02/09/2021 Author: VT-METALL

Issues discussed in the material:

- Description of non-ferrous metals

- Groups of non-ferrous metals

- Scope of application of non-ferrous metals

- Processing of non-ferrous metals

- Specifics of mechanical processing of non-ferrous metals

- Turning of non-ferrous metals

- Advantages of turning non-ferrous metals

- Specifics of operations carried out on turning units

- Units for turning non-ferrous metals

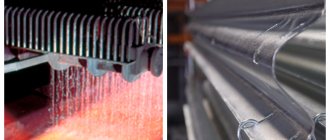

Turning of non-ferrous metals is widespread among all the various methods of manufacturing parts with given geometric parameters. The essence of this type of processing is that the required layer of metal is removed from the workpiece using a cutting tool, while observing the required dimensions and surface roughness parameters.

Metal products can be processed using various methods, as a result of which parts are obtained from blanks that are suitable in size and other parameters for various mechanisms. To perform them on lathes, you need multifunctional devices and cutting tools in the form of cutters, with which you can produce parts of various geometric shapes and configurations.

History and origin of the name

Discovered in 1778 by the Swedish chemist Karl Scheele, who, by calcining molybdic acid, obtained the oxide MoO3.

It was first obtained in the metallic state by P. Guelm in 1782 by reducing the oxide with coal: he obtained molybdenum contaminated with carbon and molybdenum carbide. Pure molybdenum was obtained by J. Berzelius in 1817. The name comes from the Greek. μολυβδος, meaning "lead". It is given because of the external similarity of molybdenite (MoS2), the mineral from which molybdenum oxide was first isolated, with lead luster (PbS). Until the 18th century. Molybdenite was not distinguished from graphite and lead luster; these minerals bore the common name “molybdenum”.

Analysis and synthesis

The new metal and its compounds interested chemists of the 19th century. Pure molybdenum did not change at all during storage; it perfectly resisted the action of moisture and air. But this happened only at low temperatures: as soon as it was heated, it began to react with oxygen; at a temperature of about 500°C it turned into an oxide entirely. This, of course, was upsetting. A metal with good physical and mechanical properties and also refractory lost its metallic properties with relatively little heating. This circumstance (together with the difficulty of obtaining molybdenum metal) long delayed the time when this metal found its first practical application.

Compounds of element No. 42 began to be used much earlier. In 1848, the Russian chemist G.V. Struve, together with the Swede L. Svanberg, studied the properties of molybdic anhydride and the acid it forms. They dissolved MoO3 in a concentrated ammonia solution and added wine alcohol to the resulting solution. A canary-yellow precipitate formed—ammonium molybdate. This salt was destined to play a major role in analytical chemistry.

It was during these years that the science of fertility arose, and it was at this time that, thanks to the work of Liebig and other scientists, agricultural chemistry developed quite rapidly. Special factories began to produce fertilizers containing phosphorus and nitrogen. And we immediately needed reagents with which we could easily and accurately determine the content of these elements in various substances.

The ammonium molybdate obtained by Struve and Svanberg turned out to be an excellent reagent for phosphorus - a reagent that completely precipitates phosphorus from solutions, making it possible to determine its content in any products - fats, metals, ores. The reagent turned out to be so good that today it is readily used in analytical laboratories when it is necessary to determine the phosphorus content in a sample.

Ammonium molybdate has found other uses. It turned out that it has a detrimental effect on microorganisms, and they began to use it as a disinfectant. Initially, silk and cotton fabrics were impregnated with this substance only to extend their service life. But later another feature of the effect of this substance on tissue was discovered.

If a fabric soaked in ammonium molybdate is then pulled through a solution of a reducing agent (tin chloride), then depending on the concentration of the reagents, it turns sky blue or blue. This is generally typical for acidic solutions of molybdic acid salts: under the influence of reducing agents they turn blue. This paint is called molybdenum blue, or mineral indigo. Many recipes have been compiled for dyeing fabrics with molybdenum salts not only blue, but also red, yellow, black, and brown. Wool, fur, leather, wood and rubber were dyed with these salts. Molybdenum compounds were used both for the preparation of varnishes and for painting ceramics. For example, porcelain is colored blue with sodium molybdate, and yellow with the same ammonium molybdate. Orange paint made from molybdate and lead chromate is highly prized.

And molybdenum sulfide, from which pencils were made in ancient times, began to be added to clay, coloring ceramic products yellow or red during firing (depending on the amount of MoS2).

Construction materials for turning

Machining of parts during turning is usually carried out in two steps. First, the outer layer of metal (material) is removed from the workpiece being processed and all defects and irregularities in the outer layer are removed with it; this is rough turning. Then, a thin layer of metal is removed from the machined surface in order to obtain the desired size, shape and appropriate surface quality along the outer diameter of the part; this is fine turning.

The machinability of materials by cutting depends on their chemical composition, structure, mechanical and physical properties.

During rough turning, machinability is assessed by the durability, retention of cutting properties and shape of the tool at the appropriate speed and cutting force, and during finishing - by surface roughness, dimensional accuracy of the workpiece being processed, and tool life.

The machinability of metals is determined by methods based on assessing changes in the durability of a cutting tool at different cutting speeds. The permissible cutting speed as a criterion for assessing machinability is used most often, since the cutting speed has a very significant impact on productivity, and therefore on the cost of processing. It is believed that the best machinability is that material which, all other things being equal, allows a higher cutting speed.

The following structural materials are processed on lathes:

- cast iron,

- steel,

- non-ferrous metals and their alloys,

- plastics.

Cast iron is an alloy of iron with carbon (2.14-4.5%) and some amount of silicon, manganese, etc. There are gray, high-strength, malleable and alloy cast irons.

Gray cast iron is marked with the letters SCH and a group of numbers. The letters SCH indicate gray cast iron, the group of numbers indicates the tensile strength σв in MPa·10-1. According to their mechanical properties, gray cast irons are divided into low-strength cast irons from SCh10 to SCh15 and high-strength cast irons from SCh20 to SCh35. For the manufacture of parts, gray cast iron of the SCh15, SCh20, SCh30 grades with a hardness in the range of HB163–255 and less often SCh35 is used.

High-strength cast iron is produced by introducing pure magnesium (0.3-1%) and cerium (up to 0.05%) into liquid gray cast iron. Unlike gray cast iron, high-strength cast iron is marked with the letters HF and a group of numbers. A group of numbers indicates the minimum value of tensile strength in MPa·10-1, for example, grades VC35, VC40, VC45. The hardness of high-strength cast iron varies within the range HB140-360.

Malleable cast iron has high viscosity; denoted by the letters KCH and two groups of numbers. Of these, the first group of numbers indicates the tensile strength in MPa·10-1, and the second - the relative elongation in percent, for example, grades KCh 45-7, KCh50-5. The hardness of malleable cast iron does not exceed HB320.

Alloyed cast irons are produced by introducing alloying elements (chromium, silicon, aluminum, manganese, etc.); they are marked with letters and numbers, for example ChH1, ChH9N5, ChS5Sh, where the letter Ch means cast iron, X, N, C are alloying elements, and the numbers are their content in%; the letter Ш indicates the spherical shape of graphite.

