Both stainless steel and galvanized steel are often used in the same industries, mainly as raw materials for the production of corrosion-resistant products, parts and assemblies of machines, installations and units. The main difference between stainless and galvanized steel lies , first of all, in the service life, that is, the period of time during which the material retains its anti-corrosion properties.

Given the significant difference in price between stainless steel and galvanized steel , it is possible that the buyer may be supplied with galvanized steel stainless steel .

How can you distinguish galvanization from stainless steel ?

The most accurate and reliable method is spectral analysis, determining the chemical composition of steel using special instruments. This method requires special equipment and time. However, there are simpler but less accurate methods based on the differences between stainless and galvanized steel .

The external differences between stainless steel and galvanized steel can provide a quick answer. Galvanized steel may have characteristic spots, known to many from galvanized buckets produced once during the Soviet era, the so-called crystallization pattern.

In addition, visually, stainless steel usually has a more matte surface than galvanized steel , especially if the stainless steel has not been subjected to a fine mirror finish. Galvanized steel without crystallization patterns almost always has a mirror surface, with a subtle bluish tint. However, with high-quality processing of stainless steel, for example, according to the BA standard, it is quite difficult to visually distinguish it from galvanized steel . If the sheet is thick enough, it would be useful to carefully examine the cut location for uniformity.

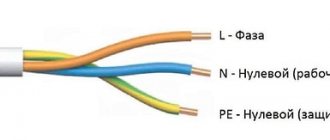

You can use the electromagnetic differences between galvanized and stainless steel . If a magnet is attracted to steel , then with a high degree of confidence we can say that it is galvanized steel , while most stainless steels and titanium alloys are not magnetic.

The chemical method, which uses hydrochloric acid, is based on the properties of zinc, which, when interacting with the coating of a galvanized sheet, actively releases hydrogen. A small drop of hydrochloric acid is enough for a chemical process noticeable to the naked eye to begin - the surface begins to bubble, the zinc layer gradually disappears.

And another way is to choose a reliable, trustworthy supplier of stainless steel and legally formalize the transaction.

When manufacturing metal containers or structures (for example, the widespread construction of hangars or warehouses), the quality of the metal, and, in particular, its corrosion resistance, is important. For this purpose, steels with protective (usually zinc) coatings, as well as stainless steel and aluminum are widely used. How can you distinguish between these metals and protect yourself from the actions of unscrupulous dealers?

Distinguishing aluminum from galvanization

In order to reduce the load on supporting structures, they are often made of aluminum. It is easy to distinguish aluminum from galvanized steel, especially if the buyer is not presented with a finished assembly, but with blanks made from rolled sheets or profiles. Main methods:

- By density/weight. The density of aluminum (2700 kg/m3) is almost three times less than the density of steel (7600...7900 kg/m3).

- In terms of surface hardness, aluminum is softer, and when scratched it will leave a deeper groove on a smooth surface.

- According to the effect on the tissue organs of the fingers. The thinnest film of aluminum dioxide upon frictional contact with wet skin of the hands will leave particles of aluminum on the surface of the fingers. When you touch them to a sheet of clean paper or cardboard, dark gray stripes will remain on it.

Externally, aluminum looks more silvery than steel, especially hot-rolled steel.

Which is better: black metal, galvanized steel or stainless steel?

Any manufacturer sooner or later is faced with the choice of material that best suits its requirements and budget. In this article we will look at the fundamental differences between black, galvanized and stainless steel, their corrosion resistance (the most frequently asked question) and give the estimated cost of each type of metal.

Black steel

Black steel

(colloquial ferrous metal, chernyaga) is an alloy of iron and carbon with a carbon content of up to 2%; with a carbon content of 2% to 4.5%, the alloy is considered cast iron. Depending on the proportion of carbon content in the alloy, steel is divided into: • Low-carbon (carbon fraction less than 0.25%) • Carbon (carbon fraction 0.25 - 0.6%) • High-carbon (carbon fraction more than 0.6%)

According to the method of obtaining rolled products, ferrous steel is divided into hot-rolled and cold-rolled. Their main difference is the processing temperature.

In the production of hot-rolled steel, low-grade steel is mainly used, due to which its cost is lower than cold-rolled steel. However, the thickness of hot-rolled steel in most metal warehouses varies from 3 mm to 160 mm.

