloy is a good structural material even at low temperatures. Plasticity is maintained at lower temperatures down to helium temperatures. At average temperatures (200-600°C) the alloy exhibits the phenomenon of brittleness due to the multiphase structure of the material. Impact strength decreases with increasing temperature. The material may crack, so the alloy is not suitable for forging. Brass LS59-1 has good strength and corrosion resistance to various environments. The alloy has good anti-friction properties. It can be used in the production of small parts that are designed to operate under high friction (for example, plain bearings). The electrical and thermal conductivity of LS59-1 is less than that of copper.

The high hardness of the alloy and its abrasion resistance make it possible to use sheet blanks for the production of guide elements for various machine tools. In terms of tensile strength, LS59-1 brass is inferior to L63 alloy. The high hardness of cold-worked alloy sheets with good wear resistance determines their use for machine guides.

Rolled metal

Pipes in accordance with GOST 494 from LS59-1 are produced by pressing. In addition, a wide range of products from this material are produced in accordance with GOST. Since the alloy has low mechanical properties for pressure processing, although it is generally considered pressure-processable, pipes are made from it using continuous casting methods. And their cost is much lower than pressed ones.

Cold-deformed general-purpose wire is produced in accordance with GOST 1066, and has a square, round or hexagonal cross-section.

Cold-worked sheets LS59-1 have high hardness and wear resistance, and, as mentioned above, are used in machine tool construction. This is one of the most popular types of rolled brass sheets. In addition, sheets are produced from LS59-1 in soft, semi-hard, and hard states.

LS59-1 bars of hexagonal and square shape have found the greatest use. This is a very inexpensive type of rolled product that is easy to cut, and in addition, it has strong ribs. Thanks to this, at minimal cost it is possible to produce all kinds of small and large parts with good anti-friction properties from rods. This alloy is used to produce drawn and pressed rods in hard, soft or semi-hard states.

LABELING, PACKAGING, TRANSPORTATION AND STORAGE

4.1. Rods with a diameter of up to 35 mm inclusive are tied into bundles weighing no more than 80 kg. Each bundle must consist of at least three rods and must be tied with two turns of wire with a diameter of at least 1.2 mm in accordance with GOST 3282 or other material according to regulatory and technical documentation in at least two places, and with a rod length exceeding 3 m in at least three places in such a way that mutual movement of the rods in the bundles is excluded, evenly along the length of the bundle.

The ends of the wire are connected by twisting at least five turns.

Drawn rods with a diameter of up to 12 mm inclusive are packaged in 1 - 2 layers in synthetic and non-woven materials that ensure the preservation of the quality of the rods, according to regulatory and technical documentation and tied over the packaging material with wire with a diameter of at least 1.2 mm in accordance with GOST 3282 in at least two places.

Cargo items must be formed into transport packages. Overall dimensions of packages - according to GOST 24597.

Bundles of bundles and individual rods not connected into bundles are carried out on pallets in accordance with GOST 9557 or without pallets using bars with a height of at least 50 mm and tied with wire with a diameter of at least 2 mm in two turns in accordance with GOST 3282 or with tape measuring at least 0.3 ´30 mm according to GOST 3560, or using bundled wire slings according to GOST 3282 with a diameter of at least 5 mm with a twist of at least three turns. The ends of the wire are connected by twisting at least five turns, the tapes are connected into a lock.

Packaging of rods intended for the Far North and hard-to-reach areas is carried out in accordance with the requirements of GOST 15846.

(Changed edition, Amendment No. 1, 3).

4.2. A metal or plywood label in accordance with GOST 14192 must be attached to each bundle of rods indicating: the trademark or name and trademark of the manufacturer, the symbol of the rods, the batch number, the designation of this standard, the technical control stamp.

On rods with a diameter of 25 - 35 mm, the alloy grade must be stamped, and on rods with a diameter over 35 mm, the alloy grade must be stamped and a technical control stamp must be applied.

4.3. Transportation of rods is carried out by all types of transport in covered vehicles in accordance with the rules for the transportation of goods in force for this type of transport.