The surface layer of metal (casting skin) with a thickness of 0.15-0.50 mm and a hardness of HB 285-321 has a great influence on the machinability of cutting cast workpieces made of gray cast iron.

As you move away from the surface, the hardness decreases to HB 187-229. The cutting speed of the casting skin is 20-30% lower than the cutting speed of the internal layers of metal. High-temperature annealing of cast iron castings allows you to increase the cutting speed by 1.5-2 times.

Steel is an alloy of iron with carbon (up to 2.14%) and other elements. With increasing carbon content, the mechanical strength of steel increases and, accordingly, its cutting resistance increases.

Carbon steels of ordinary quality are designated by the letters St and numbers in order from 0 to 6 (for example, St3). The higher the number in the brand designation, the more carbon there is in the steel. High-quality carbon steels are designated by numbers, for example grade 08; 10; 15; 20; 25. The numbers indicate the average carbon content in hundredths of a percent. For example, steel 15 contains about 0.15% carbon. The hardness of steel does not exceed HB 230.

Automatic structural steels are designated by letters and numbers, for example, grades A11, A12, A20, A30, AC40, where A is automatic sulfur steel, AC is automatic lead-containing. The tensile strength of these steels is in the range σв=600-800 MPa for cold-drawn and σв=400-750 MPa for hot-rolled, their hardness is НВ160-207. Automatic steels are characterized by a high content of sulfur and phosphorus (up to 0.35%), as well as the presence of lead (up to 0.35%), therefore they are processed better than structural steels.

Alloy steels are designated by numbers and letters, for example grades 20Х, 40ХС, 30ХГН, 20ХНЗА. The first numbers show the average carbon content in hundredths of a percent, and the letters indicate the presence of alloying elements. The numbers after the letters indicate the percentage of alloying elements. The letter A at the end of the brand indicates high-quality steel. The tensile strength of these steels increases from σв=700 MPa (steel 15Х) to σв=1300 MPa (steel 20Х2Н4А).

An increase in the content of certain alloying elements, such as chromium (C), molybdenum (M), vanadium (F), tungsten (V), nickel (N), increases the strength of steels and reduces thermal conductivity, which leads to a deterioration in their machinability. Silicon (C) impairs the machinability of steel due to the formation of silicate abrasive inclusions in it. Workpieces made from coarse-grained steel are processed better than those from fine-grained steel. Symbols of the main alloying elements in grades of metals and alloys are given in Table. 1.

Table 1. Symbols of the main alloying elements in grades of metals and alloys

| Element | Symbol | Accepted designation of elements in grades of metals and alloys | Element | Symbol | Accepted designation of elements in grades of metals and alloys | Element | Symbol | Accepted designation of elements in grades of metals and alloys | |||

| black | colored | black | colored | black | colored | ||||||

| Nitrogen | N | A | — | Cadmium | Cd | CD | CD | Ruthenium | Ru | — | RU |

| Aluminum | Al | YU | A | Cobalt | Co | TO | TO | Samarium | Sm | — | Myself |

| Barium | Va | — | Br | Silicon | Si | WITH | Kr(K) | Lead | Pb | — | WITH |

| Beryllium | Be | L | — | Lanthanum | La | — | La | Selenium | Se | E | ST |

| Bor | IN | R | — | Lithium | Li | — | Le | Silver | Ag | — | Wed |

| Vanadium | V | F | To you | Lutetium | Lu | — | Lum | Scandium | Sc | — | SCM |

| Bismuth | Bi | In and | In and | Magnesium | Mg | Sh | Mg | Antimony | Sb | — | Su |

| Tungsten | W | IN | — | Manganese | Mn | G | Mts(Mr) | Thallium | T1 | — | Tl |

| Gadolinium | Gg | — | Um | Copper | Cu | D | M | Tantalum | Ta | — | TT |

| Gallium | Ga | Gl | Gl | Molybdenum | Mo | M | — | Tellurium | Those | — | T |

| Hafnium | Hf | — | Gf | Neodymium | Nd | — | Nm | Terbium | Tb | — | Volume |

| Germanium | Ge | — | G | Nickel | Ni | N | N | Titanium | Ti | T | TPD |

| Holmium | But | — | GOM | Niobium | Nb | B | Nb | Thulium | Tu | — | TUM |

| Dysprosium | Dy | — | DIM | Tin | Sn | — | ABOUT | Carbon | WITH | U | — |

| Europium | Eu | — | Ev | Osmium | Os | — | OS | Phosphorus | P | P | F |

| Iron | Fe | — | AND | Palladium | Pd | — | front | Chromium | Cr | X | X(Xp) |

| Gold | Au | — | Evil | Platinum | Pt | — | Pl | Cerium | Ce | — | Xie |

| Indium | In | — | In | Praseodymium | Pr | — | Etc | Zinc | Zn | — | C |

| Iridium | Ir | And | AND | Rhenium | Re | — | Re | Zirconium | Zr | C | TsEV |

| Ytterbium | Yb | — | ITM | Rhodium | Rh | — | Rd | Erbium | Er | — | Erm |

| Yttrium | Y | THEM | Mercury | Hg | — | R | |||||

Non-ferrous metals and alloys. Copper, aluminum, zinc, manganese, titanium and other non-ferrous metals are widely used in industry (instrument making, aircraft manufacturing, etc.). However, their alloys are more often used as structural materials. The alloys of non-ferrous metals most often processed on lathes include bronze, brass, aluminum alloys, etc.

Bronze is an alloy of copper with tin, aluminum, manganese, silicon and other elements. Bronze is designated by the letters Br, the initial letters of the main elements included in the alloy, and numbers indicating the average percentage of these elements. For example, the alloy BrO3Ts12S5 contains on average 3% tin (O), 12% zinc (Z), 5% lead (C) and the rest is copper. To improve the machinability of bronzes and improve their anti-friction properties, lead is added to the composition of bronzes.

Brass is an alloy of copper and zinc; denoted by the letter L and a two-digit number indicating the average copper content (the rest is zinc). For example, L62 brass contains 62% copper and 38% zinc. To improve machinability, 1-2% lead (C) is added to brass, and aluminum (A), nickel (H) and other elements are added to increase strength. For example, brass LZhMts59-1-1 contains 59% copper, 1% iron (I), 1% manganese (M), the rest is zinc.

Aluminum alloys are an alloy of aluminum with additives to increase the strength of silicon, manganese, copper and other components. For example, the AK.12 alloy contains 12% silicon, the rest is aluminum; alloy AK21M2.5N2.5 - 21% silicon, 2.5% copper, 2.5% nickel, the rest is aluminum. An alloy of aluminum and silicon (12-13%) with the addition of iron (0.2-0.7%), manganese (0.05-0.5%), calcium (0.07-0.2%), titanium ( 0.05-0.2%), copper (0.03%) and zinc (0.08%) are called silumin.

Plastics as structural materials have low heat resistance (70-150°C) and thermal conductivity, which is 200-300 times less than the thermal conductivity of steel and cast iron. Plastics contain compounds that have abrasive properties, which causes intensive wear of the cutters on the back surface and dulling of the cutting edges.

