Products made from bent pipes are quite popular when decorating a personal plot and finishing a house. Fences, decorative fences, frames of greenhouses, canopies and canopies, trellises made of bent round or profile pipes sometimes look better than forging. A homemade pipe bender for a round pipe can be made in several versions - from a primitive template (for manual bending of thin-walled pipes of small diameter) to rolling and winding with an electric drive.

Let's consider the main types of homemade pipe benders from the standpoint of their efficiency and manufacturing complexity. For a home craftsman, making some types of pipe bending machines with your own hands will not be a problem if you have the skills to work with welding or on a lathe. But there are also quite complex installations that can only be implemented in a metalworking workshop or metalworking shop. It should be noted that homemade pipe benders can also bring a lot of benefits there.

Design and principle of operation of a pipe bender

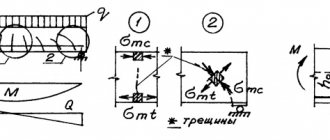

The pipe bending procedure itself is practically not complicated, but requires special attention. During the bending process, it can receive defects in the form of stretching of the wall and a decrease in its thickness at the bending point, which will lead to a decrease in the strength of the pipe. Also, the bend location can change the configuration of the cut and take the shape of an ellipse instead of a circular cross-section, which significantly reduces the internal throughput of the liquid passing through the pipe.

Design Features

To ensure that bending defects are minimal, when choosing or manufacturing a pipe bender for work, you need to understand how it works. The manufacture of a pipe bending device consists of three stages:

- A punch (template) is attached to a special holder of the pipe bending device, along which the pipe blank will be bent.

- Using a pipe cutter, a pipe blank is cut to a certain length and installed in this bending device.

- Using a lever, a certain force is applied to the workpiece, as a result of which it bends at a certain angle.

Such manual devices for bending tubular blanks can be mechanically or hydraulically driven, and these two options are perfect for a home workshop.

The operating principle of almost all pipe bending devices is the same . The workpiece is fixed in a special device and, under a certain force, takes the required bending angle.

There are various pipe bending devices, and, naturally, each of them uses its own force system. For example, in crossbow or hydraulic type devices, a point force is applied to the bending section of the pipe.

According to another scheme, bending is carried out using several rollers, between which the workpiece is rolled, obtaining a certain bending angle. Pipe benders equipped with special inserts for pipes (mandrels) work according to this scheme.

What is a mandrel used for?

To understand the purposes for which mandrels are used, you need to know what can happen to a pipe during bending if you do not use a mandrel. For example, when bending a workpiece, two opposing forces act on some of its sections at the bending point:

- Compression of the wall of the inner radius, in which the metal, deforming, forms a wavy surface (corrugation).

- Stretching. In this case, the metal wall of the outer bending radius is stretched, due to which it becomes thinner. Naturally, this can weaken the strength of the pipe in the area of the bend by almost 50%.

If you do not use a mandrel, thin-walled copper, aluminum and other pipes made of soft materials can become especially deformed.

For the mandrel inserted inside the pipe before the bend, steel springs are usually used, selected to match the inner diameter of the pipes being bent. Sometimes the surface of the springs is coated with polyurethane to provide better stabilization of the pipe walls.

Clamping mechanism

Many craftsmen make a clamp from a regular car jack (mechanical or hydraulic). The forces that it is capable of creating are quite sufficient to give the metal workpiece the desired configuration.

greysv FORUMHOUSE user

I used an old gazelle screw jack as a clamping screw. Easily bends two 20x20 tubes.

If a hydraulic jack is used, it must be rated for 2 tons or more. The main advantage of a hydraulic clamp is that it can be operated without much effort. Advantages of a screw jack: it is easier for them to set the bending radius.

Instead of a mechanical jack, homemade screw clamps are often used. They also allow you to bend workpieces exactly according to specified parameters.

moning

Why is a screw worse than a jack? Order a screw with a smaller thread pitch from a turner so that less effort is applied when rotating. This will cost an order of magnitude cheaper than a jack.

Types and production of bending devices

There are not so many ways to bend a pipe, but there are quite a large number of devices for performing these actions. Moreover, they can be of very different types. In order to make a pipe bender for a round pipe correctly with your own hands, you can draw up drawings yourself or download them freely from the Internet.

Based on the principle of influencing a round pipe workpiece to bend it at a certain angle, there are various types of pipe benders.

Crossbow type model

These models of pipe bending devices are driven by hydraulic or screw drives. During the processing of the workpiece, the model is bent in the form of a crossbow arm, from which the name of the bending device comes.

The design of a crossbow pipe bender has some difficulties in manufacturing, but its power and technical capabilities are quite large. The device itself can be made with several functions, for example, using it as a bending machine and a hydraulic press.

Depending on the design of the rigid metal frame, the machine can operate in a horizontal position (the jack or other power device is located horizontally) and in a vertical position.

The design consists of a rigid frame and two rollers mounted on special racks welded to the platform. A jack is located in the center between the racks, and clamps are attached to the axes of the rollers, ensuring free fixation of the workpiece that is placed on them.

A punch for a pipe bender (shoe, template) can be made from old rollers, pulleys, or bent and cut along pipes.

The work of the crossbow machine is carried out in this way:

- The pipe blank is placed on the rollers and secured with clamps.

- A shoe (a template with a certain bending angle) is attached to the jack.

- The jack presses on the center of the workpiece with a shoe and smoothly bends it to a given angle.

Using the same technique, you can make a small manual pipe bender, with which you can easily bend durable thick-walled pipes of medium and small diameter. For this purpose, you will need to purchase a small hydraulic jack, two rollers, make a punch and a durable T-shaped metal nozzle for the jack.

The entire design of the “crossbow” mechanism must have a large margin of safety. Otherwise, if the workpiece falls out of the fixing brackets under the pressure of the jack, the operator may be injured.

Roller system

Such pipe bending models are also called rolling models. Using this system, you can bend round or profile pipes, as well as steel reinforcement to a large radius. An ideal device for preparing arcs for canopies or greenhouses.

The main elements of this type of device are three metal rollers, matched to the diameter of the pipe workpiece being bent. The workpiece is placed on two outer rollers and the third, located in the center, is rolled along the pipe. Under its force, the part gradually bends, acquiring a certain bending radius.

The system can be driven by a hand crank or an electric motor through a special gearbox for a pipe bender. The quality of the resulting product processed using this device is quite high, and the pipe itself, in contact with the metal rollers, receives virtually no damage.

The advantage of a rolling pipe bender is its small size, due to which the tool takes up little space in any home workshop and can easily be mounted on a workbench or wall. And due to the fact that it is made entirely of metal, the workpiece can be heated with a blowtorch or gas torch during its bending to facilitate work.