It is allowed to transport rods tied into bundles weighing no more than 80 kg in standardized containers in accordance with GOST 20435 or in specialized containers in accordance with regulatory and technical documentation.

4.4. Transport marking of cargo packages is in accordance with GOST 14192 with the additional application of the handling sign “Keep away from moisture” and the inscription of the batch number in a place free from transport markings.

Transport marking is applied in any way provided for by GOST 14192.

4.5. Rods must be stored indoors, in conditions that exclude mechanical damage, exposure to moisture and active chemicals.

4.2 — 4.5. (Changed edition, Amendment No. 1).

4.6. During storage and transportation, rods must be protected from mechanical damage, moisture and active chemicals.

How is brass melted in metallurgical plants?

The alloy is usually melted in metallurgical plants, since favorable conditions for remelting are created there. During factory melting, the material retains all its physical properties - strength, electrical conductivity, retention of shape during deformation, and so on. The technology for remelting brass at a factory depends on what category of brass the material belongs to. Two-component alloys (with added zinc) are usually melted in induction furnaces that have quartz-lined walls. This coating minimizes overheating of the furnace and also protects the walls from deformation and cracking.

Double brasses melt at relatively low temperatures (the liquidus point for them is in the region of 910-930 degrees Celsius). Therefore, there is no point in melting dual alloys in powerful electric arc furnaces. For the melt, it is recommended to use a charcoal-based protective layer. It is also recommended to introduce a small amount of cryolite into the melt (about 0.01-0.1%) - this helps reduce metal defects during smelting. Instead of charcoal, you can use a flux consisting of glass and spar in a 1 to 1 ratio.

To remelt two-component brass, you must first melt the copper and then the zinc. To melt metal, you need to heat it to a temperature of about 1000-1100 degrees. After this, zinc and alloying additives should be added if available.

Please note that there is no need to deoxidize brass, since zinc performs this function perfectly

Complex non-siliceous brass

Melted according to a similar algorithm. These alloys contain zinc in small quantities. Therefore, such a metal must be deoxidized in order to preserve all its beneficial physical properties. Phosphorus is suitable for deoxidation, although other deoxidizers can be used. When melting, complex brass often produces large debris fractions - to get rid of them, you should perform manganese refining or filtration.

Complex silicon brasses

They have complex crystallization dynamics, which is explained by the presence of silicon and aluminum additives in the alloy composition. Due to the presence of these components, the alloy has an increased tendency to absorb atmospheric hydrogen at high temperatures (more than 1000 degrees).

When the alloy is heated to temperatures above 1100 degrees, batch releases of dissolved carbon may occur, which can lead to the formation of “blisters” on the alloy after it hardens. Therefore, approach the remelting of silicon steels responsibly. To avoid the release of dissolved carbon, smelting should be carried out in an acidic environment. Saturating the air with an acid flux based on sodium carbonate, calcium fluoride and silicon oxide works well.

It is important to monitor the heating temperature, since the protective properties of the gas oxidizer are noticeably reduced when the temperature reaches 1100 degrees

After melting all components in a protective environment, it is necessary to perform a mandatory check of the metal for all main indicators (fracture, saturation, presence of contaminants, and so on).

Rental products

Various rolled metal products are manufactured from the brass of the brand in question, the requirements for the chemical composition and mechanical characteristics of which are specified by GOST 15527-2004. The range and parameters of the latter are regulated by other regulatory documents. Pipes for the manufacture of which this alloy is used can be produced either by plastic deformation or by continuous casting. At the same time, the production of pipes from brass LS59-1 by casting is much cheaper than the production of similar products obtained using deformation processes.

Brass pipe is easy to install by welding or soldering

Work algorithm

Pouring molds with brass melt

Brass casting begins with the preparation of the material. If a crowbar is used, it must first be cleaned. The rental is simply cut. The prepared metal is placed in a crucible. The smaller the cut, the easier it will be to melt. The filled crucible is taken with tongs and placed in the oven. After this, the oven heats up to the desired temperature. When all the deposited material has turned into a liquid state, it is time to remove the crucible from the furnace. This can also be done using forceps.