Hardness of workpieces. The turning method is accompanied by overcoming the various properties of the metal of the workpieces from which the parts are made. Among the various properties of metals, such as brittleness, toughness, hardness, elasticity, ductility, etc., hardness during turning is the determining factor for choosing the turning mode (choice of tool, chip thickness, cutting speed and feed, etc.). In some cases, to improve machinability, steel blanks are subjected to heat treatment.

Heat treatment is one of the most important logical processes used in all branches of mechanical engineering. Heat treatment is the heat treatment of metals and alloys, during which a change occurs in their structure, and therefore properties, mechanical properties, which change over a very wide range.

The heat treatment process consists of three transitions, one after the other: heating to a certain temperature, holding at a given temperature and cooling at different rates from a given temperature to room temperature. Thus, the heat treatment process depends primarily on temperature and time. Consequently, any heat treatment process can be depicted in the form of a graph on which temperature is indicated on the ordinate axis, and time is indicated on the abscissa axis (Fig. 1).

Rice. 1 . Heat treatment schedule

By adjusting the temperature and time, the following types of heat treatment of steel can be carried out: annealing, normalizing, hardening and tempering.

Annealing is a heat treatment process in which a metal is first heated to a certain temperature, held at that temperature, and then slowly cooled, most often in a furnace. As a result of annealing, equilibrium structural components are formed in steel

Annealing is most often a preliminary heat treatment operation carried out to eliminate defects from previous operations (casting, forging, etc.) or to prepare the structure for subsequent cutting or hardening. By annealing, it is possible to change the shape and size of the grains of the steel structure, reduce harmful internal stresses, eliminate the heterogeneity of its chemical composition, as well as work hardening, and thus significantly improve the properties of steel. Depending on the purpose of annealing, its mode is set: heating temperature, holding time, cooling rate.

To obtain a fine-grained structure, complete annealing is carried out. Products (most often made of structural steel) that are overheated during pressure treatment or heat treatment, as well as forgings, rolled products, and shaped castings, are subjected to annealing. This annealing is performed to relieve harmful internal stresses. When grain is refined, the hardness of steel decreases, its viscosity and ductility increase, internal stresses decrease, and machinability improves. Products made from such steel are more reliable during operation.

This annealing does not require high temperature. It is enough to heat the products to a temperature at which the plastic properties of steel appear, i.e. up to 500 - 600°C, maintain at this temperature for some time and then slowly cool along with the oven.

To reduce the holding time, practically annealing is carried out at 650-680°C, i.e. at temperatures below critical (727°C), therefore, structural transformations do not occur during such annealing. This type of annealing is also called low annealing or high tempering.

With low annealing, due to the removal of internal stresses, a slight decrease in the hardness of the product is achieved. Therefore, this type of annealing is sometimes used to reduce the hardness of products in order to improve their machinability on machines. It should be borne in mind that if the steel is annealed to obtain a fine-grained structure or granular cementite, then special annealing is not required to eliminate internal stresses. In the process of carrying out this annealing, internal stresses will also be relieved.

Steel blanks and thin-section products are often produced by stamping, rolling or cold drawing. When steel is processed by pressure in a cold state, it hardens - significant internal stresses are formed in the steel workpieces, it becomes very strong and hard and at the same time: brittle. The structure of cold-worked steel consists of grains elongated in one direction, its crystal lattice is distorted.

In order to eliminate the harmful condition of work hardening, it is necessary to change the structure of the steel, eliminate the distortion of the crystal lattice, and instead of elongated grains, obtain equiaxed grains (with approximately the same axes along and across the grain). This process of restoring the structure; steel is called recrystallization, and the type of heat treatment by which this process is carried out is called recrystallization annealing. This kind of annealing is performed at temperatures of 450-700°C. After a short exposure at the indicated temperatures (to warm up the entire cross-section), the product is cooled in air. As a result of heat treatment, the hardness and strength of steel decrease, but at the same time its toughness and ductility increase

Large ingots of alloy steel, which undergo significant segregation during solidification, are subjected to annealing to eliminate chemical heterogeneity.

Liquation - heterogeneity of steel in chemical composition - can be zonal (in individual parts of the ingot) and intracrystalline or dendritic (within individual crystals). It adversely affects the properties of steel, especially the impact strength in cross sections. Zonal liquation is practically impossible to eliminate. Intracrystalline segregation can be significantly weakened by annealing. The steel is heated to 1100-1200°C, maintained at this temperature for 10-15 hours, after which it is slowly cooled together with the furnace to 200°C. Further cooling is carried out in air. The whole process takes 80-100 hours.

At high temperatures, atoms of sulfur, carbon and other elements slowly move from areas where they are found in large quantities to areas where they are less abundant. Thus, a diffusion process occurs, as a result of which the chemical composition of the steel is leveled. Therefore, such annealing is also called diffusion annealing. As a result of prolonged exposure at high temperatures, the steel acquires a coarse-grained structure, which is easily eliminated during further forging or rolling of the ingot. If the chemical heterogeneity of the steel is not very significant, it can be eliminated by hot pressure treatment of the ingot without preliminary annealing.

Diffusion annealing is used mainly in metallurgical plants producing steel ingots. Some steel castings are also subjected to this annealing, but after diffusion annealing they must undergo re-annealing to obtain a fine-grained structure.

The hardness of steels after annealing is in the range of HB 180-270.

Normalization is one of the types of heat treatment. During normalization, steel is heated to a temperature at which the plastic properties of steel appear. Maintain at this temperature for some time and then cool in still air to obtain a thin-plate pearlite structure. Normalization differs from annealing in that it cools faster (about twice as fast). In addition, this process is more economical, since the cooling of products during normalization is carried out outside the furnace. However, it is not always possible to use normalization instead of annealing, since in some steels after it the hardness increases significantly (for example, in steels containing more than 0.4% carbon). Such steels are better annealed, although in practice they are often subjected to normalization and then high tempering at 650-700°C to reduce hardness.

Normalization is used to obtain a fine-grained structure in castings and forgings, eliminate work hardening, and prepare steel for hardening. It is recommended to normalize low-carbon steels, since they have virtually no difference in properties after annealing and normalization. For some products, normalization is not a preliminary, but a final heat treatment operation. In this case, after normalization, the products must undergo a high tempering to relieve internal stresses formed during cooling in air.

Hardening is the most common and at the same time the most complex type of heat treatment, since it occurs at very high cooling rates, which leads to the formation of significant internal stresses. When hardening, steel is heated to the temperature of obtaining an austenite structure (above 800-1000°C), maintained for some time at this temperature, and then quickly cooled in water, oil, solutions of salts, acids, alkalis, in air and other media, as well as using metal plates. The cooling process is most often used to increase the hardness and strength of steel products. Shafts, gears, springs, dies, chisels, cutters, cutters, etc. are subjected to hardening. Hardening followed by tempering allows you to change the properties of steel over a wide range.

When choosing a hardening medium, you need to know how it cools the product in different temperature ranges. The best quenching medium is one that, in the temperature range from 550 to 650°C, cools products at a rate above the critical hardening speed, and at temperatures of 200-300°C provides slow, quiet cooling.

