In home workshops, flexible shafts for electric drills are used less often than other tools. However, when you need to make holes or tighten screws in areas inaccessible to an electric drill, then in these cases such a tool, or rather, a mechanism, is indispensable. In addition, it is convenient to use even in an open place where holes are supposed to be made.

For example, if there is a need to drill holes under the ceiling, then it will be much more convenient to use just such a device. After all, it weighs less than any electric drill or even a screwdriver, so such a shaft is much more convenient to use. In addition, the flexible shaft, in addition to electric drills, can be used in combination with engravers or drills.

Homemade engraver with flexible shaft

In a home workshop, cases periodically arise when, during the manufacture of a part, it becomes necessary to process or modify a surface that cannot be reached with universal equipment. So the part may turn out to be bulky, fragile or not rigid, there is no way to secure the part or the surfaces need to be modified in place.

For this case, a hand-held device with a flexible shaft and mechanical rotation of the cutting tool is used. The device is called differently - an engraver with a flexible shaft, a mini-drill, a drill, etc.

This is a device that looks like a fountain pen, with a rotating, replaceable processing tool connected by a flexible shaft to an external electric drive. A hand engraver, used in conjunction with a flexible shaft, allows you to process hard-to-reach places on any product.

This device is universal because, using a set of various tools, it can be used to mill, grind, polish, engrave and cut material, drill small-diameter holes, and clean surfaces. By equipping the device with an appropriate working attachment, you can successfully use it for working on ferrous and non-ferrous metals, wood, bone, stone, glass, ceramics, plastics and other materials.

Although it is not difficult to purchase such a device on the modern market, many people act differently and make an engraver with their own hands. A homemade device will be inexpensive and will not cause any special problems during manufacture. Despite the simplicity of the design, a homemade engraver allows you to successfully perform the same operations as a serial model engraver.

To make a simple yet easy to use functional engraver, you will need some components. — Flexible shaft (located on the farm or purchased). — Working attachment (research or manufacturing). — Two ball bearings with a diameter of 22 x 8 mm. — Engraver drive. — A set of tools with which processing will be performed. For a homemade working attachment, any tool with a shank diameter from 1 to 3.5 mm is suitable.

However, as a flexible shaft for the engraver, it is possible to use the drive shaft from a drill or the shaft for the speedometer of a car or motorcycle. We use this option for our homemade product.

Due to the flexible shaft, the device has an advantage. There is no unnecessary strain on your hands during operation of the device. This is due to the fact that the shaft head is several times lighter than a power tool with a built-in drive.

Making a working attachment

The threaded part of the housing is designed to connect it to the used flexible speedometer shaft and corresponds to it in thread. In our case, it is M18x1.5 with a length of 10 mm. The 70 mm long body is bored out for two ball bearings with a diameter of 22 x 8 mm. As a drive shaft with a collet clamp, which will be installed in the housing, we use a double-sided hand tool with replaceable collets, which is sometimes used for drilling holes in boards. It's time to mechanize this tool.

For the width of the bearing, to ensure a tight fit, we clean the corrugations from the edges of the tube. We press the bearing on one side. To fix the shaft when clamping a cutting tool in a collet, select a sleeve of suitable dimensions, install it in the middle of the tube and secure it with a pin. We drill a 3.5 mm through hole through the installed bushing, in diameter, to install a stopper when clamping.

On one side (instead of a collet), we screw a piece of copper tube with a diameter of 6 mm into the threaded hole of the tool tube. To do this, at one end we first cut an M6 thread, and carefully compress the other end until the square fits tightly at the output end of the flexible speedometer shaft. As a result, the total length of the drive shaft must match the length of the housing.

We measure the distance from the front end of the tube to the hole for the stopper. We install the assembled shaft into the housing, all the way to the rear wall. Mark the location of the locking hole on the body. We remove the drive shaft and drill a locking hole in the housing. After lubricating the bearings, we assemble the working attachment. Check the alignment of the holes for the stopper. If the bearings are unprotected, cut out and install, on the collet side, a protective washer made of plastic or felt.

After the working nozzle body is completely assembled, the open end of the drive shaft should coincide with the end of the body, and the crimped end of the copper tube should be flush with the threaded end.

Install the collet of the required size.

We attach the flexible shaft to the body.

To secure the cutting tool

We use a drift as a stopper.