The film formed on the surface is removed with a spoon. The crucible removed from the furnace is placed on a foundry ladle, after which the casting process begins. The molten metal is poured into the mold and left until it cools completely. The molds are preheated to evaporate moisture, and then placed on dry sand. The melting point of brass depends on its composition, so before starting work you need to carry out trial meltings.

Related video: How to make brass at home

Publications on the topic

Methods for smelting copper at home

Features of soldering aluminum at home

Required temperature and melting process of bronze

Other alloys from the category Pressure-processed brass

| Alloy grade | GOST | Chem. compound |

| CuZn36Pb2As | GOST R 52922 - 2008 | Cu61-63%Zn33.5-37.08%Pb1.7-2.8%As0.02-0.1%… |

| CuZn39Pb3 | GOST R 52922 - 2008 | Cu57-59%Zn36.65-40%Pb2.5-3.5%… |

| L59 | Cu57-60%Zn39.1-43%… | |

| L60 | GOST 15527 - 2004 | Cu59-62%Zn37-41%… |

| L63 | GOST 15527 - 2004 | Cu62-65%Zn34.22-37%… |

| L66 | Cu64.5-67.5%Zn32.13-35%… | |

| L68 | GOST 15527 - 2004 | Cu67-70%Zn29.7-33%… |

| L70 | GOST 15527 - 2004 | Cu69-71%Zn28.6-30%… |

| L75 | Cu75-75%Zn24.7-25%… | |

| L75mk | GOST 15527 - 2004 | Cu70-76%Zn23.1-29.47%Si0.25-0.5%Ni0.1-0.25%Mn0.05-0.15%Fe0.03-0.06%P0.005-0.02%… |

| L80 | GOST 15527 - 2004 | Cu79-81%Zn18.7-21%… |

| L85 | GOST 15527 - 2004 | Cu84-86%Zn13.7-16%… |

| L90 | GOST 15527 - 2004 | Cu88-91%Zn8.8-12%… |

| L96 | GOST 15527 - 2004 | Cu95-97%Zn2.66-4.8%… |

| LA77-2 | GOST 15527 - 2004 | Cu76-79%Zn18.2-22%Al1.7-2.5%… |

| LA77-2u | GOST 15527 - 2004 | Cu76-79%Zn16.77-21.8%Al1.7-2.5%Ni0.3-1%Si0.03-0.2%Fe0.03-0.1%Mn0.03-0.1%P0.005-0.02%… |

| LA85-0.5 | TU 48-08-495 - 71 | Cu84-85.6%Zn14-15%Al0.4-0.7%… |

| LAZ60-1-1 | GOST 15527 - 2004 | Cu58-61%Zn34.7-40%Fe0.75-1.5%Al0.7-1.5%Mn0.1-0.6%… |

| LAMsh77-2-0.04 | GOST 15527 - 2004 | Cu76-79%Zn17.98-21%Al1.7-2.5%As0.02-0.04%… |

| LAMsh77-2-0.05 | GOST 15527 - 2004 | Cu76-79%Zn18.14-22%Al1.7-2.5%As0.02-0.06%… |

| LAN59-3-2 | GOST 15527 - 2004 | Cu57-60%Zn32.6-68%Al2.5-3.5%Ni2-3%… |

| LZhMts59-1-1 | GOST 15527 - 2004 | Cu57-60%Zn37.05-41%Fe0.6-1.2%Mn0.5-0.8%Sn0.3-0.7%Al0.1-0.4%… |

| LZhS58-1-1 | GOST 15527 - 2004 | Cu56-58%Zn38.9-42%Fe0.7-1.3%Pb0.7-1.3%… |

| LK62-0.5 | GOST 15527 - 2004 | Cu60.5-63%Zn35.07-38%Si0.3-0.7%… |

| LK75V | GOST 15527 - 2004 | Cu71-78%Zn19.98-27%Si0.25-0.5%… |

| LK80-3 | GOST 15527 - 70, the latest version does not contain the material | Cu79-81%Zn13.5-18%Si2.5-4%… |