The hardness of steels after heat treatment is within the range of HRC 42-55.

Tempering is a heat treatment process in which hardened steel is heated below the annealing temperature, held at that temperature, and then cooled. During the tempering process, internal stresses are reduced or eliminated, the toughness and ductility of the steel increases, its hardness decreases, and the structure improves.

Depending on the heating temperature, three types of tempering are distinguished:

- low-temperature (low) tempering is carried out with heating to 150-200°C. This tempering reduces internal stresses in the steel while maintaining high hardness (58-63 HRC). It is used primarily for tools made of carbon and low-alloy steels, as well as for parts subjected to surface hardening, carburization and nitrocarburization, which have high requirements for hardness and wear resistance;

- medium temperature (medium) tempering is carried out at temperatures of 350-500°C. The purpose of this tempering is to obtain the troostite structure. The hardness of hardened steel is reduced to 40-50 HRC, the elastic limit reaches its maximum value. Springs and springs are subjected to medium tempering;

- high-temperature (high) tempering is carried out at temperatures of 550-680°C. The hardness of hardened steel is reduced to 250-350 HB, strength is reduced by 1.5-2 times, ductility and toughness increase several times, internal stresses are completely relieved. Hardening with high tempering is called improvement. Improved steel, compared to annealed or normalized steel, has higher strength, ductility and toughness.

Products made from structural steel grades Steel 40, 45, 40Х, 40ХНМ, 40ХМФ and others (half shafts, crankshafts, connecting rods, steering knuckles, levers, beams of the front axles of trucks, as well as bolts, nuts, screws, etc.) are subject to improvement. experiencing heavy loads.

When some alloy steels are tempered in a certain temperature range, a sharp decrease in impact strength is observed and temper brittleness occurs. To avoid the development of temper brittleness, products made from chromium-nickel and manganese steels are quickly cooled in oil or water after high tempering. For the same purpose, steel is alloyed with molybdenum or tungsten (no more than 0.6%).

The tempering temperature and holding time depend on the grade of steel, the requirements for the properties of products made from this steel, and their weight. It is recommended to temper hardened products, especially tools, immediately after hardening in order to prevent the formation of cracks due to internal stresses. When tempering temperatures are reduced or the holding time is reduced, the steel retains increased brittleness, which can be eliminated by repeated tempering. An increased tempering temperature leads to a decrease in hardness and strength. These shortcomings are eliminated by annealing the products and re-hardening them, followed by tempering.

The tempering temperature is determined by the tarnish colors.

Aging is a change in the properties of steel over time without a noticeable change in the microstructure. As a result of aging, strength and hardness increase, ductility and toughness decrease. Aging leads to a decrease in internal stresses, stabilization of the dimensions and geometric shape of products.

If aging occurs at room temperature, it is called natural, if at elevated temperatures, it is artificial. Aging is subjected to machine beds, plungers, gauges, staples and other products, the dimensions and geometric shape of which should not change during their operation.

Two types of aging are known: thermal and deformation (mechanical).

Thermal aging occurs as a result of changes in the solubility of carbon in iron depending on temperature. Strain aging occurs in an alloy subjected to plastic deformation at a temperature below the recrystallization temperature. The process of this aging lasts 15 days or more at room temperature and only a few minutes at temperatures of 200-350°C.

Artificial aging of products hardened and tempered at low temperatures is carried out after preliminary mechanical treatment at 100-180°C with holding for 18-35 hours and slow cooling. Natural aging is carried out outdoors under a canopy, where the products are exposed to temperature changes, humidity and air pressure. It lasts from 3 months. up to 2 years. The beds of precision machines, cabinet parts for very important purposes, and the frames of grand pianos and pianos are subjected to natural aging. Its result is a reduction in internal stress, stabilization of the dimensions and geometric shape of products.

The hardness of workpieces for turning is assessed in various ways known to professional craftsmen, but the most reliable data can be obtained by measuring the hardness of the metal of workpieces using instruments using the Brinell method, designated (HB) or Rockwell, designated (HRC).

The Brinell method is used to determine the hardness of both metals and polymer materials. Measurements are carried out using a ball hardness tester. The sample (part) is installed on table 3 in the lower part of the stationary frame of the press (Fig. 2), with the cleaned surface up. By manually turning flywheel 5 clockwise, the table is raised until it stops. Press button 4 and turn on motor 6, which moves crank 8 and gradually loads rod 1. Under the influence of the load imparted by weight 9 suspended from lever 10, ball 2 is pressed into the sample. The load acts for a certain time (10-60 s) depending on the hardness of the material being measured (Table 2), after which the motor shaft, rotating in the opposite direction, moves the crank and removes the load.

After the engine is automatically turned off, turn flywheel 5 counterclockwise to lower the instrument table and remove the sample. The load application time is adjusted on scale 7 of the motor relay. After testing, an imprint (hole) remains on the sample. The diameter of the print is measured with a magnifying glass, the eyepiece of which has a scale with graduations from 0.05 to 0.1 mm. The diameter of the print is measured with an accuracy of 0.05 mm (when pressing a ball with a diameter of 5-10 mm). Measurements are performed in two mutually perpendicular directions. The hardness indicator will be the average of the obtained values.

When measuring the hardness of the surfaces of large parts (cast iron frame guides), a portable magnifying glass is used. Imprints on the surface of the parts are formed by a ball on which a calibrated blow is made in the device.

Brinell hardness (HH) is the ratio of the load acting on the ball to the surface of the print:

where P is the load acting on the ball, in kgf; F—imprint surface, in mm2; D is the diameter of the pressed ball, in mm; d is the diameter of the print, in mm.

All other things being equal, the diameter of the indentation d depends on the hardness of the metal. The higher the hardness of the metal being tested, the smaller the diameter of the indentation. Hardness is measured at a constant ratio between the load value P and the square of the ball diameter D2. This ratio should be different for metals of different hardness .

Ball indentation tests are carried out with metals of low and medium hardness (for example, the hardness of steel should be no more than 450 HB).

Rice. 2. Diagram of the Brinell device

To measure the hardness of surfaces greater than 350 HB, they use instruments that measure the hardness along the depth of the pyramidal imprint - the Vickers method.

Vickers hardness (HV) is the ratio of the load on a standard pyramid when its apex is pressed into the material under study to the surface area of the pyramidal imprint.

where D is the diagonal of the print.

To measure the hardness of surfaces greater than 350 HB, they use instruments that measure the hardness by the depth of the indentation obtained by indenting a diamond cone or steel ball - the Rockwell method.

Rockwell hardness (HRC) is a conditional characteristic , hardness measuring device .

Rice. 3 . Rockwell device diagram

This method allows you to change the load over a wide range without changing the hardness values. The device (Fig. 3) for measuring Rockwell hardness has a table 4 installed in the lower part of the stationary frame. In the upper part of the frame there is an indicator 8 and a spindle unit 7, which has a tip with a diamond cone 6 (with an apex angle of 120°) or with a steel ball with a diameter of 1.59 mm. Indicator 8 has two scales (black and red) and there are two arrows - a large one (hardness indicator), which rotates along the scale, and a small one, which sets the value of the preload imparted by the rotation of the flywheel 3.

