The production of wood concrete is a special technology for the production of building materials, which in its properties is close to natural wood. Wood concrete has a low level of thermal conductivity and a fairly affordable cost. Arbolite blocks have a number of positive qualities, the main one of which is their suitability for the construction of walls of any buildings. The production features were popular back in the days of the Soviet Union, then the manufacturing scheme was replaced by other technologies. The popularity of these slabs is returning to the modern construction market.

Equipment for the production of wood concrete allows us to produce an affordable and practical building material that meets the requirements of GOST 54854-2011. Lightweight concretes based on organic fillers of plant origin have many advantages:

- resistance to biological influences;

- the material is vapor permeable;

- good sound insulation;

- wood concrete blocks are fire resistant;

- ease of installation and easy surface treatment.

Compound

The component component of wood concrete is an important stage of production technology, which requires a careful relationship of all components. When making wood blocks, it is important that the quality of the purchased materials is high. Any concrete includes binders, sand, filler (can be light or heavy).

Important! When mixing wood chips, it should be moistened in such a way that excess moisture does not release, and the layer of the needle-like structure itself is covered with a cement composition. During the tamping process, the cement will serve as a connecting link, the outer pores of the blocks will close, thus making the product airtight.

The size of the chips affects the amount of cement that will be used to prepare one cubic meter of wood concrete. When wood chips are made from dry wood, the result is a fine fraction. The needle-like structure requires more cement to be held together. The required volume of materials for the manufacture of one cubic meter of wood concrete:

- 8-10 kg of chemicals;

- 250 kg of cement;

- approximately 200-250 kg of wood chips.

The following materials are added to the chips:

- slaked lime;

- liquid glass solution;

- Portland cement;

- potassium chloride;

- aluminum and calcium sulfate mixture.

Technology

The production of wood concrete blocks is organized both at home and large-scale production is established as a profitable business. To do this, all aspects and stages of production are taken into account and are guided by regulatory documents.

The technology for the production of wood concrete according to GOST must begin with the preparation of the necessary ingredients, of which 85% are wooden components. Wood chips, sawdust, shavings are used. The most suitable types of wood: pine, fir, spruce, poplar, aspen, birch. The presence of bark, leaves and needles is allowed - no more than 5% of the total volume. The blanks are passed through a chipping machine and crushed. The recommended particle size is 5x25 mm. The multi-fraction composition will provide the required density of wood concrete.

The production of wood concrete slabs of large dimensions requires additional reinforcement of the product. A reinforcement cage made of rebar should be placed in a form that is half filled and then filled with wood-concrete composition.

The technology for preparing wood raw materials at home is carried out using various methods - constructing a chip cutter with your own hands or concluding an agreement with a sawmill for the supply of wood waste.

In industrial production, chemical reagents are added to raw materials - calcium chloride, aluminum sulfate, liquid glass. When making at home, it is recommended to keep the wood chips outside for three months, and the sawdust should be stirred periodically. To speed up the process, calcium oxide is added to the embankment - 200 liters of 1.5% solution are used per cubic meter.

Portland cement grade 400 - 600 is suitable as a binder. The mixture consists of 10-15% cement and no more than 1% plasticizers and demineralizers. Before mixing the components, the wood component is poured with a 10% lime solution; it will need to stand for 3 hours. At industrial enterprises, this method of soaking in a technical container takes up to 3 days.

All components are mixed in a concrete mixer. The result will be a homogeneous mass without lumps. The composition of water-chips-cement is 4:3:3. The mixture should have a slightly crumbly consistency and should hold its shape when compressed.

Instructions for self-production

Preparation of raw materials

- Sift the wood chips through a fine sieve to remove dust, sand, and small inclusions.

- Pour 6 buckets of filler into the concrete mixer. Start the drum.

- Dissolve 300–400 ml of chemical additive in 1 bucket of water.

- Slowly pour water into the rotating drum. Wait a few minutes until the wood chips are evenly moistened with the solution.

