Aluminum injection molding is one of the popular metal processing processes, from which products of any desired (even the most complex) configuration are created using exposure to high temperatures. Aluminum die casting is used in production to create high-quality, durable and reliable parts with unique properties.

The described process is one of the fully mechanized manipulations, during which molten metal is fed into a special split mold under artificially created pressure using a piston moving at a fairly high speed.

This method of casting guarantees no shrinkage and a high level of precision in the work. In the process of such creation of parts, the existence of defective products is practically excluded. This is one of the most important advantages of the described process. Parts and other products created in this way have found application in:

- instrument making;

- mechanical engineering;

- aircraft manufacturing

Aluminum is a soft but very durable metal that is difficult to process in various ways, but has a fairly low melting point, which allows it to be cast even at home or in a small workshop. Of course, the most accurate, streamlined process is possible when using professional equipment installed in production workshops.

Preparation for the process

In the aluminum die casting process, molten metal is poured into specially prepared molds by forcing it through a piston.

Aluminum casting process

A piston moving at high speed prevents the hot metal from changing its intended shape and completely eliminates air bubbles from its mass, ensuring no shrinkage.

The distribution of the hot mass of liquid aluminum occurs rapidly, the prepared mold is filled very quickly, after which the entire mass that filled it gradually hardens, exactly repeating the established configuration of the part.

When producing elements with cavities, machines are used that are equipped with special pistons that allow penetration into the filled mold.

The process of injection molding of aluminum alloys has become widespread, and parts manufactured in this way are in great demand due to the high malleability and ductility of the source material.

During work, so-called molds are used, in which the process of aluminum injection molding is carried out.

Aluminum casting at home

Aluminum casting can be carried out not only in industrial production conditions, but even at home. All that is needed for this is to select a form suitable in volume and create space for preparing the material.

Casting is carried out in several stages:

- preparation of source material - removing dirt from the workpiece, grinding scrap into small parts;

- direct smelting of aluminum;

- filling (filling) the mold with the required volume of material.

How to melt aluminum? As mentioned earlier, for melting it is necessary to reach a temperature of approximately 650°C. This is only possible in a confined space, since an open flame will not allow achieving such a value. Therefore, a homemade oven is quite suitable for production.

It's quite simple to do:

- take a container, for example a pan;

- make a hole on the side into which to place a pipe (in this case, a pipe from a vacuum cleaner is suitable, which will supply air, thereby maintaining the flame);

- A mold for smelting is placed inside a homemade furnace, filling it with coal around the perimeter;

- after lighting the coal, it is necessary to constantly pump in air so that the flame does not go out; The lid should not be closed tightly, leaving room for smoke to escape.

Features of the production process

Aluminum die casting is used in production to produce parts of various sizes and shapes, as well as other castings. During the production process, molten aluminum heated to a temperature of 600˚ Celsius is fed under high pressure into a steel mold.

Press form

The main distinctive features and features of casting carried out in production workshops:

- rapid heating of the metal to the melting point;

- accurate supply of a certain amount of raw materials intended for casting;

- full automation of the production process;

- creating sufficiently high pressure to perform quality work.

All this allows us to obtain high-quality parts and components of machines and devices, manufactured with high precision and in the shortest possible time. Another distinctive feature that can be recognized as an advantage of manufacturing parts from aluminum using injection molding is high productivity with minimal labor intensity of the process.

Manufacturers take advantage of these positive qualities to create a large number of high-quality parts of various configurations intended for use in a wide variety of industrial applications.

The inherent advantage of aluminum injection molding also lies in the fact that the components of devices and other elements manufactured in this way practically do not require additional processing carried out mechanically.

To carry out all the necessary operations, the use of aluminum injection molding machines used in production workshops is especially popular among manufacturers.

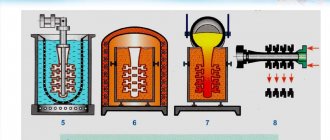

These are machines equipped with a compression chamber:

- hot;

- cold.

Many enterprises widely use horizontally installed cold pressing chambers into which molten aluminum is fed under pressure.

Die casting of non-ferrous metals

Casting materials

The following materials can be used:

- sand molds - when making it, it is necessary to choose the finest sand so that the surface of the cast part is as smooth as possible, without roughness and unevenness, as well as high quality clay. In this case, the ratio of clay and sand is determined by the quality and density of the materials. It is worth noting that sand casting is a very complex technology that requires certain skills and abilities. In addition, after casting into a sand mold, reprocessing of the part is necessary;

- polystyrene foam is one of the simplest solutions. First you need to prepare a mold for filling that follows the contour of the part. Then place it in a mold made of gypsum material. This method also requires further processing and preparation of the part for use, but much less than in the first technology;

- cement mortar is the simplest way. However, its main disadvantage is the fact that the shape can be exclusively square or rectangular;

- steel materials are a method actively used in industrial production, including in the casting of parts under pressure, which was described above.

Aluminum casting can be carried out both industrially and at home. This can be explained by its properties, including lightness and relative softness, which make working with the material quite simple. However, in order to achieve the highest quality of the manufactured part, it is necessary to know the properties of this metal and follow the rules for its processing.