The flat surface of the test specimen into which the cone or ball is pressed shall be thoroughly ground. The opposite parallel surface must also be smooth and clean. By turning the flywheel 3 clockwise, the table 4 is raised so that the tip can be pressed into the surface of the installed sample.

As the table is further raised, the arrows on the indicator begin to move. Raising the table continues until the small arrow reaches a vertical position (red dot on the indicator). This means that the tip was pressed into the sample under a preload of 100 N (10 kgf). Preliminary loading is carried out in order to exclude the influence of elastic deformation and surface roughness of the sample on the measurement results.

When the sample receives a preload of 100 N, the large needle on the indicator will assume a vertical position or close to it. To ensure measurement accuracy, it is necessary that the large arrow coincides with zero on the black scale of the indicator. If the large arrow does not coincide with zero, without changing the preload value and, therefore, without rotating the flywheel, turn the indicator scale (circle) with drum 2 through cable 5 so that the zero on the black indicator scale coincides with the large arrow. Deviation of the arrow from the vertical is allowed within ±5 scale units.

With a smooth movement, press key 1, which activates the drive of the mechanism for applying the main load, determined by load 9. One load on the lever imparts an additional load of 500 N (50 kgf) to the sample, therefore, the total load will be 600 N (60 kgf), two loads - 900 N (90 kgf) with a total load of 1000 N (100 kgf), three loads - 1400 N (140 kgf) with a total load of 1500 N (150 kgf). The total load is indicated on the device. When a load is applied, the large needle moves along the scale to the left, counterclockwise. The time for applying the main load is 5-7 s. The arrow returns in the opposite direction automatically when the main load is removed (pre-load remains). The number indicated by the large arrow on the indicator scale is the Rockwell hardness indicator. Having written down this figure, turn the flywheel counterclockwise, lower the instrument table with the sample and thereby remove the preliminary load.

It is recommended to carry out at least three tests for each part. The device is used to measure the depth of the indentation from a diamond cone (steel ball), or, more precisely, the difference between the depths of the indentations obtained from indentation of the tip under the influence of the main and preliminary loads. Rockwell hardness increases with material hardness, allowing comparison of Rockwell and Brinell hardness values. At the same time, Rockwell hardness does not have the same dimension and physical meaning that Brinell hardness has.

However, the Rockwell hardness index can be converted to the Brinell hardness index using a diagram (Fig. 4) or tables constructed on the basis of numerous experimental works.

Rice. 4. Diagrams for converting Brinell and Rockwell hardness readings: a - when indenting a diamond cone; b - when pressing a steel ball.

Rockwell hardness can be measured with a diamond cone with a total load of 1500 N (150 kgf); in this case, the hardness value is characterized by the number indicated by the arrow on the black scale C of the indicator; hardness is indicated by HRC; for example, 65 HRC means the material has a hardness of 65 Rockwell C with a load of 1500 N (150 kgf).

A diamond cone with a load of 1500 N (150 kgf, HRC) measures the hardness of: hardened or low-tempered steel (hardness more than 450 HB), that is, in conditions where pressing a steel ball (according to Brinell or Rockwell) into a solid material can cause deformation of the ball and distortion of results; materials of medium hardness (more than 230 HB), since testing with a diamond cone is carried out quickly and leads to less change in the measured surface than with the Brinell test; thin surface layers, but more than 0.5 mm thick (for example, a cemented layer).

Rockwell hardness can also be measured with a diamond cone with a total load of 600N (60kgf); in this case, the hardness value is also characterized by the number indicated by the arrow on the black scale C of the indicator, but the hardness is indicated by HRA; Hardness HRA can be converted to hardness HRC using the formula:

A diamond cone with a load of 600 N (60 kgf, HRA) is used to measure the hardness of very hard metals (more than 70 HRC), such as hard alloys, when pressing a diamond cone with a higher load can cause chipping of the diamond, as well as hard surface layers (0.3-0. 5 mm) and thin samples (plates).

Rockwell hardness can also be measured with a steel ball with a total load of 1000 N (100 kgf); in this case, the hardness value is characterized by the number indicated by the arrow on the red scale B of the indicator; hardness is designated HRB.

A steel ball with a load of 1000 N (100 kgf, HRB) determines the hardness of mild (annealed) steel or annealed non-ferrous alloys in parts or samples with a thickness of 0.8-2 mm, i.e. in conditions where Brinell hardness measurements performed with a larger diameter ball may cause the sample to collapse.

The choice of scale (A, B or C) is made according to the table. 2. The distance from the center of the print to the edge of the sample or to the center of another print must be at least 1.5 mm when pressing a cone and at least 4 mm when pressing a ball, the thickness of the sample is at least 10 times the depth of the print.

Table 2. Conditions for selecting a scale when testing the hardness of metals

| Approximate hardness | Designation of instrument scales for Rockwell testing | Tip type | Load, kgf | Permissible limits for hardness measurement on the Rockwell scale | |

| According to Brinell NV | according to Vickers HV | ||||

| Up to 240 | 60-240 | B | steel ball | 100 | 25-100 |

| 240-670 | 240-900 | C | Diamond cone | 150 | 20-67 |

| 375-670 | 390-900 | A | « » | 60 | 70-85 |

Hardness should be measured at at least three points (especially with a diamond cone), i.e. at least three times on one sample. For calculations, it is better to take the average value of the results of the second and third measurements and not take into account the result of the first measurement. Determining Rockwell hardness requires less time (30-60 s) than Brinell hardness, and the measurement result is visible on the scale (indicated by an arrow).

When measuring Rockwell hardness, a smaller imprint is left on the surface of the part. The hardness of very thin metal layers (less than 0.3 mm thick) cannot be measured at loads of 600 and 1500 N (60 and 150 kgf), since the diamond cone penetrates to a depth exceeding the thickness of these layers. At the same time, with an increase in the hardness of the material being measured, indentation decreases, as a result of which the measurement accuracy decreases (especially for metals with a hardness of more than 60 RC). For these purposes, super-Rockwell-type devices are sometimes used, with which hardness is measured at a lower load and with a smaller indentation depth. The preliminary load in this case is 30 N (3 kgf). Each division of the indicator scale of such a device corresponds to an indentation depth of 1 micron. Therefore, the sensitivity of this device is noticeably higher.

Production, deposits

Molybdenum is a rare metal. In nature, its presence in its pure form is impossible.

Almost two dozen molybdenum-containing minerals are known:

| Mineral | Ore-forming metal content |

| Molybdenite | 57-60% |

| Ferrimolybdite | 40-60% |

| Will command | 48% |

| Wulfenite | 27–46% |

| Zeirigit | Up to 24% |

Other molybdenum-containing ores (chillagite, comosite, kechlinite, jordisite and others) are not of interest for industrial use.

Significant metal deposits belong to:

- USA;

- Chile;

- Canada;

- Kazakhstan;

- Peru;

- China.

The ranking of molybdenum ore production is headed by China, the USA is in second place by a wide margin, and Chile is in third place.

The State Balance of Mineral Reserves of the Russian Federation lists 34 molybdenum deposits.

The origin of molybdenum ores is from skarn, greisen, and hydrothermal deposits.

