During operation, the profile of abrasive wheels changes, and their granular surface becomes clogged with processing waste, which ultimately leads to a decrease in the effectiveness of this device. In order to return sharpening and grinding wheels to their original characteristics, a tool such as a roller cutter is used to dress abrasive wheels.

Sprocket cutters: blunt-toothed on the left, sharp-toothed on the right

Star rollers, simple in their design, are divided into two types:

- with sharp teeth;

- blunt-toothed.

They differ from each other not only in the shape of the teeth, but also in thickness and scope of application.

Dimensions of cutters for dressing abrasive wheels

What is a diamond pencil, its composition

A diamond pencil has the form of a metal rod with a length of about 5 cm. The abrasive component in the form of diamonds is located on the bottom side; the type of placement and shape may differ depending on the type of device and its purpose.

To bind and fasten diamond crystals, a special binder is used, which is an alloy with a special composition that has a coefficient of thermal expansion similar to diamond. Thanks to this feature, the stones will not be deformed when heated.

Advantages and features of using diamond pencils

Dressing a wheel using this device allows you to obtain high precision of the working surface, restore the shaped profile to achieve optimal sharpening of the working tool. This requires the correct selection of tools, according to the operation and the hardness of the wheel.

As for the question of how to use a diamond pencil, the method of work depends on the operation. In the general case, the tool is fixed on the tool rest and the working area is brought into contact with the rotating circle. Thus, the abrasive layer is removed, the geometry of the circle is restored and the surface is renewed with the restoration of the original properties.

The cost of a pencil depends on the weight of diamonds, the type, and the use of natural or synthetic stones. But in any case, its use is economically justified by a significant increase in the service life of abrasive wheels and a reduction in operating costs.

Types of diamond tools

The type of diamond pencil depends on the location of the diamonds in the working part, as well as on their characteristics. Main types of devices:

- Type C. In this type of pencil, diamond crystals are placed in a chain. To make the device, high-quality stones are selected, the weight of each of them is 0.03-0.5 carats. These tools are used for dressing wheels intended for centerless shaped, internal and cylindrical grinding.

- Type C. In this case, the stones are arranged in layers, and the layers may or may not overlap. To make a pencil, two grades of diamonds are used: the first grade includes stones with small grains, the number in one layer is 10 pieces; the second brand includes small-grained diamonds, weighing 0.1-0.2 carats each, 2-5 stones fit in one layer. The device is characterized by increased wear resistance and is intended for straightening abrasive discs during fine grinding.

- Type N. Such pencils are distinguished by a chaotic (not oriented) arrangement of stones, as well as the use of diamonds with different weights and sizes, up to the inclusion of chipped and crushed crystals. In addition, devices are characterized by belonging to different brands and various dimensions of the frame and insertion of stones. Diamond pencils type H are used for dressing grinding discs with a fine grain structure during centerless and cylindrical grinding, as well as as a device for dressing spline and gear grinding wheels of disc, flat and single-filament types.

Depending on the design, there are cylindrical, conical and stepped pencils.

In addition, diamond pencils may differ in purpose: there are types for hard or soft circles. To make it easier to make a choice, each device has its own marking:

- pencils No. 0051 - 0055 belong to type C, the mass of diamonds is:

0051 – 05 carat,

0052 – 05 carat,

0053 – 0,5,

0054 – 1;

- pencils No. 0081 – 0085 are type C, the weight of the stones is 1 carat, with the exception of No. 0084, where the stone weighs 2 carats;:

- pencils No. 0086 – 0088 belong to type C, the weight of all diamonds is 1 carat.

- pencils No. 0059-0068 belong to type H and are distinguished by the weight of diamonds of 1 carat.

Technical requirements and control rules

- In type 03 pencils, the diamonds should be spaced evenly around the sphere.

- The diamonds on the working surface of the pencil must be exposed.

- The surface of the diamond element should not have holes or cracks visible to the naked eye.

- The following markings must be clearly marked on the surface of the pencil: trademark of the manufacturer;

- pencil designation (except for the first 6 digits);

- designation of the subgroup of rough diamonds - for pencils made from natural raw materials: subgroup “o” is not marked; subgroup “a-1” is marked with the number 1, “a-2” with the number 2, “a-3” with the number 3;

Rules for installing diamond pencils in a tool

To obtain high quality machining, fixtures must be firmly fixed in the tool holder. Pencils belonging to types C and C must be installed at a slight inclination on the side of rotation of the grinding wheel - the angle of inclination should be 10-15 degrees, while the cutting edge of the diamond crystal should be located at the level of the center line or below it by 1-2 mm .

