Structural changes in metal

When heating special structural steel 45 to the austenitic level, the state of the structural lattice of iron changes with a transition from a body-centered to a face-centered structure. The carbon included in pearlite and representing the smallest crystals of Fe3C (cementite) moves into a face-centered modified iron lattice.

Structure of steel 45 after annealing and hardening

During cooling, the temperature of the steel being processed rapidly decreases, but due to the slowdown in the speed of movement of carbon atoms, they remain embedded in the new iron lattice, forming a solid supersaturated structure with internal stress. The lattice is transformed into a tetragonal lattice with orientation in one direction.

The formation of needle-shaped small structures called martensite occurs. This type of crystal gives the metal high strength, hardness and improved characteristics. Two types of austenite and martensite crystals are simultaneously formed, which act on each other, creating internal excess stress. When external forces actively influence the metal, mutual compensation of the two types of crystals occurs, imparting strength to the structure.

Foreign analogues steel 45

| USA | 1044, 1045, 1045H, G10420, G10430, G10440, G10450, M1044 |

| Germany | 1.0503, 1.1191, 1.1193, C45, C45E, C45R, Cf45, Ck45, Cm45, Cq45 |

| Japan | S45C, S48C, SWRCH45K, SWRCH48K |

| France | 1C45, 2C45, AF65, C40E, C45, C45E, C45RR, CC45, XC42H1, XC42H1TS, XC45, XC45H1, XC48, XC48H1 |

| England | 060A47, 080M, 080M46, 1449-50CS, 1449-50HS, 50HS, C45, C45E |

| European Union | 1.1191, 2C45, C45, C45E, C45EC, C46 |

| Italy | 1C45, C43, C45, C45E, C45R, C46 |

| Belgium | C45-1, C45-2, C46 |

| Spain | C45, C45E, C45k, C48k, F.114, F.1140, F.1142 |

| China | 45, 45H, ML45, SM45, ZG310-570, ZGD345-570 |

| Sweden | 1650, 1672 |

| Bulgaria | 45, C45, C45E |

| Hungary | A3, C45E |

| Poland | 45 |

| Romania | OLC45, OLC45q, OLC45X |

| Czech | 12050, 12056 |

| Austria | C45SW |

| Australia | 1045, HK1042, K1042 |

| Switzerland | C45, Ck45 |

| South Korea | SM45C, SM48C |

- Structural steel

- Tool steel

Heat treatment of metal

To change the characteristics of steel, heat treatment is carried out in compliance with the necessary exposure modes.

The heat treatment process consists of the following processes:

- annealing;

- normalization;

- aging;

- hardening and tempering.

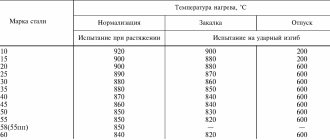

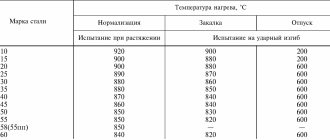

Heat treatment modes for steel 45

Hardening and tempering of steel largely depends on a number of factors:

- temperature conditions;

- rate of temperature increase;

- time period of exposure of metal to high temperatures;

- cooling process (rate of change in cooling temperature of a medium or liquid).

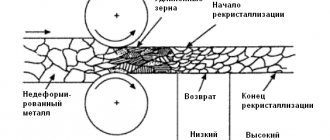

Types of annealing

It is customary to divide this operation into two main types. Annealing of steel can be of the 1st and 2nd type. In the first case, phase recrystallization does not occur, but the metal acquires the desired qualities. The consequences of mechanical processing of metal in rolling mills and dies are eliminated.

Hardening of the steel surface after physical impact at a metallurgical plant is called cold hardening.

The main purpose of annealing steel of the 1st type is to reduce strength and increase ductility necessary for further processing. Partial recrystallization reduces internal stresses, which makes products more reliable and durable.