The simplest device

For urgent work that requires a hand-held round pipe bender to quickly bend an angled elbow, such as for a home plumbing project, a simple bending device can be made using the tools at hand. To do this, you should prepare a lever from a piece of metal round pipe with a diameter of approximately 32-42 mm or thick, preferably smooth fittings. The length of the lever should be in the range of 1−1.5 m, depending on the workpiece being bent.

A ring of thick-walled pipe trim approximately 30-40 mm wide is welded to one end of the lever. The inner diameter of the ring must be larger than the outer diameter of the workpiece prepared for bending.

Read also: Mathematical model of an axial piston pump regulator

Instead of a ring, you can weld two rods from a thick smooth rod to the lever. The rods are welded perpendicular to the lever and parallel to each other. The distance between them must be greater than the outer size of the workpiece prepared for bending.

The bending process is carried out as follows: P

- The workpiece is laid on a hard, flat surface, it can be asphalt, concrete floor, reinforced concrete panel or thick board.

- The tubular blank prepared for bending is threaded into the ring of the manufactured device or inserted between its pins, after which, acting on the lever with muscular force, it is bent.

Winding machine

Pipe bending machines of this type differ from other bending devices in that the pressure roller presses the workpiece directly against the template itself, as if winding the pipe around it. This allows you to bend ring-shaped and spiral parts from workpieces, which is completely impossible to do on conventional pipe bending machines.

During operation, the roller itself is stationary, but the template, to which the end of the workpiece is rigidly attached, rotates around its axis, winding the pipe around itself, which is why machines of this type are called winding machines.

The drive on such devices is most often electric, since twisting the pipe into a ring requires a lot of force. The mandrel for the template must be removable, otherwise it will be quite difficult to remove the spiral-curved workpiece from it. The template can be made of wood, PCB or metal .

The advantage of the winding machine is its simple design, but the disadvantage is some limitation in the size of the template and the need for a powerful lever.

Wooden conductor

This design can be considered a break-in device, and the difference is that there is no pressure roller. To make this device you will need thick plywood or boards; you can use a workbench or a massive chipboard slab as a base.

A template is made from a thick board, one side of which is rounded to a certain radius. It is rigidly fixed to the edge of the workbench in such a way that the workpiece prepared for bending can be freely wrapped around it.

The end of the workpiece can be fixed with a primitive wooden stop made of timber or by cutting the same board from which the template was made. The pipe is bent using muscular force smoothly, without sudden movements, then its damage will be insignificant, and the acquired geometric shape will be accurate and even.

To prevent the bent part from jumping off the template (punch), it is advisable to make a semicircular recess around the perimeter of its rounded part, treating the end with a round rasp.

Fixing the pipe on the template can be done in another way by stuffing a rounded piece of plywood on top of it, which should protrude beyond its edge within 6-10 mm. True, this option is well suited if the tube has thin walls, since bending parts with thick walls requires more powerful forces, and the wooden punch may simply collapse.

Before you start bending the pipe, it is recommended to pour dry sand into it and plug both ends with wooden plugs.

This will help to avoid the appearance of waves (corrugations) on the workpiece on the inside of the curved section, and large stretching of the metal on the outer wall of the bend.

Of all the existing pipe bending machines, the most widely used is the self-made pipe bender, which operates on the principle of a rolling device. This model of pipe bender has virtually no disadvantages; it is light in weight and size, can be easily transported and takes up little space during storage.

A pipe bender is a machine used to bend round and profile pipes at a given angle of 45, 60, 90 and 180 degrees. Every home craftsman dreams of having a pipe bender in his tool kit for bending round and square pipes. Many are considering the option of making such a machine at home.

For profile pipe

Profile pipe is often used to assemble the frames of greenhouses, gazebos, gates and wickets, canopies and much more.

Therefore, the owner of a garage or summer cottage sooner or later faces the question of how to bend a corrugated pipe at home.

A pipe bender will come to the rescue.

However, ready-made solutions cost a lot of money. Therefore, the best option is to do it yourself.

To make such a device you will need the following tools:

- Angle grinder, in common parlance – grinder;

- Drill with a set of metal drills;

- Welding machine, best of all – a household electrode inverter;

- A set of keys or sockets.

Before starting work, you need to draw up a drawing of the future bending machine so that all the parts relate to each other.

The main elements of a home pipe bender are:

- Frame welded from a steel channel or I-beam with a thickness of at least 4 mm;

- Roller shafts;

- The videos themselves;

- Sprockets for connecting a chain drive;

- Drive chain from an old bicycle or timing gear;

- Screw lowering the pressure roller;

- The rotation handles for the pressure screw and shafts are a hollow steel tube or a solid rod;

- Various accessories: nuts, bolts, washers, grommets, cotter pins.

It’s worth mentioning right away that if you don’t have rollers and shafts in your arsenal, it’s not possible to make them yourself without a lathe. As a last resort, you can cut the existing metal rods to size and sand them down. Barrels with an internal hole can be used as rollers.

Another option is old bearings. If you place them on a shaft, preheat them in the flame of a propane burner, and then boil them so that they rotate with the shaft, you will get a roller with a perfect circular surface.

With central roller

The sequence of actions when assembling a homemade pipe bender with a central pressure roller will be as follows:

- Using a grinder, cut the channel or I-beam into pieces of the desired size. Tack them pointwise, and then, when the frame is ready, weld along the entire length. Afterwards, for aesthetic reasons, you can grind the seams with a grinding wheel.

- Provide either legs from scraps of the same channel, or mounting holes for bolts that will allow you to clamp the machine to the workbench.

- Drill holes for the shafts. Also, using a drill and grinder, make slits in the vertical part of the frame. The pressure roller shaft will move up and down in them. Insert the shafts with the rollers on into the holes made and secure them with cotter pins.

- The threaded connection between the pinch roller rod and the blind frame is made either using a lathe or using a tap. Remember that large diameter threads are very difficult to cut. Be sure to use drill or other cheap lubricant when cutting threads.

- Carefully grind off the outer part of the shafts on both sides so that the sprockets can be put on them. Put on the chain with a slight slack; if you make the grip too tight, additional force will be spent on overcoming the resistance.

- Attach a lever to one of the shafts - to secure it, use the same lock as for the sprockets. If you want to strengthen the lever on the shaft, drill a hole and cut the internal thread. After screwing the bolt in, the lever will lock, and by unscrewing the bolt, the lever can always be removed for transportation. By rotating the lever, you can pull the workpiece through the rollers. By tightening the clamping screw, you can change the radius of curvature of the bent pipe.

Drawings and dimensions of a homemade structure:

With breaking frame

No less popular when making it yourself is a pipe bender with a breaking frame. Structurally, it differs in that all the rollers in it are stationary, that is, they only rotate, but move up and down.

Pressure on the pipe occurs by lifting the part of the frame where one of the outer rollers is mounted. The assembly process is similar to the previous one, but has its own nuances:

- Make the frame for the fracture bender not one-piece, but consisting of two parts. The two parts can be connected with a stud and two nuts.