To ensure that the diamond wears evenly, you should at least occasionally turn the stone using special turning heads. Dressing of grinding discs is carried out at high speeds, which guarantees good productivity and processing accuracy.

In the process of dressing and finishing the cylindrical surface of a disk or when dressing the end surface, the tool is fed longitudinally, and it is directed parallel to the axis of the circle. Straightening and finishing of the shaped surface is carried out by longitudinal feeding of the tool directed along the surface of the circle.

Application area

Using cutters equipped with sharp teeth, grinding wheels are dressed, the dense structure of which consists of abrasive grains of minimal size. If, with the help of sharp-toothed cutters, you start dressing wheels made of abrasive grains of medium and coarse fraction, then the dressing tool will simply ruin their working surface, causing serious damage to it. In such cases, a blunt-toothed cutter is used, specially designed for dressing medium- and coarse-grained abrasive wheels.

The high efficiency of using star cutters is ensured by the fact that processing with their help is carried out at a high rotation speed. It should be borne in mind that the dressing of grinding and grinding wheels is carried out not with one cutter, but with a whole set of them, placed on a special axis equipped with a lubricating nipple.

Special holder for cutters

Considering the fact that the roller-cone tool experiences serious mechanical impact from the abrasive wheel during use, its working part must be subjected to high-quality hardening.

Types of Diamond Pencils

- With a chain arrangement of crystals. The weight of stones in this instrument ranges from 0.03 to 0.5 carats. This diamond pencil is suitable for shaped centerless grinding and is used for processing internal and curved surfaces.

- With a layered arrangement of crystals. The diamonds in this tool can be either small or large. Small ones are arranged in a layer of up to 10 pieces, the number of large ones in one layer does not exceed 5 pieces. Due to the increased working surface, such diamond pencils are characterized by increased resistance to wear and are used for finishing abrasive wheels.

- With a non-oriented arrangement of stones. Crystals of different qualities are suitable for the production of this instrument. With its help you can create a perfectly flat plane. It is especially effective when processing fine-grained abrasives and is used in circular and centerless grinding.

The main advantages of diamond pencils are:

- durability, resistance to corrosion and wear, due to the uniform distribution of load between the crystals;

- ease of operation (no special preparation required before use) and storage.

It is also worth noting the wide price range of the tool. The price depends on what kind of stones are used for its production. Pencils with diamond inserts of natural origin are more expensive and are more often used for industrial purposes to perform large volumes of work. Models with synthetic stones are cheaper and are designed for everyday use. In any case, purchasing a diamond pencil is more economically feasible than regularly purchasing new grinding materials.

GRINDING WHEELS

GOST 607-80

Specifications

This standard applies to diamond pencils for dressing grinding wheels manufactured for the needs of the national economy and export.

1. TYPES AND MAIN DIMENSIONS

1.1. Diamond pencils should be manufactured in the following types:

01 - with diamonds arranged in a chain along the axis of the pencil;

02 - with diamonds arranged in layers;

03 - with diamonds located on a spherical surface;

04 - non-oriented arrangement of diamonds.

1.2. Diamond pencils must be manufactured in the following designs: A - cylindrical;

B - with a conical body;

C - stepped.

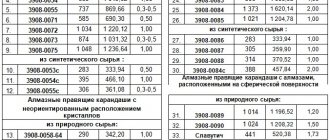

1.3. The main dimensions of pencils must correspond to those indicated in the drawing. 1-3 and in table. 1-3.

Types 01 and 04

Version A

Table 1 (Dimensions, mm)