Tool

The following tools are used to transform a compact engraving device into a multifunctional processing device: - drills, with the help of which the engraver turns into a mini-drill; — milling cutters of various designs, allowing processing of flat and shaped surfaces, as well as holes, grooves and recesses of various configurations; — disk tools used to perform cutting operations on materials of small thickness; — metal brushes, which are used to clean the treated surfaces from traces of corrosion and other contaminants; — abrasive tools with working heads of round, semicircular, oval and cylindrical shapes, used for grinding and polishing surfaces; — tools with a conical working head for applying inscriptions and patterns to the surface of the workpiece; — tools, the working head of which is made of felt, for performing polishing operations.

Sufficiently high-quality cutters for engraving machines can be made from broken drills, if you give their working part the required configuration using a regular sharpening machine.

Device drive

A drive electric motor, which can be used as any motor powered by an electric current of 220 volts. This could be the motor from a washing machine or other household appliance that you do not use.

An electric motor from a sewing machine is optimal for a homemade engraver, since it is possible to regulate the shaft rotation speed within a fairly wide range. Such motors, as a rule, are capable of shaft rotation speeds of up to 6 thousand rpm, which is quite enough for a household engraver. It is better to work with soft materials at slow speeds, since a high rotation speed will lead to overheating of the tool or melting of the edges of the workpiece. It is recommended to work with metal at medium speed. It is best to process hard natural stone at maximum speed.

Make your own flexible shaft for a drill

The cost of a high-quality device is high, especially considering the fact that if the product needs to be used, it will be in a one-time quantity. To avoid having to buy one, you can easily make a flexible shaft for your drill yourself.

To make flexible shafts for drills with your own hands, you will need to take any braided wire. It can also be purchased, which will cost ten times less than buying a ready-made nozzle. If you plan to wind a spiral wire around the cable yourself, then you need to understand that it is impossible to do this at home. After all, armor steel is used as a spiral base. When such a device operates, the steel cable rotates inside the shell, and the armor in the form of a spiral wire bends in any position, but does not move. During operation, the device is held by hand by the spiral wire.

This is interesting! To make a homemade device, you can use a speedometer cable from a car or motorcycle in the garage.

Finally, a shank is made for the flexible shaft, which is installed in the drill chuck. To do this, use the tail part of a damaged drill. The cable is connected to the shank by welding (other connection methods are unacceptable). A collet chuck is attached to the second end of the wire, which can be taken from another power tool. A homemade flexible shaft for screwdrivers and drills has many advantages, but the most important thing is its low cost. Having used such a nozzle once for work, you can find out what its main advantage is and why manufacturers came up with this device. The ease of making an attachment in the form of a flexible shaft for a drill yourself makes it more interesting to make it yourself than to buy it on the Internet or a tool store.

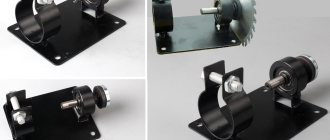

DmitrijAppliancesAdded Greetings to those who like to tinker, today we will look at how to install a flexible shaft from a drill onto an angle grinder. This will be useful for those whose drill has broken down and is left with a flexible shaft. Among other things, we will get a fairly powerful tool when compared with common Chinese and inexpensive drills. Such a tool will easily process iron, but it is desirable that the grinder has the ability to adjust the speed

If you are interested in a homemade product, I suggest you study the project in more detail!

List of materials: - flexible shaft from a drill; - nut and bolt (according to the diameter of the grinder shaft); - iron plates; - bolts and nuts. List of tools: - grinder; - welding machine; - drill; - wrenches. Attention! When working with a flexible shaft, observe safety precautions. If the attachment becomes jammed, the shaft begins to twist, which can lead to serious hand injury! Everything happens very quickly and you won’t have time to do anything.

Hold the shaft so that it cannot twist around your hand. The homemade process: Step one. Coupling First of all, we will make a coupling, thanks to which it will be possible to connect the cable of the flexible shaft with the shaft of the angle grinder. We will need a long nut with the same thread as on the angle grinder shaft. We wrap the bolt halfway into the nut and cut off the excess. Now the wrapped part needs to be turned out and, armed with a grinder, we make cuts in it, in the end you should get a cross. We wrap the part back into the nut, now you need to make a rectangle in the center, this is exactly the shape of the tip of the flexible shaft cable. To cope with the task, we need a special punch. We take a tap or other hard rod and sharpen it to a rectangle. Well, then we hammer this punch into the center of the coupling. That's all, now the coupling is ready and can be installed on the angle grinder shaft.