| LKBO62-0.2-0.04-0.5 | GOST 15527 - 2004 | Cu60.5-63.5%Zn34.62-38.57%Sn0.03-0.7%B0.03-0.1%Si0.01-0.3%… |

| LKS65-1.5-3 | Cu63.5-66.5%Zn27.5-33%Pb2.5-3.5%Si1-2%… | |

| LMts58-2 | GOST 15527 - 2004 | Cu57-60%Zn35.8-42%Mn1-2%… |

| LMtsA57-3-1 | GOST 15527 - 70, the latest version does not contain the material | Cu55-58.5%Zn35.2-42%Mn2.5-3.5%Al0.5-1.5%… |

| LMsh68-0.05 | GOST 15527 - 2004 | Cu67-70%Zn29.64-32%As0.02-0.06%… |

| LN65-5 | GOST 15527 - 70, the latest version does not contain the material | Cu64-67%Zn26.2-31%Ni5-6.5%… |

| LO60-1 | GOST 15527 - 2004 | Cu59-61%Zn36.5-40%Sn1-1.5%… |

| LO62-1 | GOST 15527 - 2004 | Cu61-63%Zn35.6-38%Sn0.7-1.1%… |

| LO70-1 | GOST 15527 - 2004 | Cu69-71%Zn37.2-30%Sn1-1.5%… |

| LO90-1 | GOST 15527 - 2004 | Cu88-91%Zn8-11.7%Sn0.2-0.7%… |

| LOK59-1-0.3 | GOST 15527 - 2004 | Cu58-60%Zn37.92-40%Sn0.7-1.1%Si0.2-0.4%… |

| LOMsh70-1-0.04 | GOST 15527 - 2004 | Cu69-71%Zn27.08-29.68%Sn1-1.5%As0.02-0.04%… |

| LOMsh70-1-0.05 | GOST 15527 - 2004 | Cu69-71%Zn27.14-29%Sn1-1.5%As0.02-0.06%… |

| LS58-2 | GOST 15527 - 2004 | Cu57-60%Zn34.39-41%Pb1-3%… |

| LS58-3 | GOST 15527 - 2004 | Cu57-59%Zn36.3-40%Pb2.5-3.5%… |

| LS59-1 | GOST 15527 - 2004 | Cu57-60%Zn37.05-42%Pb0.8-1.9%… |

| LS59-1V | GOST 15527 - 2004 | Cu57-61%Zn35.6-42%Pb0.8-1.9%… |

| LS59-2 | GOST 15527 - 2004 | Cu57-59%Zn37.5-41.3%Pb1.5-2.5%… |

| LS60-1 | GOST 15527 - 70, the latest version does not contain the material | Cu59-61%Zn37.5-40%Pb0.6-1%… |

| LS63-3 | GOST 15527 - 2004 | Cu62-65%Zn31.65-35%Pb2.4-3%… |

| LS64-2 | GOST 15527 - 2004 | Cu63-66%Zn31.7-35%Pb1.5-2%… |

| LS74-3 | GOST 15527 - 2004 | Cu72-75%Zn21.75-25%Pb2.4-3%… |

Application

Brass L63 and other alloys of copper and zinc

The main industries in which bronze rods are used are:

- mechanical engineering;

- automotive industry;

- shipbuilding;

- aerospace industry;

- military-defense complex;

- instrument making;

- electrical engineering, etc.

A variety of parts and mechanisms are made from them. Among them:

- elements of mechanisms;

- parts of pumps, valves and sensors;

- shafts and spindles of various configurations;

- components of water and gas pipes and fittings;

- washers, screws and bolts;

- bushings for bearing mechanisms;

- accessories, etc.

The part is made of bronze rod and copes well with the influence of frictional forces on it. They inevitably arise in all functioning mechanisms without exception. Due to the fact that the hardness of the part is not very high, it can protect other more expensive components.