Annealing of type 2 steel is characterized by dramatic changes in the structure. Phase recrystallization is achieved by heating the metal above critical points and precisely implementing the cooling regime in temperature and time. These types of annealing and their purpose are determined by production tasks to obtain the necessary qualities of the metal. Critical temperatures are a serious risk factor. In some cases, for example, when burned, irreversible changes in the structure occur. This metal is sent for smelting. Heat treatment, annealing and normalization of steels is a complex process that makes it possible to obtain products from initial raw materials that meet the requirements of manufacturers of final products according to the specified characteristics.

Steel hardening

The steel hardening process involves heat treatment of workpieces with heating to a temperature above critical with further acceleration of cooling. This condition helps to increase the strength and hardness (HRC) of steel while reducing ductility and improving consumer characteristics.

The mode of influence of the metal cooling temperature depends on the amount of carbon content and alloying additives in the steel.

After hardening the steel, the workpieces are covered with a coating of scale and partially lose the carbon they contain, so the technology must be followed in accordance with the established regulations.

Cooling of the metal must occur quickly to prevent the transformation of austenite into sorbitol or troostite. Cooling must be carried out exactly according to the schedule; rapid cooling of the workpieces leads to the formation of small cracks. During the cooling process from 200 °C to 300 °C, an artificial slowdown occurs as the products gradually cool down; for this, coolants can be used.

Steel cementation - the essence of the process

The chemical-thermal method of processing steel is a change in the composition of the material in a certain layer. It is this method that steel carburization refers to. At its core, this steel processing process consists of enriching its surface with a certain amount of carbon when heated in a certain chemical environment. Using this technique, a product with a set of very useful properties - a hard surface layer on a soft inner one. Thus, the soft core layer resists impacts quite well, and the outer layer of the part, on the contrary, has good hardness and increased wear resistance. An ideal combination that allows parts made using this method to work for a long time and be very reliable.

The process of steel carburization is especially effective in cases where it is low-carbon types that are enriched. As a rule, such a metal contains no more than 0.2% carbon. However, for medium-carbon steel grades this procedure also brings positive results. The technological process is relatively simple: a special environment is created in a special chamber, capable of releasing a large amount of active carbon when heated to a certain temperature (approximately in the range from 850°C to 950°C). It should be noted that steel carburization is a rather lengthy technical process . Typically, the saturation rate of a metal surface, at which it acquires specific properties, is approximately 0.1 mm per hour. For high-quality processing of the product and its reliable operation, a cementitious layer of approximately 0.8 mm or more is required. And, therefore, for effective carburization of steel it will take at least 8 hours. The main media (or carburizers, as they are also called) for this process are:

- solid medium;

- gas environment;

- pasty medium;

- a medium consisting of electrolyte solutions;

- fluidized bed

Hardening steel using HDTV

When carrying out surface hardening using high-frequency frequencies, the process of heating products is carried out to a higher temperature.

This is caused by two factors:

- Heating is carried out in a short time with accelerated change and transition of pearlite to austenite.

- The transition reaction must be carried out in a short time within a short period of time at high temperature.

Hardening with high-frequency currents

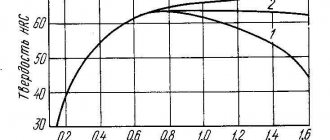

The processes occurring during conventional hardening in a furnace using high-frequency frequencies have different characteristics and lead to a change in the hardness (HRC) of the workpieces:

- When heated in an oven, the speed is 2-3 °C/sec up to 840 – 860 °C.

- Using HDTV - 250 °C/sec to a temperature of 880 - 920 °C or in mode at 500 °C/sec - up to 980 - and 1020 °C.

When using HDTV, parts are heated to a higher temperature, but the workpiece does not overheat. In the process of processing using HDF, the heating operation time is significantly reduced, which helps maintain grain size and structure. During the high-frequency hardening operation, the metal hardness (HRC) increases by 2-3 units. according to Rockwell.

Introduction to Metals Technology

The steel we deal with most often is an alloy of iron and carbon.

The most widespread are structural steels of ordinary quality. They contain a small amount of carbon (less than 0.8%), so any attempts to harden products made from such material are doomed to failure. A small amount of carbon does not form grains of cementite (iron carbide, Fe₃C). It is this ingredient that is responsible for producing the hardness of hardened steel.