Step two. Frame and clamps

Step three. Assembly and testing

Delivery of new homemade products to the post office

Receive a selection of new homemade products by email. No spam, only useful ideas!

*By filling out the form you agree to the processing of personal data

- https://stankiexpert.ru/ehlektroinstrument/gibkijj-val.html

- https://moiinstrumentu.ru/gibkiy-val-na-drel-konstrukciya-i-prim.html

- https://usamodelkina.ru/14252-gibkij-val-na-bolgarku-jeto-ne-slozhno.html

Why do you need a flexible shaft and where is it used?

Using a flexible shaft is very convenient when you need to tighten or unscrew fasteners in narrow places with difficult access, where you cannot insert a screwdriver in the working position

Flexible shafts are also used to drive hand tools for fine and precise work. Placing a heavy, high-speed electric motor in the tool itself would lead to rapid operator fatigue and loss of precision in operations. An example is a dentist's or engraver's drill.

As a result, the user gets the opportunity to work for a long time with a comfortable, light and small-sized device, and the level of vibration from the electric motor transmitted to the hand is reduced.

Flexible shaft for screwdriver

A feature of the use of a flexible shaft is the limitation of the maximum torque that it is capable of transmitting. If this limit is exceeded, the cable becomes twisted and the shaft fails.

Bracket for receiving drilling machine

The multifunctional bracket will help you convert a standard hand drill (corded, with battery) into a stationary drilling machine. The body is made of heavy-duty aluminum alloy. Massive, allows you to securely install the drill for subsequent drilling. The fasteners are designed in such a way that they are suitable for all modern power tools.

The sole is equipped with a vice, which allows you to fix the workpieces in the desired position and avoid their displacement while drilling holes. The adjustable bracket allows you to set the desired height, taking into account the size of the tool itself. For convenient operation, there is a handle with a rubber pad that smoothly lowers the drill.

Multifunctional bracket for drill and screwdriver

| Price | 2,077.21 - 2,345.32 rub. |

| Rating | 4,6 |

| Reviews | 115 |

| Orders | 188 |

| Delivery to Russia | Free |

Design Features

The main design feature and at the same time the main advantage in application is the ability to bend it anywhere in any direction. This is achieved by using the following components:

The outside of the wire is covered with a corrugated plastic sheath, inside of which there is a grease. It reduces friction, prevents abrasion of the core cable and protects it from moisture and dust.

The design of the flexible drill drive also includes bearings to which the cable is attached. They keep it spinning. At one end the cable is fixed in a socket, at the other it is provided with a mount for a tool.

Extension shaft with collet clamp

Such a drive is intended for light and delicate work; you should not count on using it to unscrew a soured bolt or screw in a 130 mm self-tapping screw at full speed; you must remember that the torque transmitted by the flexible shaft is limited.

Conditions for successful operation of the structure

Bearing operation

If the bearing is correctly selected for the load and all landing conditions are met, long-term operation is guaranteed, since by standard all bearings are designed to operate up to 5 million revolutions. The standard also provides for the permitted bearing heating temperature. The heating temperature during operation should not exceed 35°C in front of the environment, the maximum heating should not exceed 80°C.

Work of the entire assembly

In industrial versions of the vibrator manufacturing, protection is provided by the design; in home-made ones, when the hammer drill chuck is rigidly connected to the drive, the entire load falls on the gearbox and the protection provided in the drills may be triggered (slippage of the protective clutches - ratchets, or power failure). Therefore, it is best to start with minimal resistance of the drive cable, positioning it strictly in a straight line.

How to make it yourself

Those who like to make tools with their own hands can easily make a flexible drive for a drill on their own.

Important! You won’t be able to make armor braiding yourself; this requires industrial equipment. It is also important to understand that a homemade flexible shaft for a drill will be inferior to a factory one, first of all, in terms of working life. And it’s better to use it occasionally - then it won’t let you down at a crucial moment. For professional work in large volumes, it is better to invest in a purchased extension cord.

As an option, you can take a cable from a car speedometer, as well as a motorcycle gas or clutch control drive as a starting material.

Do-it-yourself drill for small jobs

The drill has long ceased to be an exclusively professional dental instrument. Today, a drill with a flexible shaft is actively used to perform small decorative work, grinding, polishing, and cutting various products.

At the same time, it should be taken into account that for high-quality work of the homemade product you will need a fairly powerful motor. So, an 18V motor from a screwdriver is perfect for powering drills. The easiest way would be to make an engraver from an old blender.