Rate this article:

Rating: 0/5 — 0 votes

Variety and use of alloys, required machines and molds

Products made of aluminum alloys are in high demand:

- Silumin is an alloy of aluminum and silicon. After adding magnesium to its composition, the final product becomes extremely durable. This is one of the most low-shrinkage and highly airtight alloys. It is not subject to cracking during manufacture and is used to create elements subject to light loads.

- In order to create shaped castings, an alloy is used, which, in addition to aluminum itself, includes copper, silicon and iron. This workpiece is perfectly separated from the mold and is highly durable.

- When creating high-strength elements, an aluminum alloy with the addition of silicon, nickel, copper and zinc is used.

A particular alloy is selected depending on the tasks to be performed by the manufactured parts and the loads that the finished elements will have to withstand.

All operations are carried out on specially created equipment, which can be used both in a production workshop and in a small private workshop.

Using special equipment for aluminum casting, you can create items necessary in everyday life and parts that are very important when assembling various machines and units.

To create the above alloys, it is necessary to use machines equipped with both cold and hot chambers designed to melt the metal. Machines with hot chambers are necessary in the production of alloys containing zinc. The molten metal is introduced into the internal space of the mold gradually. He fills out the entire form.

When working with alloys that contain magnesium and copper, castings are produced due to the fact that the molten composition is introduced into the mold under fairly high pressure. Its level in certain situations reaches 700 MPa. It is this production method that makes it possible to significantly increase labor productivity without increasing the labor intensity of the process, and parts manufactured in this way do not require mechanical processing.

The choice of equipment when creating a workshop or organizing a casting process is based on the characteristics of the technological process. When casting aluminum under pressure, it is as follows:

- In a hot furnace, the metal is heated to the melting point and turns into a liquid state.

- At this time, a special mold must be prepared in the workshop, the internal contour of which fully corresponds to the parameters of the future part.

- Molten metal is fed under high pressure into a prepared mold.

- After cooling, the finished product is removed from the split mold.

Aluminum product in a mold

Today, some manufacturers use other casting methods. This can be casting into earth, sand or cement, but aluminum injection molding makes it possible to obtain a product with a minimum wall thickness of less than a millimeter. And everything can reach from 4 to 12 kg.

What is metal casting and how can you make money from it?

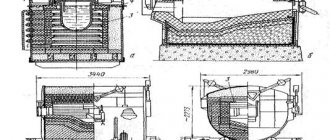

Casting is one of the methods of processing various metals. With it you can create objects of different sizes and configurations. This is the simplest and most affordable method, which is carried out using special equipment. Now many manufacturers offer mini construction.

Mini foundry

This means that an individual project of the production complex will be developed, the layout of the workshops, the placement of equipment, and the provision of all necessary communications.

Why is it beneficial to pay attention to ready-made turnkey complexes? Because:

- manufacturers accurately calculate the required production area;

- place communications as efficiently as possible;

- provide a full range of equipment setup services;

- By purchasing, you can immediately begin the production process.

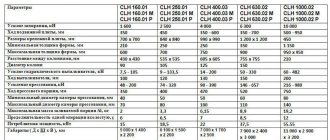

Technical characteristics of foundry equipment

If the choice is made in favor of such a complex, then the next step in organizing a business will be to search for customers. Die-cast metal products are in great demand in almost all industries:

Sheet metal bending

- machine tool industry;

- automotive industry;

- instrument making;

- production of household appliances;

- shipbuilding;

- production of medical and dental equipment;

- jewelry art;

- production of home and garden decor items;

- construction materials industry.

The advantages of a mini-factory are its compact size and the ability to produce products in small batches. Often large enterprises are forced to refuse small wholesale customers, since reconfiguring equipment is quite problematic.

A mini-factory is an automated complex: in order to switch to a new type of manufactured products or metal blanks, you only need to make changes to the software package and make new molds. And the cost of non-standard parts made to order is several times higher than standard production.

Foundry

Another advantage of the mini ones is that they are designed so that they can process all types of metals, while the large-scale lines have separate workshops for this.

Devices

Aluminum die casting machines have a number of special technical characteristics. Knowing some parameters and choosing the most suitable equipment to work on:

- Performance. The cost of an aluminum die casting machine directly depends on how many parts it can produce in one hour and, when used in production mode, in 8-10 working hours. The higher the productivity, the higher the cost of the machine.

- Mass of castings. This characteristic also depends on what pumps, engines, pistons and tips the device should be equipped with.

- Dimensions and weight of equipment. The choice depends entirely on the size of the production facility and the total production area.

Machines designed for aluminum injection molding are directly related to large-scale production equipment, although modern manufacturers also offer equipment designed for use in mini-factories. The cost of the car plays a big role in the choice. It is based on the combination of all the above qualities that equipment used both in production and in a small workshop must have.

Most modern models of aluminum die casting machines are equipped with a computer unit, numerous sensors capable of reading and analyzing data on operations, and a high-quality hydraulic system. You can make the right choice only by comparing the capabilities of the purchased equipment and the user’s needs.