Bar

Brass rod We offer you to buy brass rod in a wide range. The properties of a brass rod depend on the production method, material and chemical composition. It can be made from any brand of brass, but the most widely used are pressed hard and semi-solid circles from inexpensive brass L63 and LS59-1, manufactured according to GOST 2060-2006 with a diameter of 5 to 160 mm. Applications Brass rods are widely used in the automotive, aerospace, watch, instrument, shipbuilding and life support systems industries. All kinds of fasteners, fittings, fittings, and parts of electrical devices are made from brass. Due to the good anti-corrosion properties, malleability, lightness and aesthetics of products made from various brass alloys, brass rods are sold in a wide range to satisfy the most highly specialized needs of a particular industry. Technical instructions • The production of brass rods from brass alloys of grades LS59-1, LO62-1, L63, LZhS58-1-1, LZhMts59-1-1, LMts58-2, LO62-1, LS63-3LAZH, 60-1-1 is regulated according to GOST standards. The main document regulating the production of square, round and hexagonal brass rods is GOST 2060-2006. • For other grades of alloys, various types of Technical Instructions are used

For the alloy LS58-2, for example, TU 48-21-5010-77 is taken into account, and for MtsSKA58-2-2-1-1 standardization takes place according to TU 48-21-356-74. In short, the range of different brass rods is extremely wide, and in this area there are constantly additions

Here you can find out prices for brass rods made of the alloy you are interested in, or buy brass rods of the class you need. Classification of brass rods Brass rods are manufactured using different technologies. They are: • Drawn • Pressed Brass products are distinguished by a wide selection of different sections: • Round • Square • Hexagonal • Rectangular Brass rods are made from alloys of different hardness: • Soft (annealed) • Semi-hard • Hard. They are distinguished: Brass rods for automatic processing. You can buy brass rods with antimagnetic properties. Marking Based on the presented classification, the marking corresponds to the following form: • Product name: Rod • Manufacturing technology: D – drawn and cold-deformed, G – pressed and hot-deformed. • Section shape: KV, KR, SHG, PR • Requirements for accuracy: normal accuracy - or N, P - increased, V - high. • Hardness: M, PT, T. • Diameter: indicated in mm. • Length with indication of dimension: unmeasured - ND, multiple of the size - KD, in a coil - BT. • Alloy: one of the above. • Scope of application: AB – automatic, AM – antimagnetic. Standard: GOST 52597-2006, GOST 2060-2006 or TU. The application can be sent by email or by phone;