To make a drill you will need:

- Disconnect the top part of the blender from the working part;

- Using a utility knife, remove the rubber cover on the button and use a screwdriver to unscrew the bolts located under it;

- Using a screwdriver, from the side of the power cable, pry up the top cover of the case and carefully remove it;

- Remove the circuit connected to the power cable from the blender body;

- Remove the plastic part located above the rotator from the housing;

- Remove the plastic tip from the electric motor shaft;

- Measure the diameter of the shaft with a caliper (if you don’t have one, a ruler will also work for this purpose);

- Clean the electric motor housing from oil and degrease its surface using an alcohol wipe;

- Place a collet chuck of the appropriate size onto the shaft;

- Replace the power button with a push mechanism that controls both turning the device on and off;

- Assemble the blender.

Parts for making a drill can be found at a flea market.

The hand drill is ready! Such a tool will be powered via a power cable with a plug. You can power the tool with batteries, but then the batteries will have to be changed or charged from time to time.

Flexible shaft for engraver

The engraver, or drill, develops high speeds - up to 30 thousand rpm. The device is small-sized and fits comfortably in the hand and is used for operations:

Working as an engraver requires high precision of the master's movements. The effort involved is small, compared to, say, tightening self-tapping screws. The torque is also low. Such devices are used by jewelers and artists who create works that are not inferior to the best examples of wood, stone, and embossing carvers. Engraving is performed on materials such as:

Flexible Shaft Engraver

The flexible shaft for the engraver allows the user's manual efforts to be reduced to a minimum, turning many hours of work into an exciting activity.

Job

Externally, a flexible shaft is almost no different from a thick cable, only its surface is often corrugated. Tight hinge joints are installed on the flexible shaft, which remain motionless during operation. You can notice how when you turn on the screwdriver, only the tips begin to move.

The user can hold the adapter in his hand and tighten or unscrew the screws without fear of damaging his palm. Some models have a limit when using self-tapping screws, and it reaches 4*70 mm. If this indicator is, for example, 4 * 100 mm, then after crossing 80 mm into the beam, the flexible shaft simply curls into a loop and cannot complete the task. If you try to continue working, the cable inside simply breaks off near the nozzle. The maximum load is 6 Nm.

Shafts for lawn mowers

Mechanical scythes with electric and gasoline drives use both flexible and rigid shafts.

Powerful brush cutters, capable of cutting tall, hard and dense grass and even small bushes, use all-metal rigid drives. Such devices are designed for long-term operation and have high torque. They are also large in size and weight and are worn on shoulder straps. The working tool is thick, rigid fishing line or powerful steel knives - two, three or four - bladed.

Speedometer flexible shaft

The flexible shaft transmits torque from the car or motorcycle transmission to the magnetic speedometer sensor. If the speedometer needle, when driving at a constant speed, begins to twitch or goes to the extreme position, it means the cable is faulty. You can replace it yourself. The flexible shaft is selected according to the parts catalog for your car brand. It must match in terms of attachment points and length. If the cable is too long or too short, there is a risk of bending it at too small a radius. This leads to extraneous noise (similar to howling), increased wear and premature failure of the unit.

Source

Features of using a flexible shaft for an engraver, drill and screwdriver

A flexible shaft, the main purpose of which is to transmit torque over a considerable distance, is most often used to equip engravers. This type of equipment, which is essentially a miniature grinding machine, is actively used for processing small-sized parts. In particular, the engraver is used as a mini-drill; it is used to perform miniature cutting, selective grinding of small elements of products and a whole list of other works.

The flexible shaft simplifies the use of the engraver, eliminating the need to hold the tool above the work site

The most common areas where flexible shaft engravers are used are the jewelry and electronics industries. Such equipment is actively used by design specialists, employees of car repair stations and workshops involved in the repair of household appliances and electronic equipment.

An electric engraver, on which a flexible drive is installed, is especially relevant in situations where processing must be performed in hard-to-reach areas of the product. Using replaceable attachments, such equipment can be used in all stages of processing, from roughing to finishing.

Flexible engraver shaft with protective springs at the ends that protect the rubber casing from damage

Design

This adapter has special requirements regarding bending rigidity. In the center of the structure there is a special cable or wire rod. They are made from materials that can withstand torsional loads. It is based on a metal core onto which the wire is wound. There can be several layers.

The safety of the tool is ensured by a rubber shell, which also provides additional protection for the core from damage and retains lubricant inside. In relation to the rotating rod, this shell remains motionless. On one side of the adapter there is a cartridge through which you can change attachments. On the other side there is a union nut or fastening fittings, through which fixation occurs with a screwdriver.