- Add 1 bucket of dry cement M500 to the drum in small portions. Bring the mixture to a homogeneous state.

Molding

Pour the finished mixture into a trough or tray, from where it will be convenient to scoop it up with a shovel. Cover the tray on which you will form the blocks with film. Place the mold in the corner of the tray. Using a shovel, fill the mold to the brim and compact the mixture with a block. Its shrinkage will be about 30%

If necessary, add concrete. Place the lid in the mold, tap it evenly with a hammer until it drops to the internal height marks of the block. Carefully, maintaining an upright position, remove the box from the unit.

- Remove the cover.

- Place the mold box 15–20 cm from the finished product and begin molding the next one.

To obtain the highest quality blocks, stripping should be done no earlier than 24 hours after molding the product. During this time, the strength of the block will reach 30%. In this case, it is better to make several dozen wooden formworks that can be removed and used every 2-3 days. The blocks will reach 100% strength after 30 days of storage in a warm place, protected from rain and wind.

The process of obtaining wood blocks

At the molding stage, trays are used to give the products standard dimensions. If it is necessary to make blocks of non-standard dimensions, plates are inserted into the molds, which increase the size and weight of the product. The slab can be triangular or trapezoidal.

To speed up hardening, add a dry calcium chloride mixture to the solution. The solution is poured in layers in three stages into pre-treated molds with lime. Next, the mixture will need to be compacted.

It is recommended to level the upper surface of the blocks with a spatula or rule. Then fill it with plaster mixture to about 20 mm.

When the building material has formed a shape, it is compacted using a wooden device covered with a metal frame. The most durable and reliable building material is one that has withstood and hardened for 10 days at a temperature of +150 degrees Celsius. To prevent the blocks from drying out, they are periodically watered.

Equipment

The necessary units for the production of wood concrete are sold assembled and include all processing and preparation cycles. Advanced technologies make it possible to produce various volumes of building materials with different sizes. To build a machine with your own hands, you will need the following units:

- wood chip cutter, which you can also design yourself;

- concrete mortar mixer or mixing apparatus;

- Press forms;

- vibration machine.

You can produce wood concrete by organizing the production of blocks yourself, and at the same time minimizing the costs of the necessary equipment. A machine for crushing wood chips can also be made by hand using improvised devices. To save money, the vibrating sieve is replaced with a manual sifting method.

It is recommended to replace the unit for producing the working solution with a concrete mixer. The manual mixing method is unacceptable in this method, as there is a risk of lumps and clots forming in the solution.

Forms of the required size are made from ordinary wooden boxes. It is recommended to cover the bottom and sides with linoleum or polyethylene film, this will allow the composition not to stick to the walls.

When the molds are filled according to the technology, the mixture is compacted. To do this, you will need a hammer for tapping the walls of the container and a drill, which is used to make a brick press. They also use a self-made vibrating table. This machine will reduce production time and increase productivity.

If the conditions for drying the material are not suitable, it is recommended to use a drying chamber. This drying method will increase production costs and make the blocks stronger.

Do-it-yourself machine for wood concrete blocks drawing

- Vibropress with a mold fixation mechanism.

- Form with self-sealing function.

- Lifting and rotating hopper with mechanical suspension.

- Winch for bunker control.

- Mixer.

- Winch for lifting dispensers with suspension.

- Trolley with dispenser for wood chips.

- Cement dispenser on a trolley.

- Container for preparing wood preservative.

- The platform is inclined.

- Pallet.

- Rokla.

- Metal construction.

Chip cutter for wood concrete

If large-scale construction is underway, but it is not always possible to buy the amount of wood chips, then you can’t do without a wood chip cutter. This device crushes the boards into chips, which are then completely ready for use (if the wood is seasoned).

The principle of the device is very simple - a metal disk (usually 50 cm in diameter) is placed on the shaft, in which there are openings (3-4, depending on the model), located relative to each other at an angle of 120° or 90°. Near each cutout, at an angle to it, there is a knife attached, which cuts off a piece of the board and feeds it into the armhole, after which it enters the crushing chamber, where it is brought to final dimensions.