Pencil designation

| Type | D h14 | d f9 | L+/-IT16/2 | Diamond raw materials | Diamond powders according to GOST 9206 | |||||

| Group, subgroup, type | Number of diamond grains in one carat, pcs./carat | Weight of one diamond grain, car | Size of one diamond grain, mm | |||||||

| Brand | Grain | |||||||||

| 3908-0051 | 01 | 10 | 10 | 55 | XV "a", "a-1", type 1 | 30-20 | — | — — | — | |

| 3908-0052 | 45 | XVI "a", "a-1", type 1 | — — | 0,05—0,10 | ||||||

| 3908-0053 | 0,10—0,20 | |||||||||

| 3908-0054 | 0,20—0,50 | |||||||||

| 3908-0055 | XVI "a-3", type 1 | 0,31—0,50 | ||||||||

| 3908-0056 | 04 | 6 | 6 | 45 | — | — | A3 | 100/80 | ||

| 3908-0057 | 125/100 | |||||||||

| 3908-0058 | 200/160 | |||||||||

| 3908-0059 | 8 | 8 | 63/50 | |||||||

| 3908-0060 | 100/80 | |||||||||

| 3908-0061 | 125/100 | |||||||||

| 3908-0062 | 200/160 | |||||||||

| 3908-0063 | 315/250 | |||||||||

| 3908-0064 | 400/315 | |||||||||

| 3908-0065 | 10 | 10 | 500/400 | |||||||

| 3908-0066 | 630/500 | |||||||||

| 3908-0067 | 800/630 | |||||||||

| 3908-0068 | XV "o-2", type 1 | -1,0 +0,8 | — | — | ||||||

| 3908-0069 | — | — | ARS4 | 1000/800 | ||||||

Note : It is allowed to use rough diamonds of group XII, subgroup “c”, group XV, subgroup “a” of 1st and 2nd quality, subgroup “c”, 0.8 sieve and group XVI, subgroup “a” of 1st and 2nd quality -th quality.

An example of a symbol for a pencil type 04, diameter D = 8 mm, made of diamond powder, grit 125/100:

Pencil 3908-0061 GOST 607-80

Types 01, 02, 04

Version B

Table 2 (Dimensions, mm)

| Pencil designation | Type | D h14 | L+/- IT16/2 | Diamond raw materials | Diamond powders according to GOST 9206 | ||

| Group, subgroup, type | Weight of one diamond grain, car | Brand | Grain | ||||

| 3908-0070 | 01 | 10 | 70 | XVI "o", "0-1", type 1 | 0,05-0,10 | — | — |

| 3908-0071 | 65 | 0,10-0,20 | |||||

| 3908-0072 | 0,20-0,50 | ||||||

| 3908-0073 | 60 | XVI "o-Z", type 1 | 0,31-0,50 | ||||

| 3908-0074 | 02 | XVI "a" "0-1" "o-2" type 1 | 0.05_=01]op | ||||

| 3908-0075 | 0,10-0,20 | ||||||

| 3908-0076 | 12 | 0,05-0,10 | |||||

| 3908-0077 | 0,10-0,20 | ||||||

| 3908-0078 | 04 | 10 | — | — | A3 | 500/400 | |

| 3908-0079 | 630/500 | ||||||

| 3908-0080 | 800/630 | ||||||

Note : It is allowed to use rough diamonds of group XII, subgroup “c” and group XVI, subgroup “a” of 1st, 2nd, 3rd, 4th quality.

An example of a symbol for a pencil type 02, diameter D = 10 mm, made from rough diamonds weighing one grain 0.10-0.20 carats:

Pencil 3908-0075 GOST 607-80

Type 02, 03, 04 Version C

Table 3

| Pencil designation | Type | Diamond raw materials | Diamond powders according to GOST 9206 | ||||

| Group, subgroup, type | Number of diamond grains in one carat, pcs./carat | Weight of one diamond grain, car | Size of one diamond grain, mm | Brand | Grain | ||

| 3908-0081 | 02 | XV "a", "a-1" "i-2" type 1 | 60-40 | — | — | — | |

| 3908-0082 | XVI "a", "a-1", "a-2" type 1 | — | 0,05-0,10 | ||||

| 3908-0083 | 0,10-0,20 | ||||||

| 3908-0084 | |||||||

| 3908-0085 | XII "b", "5-1" type 1 | 0,11-0,20 | |||||

| 3908-0086 | — | — | ARS4 | 1250/1000 | |||

| 3908-0087 | 1600/1250 | ||||||

| 3908-0088 | 2000/1600 | ||||||

| 3908-0089 | 03 | XVI "o", "0-1" type 1 | 0,05-0,10 | — | |||

| 3908-0090 | 0,10-0,20 | ||||||

| 3908-0091 | 04 | — | — | ARS4 | 1000/800 | ||

| 3908-0092 | XV "a-2" type 1 | -1,0+0,8 | — | — | |||

| 3908-0093 | — | — | ARS4 | 1250/1000 | |||

Note: It is allowed to use rough diamonds of group XII, subgroup “a” of 2nd quality, group XV, subgroup “a” of 1st and 2nd quality, subgroup “b”, 0.8 sieve and group XVI, subgroup “a” 1 -th, 2nd, 3rd, 4th quality.