Cold-rolled steel is widely used for metal structures that require thin sheet metal - from 0.4 mm to 3 mm; in some metal warehouses you can find sheet thicknesses up to 5-6 mm. Cold-rolled steel is considered to be of higher quality than hot-rolled steel, and therefore its cost is slightly higher than hot-rolled steel.

Black steel is often used in mechanical engineering, construction and industrial production.

We distinguish between galvanized and stainless steel

It is not easy to visually distinguish stainless steel from galvanized steel, since the difference in density is hardly noticeable (as is the appearance of the metal). The following types of tests must be used:

- For mechanical strength in the original state. Most grades of stainless steel have a tensile strength of at least 450 MPa. For galvanizing, this figure is much lower - up to 300...350 MPa.

- For hardness according to Brinell HB. For stainless steel, normal values are considered to be HB 230...300, for galvanized steel - HB 200...250.

- For plasticity. The specific force at which cracks appear on the workpiece is 170...230 MPa for galvanized steel, and 350...400 MPa for stainless steel.

If mechanical tests are not enough, chemical tests are carried out using hydrochloric acid. The method is based on the properties of zinc, which, when interacting with a galvanized sheet coating, actively releases hydrogen. A small drop of hydrochloric acid is enough for the galvanized surface to begin to bubble, and the zinc layer gradually disappears. The surface of stainless steel is chemically inactive.

Electromagnetic differences between galvanized and stainless steel can also be used for evaluation. If a magnet is attracted to the workpiece, then with a high degree of certainty we can say that it is galvanized steel, while most stainless steels are non-magnetic.

Corrosion irreversibly destroys any metal, due to which metal products completely lose their operational properties, turning into rusty dust and becoming unsuitable for use.

Fortunately, humanity has found effective ways to increase the corrosion resistance of metals - the most effective of them are alloying and applying protective coatings to the surface to prevent destruction.

Stainless steel vs galvanized: which is better?

Stainless steel and galvanization are almost Khabib and Conor in the world of corrosion control. Both cope with the tasks assigned as they should. This means there is a reason to compare and find out which is stronger.

In this article, we will understand why production features decide what is more durable, stronger, more environmentally friendly, cheaper, and which option is worth choosing.

How do stainless steel and galvanization work?

The differences between stainless and galvanized metal are associated with different chemical structures.

In fact, galvanized steel is an ordinary ferrous metal that is protected from corrosion only on the outside by a thin layer of zinc. Hence the name.

Most often, galvanizing is done this way: zinc is melted in a technological bath at a temperature of about 460 degrees and a steel sheet is immersed there. In air, molten zinc mixes with oxygen, and a thin film of zinc oxide appears on the metal surface. It protects it from corrosion in the future.

Hot galvanizing process for metal structures

Stainless steel is usually obtained using a more “hard” method. Depending on the grade of stainless steel, technological nuances may vary, but the general principle is production using an oxygen convector.

Molten cast iron is poured into the apparatus, alloying additives are added (the base is chromium; in addition, nickel, titanium, cobalt and other metals can be used). Oxygen is then introduced into the system. Next, a chemical reaction occurs. The carbon that is part of cast iron oxidizes and burns. Something like an “exhaust” appears - carbon monoxide.

After a time determined by the technology, the “excess” carbon burns out, and steel is obtained. And alloying additives provide high anti-corrosion properties. The fundamental difference is that the additives do not form a surface film, as is the case with galvanizing. They permeate the entire structure of the material, so damage to the surface layer does not lead to acceleration of corrosion processes.

Stainless steel smelting process

Which retains anti-corrosion properties longer

It is already clear from the previous subsection that the anti-corrosion resistance of stainless steel is higher. It’s one thing when only a thin layer of zinc protects from air, and quite another when the entire structure of the material is designed to interfere with the process of iron oxidation.

The maximum service life of galvanizing is significantly less than that of stainless steel:

- Service life of galvanized metal: 25 years.

- Service life of stainless steel: 50 years.

But in reality, galvanizing may be enough for a shorter period. The maximum durability of the surface is provided that paint is applied. In places where the paint is peeling or when there is mechanical damage to the surface, the service life is reduced.

Which is stronger

In all main strength characteristics, stainless steel is ahead of galvanized steel.

Tensile strength measures the ability of a material to resist stress before it breaks. Until the maximum load is reached, the material will “burst at the seams”, but will hold.

Tensile testing of a metal bar

Crack resistance is the maximum load that a material can withstand before its surface layer begins to collapse.