- It is very convenient to lift the end roller using a screw lifting device or a jack.

- To rotate the sprockets, some craftsmen use an alternating current electric motor or even a gasoline motor, removed from a walk-behind tractor or fuel generator.

Preparing for the manufacture of the machine

Let's look at the option of making a pipe bending machine with your own hands.

Firstly, it is necessary to decide what size the machine will be, that is, whether it will be used permanently, in some room, or whether it will be mobile so that it can be moved and pipe bending work done in a convenient place.

Secondly, it is necessary to prepare a drawing, according to which the machine for making a bent pipe will then be assembled. You can do this yourself or find it on the Internet. Later in this article we will offer ready-made designs for a medium-sized machine, which we will analyze in detail based on its design.

The pipe bender must have a strong base, onto which all other parts, mechanisms and other equipment involved in pipe bending work are then attached. This base is best made from sheet metal 16-20 mm thick.

Devices for bending pipes can have different drives, namely: manual, electric, hydraulic, pneumatic or hybrid.

Main rules

The main causes of defects in pipe bending are incorrect (usually too small) bending radius and a short technological shank (“tail”), the distance from the end of the pipe closest to the bend to its beginning. The “tail” is needed not only for reliable fastening of the pipe, the “tail” is also an absorber for the release of technological stresses. A perfectly correct pipe bender can produce a wave or a defect (parasitic bend).

The rules for choosing the bending radius of the pipe RIZG and the length of the technological shank L are summarized in the table:

IZGIZG

- If the difference between the real and the nearest tabulated values of the pipe diameter P is more than 10%, the values of the initial calculated values are calculated by interpolation. Otherwise, we take the nearest one.

- The tabulated RIZG is reduced to the relative value rIZG, i.e. It is expressed in pipe diameters D or heights H.

- For pipes with a diameter of up to 10 mm, 1 is subtracted from rIG.

- For pipes with a diameter of 11 to 15 mm, 0.85 is subtracted from rIG.

- For pipes with a diameter of 16 to 24 mm, 0.75 is subtracted from rIG.

- For pipes with a diameter of 25 to 40 mm, 0.65 is subtracted from rIG.

- For pipes with a diameter of more than 40 mm, 0.5 is subtracted from rIG.

- Convert the relative rIZG back to the numerical (millimeter) RIZG.

- From the obtained value of RIZG, take the nearest practically convenient larger one.

Example: you need to bend 24x24x1.5 from a steel pipe, i.e. already classified as thin-walled, complex semi-arches for a flower house or hut. The structure is non-residential, light, the complex semi-arch is not a load-bearing structure (see below), i.e. "plumbing" wave and taffy are acceptable. We take data for the pipe H=25. According to the table we find rIZG = RIZG/H = 80 mm/25 mm = 3.2. Subtract the correction (for pipe H=25!): 3.2 – 0.65 = 2.55. Convert back to millimeters (again according to the table H=25!): 2.55x25 = 63.75 mm. That is, if we take a new bending radius of 65 mm instead of the “defect-free” 80, then the selection of bending devices and work will be simplified, the possibilities of artistic expression by the shape of the structure will increase, and there will be no visible and/or dangerous defects in the finished structure.

Simple - radius

A specific pipe bender is designed for a bend radius within certain limits. But to select a design prototype, you immediately need to know only its very general meaning:

- for small radii RIZG<5D (or 5H);

- for average radii 5IZG<20 D or H;

- for large radii 20D(H)IG;

Pipe bending methods

A pipe bender may have one of the ways to bend a pipe blank. These are rolling, winding, crossbow method, rolling and rolling.

Run-in

With this method, two bending rollers are used, where one is fixedly fixed, and the second is directly used to bend the pipe.

One end of the workpiece is secured to a stationary roller with a screw, and using the second end and a long lever, the pipe is bent to a certain angle. The longer the lever, the greater the force that can be created and the deformation process easier.

Two corners with a cross-section of 50x50 mm and a length of 400-500 mm, having holes for fastening, are installed on the base. You can use a corner of other sizes and sections. A channel is attached to them, which has a groove in the middle along which the clamp moves.

Winding

This device uses three rollers, two of which are small in diameter and the third is large. The two small ones are clamping; the larger one has a lock for clamping the pipe blank and a lever for a manual drive, with the help of which the bending process itself is carried out.

Crossbow method

The crossbow type pipe bender actually looks like a crossbow. The production of such a machine requires quite a lot of material, such as a channel and an angle 75. A frame is welded from this profile and two rollers involved in the production process are attached on top. A so-called shoe is installed on the jack rod, with the help of which the workpiece takes on a profile of a certain diameter desired for the finished product. This type of pipe bender is best used in the production of identical bent products in large quantities.

Rolling and rolling

The production of bent pipe products by the rolling and rolling method requires more serious equipment than for the above methods.

In order to make a rolling machine, you will need three rollers, one of which will move vertically, pressing the workpiece, and the other two will remain stationary.

The drive roller will be on the top, the drive is the simplest - manual, but if possible, you can install a gear motor with the rotation of the output shaft up to 100 rpm. This speed will be enough. The final product must have an ideal and uniform shape.

What types of devices are there for transforming pipes?

Transforming the curvature of a thin-walled pipe of small diameter is a completely accessible stage in obtaining metal blanks for frame-type structures.

It is enough to look at the drawings and photos of pipe benders, and it will become obvious that structurally they have a lot in common:

- base (support, emphasis);

- frame or frame (open or closed);

- strips, pipe stops or holders;

- screws or vice for fastening;

- injection, mechanical or operating device (alternative power part).

The forming of aluminum, standard steel and metal-plastic pipes can be done using the simplest manual template-type device.

Most pipe benders resemble a compact machine, but they have their own classification:

- by type of impact on pipes (running, winding, drawing, rolling);

- moving if possible (stationary and portable).

The drive type is also different:

- electric;

- manual;

- hydraulic;

- electrohydraulic.

If you use an electric drive or a hydraulic jack, it will take on the entire power load, saving time and effort. But its construction requires at least basic knowledge and experience in constructing household machines for metal processing. But such devices are several times cheaper than ready-made devices and their repeated rental.

The most popular and simplest in design are manual pipe benders of the template type. By bending around a profile or regular pipe along part of its circumference, a section of pipe is transformed at a given angle or the required curvature.

Pipe bending machine drive

There are many drive options for this machine, the main thing is that it is inexpensive to purchase and further maintain, simple to implement, and has affordable spare parts and components.

Drive options for bending machine:

- Manual. The simplest, most reliable and cheapest. For it, you need to make a lever that will be convenient for carrying out production work.

- Hydraulic. A hydraulic pipe bender for round pipes is already professional equipment and is used to perform work on an industrial scale.

- Electric. For such a machine, the drive is a gear motor, which is powered by a 220 or 380 volt network.