The content of rare metal in the earth's crust is only 0.02%. But it is necessary for the existence of humans as a biological species. But there is suspiciously a lot of molybdenum in space. Red giants are especially rich in it - old stars, for which “everything is in the past.”

Advantages of turning non-ferrous metals

When producing metal parts, turning operations are almost always carried out.

Advantages of turning:

- Manufacturing of complex shaped parts. The use of computer-controlled machines makes it possible to manufacture even the most complex parts.

- Economical. The amount of waste during production is minimal - shavings account for no more than 10% of the metal, which, moreover, is then sent for recycling.

- Obtaining high-quality finished parts that can be immediately used for their intended purpose, without additional operations.

- High precision production. When using CNC machine complexes, products made of metal satisfy aesthetic and technical parameters to the highest degree. In production there is no such thing as a “human factor”, i.e. a person is practically not involved in the processing process, and therefore does not make mistakes. The equipment carries out all movements according to a given program, and, if necessary, can be easily reprogrammed to produce another part.

Physical properties

Molybdenum is a light gray metal with a body-centered cubic lattice of the α-Fe type (a = 3.14 Å; z = 2; space group Im3m), paramagnetic. Mechanical properties, as with most metals, are determined by the purity of the metal and previous mechanical and thermal treatment (the purer the metal, the softer it is). Has an extremely low coefficient of thermal expansion.

Physical and mechanical properties

Property Meaning

| Atomic number | 42 |

| Atomic mass | 95,94 |

| Unit cell parameter, nm | 0,31470 |

| Atomic diameter, nm | 0,272 |

| Density at 20°C, g/cm3 | 10,2 |

| Melting point, °C | 2610 |

| Boiling point, °C | 4612 |

| Heat of fusion, kJ/mol: | 28 |

| Heat of evaporation, kJ/mol: | 590 |

| Molar volume, cm³/mol: | 9,4 |

| Specific heat capacity, J/(g K) | 0,256 |

| Thermal conductivity, W/(m K) | 142 |

| Linear expansion coefficient, 10-6 K-1 | 4,9 |

| Electrical resistance, µOhm cm | 5,70 |

| Young's modulus, GPa | 336,3 |

| Shear modulus, GPa | 122 |

| Poisson's ratio | 0,30 |

| Hardness, HB | 125 |

| Spark color | Short yellow intermittent beam of sparks |

| Group of metals | Refractory metal |

Where is molybdenum used?

In history, the very first use of molybdenum was recorded in Japan back in the 10-13th century. There is a possibility that in those distant times, this metal served as a material for the manufacture of edged weapons.

Today the molybdenum industry is a fairly developed industry. And, in addition to the fact that pure molybdenum and its alloys continue to be produced at present, there are also many grades of it, each of which is intended for specific purposes. The most famous brands of molybdenum:

- MP is pure molybdenum without additives. This brand is used to produce tungsten filament holders, incandescent filaments, and generator lamp anodes.

- MChVP is pure molybdenum without additives, produced by vacuum melting.

- MRN - molybdenum for various purposes, does not contain additives, includes a larger number of impurities compared to the MCh and MChVP brands. Intended for use in the production of high-temperature heaters, screens, electrical inputs into vacuum devices and installations.

- MK - contains a silicon-alkaline additive.

- CM - zirconium and/or titanium are used as an additive.

- MR is an alloy of molybdenum and rhenium.

- MV is an alloy of molybdenum and tungsten.

Thus, after centuries, molybdenum has become an indispensable component in many industrial sectors. It applies:

- as an alloying element of steel;

- in the production of heat-resistant alloys, which aviation, rocket and nuclear technology cannot do without;

- for the production of alloys with anti-corrosion properties;

- during the production of parts for electric vacuum devices, filaments of incandescent lamps;

- for the manufacture of turbine blades;

- in power nuclear reactors;

- as lubricants and as a hydrogenation catalyst;

- in the production of paints and varnishes;

- in the chemical and petroleum industries, as well as in metallurgy.

Scope of application of non-ferrous metals

Non-ferrous metals are increasingly used in the developments of modern technology manufacturers. At enterprises specializing in the manufacture of nuclear technology, as well as in aircraft construction, and in the chemical industry, metals such as niobium, titanium, and molybdenum are in high demand.

Each non-ferrous metal has its own scope of application. Copper and copper alloys are often used for the production of pipes, containers, and various vessels. They are widely used in chemical engineering.

In the food industry, the use of aluminum and alloys made on its basis is widespread. They are used to make various structural elements of ships, missiles and aircraft. Such alloys are also common in the construction industry. This need for the use of aluminum in various industries is associated with its excellent characteristics: anti-corrosion properties, high strength parameters at a relatively low density, good mechanical properties that do not change even at sub-zero temperatures.

Electricity and radio engineering

The filaments of conventional electric lamps are made of tungsten, which is more refractory than all other metals and gives the greatest light output. But if you solder a tungsten filament into a glass rod in the center of a light bulb, it will soon crack due to thermal expansion of the filament.

When the physical properties of molybdenum were studied, they found that it has a negligible coefficient of thermal expansion. When heated from 25 to 500° C, the dimensions of the molybdenum part will increase by only 0.0000055 of the original value. And even when heated to 1200°C, molybdenum hardly expands. Therefore, tungsten filaments began to be suspended on molybdenum hooks soldered into glass. Subsequently, molybdenum played an even greater role in electric vacuum technology. Electric current is supplied to vacuum devices through molybdenum rods, soldered into a special glass that has the same coefficient of thermal expansion as molybdenum (this glass is called molybdenum glass).

Heat-resistant alloys

The technology of ultra-high-speed and space flights poses the task of metallurgists to obtain increasingly heat-resistant materials. Strength at high temperatures depends primarily on the type of crystal lattice and, of course, on the chemical nature of the material. The operating temperature limit for titanium alloys is 550-600° C, molybdenum alloys - 860, and titanium-molybdenum alloys - 1500° C!

How can we explain such a significant jump? Its reason is in the structure of the crystal lattice. Foreign atoms are introduced into the body-centered structure of molybdenum, this time titanium atoms. The result is a so-called interstitial solid solution, the structure of which can be represented as follows. Atoms of molybdenum, the base metal, are located at the corners of the cube, and atoms of the added metal, titanium, are located in the centers of these cubes. Instead of a body-centered crystal lattice, a face-centered one appears, in which the processes of softening under the influence of temperatures occur much less rapidly.

This purposeful change in the crystal structure of metals is one of the basic principles of alloying.

Another reason for such a sharp increase in heat resistance lies in the fact that very dissimilar metals are fused - molybdenum and titanium. This is a general rule: the greater the difference between the atoms of the alloying metal and the base metal, the stronger the bonds formed. The metallic bond is, as it were, complemented by the chemical one.

Alloying, however, is not the last word in solving the problem of heat-resistant alloys. Already in our time, the extraordinary properties of threadlike crystals, or “whiskers,” have been discovered. Their strength, compared to metals commonly used in technology, is amazingly high. This is explained by the fact that the crystalline structure of the whiskers is practically free of defects, and the technology of ultra-high-speed flights takes the whiskers into service, creating composite heat-resistant materials with their help. One of these materials is aluminum oxide reinforced with molybdenum whiskers, the other is technical titanium stuffed with the same reinforcement. Compared to conventional titanium, this material can last 1000 times longer under harsh conditions.