In addition to structural steel, metallurgical enterprises produce steel of specified properties, including carbon alloys. Their carbon content is in the range of 0.8...2.14%. With a higher content of the second component, you have to deal with cast iron. This is also a ferrous metal, but the properties are radically different.

Checking the production of austenite when heated using a magnet:

When producing metal products, plastic materials are used. Using the pressing method, special original shapes are obtained. For example, car body parts are cold stamped using special dies. This tool consists of a matrix and a punch. The sheet blank is compressed between the components (die and punch) to obtain the final shape.

The tool requires hardness, so during manufacturing, a material is chosen that can be hardened so that it does not deform in the future during use for stamping parts.

Hardened products from high-quality alloy steels:

In addition to carbon steels, in practice alloys with manganese, chromium, molybdenum, titanium and other elements are used. Their presence in the composition in a certain quantity is characterized by a certain brand. Components that improve the properties of the alloy are called alloying. They noticeably change the properties:

- Increases surface strength.

- Increases the hardness of parts at the blank stage.

- Can be hardened during hardening.

- Do not rust when exposed to aggressive environments.

Alloy steels are marked using their own method, in which certain alloy metals are designated by their own letters. The numbers after the letters indicate the content of a particular component in tenths of a percent. If it has only a letter, and no numbers follow it, then the ingredient can reach up to 1% in the alloy. For example, chronic hepatitis is characterized by the presence of:

- about 1% carbon;

- 0.8...1.2% chromium (X), this component gives stainless properties;

- 0.9...1.1% tungsten (B), this ingredient increases hardness and allows you to harden products;

- 0.8...1.4% manganese (G, that’s what the metallurgists agreed upon). Mn in steel imparts spring properties.

Attention! HVG is one of the best steels for making knives. Features stainless steel properties. When hardening, a high hardness value can be achieved. At tool factories, cutters, broaches and broaches are made from this material.

Application of protective measures

During the heat treatment process, carbon gradually burns out and scale forms. To prevent deterioration of the quality of the metal and protect it, shielding gases are used, which are pumped during the hardening process. Ammonia or methane gas is pumped into the furnace, which has a sealed chamber, where heat treatment occurs using a special generator.

In the absence of sealed furnaces, processing operations are carried out in a special sealed container, into which cast iron shavings are first poured to prevent carbon burnout.

When processing workpieces in salt baths, the metal is protected from oxidation, and to create the necessary conditions for maintaining the carbon level, the contents of the bath are deoxidized 2 times during the day with boric acid, blood salt or borax. At processing temperatures in the temperature range of 760-1000 °C, charcoal can be used as a deoxidizing agent.

Types of metal that can be processed

There are three main groups of metal used for hardening:

- Steel with non-hardening core. This group includes the following grades of steel suitable for cementing - 20, 15 and 10. These parts are small in size and are used for use in domestic conditions. During hardening, austenite is transformed into a ferrite-pearlite mixture.

- Steel with a weakly hardened core. This group includes metals of such grades as 20Х, 15Х (low-alloy chromium steels). In this case, an additional ligation procedure is performed using small doses of vanadium. This ensures a fine grain, which results in a more ductile and ductile metal.

- Steel with a highly hardened core. This type of metal is used for the manufacture of parts with complex configurations or large cross-sections that can withstand various shock loads and are exposed to alternating current. During the hardening process, nickel is introduced or, if it is deficient, manganese is used, while small doses of titanium or vanadium are added to crush the grain.

Use of special coolants

During the technological process, water is mainly used to cool parts. The quality of the coolant can be changed by adding soda or special salts, which can affect the cooling process of the workpiece.

To preserve the hardening process, it is strictly forbidden to use the water contained in it for extraneous operations. The water must be clean and have a temperature of 20 to 30 °C. It is forbidden to use running water to harden steel.

Composition of mixtures of salts and alkalis used as quenching media

This hardening method is used only for cemented products or those with a simple shape.

Products with complex shapes made from special structural steel are cooled in a 5% caustic soda solution at a temperature of 50-60 °C. The hardening operation is carried out in a room equipped with exhaust ventilation. Mineral oils are used to harden workpieces made of high-alloy steel, and the cooling rate in an oil bath does not depend on the oil temperature. Mixing oil and water is unacceptable, as this can lead to cracks in the metal.

