How long a grinding wheel lasts depends on several factors, in particular:

- What tool is used. At high speeds wear often occurs faster than at low speeds.

- Wheel type - wheels with a highly abrasive surface have a higher grain size, so they can also wear out faster. For grinding, sanding wheels are most often used, which, depending on the type of material being sanded, can wear out quite quickly.

Consumption rates for wheels

The consumption rate of grinding wheels is determined by how quickly wear occurs. This fact is greatly influenced by the material the tools are used to grind or trim.

Thus, the consumption of grinding wheels per 1 m2 for wood will be slightly lower than the same figure for metal. Exact standards can be calculated experimentally for a specific material by determining the grinding area that can be completed before signs of wheel wear appear.

Raw materials for processing

Grinding grain is the main component that is used for processing abrasive scrap. Discs that have a ceramic or bakelite base are in high demand and are characterized by the fact that the technology for processing scrap abrasive metals using annealing allows for high-quality cleaning of the bakelite binder.

There is an additional requirement; companies that specialize in one of the technologies are asked to remove wires and other metal parts from disks that have become unusable before delivery. As a rule, waste is sorted and delivered in different batches.

In order to know exactly how much waste is needed, two formulas for calculating waste generation are used.

Formula 1: Mabr = Pabr × Ciz × N, where:

- Mabr – mass of used abrasive wheels, abrasive scrap, t/year;

- Rabr – initial mass of the abrasive product, t;

- Cs is the degree of wear of abrasive products at which they must be replaced, fractions from 1 (0.50..0.60 - for flat wheels and bars, 0.60..0.70 - for profile wheels, 0.25.. 0.50 - for cutting wheels);

- N is the number of abrasive products of this type.

Formula 2: Q = (q1+q2+q3)/3, where:

- Q—waste generation standard, t/year;

- q1, q2, q3—mass of waste generated in previous years, t/year;

How long does a grinding wheel last?

Grinding wheel wear is determined visually - by the presence of destruction or damage on the surface of the material. During operation, grains often tear out from the edge of the circle - the disc “crumbles”. For wheels with a self-sharpening function, grains with a worn upper edge are removed and the load falls on the unworn elements. Accordingly, such wheels have slightly lower consumption than those that do not self-sharpen during operation.

Performance of circles made from conventional and aggregated CBN. Table

Primary wear occurs most intensively when a newly installed grinding wheel grinds against the surface upon first use. According to the standards, it can range from 10 to 20% of the total volume. This period takes a very short period of time.

Dependence of wear on the method of wheel dressing

If there are signs of wear, it is ineffective to use the wheel without correcting it. A worn wheel has dull edges of the grains. Editing effectively solves two problems at once:

- corrects the geometric shape of the circle;

- restores its cutting ability.

Dressing the grinding wheel. Scheme

Editing can be done in a variety of ways. The wear rate of the wheel depends on the choice of a specific option. According to the existing standardization it is:

- when straightening with a circle - 1.8;

- for a steel disk - 2.5;

- for a carbide disk - 2.2;

- for diamond tools - 1.

Thus, choosing a tool with a diamond attachment for dressing wheels allows you to extend their service life for some time.

The consumption of a wheel is influenced by a large number of factors, which are not possible to take into account within the framework of any standards. In order for flow rates to be as accurate as possible, it is recommended that flow measurements be carried out taking into account all available criteria. You can select a suitable grinding wheel in the catalog of our online store.

Important element

The type of bond is the main element for processing; it determines the strength of the grinding disc and its operating mode. For the regeneration procedure, the essence of which is to separate the grinding grains from the used product, it is also very important

If we take inorganic bonds, then ceramic ones are the most common. This is due to the fact that they are universal for all types of work. But in order to sharpen a tool or polish steel, metal silicate or magnesium are used.

Organic binders are represented by the bakelite variety and are the most popular, while vulcanite, glyphthalic and a number of epoxy types are used for a certain type of activity.

Outer and inner diameter of cutting wheels

Due to the fact that angle grinders differ in size and power, for each of the existing tool variations, discs of the appropriate sizes in internal/external diameters are used. Modern manufacturers produce circles with the following dimensions (in millimeters) for various types of grinders:

- 115 - used exclusively for low-power household equipment;

- 125 – suitable for both household and semi-professional models of “grinders”;

- 180 – aimed at the segment of medium and high power angle grinders;

- 230 – used on powerful equipment for direct professional use.

Circles can be larger than 300 millimeters, but they are used exclusively on special equipment and working machines.

Regarding the mounting holes, i.e. their internal diameters, then the “dispersion” in numbers is much smaller there - there are only three main types (in millimeters):

- 22;

- 22,23;

- 32.

The second type is the most popular, because it is suitable for “grinders” with double landing shaft sizes – 22.23 and 22 millimeters. The 32mm holes in the circles indicate their use only on special machines. There are also smaller internal diameters, such as 10, 13 and 16 millimeters. They are mostly intended for fine (“jewelry”) work, and the outer diameter of such disks does not exceed 100 millimeters.

How to replace

The grinder disc is a consumable item. Therefore, it has to be changed frequently. There is a simple algorithm in which an important role is played by the original design of the key supplied to the consumer along with the grinder.