What can be opposed to a fiery tornado that hits a spaceship upon entering the dense layers of the atmosphere? First of all, heat-protective coating and cooling. Yes, cooling, similar in principle to cooling car engines using radiators. Only more energy-intensive processes must work here. A lot of heat is needed to evaporate substances, but even more for sublimation - transfer from a solid state directly to a gaseous state. At high temperatures, molybdenum, tungsten, and gold can sublimate. Coating the bow of the ship with molybdenum or other of the listed (more expensive) metals will significantly weaken the force of the firestorm through which the spacecraft's return vehicle must pass.

Other industries

The lion's share of products made from molybdenum and metal alloys is taken by manufacturers of radio and electric lamps, radio electronics.

There is enough material for other purposes:

- Molds, machine parts for injection molding of alloys.

- Electrovacuum production (X-ray tubes).

- Positive electrode of lithium-based current sources.

- Shells of nuclear reactor parts.

- Heaters for electric furnaces operating in harsh conditions.

- The outer layer of the “nose” segment of the body of supersonic aircraft.

- Electrodes for glass melting.

- Catalysis of chemical reactions.

- Varnishes, paints for porcelain, textiles, furs.

These products are created on the basis of natural compounds and metal alloys.

The newest area of application of molybdenum is space technology.

Assortment: components of rocket (ion, plasma) engines; skin of descent vehicles; heat exchangers. Here, the properties of molybdenum are corrected by alloys with niobium and tantalum.

Pure crystalline Mo is used as a component of mirrors for special purpose lasers.

Microdoses of metal are added to agricultural fertilizers.

Units for turning non-ferrous metals

The turning group, in addition to universal machines, includes a variety of machining centers and complexes. For piece or small-scale production with many operations, screw-cutting lathes are used. It is more expedient to process parts made from calibrated rods on turret lathes.

Large-sized workpieces are processed mainly using rotary-turning equipment. They are used to perform operations such as trimming end surfaces and cutting grooves. You can also perform activities such as milling, grinding, boring and turning. It is more efficient to process flanges and discs using lobotowing units. Professional machine operators can produce surfaces of any configuration and complexity: cylindrical and conical, as well as shaped and frontal.

Some machining systems can simultaneously perform both turning and milling. Such equipment is used for the manufacture of parts with complex surface configurations (for example, crankshafts). Therefore, turning and milling machining centers are especially popular.

Manual operations are performed on universal standard-type screw-cutting lathes, and automatic machining is carried out on CNC machine units without human intervention in the work process. CNC machining is designed to perform high-precision work and increase productivity.

Today, turning is used in almost all manufacturing industries. Therefore, despite a fairly high level of development, this type of work with metals continues to develop rapidly, providing the highest quality and speed characteristics.

Advantages/disadvantages

- Advantages:

- has a high melting point, and therefore heat resistance;

- because the density of this metal (10200 kg/m3) is almost two times less than the density of tungsten (19300 kg/m3), then molybdenum-based alloys have significantly greater specific strength (at temperatures below 1370 °C);

- has a high elastic modulus;

- low temperature coefficient of expansion;

- has good heat resistance;

- small cross section for thermal neutron capture;

- Molybdenum is characterized by high corrosion resistance. This metal is stable in most alkaline solutions, as well as in sulfuric, hydrochloric and hydrofluoric acids at different temperatures and concentrations.

- Flaws:

- has little scale;

- high fragility of welds;

- low plasticity at low temperatures;

- work hardening can be used only up to 700-800 °C; at higher temperatures, softening occurs due to return.

Molybdenum Processing

Processing of molybdenum is difficult due to its low viscosity at low temperatures. It also has low ductility, so the following methods are used for its processing:

- hot deformation:

- forging;

- rolling;

- broach;

- heat treatment;

- mechanical restoration.

When processing small workpieces, crimping machines are used. Large billets are rolled on small mills or shaped on broaching machines.

Appearance of molybdenum

If there is a need for machining by cutting, then machining of molybdenum is carried out with a tool made from high-speed steel grades. The sharpening of tool corners during turning should correspond to the sharpening angles for machining cast iron.

The heat treatment of molybdenum is characterized by high hardenability due to its content in steels. The hardening carried out increases the hardness and wear resistance of critical parts.

Turning of non-ferrous metals

The use of metal parts is ubiquitous. They are used in various spheres of human activity and are mainly manufactured using turning equipment. With the help of such machines, gears, pulleys, nuts, disks and much more are produced.

Therefore, processing metal products on lathes will always be relevant, especially when using program-controlled equipment. CNC machine complexes make it possible to process parts with high precision and produce high-quality products of any complexity according to developed drawings.

Molybdenum Products

The industry produces a wide variety of products. The most common are molybdenum wire, molybdenum rods, molybdenum powder, rod, sheet. Molybdenum rods, as well as wire and tape, are used for the manufacture of heaters for high-temperature electric furnaces. In addition, rods are used for the manufacture of bushings for electric vacuum devices. The wire has found application in the production of high-temperature thermocouples, incandescent lamps, receiving-amplifier and generator lamps, and X-ray tubes. The sheets are used as a structural material for the production of products in the aviation and space industries. Molybdenum powder acts as an alloying additive to various steels and alloys. It is also the starting material for the production of compact molybdenum.

Molybdenum alloys

Two alloys based on this metal are used: tungsten (MV) and rhenium (MR).

Alloys of molybdenum with tungsten are necessary to increase the heat resistance of the former. At the same time, deformability deteriorates and specific gravity increases. Such alloys contain from 48% tungsten and from 49 to 51% molybdenum, the rest are impurities. MV is refractory, has high strength and corrosion resistance. Used to make thin wire that is rolled into coils or coils.

Rhenium is necessary to increase the ductility of molybdenum. MR alloys contain more than 50% rhenium and about 47% molybdenum. They are also used to produce thin wire, which is used in special instrument making.

Main grades of molybdenum

The industry uses pure molybdenum and with various additives. Among the most common are the following brands:

Production stages:

- The concentrate is subjected to oxidative roasting at a temperature of 600 ⁰C. The output is molybdenum oxide, which contains a significant amount of impurities.

- The oxide is purified from impurities by distilling or leaching the cinder and further neutralization.

- Molybdenum metal powder is produced from pure oxide in a tube furnace. For this process, a current of dry hydrogen is used.

- The powder is turned into metal. Typically, one of two methods is used for this - smelting or powder metallurgy.

To obtain ferromolybdenum, a reduction reaction is used to reduce molybdenite concentrate, which is preliminarily roasted.

Molybdenum in the human body

Molybdenum is one of the microelements necessary for humans. It is found mainly in the bones, kidneys and liver, as well as in the brain, thyroid and pancreas, and adrenal glands.

The role and functions of molybdenum for the body:

The daily requirement for molybdenum ranges from 70 to 300 mcg, depending on body weight. In case of microelement deficiency in the body and diseases caused by it, the daily norm increases.