- Pneumatic. To drive such equipment, a compressor is required that will drive the feed and forming rollers.

- Combined or hybrid drive. In this case, several of the above methods are used in one machine.

For household work there is no need to use expensive equipment; a manually driven mechanism will be sufficient.

Types of pipe bending devices and mechanisms

Nowadays, you can find examples of pipe bending equipment that have different designs: from relatively simple devices for manual bending to homemade machines with manual or electric drive.

According to their purpose, pipe benders are divided into two types.

The first type is angular (they allow you to give the desired radius to a certain area of the workpiece).

The second type is three-roll pipe benders - machines and devices that allow you to form a given bending radius along the entire length of the workpiece.

Depending on the method of adjusting the radius, pipe benders are mechanical.

And hydraulic.

The support shaft drive can be either manual or electric.

Operating rules

In order for a homemade device to perform its functions correctly, you must adhere to a few simple operating rules:

- when using a welded pipe with a straight weld, the seam should be positioned towards the bend;

- in order to bend a pipe of larger diameter, it is recommended that at least two people work together;

- daily inspect equipment, various mandrels, and additional equipment to ensure that there are no loose nuts on bolts, cracks in welding or other visual defects on working surfaces;

- Periodically lubricate bearings, chains and other rotating and rubbing parts and mechanisms using high-quality lubricant.

Rolling or rolling pipe benders and their principle of operation

Rolling type equipment consists of two fixed and one movable rollers. The moving element acts on the material, and depending on its position, the bending radius is determined. A rolling type pipe bender is considered universal, as it allows you to obtain bends of different radii. The photo below shows a rolling machine for bending pipes and profiles.

Safety precautions

When carrying out production work on machines for deforming round and profile pipe blanks made of ferrous and stainless metal, basic safety rules should be observed:

- All work is carried out using personal protective equipment (mittens or gloves, glasses, special clothing).

- Work related to the deformation of large diameter pipes should only be carried out with a partner.

- The workplace must be kept clean. There should be no oil wrinkles, unnecessary objects near the machine, other debris, etc.

- All manual pipe benders for round pipes and profile workpieces must be very rigidly mounted on a stationary surface to avoid traumatic situations during production work.

Each home craftsman has the right to independently choose the size, type of drive and maximum performance of his machine.

To work with pipes or angles, a special machine called a pipe bender is required. This design allows you to bend metal elements at a given angle. If necessary, you can make a professional pipe bender with your own hands, which is used in a wide variety of industries. Unlike the industrial version, a homemade pipe bender is much cheaper. When carrying out the work, you can use available materials, which will greatly reduce the cost of the structure. Let's take a closer look at how to make a pipe bender with your own hands at home.

Making a manual roller model

Making a manual pipe bender with your own hands is made from steel parts alone without the use of special mechanical devices. This device is designed for local pipe bending. Direct manual force is used to deform the profile, so the pipe bender must be equipped with a long and strong lever.

Next, we will consider the process of manufacturing a two-roller pipe bender attached to a support frame. Tool sizes may differ from those suggested, depending on needs and materials.

Required materials and tools

Pipe deformation is a labor-intensive process that requires good and durable materials, otherwise, instead of the profile, the working tool itself can be bent.

To make a mechanical manual radial pipe bender you will need:

- Welding machine.

- Two rollers made of durable steel (eg 1045 grade) that have been pre-turned. The diameter of the larger one is 100 mm, and the smaller one is 60 mm. Both are 35 mm thick and have a 0.5 inch outer cavity radius.

- Steel pipe with a diameter of at least 1.5 inches with a thick wall (minimum 3 mm). It will serve as a lever, so its minimum length is 1.5 meters.

- Four steel strips measuring 15 x 6 cm and 4-5 mm thick for fixing the base of the pipe bender in a vice, supporting the pipe and making a handle. You will also need 20-25 cm of steel plate with a width of 60 mm and a thickness of 3 mm.

- Two bolts: the first is 0.75" in diameter and 60mm long for the large roller, and the second is 0.5" in diameter and 40mm long for the small roller.

- Steel plate 300 x 300 mm and a minimum thickness of 3 mm.

- Vise.

During the work process, you may also need other general household tools: a hammer, files, sandpaper, a ruler, etc. The above rollers are designed exclusively for pipes with a diameter of 1 inch, but by eliminating the circumferential recess from them, you can get a universal tool for bending a metal profile.

Pipe bender device

There are simply a huge number of different types of the device in question. Before creating it yourself, you should develop a drawing of a pipe bender or download it on the Internet.

You can make a pipe bender for a round pipe with your own hands, taking into account the following features of its design:

- Run-in. This type of pipe bending machine is characterized by the fact that one end of the workpiece is fixed, and a stationary template is used for bending. Running in is carried out using pressure rollers. This manual pipe bender design has been used for many years.

- Winding. A special pipe bender for aluminum pipes is characterized by the fact that the workpiece is pressed against a movable template, which is used as a roller. The broaching is carried out between the roller in motion and a special stop. As a rule, the drive is electric, since the required force is quite high.

- Crossbow design. This scheme is represented by a combination of two fixed rollers, as well as a movable template. The force is transmitted to the workpiece through a movable template, which is located between two rollers. By controlling the movement of the moving element, the most suitable bending angle is selected. It is worth considering that the pipe bender punch, which acts as a template, can have a different shape.

- Rolling or rolling. In this case, the scheme is represented by a device with three rollers, two of which are supporting and one is movable. The bending radius is adjusted by changing the position of the central roller. It is worth considering that such a device is considered universal, since the bending radius can be adjusted over a fairly large range. The dimensions of this type of pipe bender are relatively small; a homemade design can be compact.

When choosing the most suitable design for home-made production, it should be borne in mind that the version operating on the knurling principle is often produced industrially due to the high complexity of the main mechanisms. The crossbow bending method is used extremely rarely today, as it has one significant drawback: the pressure is concentrated on the upper part of the template. When using a crossbow machine, there is a possibility of a significant reduction in the thickness of the pipe wall, as well as its rupture. It is not recommended to use such a device for bending thin-walled workpieces.

The most widespread design is one that operates on the rolling principle. It is practically devoid of all the above disadvantages, has a relatively small size, can be portable, and has the ability to adjust the bending angle.

A homemade machine can have a very different design. When choosing a type, attention is paid to what radius should be obtained. The most important parameters of the workpiece, which can influence the choice of a suitable design, are the thickness of the pipe walls and its diametrical size.

How to make a pipe bender with your own hands instructions

If you have an example or diagram of a pipe bender, then making the machine yourself will not be difficult. You must adhere to the appropriate sequence of actions. To make a pipe bender for a profile pipe, the following manipulations are performed:

- On the shaft you need to place gears, as well as bearings and rings. The production of shafts is entrusted to an experienced turner. If you plan to create all the parts yourself, then you will need three shafts, two of which are distributed on the lower base (a channel serves), and the third is suspended on springs.