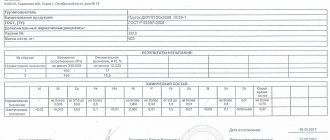

| 1 | Name | Unit. | Weight | |

| 2 | Rod LMTs58-2 | f20 | kg | 204,00 |

| 3 | Rod LMTs58-2 | f25 | kg | 350,00 |

| 4 | Rod LMTs58-2 | f30 | kg | 145,00 |

| 5 | Rod LMTs58-2 | f35 | kg | 90,00 |

| 6 | Rod LMTs58-2 | f38 | kg | 190,00 |

| 7 | Rod LMTs58-2 | f45 | kg | 70,00 |

| 8 | Rod LMTs58-2 | f50 | kg | 100,00 |

| 9 | Rod LMTs58-2 | F55 | kg | 150,00 |

| 10 | Rod LMTs58-2 | f60 | kg | 350,00 |

| 11 | Rod LMTs58-2 | F80 | kg | 260,00 |

| 12 | Rod LMTs58-2 | f90 | kg | 345,00 |

| 13 | Rod LMTs58-2 | f100 | kg | 115,00 |

| 14 | Rod LMTs58-2 | f110 | kg | 635,00 |

| 15 | Rod LMTs58-2 | f120 | kg | 365,00 |

| 16 | Rod LMTs58-2 | f130 | kg | 220,00 |

| 17 | Rod LMTs58-2 | f140 | kg | 520,00 |

| 18 | Rod LMTs58-2 | f150 | kg | 760,00 |

| 19 | Rod LMTs58-2 | f160 | kg | 126,00 |

| 20 | Rod LMTs58-2 | f170 | kg | 285,00 |

| 21 | Rod LMTs58-2 | f180 | kg | 290,00 |

| 22 | Rod LMTs58-2 | f200 | kg | 490,00 |

| 23 | Rod L90 | f30 | kg | 155,00 |

| 24 | Rod L90 | f40 | kg | 150,00 |

| 25 | Rod L90 | f50 | kg | 350,00 |

| 26 | Rod L90 | f60 | kg | 270,00 |

| 27 | Rod L90 | f70 | kg | 250,00 |

| 28 | Rod L90 | f80 | kg | 280,00 |

| 29 | Rod L90 | f90 | kg | 240,00 |

| 30 | Rod L90 | f100 | kg | 160,00 |

| 31 | Rod L90 | f110 | kg | 550,00 |

| 32 | Rod L90 | f120 | kg | 710,00 |

| 33 | Rod L90 | f125 | kg | 125,00 |

| 34 | Rod L90 | f130 | kg | 70,00 |

| 35 | Rod L90 | f140 | kg | 1 650,00 |

| 36 | Rod L90 | f150 | kg | 260,00 |

| 37 | Rod L90 | f160 | kg | 240,00 |

| 38 | Rod L90 | f170 | kg | 1 100,00 |

| 39 | Rod L90 | f190 | kg | 110,00 |

| 40 | Rod L90 | f200 | kg | 2 850,00 |

| 41 | Rod L90 | f220 | kg | 650,00 |

| 42 | Rod L90 | f240 | kg | 310,00 |

| 43 | Rod L90 | f250 | kg | 750,00 |

Other alloys from the category Pressure-processed brass

| Alloy grade | GOST | Chem. compound |

| CuZn36Pb2As | GOST R 52922 - 2008 | Cu61-63%Zn33.5-37.08%Pb1.7-2.8%As0.02-0.1%… |

| CuZn39Pb3 | GOST R 52922 - 2008 | Cu57-59%Zn36.65-40%Pb2.5-3.5%… |

| L59 | Cu57-60%Zn39.1-43%… | |

| L60 | GOST 15527 - 2004 | Cu59-62%Zn37-41%… |

| L63 | GOST 15527 - 2004 | Cu62-65%Zn34.22-37%… |

| L66 | Cu64.5-67.5%Zn32.13-35%… | |

| L68 | GOST 15527 - 2004 | Cu67-70%Zn29.7-33%… |

| L70 | GOST 15527 - 2004 | Cu69-71%Zn28.6-30%… |

| L75 | Cu75-75%Zn24.7-25%… | |

| L75mk | GOST 15527 - 2004 | Cu70-76%Zn23.1-29.47%Si0.25-0.5%Ni0.1-0.25%Mn0.05-0.15%Fe0.03-0.06%P0.005-0.02%… |

| L80 | GOST 15527 - 2004 | Cu79-81%Zn18.7-21%… |

| L85 | GOST 15527 - 2004 | Cu84-86%Zn13.7-16%… |

| L90 | GOST 15527 - 2004 | Cu88-91%Zn8.8-12%… |

| L96 | GOST 15527 - 2004 | Cu95-97%Zn2.66-4.8%… |

| LA77-2 | GOST 15527 - 2004 | Cu76-79%Zn18.2-22%Al1.7-2.5%… |

| LA77-2u | GOST 15527 - 2004 | Cu76-79%Zn16.77-21.8%Al1.7-2.5%Ni0.3-1%Si0.03-0.2%Fe0.03-0.1%Mn0.03-0.1%P0.005-0.02%… |

| LA85-0.5 | TU 48-08-495 - 71 | Cu84-85.6%Zn14-15%Al0.4-0.7%… |

| LAZ60-1-1 | GOST 15527 - 2004 | Cu58-61%Zn34.7-40%Fe0.75-1.5%Al0.7-1.5%Mn0.1-0.6%… |

| LAMsh77-2-0.04 | GOST 15527 - 2004 | Cu76-79%Zn17.98-21%Al1.7-2.5%As0.02-0.04%… |

| LAMsh77-2-0.05 | GOST 15527 - 2004 | Cu76-79%Zn18.14-22%Al1.7-2.5%As0.02-0.06%… |