What operations are performed using an engraver with a flexible drive?

Special attachments help turn an engraver with a flexible shaft installed on it into a truly universal device, which include:

To ensure ease of operation with such a device equipped with a flexible drive shaft, you can purchase additional accessories - rubber grips on the handle, a power button lock, etc.

All kinds of holders are very useful, in which, in addition to the shaft and the engraver, you can attach various attachments

Engravers on which a flexible drive shaft is installed also include a drill used in dentistry, a manicure machine, equipment for processing natural stone and applying inscriptions and drawings to the surface of products made from it.

You can also use a flexible shaft for a drill or purchase a flexible shaft for a screwdriver. With this improvement to conventional power tools, a screwdriver attachment or drill can be successfully used to perform work even in the most difficult to reach places.

Drill attachment

The flexible shaft for the drill is made of wire to transmit rotation with several layers of braid. It has an increased safety margin, since it is designed for high speeds up to 1500 rpm. The length of the nozzles offered in stores ranges from 950–1250 mm. Other sizes are possible, but are less common or made to order.

Before starting work, unscrew the mounting sleeve on the drill and insert the end of the shaft into the hole for the tool. The locking ring is clamped, as when installing a drill, directly into the tool chuck. Now you need to fix the drill so that it does not move due to the vibration of the engine and does not fall.

In a store that sells a flexible shaft for a drill, you can also purchase a portable stand for hanging the tool. This simple device can be easily assembled with your own hands. When working in a permanent place, a clamp on a table or wall is sufficient. The flexible shaft cannot be used with high speed or impact drills. A tool with adjustable speed and reverse is best suited for performing work at a distance from the body.

How does the engraver work and how does it work?

The engraver, which allows you to process parts with high precision and productivity, works on the principle of a conventional drill, and in appearance it is very similar to a large automatic pen. The main structural elements of such a device are:

Rotation from the engine is transmitted to the axis of the flexible shaft, the reverse side of which is connected to the working nozzle. The mounting locations of the nozzles are unified, so there are no problems with choosing the required tool and replacing it.

Equipment selection criteria

When choosing an engraver, you should focus on a number of characteristics.

Based on the power level of the device, on which its performance directly depends, one can indirectly judge the operating life of the drive motor. The power of the engraver, which for serial models can be in the range of 35–300 W, should be selected based on the tasks for which it is planned to use such equipment. In addition, you need to consider how long it will work between turning on and off. The duration of the operating process depends on the hardness of the material from which the product being processed is made. The longer the engraver is used at one time, the more power it should have.

Low-power compact engraver is convenient for simple work without a flexible drive

The speed at which the motor shaft and the flexible drive shaft attached to it rotate is also selected depending on the hardness of the materials to be processed by the engraver. Models offered on the modern market can provide tool rotation speeds in the range of 10–35 thousand rpm. Low-speed models can be purchased if they will be used primarily for finishing grinding and polishing. When performing such operations, a small load is placed on the tool, so the engraver itself does not overheat, and therefore does not fail.

If you need a more universal device with a flexible shaft, it is better to give preference to engravers that provide the ability to adjust the rotation speed of the tool.

The speed controller significantly increases the functionality of the engraver

The weight and dimensions of the engraver influence how convenient and easy it will be to manipulate such a device during processing with its help. Engravers that have significant dimensions and weight are much more difficult to work with, but such devices, as a rule, have higher power and productivity. The weight of an engraver with a flexible drive shaft can be in the range of 0.5–8.5 kg. When choosing such a device, first of all take into account the required power and functionality, and only then pay attention to the weight and dimensions.

Since an engraver works by constantly holding such a device in his hands, its ergonomics, which characterizes the ease of working with the equipment, is an important factor when choosing. When assessing the ergonomics of a device, you should pay attention not only to its design, but also to the build quality, manufacturing materials, button placement and comfortable handle design.

Before purchasing a tool, you should hold the engraver in your hands and try out the buttons and latches.

These parameters are not indicated in the equipment passport. It is advisable to pay attention to them if the engraver will be used quite often. To evaluate how much noise and vibration the device makes during operation, you just need to turn it on and evaluate these parameters. As a rule, medium-power engravers make more noise, and in more high-speed equipment this problem is provided for by the manufacturers and is eliminated by including special elements in the design. You can only estimate how hot an engraver equipped with a flexible drive shaft gets during operation.