When quenching in an oil bath, a number of rules must be followed:

- Be careful not to ignite the oil.

- When the metal cools in the oil, harmful gases are released (exhaust ventilation is required).

- Plaque forms on the metal.

- Oil loses its properties when intensively used to cool metal.

When carrying out the hardening process of steel 45, it is necessary to follow the technological process in compliance with all operations.

Processing methods for steel grade 40x

The material does not weld well. To eliminate this drawback, heat treatment is used. With its help, you can obtain a more universal alloy and improve its technical characteristics. Heat treatment is carried out in several stages:

- Hardening. Carried out in an oil environment. Necessary for improving the quality of structure surfaces.

- Cooling the part. This can be done with oil or in air. It is better to use oil, as it improves the quality of the processed workpiece. If water is used, defects may appear.

- Vacation. With its help, the internal stress of the metal is eliminated. This can be done in air or with oil.

If the heat treatment was carried out correctly, the hardness increases to 217 HB. This reduces internal tension. Quenching is carried out at a temperature of 860 °C, tempering - at 200 °C. If the temperature regime has not been violated, the service life of the alloy increases.

The field of heat treatment improves the weldability of the metal; to obtain a high-quality seam, the joint must be heated before applying welding.

Steel 40x has a high cost due to the complexity of production and additional heat treatment. Alloy metal is more often used for the production of parts that are subject to heavy loads for a long time.

Heat treatment features

Heat treatment is carried out to improve the mechanical properties of 40 steel, mainly to increase strength and surface hardness. It consists of a set of operations, as a result of which the internal structure of the alloy changes. The material is subjected to strong heating, so heat treatment technology must take into account the characteristics of the alloy, for example:

- melting temperature of steel 40X;

- its chemical composition;

- content of impurities that affect the hardness of the metal;

- critical points at which the structure of the alloy changes.

GOST determines the optimal modes:

- steel hardening - oil medium with a temperature of 860 degrees;

- tempering - water or oil at 500 degrees;

- if tempering is carried out at 200 degrees, the hardness increases to 552 MPa.

As a result, the characteristics are improved:

- hardness – up to 217 MPa;

- tensile strength – 980 N/m2;

- impact strength – up to 59 J/cm2.

Slow cooling after tempering leads to brittleness of the steel. This can be avoided by rapid cooling, but this may result in the appearance of internal stresses that cause deformation of the metal. Flock sensitivity, that is, the formation of internal cracks and cavities, can be reduced by evacuation of the heating process and combining it with argon purging.

Specifications of Carbon Steel 45

The hardening process of 40X steel requires special attention, since it is used for the manufacture of parts that experience constant loads, for example, bushings, gears, and bolts. After the procedure, the hardness of the metal increases, but ductility and resistance to impact loads decrease. The ratio of these parameters depends on:

- from the time during which heating occurs to a given temperature;

- holding interval, which determines the uniformity of heating;

- cooling rate.

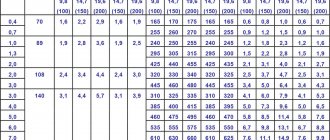

Critical diameter after quenching in various environments

With a maximum hardness of 43 to 46 HRC3 and a martensite content of no more than 50%, the diameter ranges from 16 to 76 mm.

With a critical hardness in the range from 49 to 53 HRC3 and an amount of martensite equal to 90%, the diameter is from 6 to 58 mm.

Within the indicated limits, a rod with a cylindrical cross-section is calcined through.

Steel tempering 45

The technological process of steel tempering is carried out depending on the required temperature:

- in ovens with forced air circulation;

- in special baths with saltpeter solution;

- in oil baths;

- in baths filled with molten alkali.

The temperature for the tempering process depends on the grade of steel, and the process itself changes the structure and helps reduce the stress of the metal, and the hardness decreases by a small amount. After all operations, the workpiece is subjected to technical control and sent to the customer.

When hardening and tempering metal at home, it is necessary to strictly observe the technology and safety precautions for carrying out work.