| LAN59-3-2 | GOST 15527 - 2004 | Cu57-60%Zn32.6-68%Al2.5-3.5%Ni2-3%… |

| LZhMts59-1-1 | GOST 15527 - 2004 | Cu57-60%Zn37.05-41%Fe0.6-1.2%Mn0.5-0.8%Sn0.3-0.7%Al0.1-0.4%… |

| LZhS58-1-1 | GOST 15527 - 2004 | Cu56-58%Zn38.9-42%Fe0.7-1.3%Pb0.7-1.3%… |

| LK62-0.5 | GOST 15527 - 2004 | Cu60.5-63%Zn35.07-38%Si0.3-0.7%… |

| LK75V | GOST 15527 - 2004 | Cu71-78%Zn19.98-27%Si0.25-0.5%… |

| LK80-3 | GOST 15527 - 70, the latest version does not contain the material | Cu79-81%Zn13.5-18%Si2.5-4%… |

| LKBO62-0.2-0.04-0.5 | GOST 15527 - 2004 | Cu60.5-63.5%Zn34.62-38.57%Sn0.03-0.7%B0.03-0.1%Si0.01-0.3%… |

| LKS65-1.5-3 | Cu63.5-66.5%Zn27.5-33%Pb2.5-3.5%Si1-2%… | |

| LMts58-2 | GOST 15527 - 2004 | Cu57-60%Zn35.8-42%Mn1-2%… |

| LMtsA57-3-1 | GOST 15527 - 70, the latest version does not contain the material | Cu55-58.5%Zn35.2-42%Mn2.5-3.5%Al0.5-1.5%… |

| LMsh68-0.05 | GOST 15527 - 2004 | Cu67-70%Zn29.64-32%As0.02-0.06%… |

| LN65-5 | GOST 15527 - 70, the latest version does not contain the material | Cu64-67%Zn26.2-31%Ni5-6.5%… |

| LO60-1 | GOST 15527 - 2004 | Cu59-61%Zn36.5-40%Sn1-1.5%… |

| LO62-1 | GOST 15527 - 2004 | Cu61-63%Zn35.6-38%Sn0.7-1.1%… |

| LO70-1 | GOST 15527 - 2004 | Cu69-71%Zn37.2-30%Sn1-1.5%… |

| LO90-1 | GOST 15527 - 2004 | Cu88-91%Zn8-11.7%Sn0.2-0.7%… |

| LOK59-1-0.3 | GOST 15527 - 2004 | Cu58-60%Zn37.92-40%Sn0.7-1.1%Si0.2-0.4%… |

| LOMsh70-1-0.04 | GOST 15527 - 2004 | Cu69-71%Zn27.08-29.68%Sn1-1.5%As0.02-0.04%… |

| LOMsh70-1-0.05 | GOST 15527 - 2004 | Cu69-71%Zn27.14-29%Sn1-1.5%As0.02-0.06%… |

| LS58-2 | GOST 15527 - 2004 | Cu57-60%Zn34.39-41%Pb1-3%… |

| LS58-3 | GOST 15527 - 2004 | Cu57-59%Zn36.3-40%Pb2.5-3.5%… |

| LS59-1 | GOST 15527 - 2004 | Cu57-60%Zn37.05-42%Pb0.8-1.9%… |

| LS59-1V | GOST 15527 - 2004 | Cu57-61%Zn35.6-42%Pb0.8-1.9%… |

| LS59-2 | GOST 15527 - 2004 | Cu57-59%Zn37.5-41.3%Pb1.5-2.5%… |

| LS60-1 | GOST 15527 - 70, the latest version does not contain the material | Cu59-61%Zn37.5-40%Pb0.6-1%… |

| LS63-3 | GOST 15527 - 2004 | Cu62-65%Zn31.65-35%Pb2.4-3%… |

| LS64-2 | GOST 15527 - 2004 | Cu63-66%Zn31.7-35%Pb1.5-2%… |

| LS74-3 | GOST 15527 - 2004 | Cu72-75%Zn21.75-25%Pb2.4-3%… |