- The corresponding holes are drilled in the rings, which are needed in order to cut the thread. This thread is needed to attach gears to the shafts.

- The shelf for securing the third roller is also made from a channel.

- All elements are distributed on the frame and combined by welding or bolted connections.

- The first step is to install the frame on which the corresponding structural elements are distributed.

- The shelf is welded perpendicularly to the base.

- A handle is attached to one of the shafts.

- Finally, to adjust the bending radius of the profile pipes, you need to install a hydraulic jack on the top shelf.

If you make a tool according to a template, then there will be no difficulties

To clarify some points, you should pay attention to the following factors:

- The pressure shaft located on the shelf must be additionally secured to it. It is also secured with dowels.

- The pressure roller is made by performing the following manipulations: a shaft is fixed to the shelf, as well as springs that are attached to pre-installed nuts. After making the shelf, it can be welded to the frame of the main device.

- To tension the chain, you need to use a magnetic corner. It will serve as a holder.

- The sprockets are fixed with dowels made from Grover.

- The drive handle is constructed from a steel tube.

- The jack is placed on a hanging shelf.

The design of the simplest homemade unit for bending profiled pipes is presented in the video below.

Types of pipe benders

The design under consideration can be classified according to a fairly large number of characteristics. There are universal versions on sale, as well as for narrowly targeted applications. The device differs in the following ways:

- By drive type. An important design element is the drive, which can be hydraulic, electric, manual or electro-hydraulic. Recently, the electric drive has become more widespread, as it is compact and very efficient. Hydraulic is more efficient, but it is difficult to operate, takes up a lot of free space and requires periodic maintenance. A manual pipe bender is distinguished by the presence of a mechanism that significantly increases the applied force. If we consider homemade options, then they make a manual pipe bender with their own hands. In addition, you can create an electric pipe bender with your own hands. But it’s almost impossible to make a hydraulic version yourself.

- Classification is also carried out according to the degree of mobility. There are stationary and portable design options. In most cases, a universal manual pipe bender is designed as a portable structure. A homemade pipe bender for a round pipe can be attached to the base in various ways. It is worth considering that during the execution of work, part of the resulting stress is transferred precisely to the base. Therefore, when creating a homemade version, you need to ensure reliable fixation of the device.

- According to the method of influence on the workpiece - the main sign of classification. For example, a crossbow-type pipe bender has its own special design, which is suitable for bending metal or metal-plastic pipes. In addition, there is a design that works on the principle of running, winding or rolling.

DIY pipe bender

A homemade pipe bender for metal-plastic pipes can be of various types, but most often they create a mechanical type, when, due to a special design, the transmitted force increases several times.

How to make different types of pipe benders

The principle of operation of pipe benders is different - you can influence a section of pipe in different ways. For example, a spring-type device will help deform polymer pipes due to pressure. Segmental devices will stretch them, giving them curvature.

The method of making a template pipe bender is accessible even to a beginner. To do this, you need to accurately draw a part of a circle of the required diameter (or other type of curvature). This hemisphere or other curve is drawn on a wooden blank, as in the photo of a homemade template-type pipe bender.

The resulting part must be fixed on a stable base along the plane (wall, table).

After the template stop is ready, you need to figure out how to use a pipe bender of this type. This is clear from the drawing - the pipe is secured between the template and the thrust beam.

By exposing the opposite end to a heated aluminum or thin steel billet, the desired bend is obtained. If it is necessary to obtain segments of different curvature, several suitable templates are made.

Instructions for making a pipe bender

Recently, the question of how to make a pipe bender with your own hands has become quite widespread. Such equipment is required when setting up production activities of various types. The simplest do-it-yourself pipe bender has a template type of design. This is due to the fact that it is quite difficult to make rollers for a pipe bender with your own hands.

Considering the template pipe benders for round pipes, we note the following points:

- In the manufacture of structures, solid wood is often used. This greatly simplifies work and reduces costs. However, it is worth considering that the low strength and rigidity of wood determines the use of such a machine only for bending aluminum, which has high ductility.

- The wooden block used must have dimensions that are larger than the diameter of the workpiece being processed.

- The template must have a radius that matches the bending radius. In order to simplify the process, a small groove is created in the central part of the surface that is in contact with the workpiece.

- For ease of operation, two handles are created, which have a metal fastening.

- Having created a pipe bender at home, it should be attached to a solid base, and a stop should be installed on the reverse side.

Read also: How to determine the thermal conductivity of a material

An important point is that the design in question is applicable to a greater extent for large-diameter bending. In addition, a shoe for a pipe bender of this type is not required; the load is distributed evenly, which allows processing of thin-walled workpieces.

Pipe bender manufacturing process

You can make a pipe bender with your own hands according to other drawings. Before choosing the most suitable design, you should consider how often the work will be carried out, for what type of workpiece the machine is made, and how mass production will be. The template-type design is characterized by rather large dimensions, however, to manufacture it, it is enough to carry out carpentry work; the materials used are low cost.

Making a simple template-type pipe bender

A simple rolling pipe bending machine can even be made from wood. Naturally, this will be a manual pipe bender, the design of which may not even include a pressure roller if it is used for thin-walled products. The template for such a device is made from a wooden board, the thickness of which should be such that it exceeds the diameter of the pipe itself.

Wooden template for a simple manual pipe bender

For ease of work, it makes sense to consider profiling the template from its end in order to avoid the pipe jumping off during bending. For these purposes, you can fold two boards, first sawing one edge at a time, thus creating a kind of gutter. A pre-drawn drawing will help avoid mistakes.

When using such a pipe bender, the template is attached to a reliable base, and a stop is attached to the left side of it (for right-handers). The pipe that needs to be bent to the required radius is placed between the template and the stop and carefully bent, making sure that it does not jump off the template.

Collapsible hook template

With the help of such a pipe bender, made from scrap materials, you can bend along a large bend radius. You can avoid making a wooden template and simplify the device by replacing it with metal hooks fixed to the base, located in a circle with the required bend radius. This device is convenient in that the dimensions of the bend can be changed at any time by placing the stop hooks around a circle with a different radius.

Armed with a manual winch, you can significantly expand the range of work performed due to a noticeable increase in traction force for bending pipes.

The winch will help expand the functionality of the simplest manual pipe bender

Roller pipe bender

The most complex design is considered to be a homemade roller-type pipe bender. In this case, a pressure roller is used to transmit force. When making a structure, metal and wood can be used, it all depends on how mobile it should be and what force it is designed for.

The features of this design include the following points:

- For pipes made from soft materials, wood is more suitable as the main material. It can be used to make a roller. For steel pipes, you will have to use metal, since the magnitude of the transmitted force will be significant. If desired, rollers can be purchased or made with your own hands at home.