Hardness is the ability of a material to resist plastic deformation at the surface. The wear resistance of the material and resistance to mechanical damage depend on this parameter.

In these parameters, stainless steel is superior to galvanized metal. If the product operates under conditions of increased requirements for tensile strength, crack resistance and hardness, it is made of stainless steel.

Which is more environmentally friendly?

When galvanized is exposed to heat and comes into contact with acids, compounds hazardous to health are formed - zinc phosphides and oxides. These poisons can cause serious consequences: from stomach damage to nervous system paralysis and death. Therefore, galvanized steel is practically not used in the modern food industry.

Stainless steel under no circumstances forms compounds that could harm the health of people or animals, therefore it is optimal for the production of tableware and technological equipment for the food industry.

What is steel used for?

Today it is very difficult to overestimate the role of steel products in the life of modern society. Sometimes it’s enough to look around you, look at the metal household items that we use every day and think about what makes our life easier, more comfortable and more functional. You can find a large range of steel products in our catalog.

Steel underlies the activities of any manufacturing, industrial or construction enterprise - almost all mechanical, electronic and other products, as well as structures and devices with high strength and wear resistance, are made from it.

According to purpose, steel can be:

- Structural – designed for the manufacture of various mechanisms, structures and parts used in the construction of civil and industrial structures, as well as machine, instrument, ship and aircraft construction. Structural steel is an ideal base for sheet products, shaped products, fasteners, springs, rollers, membranes, plates and many others.

- Instrumental – used in the production of cutting, measuring and stamping tools.

- Special steels can be placed in a separate category - corrosion-resistant alloys with special physical and technical properties.

Characteristics of galvanized steel

No additional alloys are added to galvanizing, but rather it is coated with a layer of zinc. This coating creates a protective layer for the base steel and helps products cope with negative external factors that cause corrosion. The base metal does not come into contact with oxygen and liquids and is more resistant to mechanical damage.

Galvanizing is usually performed after the steel has gone through all technological processes. A layer of zinc is applied to one or two sides, depending on the product being manufactured or the technical specifications. Galvanizing is also applied to long and shaped steel. Zinc can be applied to finished metal structures and after manufacturing processes such as bending or welding.

What are stainless and galvanized steels used for?

Stainless and galvanized steel are products of development and modernization of the metallurgical industry. Due to their unique properties, these types of steel have a wide range of applications. Among the general advantageous characteristics of stainless steel and galvanization, it is necessary to highlight their high corrosion resistance and resistance to aggressive environments, which allows its use in industries that require good workability, exceptional strength and the ability to obtain reliable joints by welding.

Stainless and galvanized steels provide the user with the possibility of long-term operation without loss of quality characteristics and have an excellent appearance.

Galvanized or stainless steel: the difference in price pays off during operation

You can place an order by phone.

Our specialists will be happy to help you.

Galvanized and stainless steel have common properties of corrosion resistance and resistance to environmental influences, which makes the use of these types of metal popular in construction and industrial purposes.

Stainless steel

Stainless steel is a very practical material. Modern metallurgy offers a huge selection of steel grades that can meet a wide variety of conditions of use. The chemical composition of steels can vary and directly affects their physical and mechanical properties.

Today, almost all over the world, the AISI classification is used to distinguish between the characteristics of stainless steel (the abbreviation was first used by the American Iron and Steel Institute and is relevant for most manufacturers).

The materials of the 300 series are represented by grades that are austenitic steel with a fairly low carbon content. The grades have high corrosion resistance, as well as strength and ductility, and are easy to weld. They are used in the food, textile, pharmaceutical, chemical and paper and pulp industries, as well as in the production of equipment resistant to high temperatures.

The 400 series is a basic martensitic or ferritic stainless steel that has high toughness and heat resistance. Excellent for the production of cutting and measuring tools, springs, carburetor needles, piston compressor drains, parts of internal devices of devices and other various parts subject to wear in mildly aggressive environments. Steel grades of the 400 series are effective in arranging systems intended for pumping gas, oil and pure petroleum products.

Representatives of the 200 series have proven themselves well as a material for the manufacture of metal utensils, household kitchen utensils and apparatus. Also, steel grades of this series are used in the production of railings and stair railings.