An example of a symbol for a pencil type 02, made from rough diamonds weighing one Grain 0.1-0.2 carats:

Pencil 3908-0084 GOST 607-80

The symbol for pencils must additionally include information about rough diamonds:

a) brand of natural diamond grinding powder;

b) brand of synthetic polycrystalline diamonds;

c) subgroup of rough diamonds.

Examples of symbols for pencils depending on rough diamonds:

pencil size 3908—0060, made from natural diamond grinding powder grade A3:

Pencil 3908-0060 A3 GOST 607-80

pencil size 3908-0069, made from grinding powders of synthetic polycrystalline diamonds of the APC4 brand:

Pencil 3908-0069 ARS4 GOST 607-80

pencil size 3908—0082, made from rough diamonds of group XVI, subgroup “a-1”, type 1:

Pencil 3908-0082 I GOST 607-80

(Changed edition, Amendment No. 1, 2).

Type C ruling pencil made of AKTM® composite

| The main purpose is profile dressing of abrasive wheels of medium and low hardness M1-ST2 for all grit ranges | |

| Standard size, mm | Analogue GOST 607-80 |

| Ts2-1.5 | 3908-0052 |

| Ts3-2.0 | 3908-0053 |

| Ts4-3.0 | 3908-0054 |

Type C ruling pencil made of AKTM® composite

| The main purpose is rough and finishing dressing of abrasive wheels to great depths, including for centerless grinding | |

| Standard size, mm | Analogue GOST 607-80 |

| C6 1 14-1.5 | 3908-0083 |

Diamond pencils - their purpose, functions and applications

As you know, diamond cutting of concrete and any other hard materials cannot be done without the use of special grinding wheels at the final stages of work, but sometimes they may need to be automatically adjusted, which helps ensure high accuracy of the device’s operation. To do this, use a tool such as a diamond pencil.

. It allows you to completely restore the cutting ability and the very shape of the grinding tool, and the number of edits does not in any way affect the quality of its work, which is ensured by the high strength of the pencil. In addition, even with frequent editing, the identity of the tools is maintained, that is, products processed using such abrasives always remain homogeneous.

In Russia, several large enterprises specialize in the production of diamond pencils; All products are subject to mandatory certification and comply with GOST standards.

Traditionally, there are three types of such pencils, which differ in the type of diamond construction. This

- -01 (diamonds are arranged in a chain along the axis of the tool);

- -02 (diamonds are arranged in layers);

- -03 (diamonds cover the sphere);

- -04 (diamonds are arranged randomly).

As for the shape, a diamond pencil is usually made according to certain “patterns”. So, it can be in the form of a cylinder (type A), have a conical body (type B), or be stepped (type C).

The operations of dressing grinding tools using diamond pencils can be divided into several types. Thus, there are external and internal, as well as round and flat dressing, and in addition, centerless grinding. Also, during individual work, types of cutting such as sanding and gear grinding can be successfully used. In addition to diamond pencils, some other tools are used for similar purposes, such as diamond stones, diamond drills or diamond needles. You can learn more about them from the materials on this site.

Why does it become necessary to process wheels using all these materials? Because the abrasive grains, which are located directly on the cutting surface of the wheel, wear out over time, become dull or fall out. The very plane of the circle is greased, that is, covered with processing products. Periodic editing helps to keep the tool in order, returning it to its previous cutting properties and ideal geometric shape. Editing can be done in several ways. In addition to grinding (in the process of which abrasive grains are cut off and crushed by a dressing device), these include rolling, grinding, rolling and tangential turning.

Of course, for diamond cutting to proceed quickly and successfully, you need to use only high-quality, reliable tools. If you choose a grinding wheel, try to ensure that it is always ready for work: at the scheduled time, process it with a diamond pencil, and then there will be no doubt about the excellent result of the work.