- Design features determine the presence of a movable and stationary roller. In this case, a U-shaped holder is located in the central part.

- The bending radius largely depends on the size of the rollers used. That is why the movable roller must, if necessary, be quickly dismantled to install an option with a different diameter.

- The holder you install must also be able to rotate.

- A handle is attached to the installed holder; when rotated, force will be transmitted. It is worth considering that the handle acts as a lever. That is why the force that can be transmitted depends on its length.

Such a machine is suitable for production in large quantities, since it is quite difficult to make rollers for pipe benders with your own hands. The device is suitable for working with round pipes.

A common question is how difficult it is to manufacture such a mechanism. When using this type of bending machine, the following points should be taken into account:

- First, you should study in detail the drawing or photographs of the equipment in question. Only by understanding the principle of its operation can you create effective equipment with a wide range of applications.

- This design has a relatively small number of main elements. An example is two pulleys, which can be made of wood or steel, a frame with a lever and a pressure roller. It is quite important to create a reliable foundation that will accept part of the effort.

The principle of operation is quite simple:

- The workpiece is placed in the groove of a stationary roller.

- The pipe is fixed in the desired position using a clamp.

- Using a lever, the workpiece is wrapped around a template, which also uses a roller of a certain diameter.

In order to significantly increase the efficiency of the design, an electric drive can be used. However, it is worth considering that with an electric drive it is quite difficult to control the rounding diameter indicator. In addition, the installed electric motor must transmit rotation through a reduction drive, since the rotation speed of the roller is low. To do this, install a gearbox or V-belt drive.

Winding type pipe benders

Examples of such devices are hydraulic pipe benders, which are used to bend round pipes. The design of such a device has a powerful pulley to which the pipe is attached at the bending point. This pulley is fixed on a reliable frame, and at its base there is a rod, which is driven by a jack. A significant force is created on the rod using a jack, which is transmitted to a lever that rotates the pulley and winds the pipe onto it. The lever can rotate freely around the axis of the pulley and is connected to it using holes located around its circumference.

A working example of such a pipe bender can be seen in the video below:

You can also make a similar mechanical pipe bender yourself using a rack-and-pinion jack. More physical effort is required when using this device.

Example of work on video:

Examples of devices of this type include homemade pipe benders, the rollers of which are made of wood. When working with such devices for bending round pipes, it is necessary to apply significant physical effort, which is reduced by a movable rotating roller.

An example in the video below:

Crossbow pipe benders

A crossbow-type machine has a rather unusual design. It got its name due to its similarities with medieval weapons. The crossbow pipe bender has the following features:

- The basis of the structure is represented by a frame, which can be made using angles and channels. The connection of all elements is carried out using welding; detachable methods are not recommended, since the resulting structure must have high rigidity.

- After creating the frame, two rollers are attached.

- A homemade version can be characterized by the fact that the force is transmitted directly through a mechanical jack. For a pipe of small diameter, the pressure created should be quite sufficient. The force is transmitted through a shoe made of durable metal with a low ductility index.

A crossbow-type pipe bender is more suitable for round workpieces. This is due to the fact that a product with a different cross-section can be greatly deformed under pressure.

Homemade winding machine for bending pipes

According to the principle of operation, such a tool is similar to a break-in tool. However, with its help it is possible to shape the pipes into a ring shape, which is impossible to do with any other device. If you examine the drawing of the device in detail, you will notice that the cheeks of the template pulley can be dismantled in order to remove a workpiece in the shape of a circle from it.

It is worth noting that a pipe bender of this design can be made from any available materials, including wood, metal or textolite.

Hydraulic pipe bender

When making a pipe bending machine with your own hands, you should decide what type of drive it will be. In most cases, homemade versions are manually driven, since it is easy to manufacture and inexpensive. However, such a design cannot work with workpieces that are made using hard metals. A hydraulic pipe bender allows you to work with workpieces of large diameter and with significant wall thickness, however, the design is quite complex in design and has many features.

Device of a manual hydraulic pipe bender

When making a machine for a round pipe with a hydraulic drive, the following points should be taken into account:

- The force is transmitted through a working fluid, which is oil or water. All lines must have a high degree of tightness and also be designed for a certain pressure.

- A compressor can be used to create pressure.

- Pressure is transmitted to the working element through a hydraulic cylinder.

A do-it-yourself pipe bender for metal-plastic pipes with a hydraulic drive can have a wide variety of designs. An important element in this case is the drive, which allows you to automate the bending process and increase the scope of application of the device.

Frame design

Having decided on the center distance and the design of the rollers, you can mark the blank parts for the frame. Based on the experience of FORUMHOUSE users, it should be concluded that the strongest frames are made from steel channels (at least 80 mm wide). This material is easy to get, so you can safely take note of it.

The photo shows the machine at the manufacturing stage. And here is the drawing that is taken as a basis.

Person User FORUMHOUSE

During the work, some changes were made to the original drawings.

The presented drawing is not a mandatory guide to action, but provides an objective understanding of how a rolling pipe bending machine works.

Pipe bender from a jack

Most often, when making a homemade pipe bender, a jack is used as the main element. It comes in several types. The jack itself is initially made in order to increase and concentrate the applied force, due to which the structure can lift heavy mechanisms, for example, cars.

Pipe bender from a jack

A homemade pipe bender made from a jack, as a rule, has a fairly simple design:

- The workpiece is clamped between two stationary rollers.

- The force is transmitted to the gap between the rollers.

- The distance between the fixed rollers largely determines the bending radius and the amount of force required to obtain a certain angle.

As previously noted, when using a jack, you can make a crossbow-type pipe bender.

In conclusion, we note that almost any device is a relatively simple machine, which, due to the distribution of the applied force, bends pipes and other workpieces of a similar type. They are often used for bending products made using non-ferrous alloys and steel. The industrial version of the design outperforms the home-made one, as a rule, in terms of the degree of automation of the process. However, the cost of industrial pipe benders can exceed several tens of times the costs associated with the production of a home-made version. That is why a homemade pipe bender is more suitable for household use or small-scale production.

If you find an error, please select a piece of text and press Ctrl+Enter.

Advice from the experts

In order to properly manufacture a tool, you need to choose its model taking into account the relationship between the bending radius and the cross-section of the pipes. This data can be found in special recommendations in table form. And, although the figures given there are optimal, the bending radius can still be reduced.

However, for this purpose you will need a mandrel, which will significantly complicate the work. If we talk about factory conditions, then in addition to the mandrel, hot rolling is often used in production.

At the same time, hot rolling can be performed at home if you have a stationary metal pipe bender with a fixed frame at your disposal. Then a blowtorch or gas burner is used to heat the pipes.

The most popular options for homemade pipe benders

The most technologically advanced and versatile are pipe benders that operate on the rolling principle. It is these devices, often equipped with an electric drive, that are used by professionals who are constantly faced with the need to bend pipes made of various materials, including stainless steel.