Choosing the cost of the device and manufacturer

For many specialists, the cost parameter is a priority; brands from well-known manufacturers are also quite popular. When purchasing a device from a well-known manufacturer, a person receives a guarantee of quality and service. But devices produced by famous brand manufacturers are not cheap. If you are offered a popular brand at a low price, it means there is a case of counterfeiting by low-quality Chinese manufacturers. This suggests that all that remains of the model is a beautiful name, written with taste. The list of well-known manufacturers who are responsible to the consumer for all their products looks like this: Bosch, Bort, Stayer, Gardenlux, Makita, FIT, Dremel, Prorab, Sturm, DeWalt, Vityaz. As for the differences in prices, there is a wide range. Simple, low-functional devices are purchased for the equivalent of 15–20 dollars, and for high-power devices with a varied number of processes you will have to pay about 1 thousand dollars.

For some novice professionals and hobbyists, the cost of the device and brand recognition play a purely symbolic meaning; it is much more important if the device exactly matches the job for which it will be purchased. It is this requirement that allows you to buy high-quality devices at a low cost from our domestic manufacturers.

Flexible shaft design

A flexible shaft for an engraver or any other equipment whose torsional rigidity has higher requirements than bending rigidity, as mentioned above, is used to transmit torque to elements that change their spatial position during operation.

The main part of the flexible shaft, which is responsible for the main function of such a device, can be a wire rod or a special cable. This element is made of materials with high torsional rigidity. Additional layers of twisted wire are wound onto the main core of the flexible wire shaft to give it higher rigidity. To ensure safe use of the flexible drive shaft, as well as to protect its surface from damage and retain lubricant on it, this device is placed in a flexible protective shell, which is stationary in relation to the rotating core.

This flexible shaft is equipped with a bit holder on one side and a union nut on the other to secure it to the engraver.

Depending on the design, flexible shafts can be of right or left rotation, which should be taken into account when selecting and using them. Not only the design of flexible shafts can be different, but also their length, sometimes reaching five meters.

The design of the fastener for such a device also depends on where the flexible shaft is installed - on a drill, engraver or screwdriver. Thus, fastening nuts or other types of fastening fittings can be placed at the ends of the shaft.

The tip of this shaft can be removed for cleaning and lubrication, for which there is a hole on the side

Various mechanisms and equipment are driven by flexible shafts of different designs. In addition to engravers, drills and screwdrivers, internal vibrators, brush cutters and many other types of technical devices are equipped with such shafts. The simplest and most familiar option for using a flexible shaft is to clear sewer pipes from internal blockages.

Mechanical car speedometers are also driven by a flexible shaft. Making a flexible shaft with your own hands is, of course, possible, but given the loads under which such a device operates, it is better not to experiment and purchase serial products from trusted manufacturers. You can only be puzzled by the issue of making a flexible shaft yourself if it will be used to drive low-power equipment operating at low speeds.

Make your own flexible shaft for a drill

The cost of a high-quality device is high, especially considering the fact that if the product needs to be used, it will be in a one-time quantity. To avoid having to buy one, you can easily make a flexible shaft for your drill yourself.

To make flexible shafts for drills with your own hands, you will need to take any braided wire. It can also be purchased, which will cost ten times less than buying a ready-made nozzle. If you plan to wind a spiral wire around the cable yourself, then you need to understand that it is impossible to do this at home. After all, armor steel is used as a spiral base. When such a device operates, the steel cable rotates inside the shell, and the armor in the form of a spiral wire bends in any position, but does not move. During operation, the device is held by hand by the spiral wire.

This is interesting! To make a homemade device, a speedometer cable from a car or motorcycle available in the garage is suitable.

Finally, a shank is made for the flexible shaft, which is installed in the drill chuck. To do this, use the tail part of a damaged drill. The cable is connected to the shank by welding (other connection methods are unacceptable). A collet chuck is attached to the second end of the wire, which can be taken from another power tool. A homemade flexible shaft for screwdrivers and drills has many advantages, but the most important thing is its low cost. Having used such a nozzle once for work, you can find out what its main advantage is and why manufacturers came up with this device. The ease of making an attachment in the form of a flexible shaft for a drill yourself makes it more interesting to make it yourself than to buy it on the Internet or a tool store.

Publications on the topic

Technical characteristics of cutting wheels for metal

Feather attachment for a drill and how to make it yourself

How to make a machine and sharpen a circular saw blade instructions with a detailed description

Choosing a line for a trimmer - what you need to know about consumables