The creation and operation of a wood chipper is clearly shown in the following video:

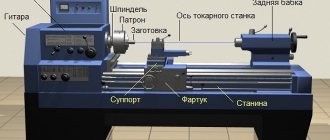

Despite the apparent simplicity of the design, not everyone has a self-made chip cutter, since a lathe and milling machine are needed to make the shaft and flywheel with knives. This equipment for processing wood concrete components will have to be at least partially ordered externally.

If a lathe is not an insoluble issue, then how to make a wood chipper is shown in the following diagram.

DIY production

The technology for making wood concrete yourself is not complicated if you have the necessary tools and devices. If you follow all the rules and manufacturing criteria and correctly calculate the components, the product will have high quality and strength.

Materials and accessories:

- Special container for components.

- Vibrating table.

- Surface with shock-shaking functions.

- Metal pallets.

- In order to obtain a high-quality solution, you need a concrete mixer. If you mix it yourself, it will take a lot of time and effort to obtain a solution of the desired consistency.

- Special plastic molds of the required sizes. Arbolite blocks have a rectangular shape, standard sizes are 500x189x300 mm and 500x188x200 mm.

- A special machine will professionally chop the wood chips.

- Using a press, a high density of material is obtained. During the compaction process, air is removed from the material as much as possible.

- The drying chamber for wood concrete blocks turns the structure into a solid one-component material.

- Shovels to load the mixture into molds.

- Reinforcing mesh is used to fasten wood blocks.

With such devices, on average, from 400 to 500 cubic meters of building mixture are produced per month. The recommended minimum size of the production premises is 500 m2. Electricity consumption will be 15-45 kWh. During preparatory work, organic components are poured with liquid cement until a homogeneous mass is formed. Observing the proportions and calculations, the resulting mixture should be free-flowing.

Bunkers and molds have a standard size of 20x40x60 cm; they can be welded or made from cut sheets of metal. It is recommended to place the blocks vertically during manufacturing; this will simplify compaction with a small press area.

Reviews and recommendations from experts for independent production of blocks

Experts and private builders who practice making wood concrete blocks leave reviews advising them to follow the rules to help achieve high quality products.

- In production technology, it is recommended to use not only large chips, but also sawdust and wood shavings.

- The consistency of the wood is processed in such a way that the sugar is removed from it. The technique will prevent further swelling of the finished material, which is strictly unacceptable in the construction of houses.

- During the manufacturing process, the mortar must be thoroughly mixed and ensure that all parts are in the cement mortar. This point is important for high-quality and durable bonding of wood and other materials in blocks.

- During manufacturing, it is important to add aluminum, slaked lime and other components. For example, liquid glass added to the composition will not allow the finished building material to absorb moisture, and slaked lime has antiseptic properties.

- Potassium chloride will not allow microorganisms and other substances that adversely affect the material to form in the structure.

- When mixing components, it is recommended to monitor proportionality so that the prepared mixture meets the requirements for the production of wood concrete blocks.

How to organize sales

Before starting to organize production, you should consider markets for finished products. Properly organized marketing and advertising campaigns, participation in exhibitions and forums, and cooperation with construction companies will quickly bring the desired results.

To work with large volumes of products, it is better to organize wholesale sales of wood concrete blocks.

You can sell products:

- through wholesale, wholesale-retail and retail bases and building materials stores;

- to private individuals;

- organizing advertising campaigns, submitting advertisements to the media.

Retail sales should not be discounted. It would be optimal to combine wholesale and retail sales of wood concrete blocks.

Despite the high competition in the construction industry, launching a workshop for the production of wood concrete will pay off fairly quickly. This building material is in increasing demand, the technology for its production is quite simple, and the raw materials are cheap and accessible. You just need to find a suitable premises, purchase equipment and start production.

07.03.2020