Tips on how to distinguish galvanization from aluminum, stainless steel and non-galvanized steel

Since ancient times, iron has become the main metal for the production of a variety of things - from construction scrap to the finest mechanisms. To increase the strength and hardness of iron, they began to alloy it with carbon, producing the well-known steel. And to combat the main enemy of iron - corrosion - two main methods are used.

The first is the production of corrosion-resistant alloys, the so-called stainless steel. In addition to carbon, chromium is an important element in such alloys. The second method is to protect the metal surface with a special coating. Metals are usually used as coating materials, forming a protective film on the surface.

The most common material used for such purposes is zinc. Galvanizing is the process of coating steel products with a layer of zinc to protect against corrosion. Products made from this material are called galvanized. An alloy of zinc and aluminum, the so-called aluzinc, is also used for these purposes.

Advantages and disadvantages of galvanized pipes

Users include the following advantages of a galvanized chimney pipe:

- long-term immunity to corrosion;

- rapid heating of the chimney and, as a result, ensuring good draft;

- simple assembly method;

- a smooth surface inside the channel, which does not allow soot to linger on the walls;

- Possibility of venting through the wall of the building.

- short service life of a single-wall outlet;

- when cutting a product, the cut lines begin to rust after a short time;

- minor damage leads to the destruction of the protective layer;

- formation of a large amount of condensate.

Selection tips and approximate price

Manufacturers offer a large selection of both single-circuit galvanized bends and sandwich pipes with a galvanized shell. There are certain parameters by which you should select elements for the chimney:

- the diameter of the boiler outlet pipe must be equal to or less than the cross-section of the chimney outlet;

- attached chimneys can have no more than three bends along the entire length of the channel.

- Manufacturers indicate the required chimney diameter for boilers in the unit’s passport;

- The wall thickness for the outer casing must be at least 0.5 mm, usually 0.55 mm is used.

Stainless steel for centuries

The ability of steel with a high chromium content to resist corrosion was discovered at the beginning of the twentieth century. Since then, many types of steel have appeared, but chromium is still the main alloying element.

Stainless steel products are used everywhere - in construction, industry, household appliances, power generation, transport, and much more. Stainless steel sheets are often used to cover roofs and other parts of buildings - its anti-corrosion properties are very important here, given the variety of precipitation that the building receives.

Stainless steel is a very practical material. Available in a wide variety of brands, so it can suit a wide variety of conditions.

An interesting area of application for stainless steel, where it is practically irreplaceable, is the food industry. Stainless steel here meets high requirements for hygiene, aesthetics and toxicology. Also, the chemical and petrochemical industries and the production of household appliances are unthinkable without stainless steel.

How it is produced

Producing stainless steel is a very labor-intensive process. Stainless steel production technology involves a targeted change in its chemical composition by saturating the material with other elements, most often chromium (alloying), resulting in a product that is highly resistant to chemical and atmospheric corrosion. Due to the process of interaction with air, a film of insoluble oxides (chromium oxide) is formed on the surface of the steel, which protects the product from negative environmental influences.

Characteristics of stainless steel

Stainless steel differs from standard carbon or other types by the presence of certain additives in its composition. They are introduced into the material to change its chemical composition and make it more resistant to corrosion. Carbon steel is mainly composed of iron and carbon. And to get stainless steel, you need to add chromium and sometimes other alloying elements. Elements are added during the melting process and before molding. This changes the chemical properties. Alloying additives in stainless steel must be at least 12%. In addition to chromium, the structure of stainless steel is improved by nickel, cobalt, titanium, copper and other elements.

Difference between stainless and galvanized steel

Products made of stainless and galvanized steel do not have significant differences in appearance. An uninformed person may not even notice the difference and purchase galvanized steel instead of stainless steel from unscrupulous sellers. It should be noted that, despite the external similarity, the difference in price is quite noticeable. The high cost of stainless steel is justified by its longer service life, that is, the period of time during which the material will retain its anti-corrosion properties.

Stainless steel is not called the queen of steels for nothing. Despite its high cost, it has excellent characteristics that form its undeniable advantages: durability, ductility, environmental friendliness, hygiene, fire safety, high electrical conductivity, ease of processing and a very attractive appearance.

CORROSION RESISTANCE, PRICE, SERVICE LIFE OF CHERNYAGI, GALVANIZED, STAINLESS STEEL

The susceptibility of various types of metals to the corrosive effects of the external environment is determined by its chemical composition. The better the chemical composition and the higher the quality of the raw materials used, the more expensive it will cost.