Homemade pipe bender option

The design of such a device is based on three rotating rollers, one of which is a pressure roller. Thanks to the gradually increasing pressure of the pressure roller and rolling repeated for each new position of the roller, bending of the pipe is carried out in the most gentle way, its walls are subjected to tensile manipulations very evenly.

Homemade electric pipe bender, made by yourself

Computer model of pipe bender

Computer model of a pipe bender Drawing of a pressure screw Drawings of shafts Drawings of shafts Drawing of a ring Components of a pipe bender Components of a pipe bender Assembly process Motor driven Motor driven View from the shafts Ready assembled pipe bender

The most important thing that such a pipe bender allows you to do is adjust the bending radius of the workpiece. There can be several design options for such a universal device: on the elements of the frame structure there are rotating thrust rollers, as well as a wheel with which the pipe is rolled; The side supporting surfaces and the base are made of sheet metal, and a screw drive is used to move the pressure roller. On devices of the second type, the minimum bending radius can be changed, which is achieved by changing the position of the support rollers.

The shafts of this pipe bender allow you to comfortably work not only with round pipes, but also with profile ones

The supporting structure for such a pipe bender can be made of wood. The roller axles, rod, fasteners and handle for turning the rollers, which can also be made of wood or polymer materials, will remain metal.

Above we looked at pipe benders in which the pulling process is ensured by rotating the pressure roller. There is also a category of devices in which the movement of the pipe is controlled by rotating support rollers.

Option with screw jack

An electric or manual pipe bender, in which rotation is transmitted to one roller, has limited capabilities. A pipe bender in which both support rollers rotate is characterized by a more complex design, since it is necessary to transmit rotation to two elements at once.

Required Tools

To assemble a pipe bender, you need at least the following tools:

- welding inverter;

- angle grinder;

- lathe (or purchase of finished parts);

- vice;

- hammer;

- metal file;

- sandpaper;

- ruler;

- drill.

But the most important thing is the pipe bender drawings. The mechanism must be manufactured strictly according to the drawing. You can take a ready-made drawing from this material or find another one and adapt it to the required dimensions.

But it is impossible to make a pipe bender without a drawing, since precise calculations are needed to ensure the operation of the mechanical parts.

Types of methods

A pipe bender for metal-plastic pipes is a basic machine that operates on one mechanics. The machine is indispensable for pipelines, including thick-walled and metal-plastic ones. It can work with different types of metal (steel, aluminum, copper, zinc and their alloys). For greater productivity, the bend areas can be pre-red to release the metal, relieve internal stress and make it softer.

Cold method

Common in garage craftsmanship. If you don’t have a blowtorch or burner, you can use it. The disadvantage is that it requires more effort. Cold metal is harder and can crack. Therefore only suitable for raw steel and soft non-ferrous metals. Safer compared to hot rolling, since you don’t have to work with high temperatures.

Hot method

Requires a torch and blowtorch. Heating relieves stress from the metal and therefore it becomes more pliable, but this is only relevant for thin-walled pipes. Thick-walled tubes cannot be heated to more than 300 degrees in a garage.

Photo of ideas for pipe bending machines for DIY production

Below are options that will help develop your idea of making homemade pipe benders at home. You can assemble a pipe bending device not only manually, but also electrically. However, this is only relevant when you have to work with a large amount of steel materials every day.

Rolling machine for bending pipes from a jack

Design of rolling machine with gears

Simple pipe bending machine

Rolling machine to bend pipe

An interesting version of the simplest pipe bender

Pipe bender for bending decorative steel pipes

To summarize, it should be noted that having a pipe bender in the garage, there will never be a need to invent anything to bend the workpiece. The devices are especially popular among craftsmen who make arches, gates, and metal fences. These craftsmen will need more than one machine, since in addition to pipes and profiles, there is a need to bend steel rods, fittings, squares, etc. Having once taken the time to make a pipe bender, you will never again have the need to think every time where and how you can bend a tube or profile.

Manual pipe bender on a roller mechanism

Making a manual pipe bender on rollers with your own hands is somewhat easier, since there are fewer mechanical elements. The device allows you to bend pipes in certain places.

The device must have a long lever, since direct manual force is required to bend the products.

How to make a manual profile bender with a rolling roller.

This type of pipe bender allows you to bend profile and round pipes at an angle of 90 degrees or more.

Bending a round pipe using the rolling method.

Bending of a profile pipe using the rolling method. Pipe bending diagram.

The principle of such a pipe bender is based on rolling a pipe with a roller. The roller profile must match the pipe profile. This condition prevents unwanted deformations of the pipe at the bend. That is, protrusion of pipe walls and creases are excluded. This pipe bender allows you to bend profile and round pipes.

To bend round pipes, you will need rollers with a semicircular profile. Here, unfortunately, it is impossible to do without turning work. But for bending pipes with a profile section, you can make rollers yourself.

How to make rollers for bending profile pipes using the rolling method.

These videos are pretty easy to make. You will need sheet metal, a drill, an angle grinder (grinder) and a bolt.

- We take sheet metal and mark a circle.

- Use a grinder to cut the metal around the marked circle.

- Drill a hole for the bolt in the center of the workpiece.

Drill a hole in the workpiece.

4. Insert a bolt into the hole, tighten it with a nut and secure the structure in the drill chuck.

A bolt inserted into a workpiece.

5. Process the edge of the workpiece using a drill and grinder. You need to install a cleaning disk in the angle grinder.

We grind the workpiece.

6. We assemble the processed workpieces into a roller. Please note that the roller has a protrusion of approximately 5 mm in the center. If you have read the entire article, you should already know its purpose. Such a protrusion in the center of the roller should be made only on the central fixed roller; it is not needed on the rolling roller.

Roller for a pipe bender made of five circles.

Making an electromechanical pipe bender

We decided to tell you how to make an electromechanical model of a pipe bender. Such equipment can cope with any amount of work without the need to apply physical force.

For study, we present two versions of instructions on how to make a pipe bending machine for round pipes with your own hands. If you have any questions after reading the text manual, we recommend watching the video materials as well.

The device consists of three working elements - one pressure roller and two support rollers, which is why it is also called a three-shaft rolling machine. This is one of the most complex bending mechanisms that you can assemble with your own hands, but we decided to start with it. If we succeed, then it will not be difficult for us to make simpler types of pipe benders.

So, we will make the device from: 204 bearings, anti-roll bar from a VAZ car, nuts, studs, pipe scraps (20 by 40 with a thickness of 2 mm, 15 by 15 by 1.5 mm; 80 - 80 - 5 mm), metal sheet 3 mm thick.

To assemble the electric bending machine, we used the following drawings.