- — The protruding rods of a special key are installed in the grooves of the fastening nut.

- — At the same time, press the lock button located on the gearbox housing. It will lock the rotor from turning.

- — Turn the key counterclockwise to release the fasteners of the worn disk.

- — The old disk is replaced with a new one of the same technical characteristics and size. The new disk is installed with the markings facing out to remind you of the disk parameters and for other good reasons (see explanation in the video above).

- — The fastening nut is first tightened by hand and finally tightened with a special wrench.

The Bulgarian is ready to continue fulfilling its functional purpose.

What are the sizes of wheels for angle grinders Bosch, Interskol and more?

Almost all large companies produce grinders covering the maximum number of works - from household to industrial designs. Each type has its own tool size. In addition to the production of angle grinders, such manufacturers (Bosch, Metabo, Interskol and others) have mastered the parallel production of consumables. They select a special composition and standard size of consumables in order to maximize the operating efficiency of the specific model they produce.

Outer and bore diameter, maximum and minimum value

The most popular range of angle grinder sizes consists of the following values.

External diameter. The most preferred sizes are: 115 mm, 125 mm, 150 mm, 180 mm, 200 mm and 230 mm. In rare cases, to perform, for example, jewelry work with small parts, portable battery-powered angle grinders with diameters of 76 mm or 100 mm are used.

The minimum diameter of 115 mm is used for simple work in the form of processing hard-to-reach surfaces in the household. Anglers with a circle with a diameter of 125 mm have greater ability to perform various household works.

The diameter of 230 mm is used in the professional context of angle grinders for large volumes of work, for example, in construction. Circles with a diameter of more than 230 mm are installed on stationary equipment.

Thickness. Cutting wheels are available in thicknesses from 0.8 mm to 5.0 mm. Moreover, a larger diameter should have a circle with a correspondingly greater thickness.

You should know! A thin disc is easy to cut, but it is also more likely to break.

Landing diameter. The standard mounting diameter for angle grinder consumables is 22.23 mm. In the vast majority of cases, it is the same for all disk sizes. It is rare to find mounting diameters of 10 mm, 13 mm, 16 mm due to the limited use of angle grinders with a diameter smaller than 100 mm. A 32 mm bore diameter is used with circles of 300 mm and larger on stationary equipment.

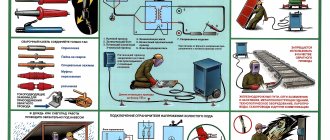

Security measures

Before starting work, you need to think about how the cutting will be carried out (the position of the grinder in space in relation to the place of cutting), determine the vector of the direction of the flow of sparks that will accompany the immersion of the disk into the metal. Remove all flammable objects and substances from the spark line. If necessary, cover finishing surfaces that are exposed to sparks with protective agents.

Inspect the power tool itself for water, dirt, sand, and check the integrity of the power cord. Carry out a test run to check the smooth operation of the unit and the smooth rotation of the cutting disc. Assess the object to be cut: it must be firmly fixed, have no deforming stress, and be away from electrical wires.

Eyes must be protected with special glasses that provide a wide and clear view. It is not recommended to use glasses with tinted lenses. The safest means of protecting the face is a shield mask made of transparent plexiglass. If the disk breaks during cutting, its fragments fly in the direction of the initial centrifugal force at high speed. This mask will protect the front part of the head from getting into it. The hearing organs also need protection. For this purpose, construction headphones or silicone earplugs are used.

The equipment of the angle grinder operator must meet the following safety measures:

- robe made of durable and natural material;

- moderately loose, but excessively long sleeves are unacceptable;

- gloves that fit tightly on the hands, made of strong material that can hold the initial cut;

- closed shoes with composite inserts on the toes.

Selection by size

The outer and inner diameters of the circle are indicated on the main surface of the consumable. There are 9 standard external sizes from 125 to 500. The indicator is selected taking into account the class of the angle grinder. It is strictly forbidden to work with a larger circle. Only for large professional tools can you purchase consumables of any diameter.

The inner or bore diameter must match the size of the drive shaft. Most shafts are produced with a diameter of 22 mm, so 22.2 mm is an almost universal mounting diameter. Both sizes must fit the instrument model!

Roughing

It’s worth mentioning right away that roughing and grinding discs go hand in hand, and in many stores in the “type” parameter of the attachment it may be written: “roughing grinding disc.” In our article we will divide this “couple” into two types. Peelers in this context are an attachment for freeing the structure being processed from the outer layer, for example, from rust. There are the following peeling attachments:

Roughing discs. Sanding discs, like cord brushes, can be flat or cup-shaped. They are intended for cleaning welds and preparing metal surfaces for grinding.

Pricing

Typically, the cost of scrap abrasive wheels is negotiable and tends to fluctuate, starting from 3,000 rubles per ton. Appearance is a fundamental part in determining the value of scrap. The price is affected by the type of grain, size, type of binding material, demand in a particular city - all these factors also tend to change the price.

Also, it’s worth figuring out who buys the abrasive scrap. Basically, scrap is purchased by manufacturers who specialize in the manufacture of abrasive tools. In order to find such factories, you just need to search the Internet and make an offer to them.