1. CORROSION RESISTANCE

Black steel is most susceptible to corrosion

. If it is not additionally treated and coated with a protective layer, for example, paint, it will quickly rust and become unusable. The quality of the coating on black steel will also determine its service life. If you make a high-quality coating, for example, clean the metal, coat it with powder paint and bake it in a polymerization oven, the black metal can last a long time and may not suffer from minor damage. However, if the quality of the coating is questionable, for example, as when coating with spray paint, then with the slightest impact the paint can come off the metal and the steel will react with air and/or water, and rust will not be long in coming.

Cink Steel

, despite the zinc coating, can also be subject to corrosion. The better the coating, the longer the galvanization will last. Often, galvanized steel is coated with powder paint, which serves as double protection for the metal: the first layer is zinc, the second is paint.

Stainless steel

Different brands have different susceptibility to corrosion. Of the most popular grades of the 300 and 400 series, stainless steel of the 300 series has greater corrosion resistance (for example, AISI 304 12Х18Н10Т, GOST 5632). If you intend to use metal in an aggressive environment, you should not be fooled by the use of the word “stainless” in the name of the brands; you need to have an idea of the chemical composition of the metal and understand its features.

By price

Of the listed materials, the cheapest option would be

black steel

.

The next most expensive option is galvanized steel

and the most expensive option would be

stainless steel

.

As an example, we give the approximate cost of 1 kg of each material (as of September 2022): – black hot-rolled steel – 46 rubles/kg – black hot-rolled steel – 50 rubles/kg – galvanized steel – 68 rubles ./kg – stainless steel 304 series – 230 RUR/kg – stainless steel 430 series – 160 RUR/kg

Stainless steel products

Thanks to the unique qualities of the alloy and high aesthetic values, stainless steel products have always been in high demand, not only in industrial sectors, but also in everyday life. The modern metallurgical industry offers a huge range of stainless steel products:

- Equipment for food production.

- Furniture.

- Fittings – sheets, round and profile pipes, circles.

- Tanks, containers, trays.

- Parts and parts blanks - transitions, tees, plugs, dampers, valves.

Stainless steel is used in construction, energy and mechanical engineering to create high-precision elements. Most manufacturers offer custom manufacturing of any stainless steel products.

What is the difference between stainless steel and galvanization - we understand all the nuances

Alexander Shishkov

SMC Consultant

Reading time: 8 minutes

What is the difference between stainless steel and galvanization - we understand all the nuances

Corrosion is the main enemy of metal. After the first contact with water, unprotected ferrous metal begins to become covered with orange-brown or yellowish rust spots. Over time, pockets of corrosion grow and penetrate deep into the metal, which over time leads to the complete destruction of metal products and structures. The main cause of rust on a metal surface is the thermodynamic instability of the metal to negative external influences.

The rapid destruction of metals and alloys as a result of corrosion has forced metallurgists to look for ways to protect metal products in order to preserve their performance characteristics. This is how technologies emerged that increase the resistance of alloys to the negative effects of external factors. Until now, anti-corrosion coatings and alloying are considered the most effective ways to protect metal. These technologies make it possible to produce various grades of stainless steel and galvanized steel.

How are galvanized and stainless steel produced? How to distinguish stainless steel from galvanized steel? What is stronger and more durable - galvanized steel or stainless steel? We have prepared answers to these and other questions in this article.

How galvanized steel is made

If galvanized metal is the same ferrous metal (carbon steel of ordinary grades), coated with a thin layer of zinc, then stainless steel is an alloy of iron and carbon, which also contains chromium. Stainless steels are often smelted in arc and induction electric furnaces, and less often in oxygen converters and open-hearth furnaces.

Chromium is the main alloying element in the production of stainless steel. The corrosion resistance of stainless steel directly depends on the chromium content in the alloy: with its content of 13% or more, the alloy does not corrode under normal conditions and in mildly aggressive environments; if the chromium content exceeds 17%, then such stainless steel performs well in more aggressive environments .

Both stainless steel and galvanized metal have increased anti-corrosion properties. The main difference between stainless steel and galvanized steel is the chemical composition and production method.

How to distinguish galvanization from stainless steel

At their core, these are two completely different materials. There are several ways to find out whether you have galvanized or stainless steel:

Visually. You can distinguish galvanization from stainless steel by external features - the color and surface of the product. Galvanization has a certain relief formed by zinc crystals when interacting with oxygen (the so-called crystallization pattern). Stainless steel has a uniform surface.