Rolling machine diagram

Shaft diagram

Fork drawing

Bearing supports

Cheek drawing

Clamp screw diagram

Let's get to work, step-by-step detailed instructions are as follows:

- We prepare the frame - for this you will need two pieces of reinforcement or profile of the same size, on the top wall of which we make 4 holes for our studs.

Parts for the frame

- We cut out two side walls of the structure from a metal sheet, make holes in the blanks for attaching them to the frame and installing the rollers, as well as a large window for the movable roller. Holes should be made in two workpieces at once so that they coincide.

Cutting out the sides

- We take the cross-section stabilizer from the Zhiguli, grind it under head 19, this will allow you to rotate the shaft with a screwdriver. A bearing with a diameter of 20 mm will be placed on it.

Making grooves on the stabilizer Putting on the bearing

- We begin to manufacture a clamping mechanism from a screw and a piece of channel, the size of which should be slightly smaller than the distance between the side walls of the structure so that the workpiece moves freely in it. We make a hole in the channel equal to the size of the screw, into which we weld a nut. Then we screw in the screw and secure it with a nut from below. We drill a hole in the top of the screw and insert a pin into it, which will serve as a handle.

Weld the nut and insert the screw

- We put two bearings on the shaft and secure them with washers. The workpiece is installed on the channel, in which we previously made holes for the pressure screw and side holes for fastening.

Assembling the pressure shaft

Let's start assembling the device:

- insert the studs into the holes of one side wall and secure them with nuts;

- the middle pins are our input and output rollers, they are stacked, the size depends on the configuration with bearings for various tasks;

Insert roller pins

- We put washers on the lower studs, and then install two blanks from the profile, which will serve as the base of our machine;

Installing a profile base

- We place the pressure shaft in the middle of the structure, pushing the screw into the hole, it should be located exactly in the center between the rollers, and between the screw and the cheeks we install gaskets made of a metal plate;

Place the pressure shaft

- We fasten the clamping screw to the shaft channel with a nut;

Fasten the clamping screw

- cover the structure with the second sidewall and tighten the nuts.

We dress the wall

If you weld a handle to the shaft, you get a mechanical device that will work from your efforts.

The machine is ready, all that remains is to put the head on the sharpened side of the shaft, and then use a screwdriver to operate the device. This is a universal ring bending machine, using it you can bend not only round, but also profile pipes; you just need to change the nozzles on the rollers.

Jack pipe bender

A simple and convenient device for bending profile pipes. For production you need the following materials:

- jack;

- 4 corners 40 cm long with equal shelves of 50 mm each;

- 2 rollers with grooves for belts. There should be through holes in the center. If they are missing, drill, measuring the middle;

- equipment for a jack in the shape of a semicircle with a recess inside;

- 2 channels 60 cm long and 10 cm wide;

- bed;

- 2 mounting bolts.

Rolling or rolling pipe benders

They are a structure with three rollers, two of which are stationary, and one, installed in the middle, is capable of moving up and down relative to the other two. This arrangement of the rolling rollers during the forward movement of the pipe allows it to be bent in an arc. With several rolling passes, you can obtain the required bending radius of the pipe.

The disadvantages of the rolling method include the low productivity of manual devices.

The advantage is the ability to bend almost all types of profiles, including thin-walled sizes.

It is worth noting that the rolling bending method has proven itself well on industrial universal bending machines, where mechanical rolling of the workpiece using an electric drive is used, and the number of rolling rollers is determined by the technological map.

Bending a round pipe using a mandrel is a fairly old technology. Thus, there are several types of mandrel, such as:

- rigid in the form of a fixed rod;

- polished with a certain curved shape;

- segmental, consisting of a set of bending segments.

The advantage of this method is that it allows you to bend a round pipe to fairly small radii, almost at a right angle.

Types of pipe benders

These mechanisms are designed for bending various rolled products, pipes and rods without destroying their cross-sectional structure.

Principle of operation:

Mechanical manual. Designed for deformation of various small-sized profiles, mainly made of soft metals.

Hydraulic. Mainly of the crossbow type, they are used to give the yoke profiles a curvilinear shape in a specific location.

With ratchet mechanism. Human physical energy is also used at the same time. fixation of the bending value is achieved after each movement of the lever.

Electrically driven. Makes work easier, but the financial costs are much higher.

How to make a rolling machine for bending pipes and plates using improvised means yourself

If you have to bend more than a dozen large-diameter pipes, then you should make a more serious device. To do this, you will need not only consumables, but also a welding machine. Rolling machines are popular due to their advantages:

- Ability to bend tubes and profiles of different diameters, thicknesses and sizes

- Pre-setting the bend radius or angle

- There is no need to do the work manually, since the process occurs automatically, and a person only needs to rotate the handle through which the material moves

- Compactness - machines of this type are mobile and do not require much space for storage

Let's consider the simplest option for making a pipe bender from improvised means according to a previously prepared drawing. To make the equipment you will need the following materials:

- Channel size 50x100 mm and length 1 meter

- Pipe with a diameter of 80 mm and a length of up to 50 cm

- Screw jack. If you have an oil jack, you can use it

- Bearings in the amount of 6 pieces, from which rolling rollers are made

- Tubes with a diameter equal to the size of the inner race of the bearings. Rolling rollers will be made from it

- Angles for securing rolling elements

- Consumables - steel plates, steel bolts and nuts, etc.

You should first draw a diagram according to which the installation will be assembled. Below is a photo of the finished installation, based on which you can make a pipe bender.

The process of manufacturing a rolling pipe bender from improvised means is as follows:

- The base is made from a channel 500 mm long. It is necessary to weld two pieces of tubes of 200 mm each at a distance of 15 cm from each other to the base

- It is necessary to weld a section of channel 250 mm long on top

- Make rollers from bearings, connecting them together with tubes

- The manufactured rollers should be placed on the top of the channel in different planes. To secure the elements to the channel, you need to use the corners, welding them to the outer surface of the channel

- The distance between the axes of the outer and middle roller is 20-25 cm

- The next step is to make a movable frame, which will be driven by a threaded jack

- The lower leg of the jack is welded to the lower frame, and the upper part is with a channel, on which the third roller of bearings and a tube should be placed. Connect the moving part to the fixed part using bolts and nuts, having previously drilled holes

- By connecting the movable frame with the stationary one, a structure is obtained, as shown in the photo below

- The final touch is the manufacture of a handle (you can use a pedal from a bicycle), through which the middle roller is activated. When the handle rotates, the fixed equipment or channel is set in motion

The bending angle is adjusted by the jack, and the pipe is activated by the handle. For measured adjustment, the device can be supplemented with a steel ruler, which can be used to guide the amount of bending. The result is a convenient machine for bending profiles, plates and reinforcement, a photo of which is shown in the diagram below.

Instead of a handle, you can connect an electric motor through a gearbox, which will increase the speed of pipe bending, which is important, for example, when making a greenhouse or arch. The video material presented below will help you make a pipe bender at home with minimal time and effort.