ABOUT

Tungsten and its alloys are among the most difficult materials to process, due to their high hardness, increased fragility, low ductility and high abrasive ability W. The machinability of tungsten alloys is negatively affected by their low ductility.In this regard, an increase in cutting speed worsens machinability, since during cutting, an increase in speed does not cause a sufficient increase in heat generation in the deformable element and a decrease in strength properties. In addition, the reduced ductility of tungsten alloys sharply reduces the contact area of the cutter with the chips and, at the same cutting force, the pressure on the cutter increases by 2-4 times. Sheets of W alloys are cut using cutting-off grinding wheels made of silicon carbide. To avoid cracking, cutting sheets in a cold state with scissors, saws and cutting with stamps is not allowed.

It is recommended to turn W-based alloys with cutters made of high-speed steels R18, R9K5, R9K10 and R9F5 or with cutters made of hard alloys VK8. When turning, coolants are not used, as this reduces the tool life. Milling of tungsten alloys is carried out with high-speed cutters made of R18, R9K5, R9K10 and R9F5 or equipped with VK8 carbide alloy. Drilling holes in W alloys causes enormous difficulties due to the high cutting forces encountered and the low rigidity of standard drills. Holes in sheets of W alloys up to 2 mm thick are pre-produced by electrical discharge or ultrasonic treatment.

It is recommended to grind tungsten alloys using green silicon carbide wheels on ceramic. bond with grain size 40-60, hardness CM1-CM2. The surface cleanliness is within the 7th-8th grade (GOST 2789-51). To improve machinability during cutting, the alloy is heated to 370-420°, while tool life increases 5-6 times, and the phenomena of cracking and chipping of the material are reduced, which makes it possible to obtain holes with a diameter of less than 5 mm in both solid and sheet metal. material. Tungsten sheet heated to 370° can be cut with scissors and die-cut.

The cutting conditions for molybdenum alloys are similar to the processing conditions for W. When processing molybdenum alloys, the cut layer (as for W alloys), due to increased brittleness, tends to chip under heavy cutting conditions. Harmful impurities and additives significantly impair workability. Depending on the technology conditions, cooling with emulsion, air or “fog” is used, i.e., spraying the emulsion with an air stream. The ingots are stripped using cutters made of hard alloy VK8. Finishing is carried out with the same cutters as stripping.

It is recommended to perform face milling of Mo alloys with cutters equipped with carbide alloy VKb or VK8. When drilling holes, standard high-hardness drills made of P18 steel are used.

Cutting threads with cutters requires special care compared to turning, and the speed is reduced to 9-12 m/min, and the cutting depth in one pass is 0.1-0.15 mm. It is advisable to cut large threads, since small ones break easily. Grinding of Mo alloys is carried out under the same conditions as for W alloys. The cleanliness of the processed surface is within the 7th class.

Alloys of tantalum and niobium have increased viscosity and ductility and have relatively low hardness. Difficulties in cutting are caused by their increased adhesion to the cutting tool. Turning of alloys is carried out with steel cutters of grades R18, R18F2. Machining with carbide cutters results in frequent chipping of the cutter tip and is therefore not recommended. The geometric parameters of the cutters are the same as when processing tungsten and molybdenum.

Cutting speeds of niobium alloys significantly affect the durability of P18 cutters. High speeds cause high temperatures in the cutting zone, which leads to oxidation of the machined surface. Drilling of Nb and Ta alloys is carried out using drills made of P18 steel and cooled with sulforesol.

Nb and Ta alloys are very difficult to grind. Grinding wheels quickly become greasy and require frequent dressing. The best results are obtained when using electrocorundum grinding wheels on ceramic. bunch. The grinding modes are the same as for W and Mo. Grinding is carried out with abundant cooling with a 2-3% soda ash solution. The cleanliness of the treated surface is within the 6th class.

Lit.: Wulf B.K., Romadin K.P., Aviation metallurgy, M., 1962;

Niobium and tantalum. Collection of translated articles , ed . ABOUT . P . Kolchina , M. , 1954;

"Machinery" (USA), 1960, v. 66, no. 10, p. 184-88; "Tool and Manufacturing Engr.", 1960, v. 45, no. 4, p. 121-22; "Metal Industry", 1959, v. 94, no. 4-7; "Machinery" (Engl.), 1953, v. 82, No. 2095, p. 72-73. Hard alloys

and mineral ceramic

MODIFICATION OF ALLOYS. Modification of cast alloy

| Usually an additive is chosen as a modifier, which forms with the components alloy refractory compounds that crystallize first. … bibliotekar.ru/spravochnik-181-3/32.htm |

LIGHT ALLOYS

.

Low-melting alloys

consist of bismuth, tin...

| All metals and alloys . |

TEP operating modes. Thermionic converters

| ... which corresponds to an emitter vapor pressure of no more than 10-* Pa. The materials used for the emitter assembly are: refractory metals, |

MECHANICAL PROPERTIES AT HIGH TEMPERATURES. With the increase...

| That's why alloys based on |

STEELS AND ALLOYS

.

Steels and alloys

based on iron, nickel, cobalt...

| All metals and alloys . |

Daily norm of molybdenum

Depending on many indicators, the body requires molybdenum in different quantities. Adults require an average of 70 to 250 mcg per day, but this varies depending on age, gender, health status and lifestyle.

Children need a minimum of 15 mcg of metal each day, taking into account the child's physical activity and weight.

Women need a minimum of 70 mcg of molybdenum per day. Moreover, pregnancy and breastfeeding are not indicators for increasing the dosage.

Men also need a minimum of 70 mcg of the element per day. This amount is sufficient to prevent the occurrence of diseases that can be caused by a lack of molybdenum, as well as to increase potency.

Elderly people over 75 years old need to reduce the dosage of the element by a quarter (the maximum dose should not exceed 200 mcg).

Molybdenum deficiency

Deficiency of the substance is rare, but still a phenomenon encountered in the practice of doctors. It can be recognized by the following symptoms:

- increased nervous excitability;

- rapid heartbeat;

- decreased activity of enzymes that contain this metal;

- decreased clarity of vision, poor vision at dusk.

With a long-term shortage of the substance, serious consequences can occur:

- stopping normal brain development;

- insufficient metabolism of nitrogen, cysteine;

- increased risk of developing esophageal cancer;

- mental retardation;

- reducing the amount of secreted uric acid and inorganic sulfate compounds;

- poor eyesight;

- disturbance in the body's elimination of sulfates;

- slow catabolism of methionine;

- formation of urolithiasis;

- accumulation of copper compounds in the body with subsequent poisoning;

- reduced breakdown of cellulose;

- slower growth and development in children.

What causes an element deficiency? There may be several main reasons:

- long-term intravenous nutrition in people with impaired functioning of the gastrointestinal tract or during a long stay in intensive care;

- a very strict vegetarian diet without a balanced diet;

- problems in the intestines with impaired absorption;

- frequent stress and anxiety, which increases the body’s need for sulfite oxidase;

- high concentrations of tungsten in the blood.

Signs of element deficiency can be eliminated after introducing a sufficient amount of products containing molybdenum or special preparations into the diet.