Using a magnet. This method allows you to determine austenitic and austenitic-ferritic alloys with a high chromium content - they are not magnetic. However, there are stainless alloys that are affected by a magnet, just like regular carbon steel. Artensitic, ferritic and martensitic-ferritic stainless steels have magnetic properties.

Using acid. Interaction with chemically aggressive environments is another way to check whether you have galvanized or stainless steel. Stainless steel will easily withstand the effects of hydrochloric acid. If you drop HCl onto galvanized steel, it will begin to bubble as the acid reacts with the zinc.

Using saline solution. Salt acts as a catalyst, accelerating the chemical reaction of corrosion. If galvanized metal is temporarily immersed in a saline solution, its surface will change color.

These are the most accessible ways to distinguish stainless steel from galvanized steel. In industrial conditions, optical and electron microscopy, as well as methods of chemical and X-ray spectral analysis, are used for these purposes.

Characteristics of stainless steel

In addition to corrosion resistance, stainless steel has a number of other properties and characteristics that significantly expand the range of applications of products made from a metal alloy with the addition of chromium.

The main characteristics of stainless steel include:

- Resistance to aggressive environments (for chromium steels with a chromium content of more than 13%).

- High ductility and good strength indicators (for austenitic chromium-nickel steels). They are well welded and can be stamped.

- High strength and surface hardness (a property characteristic of martensitic and ferritic-martensitic alloys).

- High heat resistance (a property characteristic of martensitic and ferritic-martensitic alloys). Products made from such steel retain their geometry even with significant temperature changes.

- Environmental friendliness and safety. Anti-corrosion properties prevent the development of oxidative processes; the material does not contain harmful components, therefore it is used in the food industry.

- Aesthetic component. The surface of high-quality stainless steel products remains shiny and clean for a long time.

Areas of application of stainless steel

Stainless steels are used in mechanical engineering, chemical and food industries, and energy. Pipes of various sections are produced from stainless steel; such alloys are suitable for creating welded and stamped structures. Stainless steel alloys are used for the production of boilers and other products that are exposed to high temperatures during operation. Stainless steel is used to make containers for transporting and storing aggressive liquids.

Cutting and measuring tools, as well as springs and springs, are made from certain grades of stainless steel. Food grade stainless steel is used for the production of products that come into contact with food products and liquids during operation.

When choosing rolled stainless steel, you should pay attention to its chemical composition. It is important to take into account the operating conditions of the metal, the expected load, and special properties.

Characteristics and scope of galvanized steel

Galvanized steel is a popular and relatively affordable material with wide application. This is the same flat rolled metal in a standardized size range, but with enhanced corrosion protection in the form of a thin layer of zinc. A film made of this corrosion-resistant, fusible metal protects steel structures from destruction under the influence of moisture, salts and other aggressive environments.

Key characteristics of galvanized steel:

- High corrosion resistance

- Machinability

- Long service life of galvanized products

- High mechanical strength

- Wide range of galvanized products

Galvanized metal products have found wide application in a variety of industries - automotive, shipbuilding, construction, electric power, instrument making, production of household products, etc. Galvanized sheets are used both as an independent building material and in the form of blanks for subsequent processing.

Sheet metal coated with a thin layer of zinc has a smooth, uniform surface texture. The material can be painted, spot welded and seam welded. Galvanized sheets are subject to hot and cold stamping, bending, and drawing. The material takes the form of various profiles, withstands rolling and maintains the integrity of the coating even after machining.

Galvanized steel sheets are indispensable in the production of flat and curved products: tableware products with locking joints, all kinds of profiled products, incl. and products of complex hoods, roofing and wall building materials. Corrugated sheets are made from galvanized steel sheets, which are widely used in the construction of fences, for external wall cladding, and roofing. Galvanization is used in the production of profiles for ventilation facades, drainage and smoke exhaust systems.

Service life of stainless steel and galvanized steel

What retains its anti-corrosion properties longer - galvanization or stainless steel? Under the same operating conditions, stainless alloys are more durable than galvanized metal. If galvanization lasts on average up to 25 years, then the service life of stainless metal exceeds 50 years.

The durability of ferrous metal protected by a layer of zinc depends on a number of factors:

- sheet thickness

- quality of raw materials

- thickness and method of applying zinc coating

- environment and operating conditions

- presence/absence of additional staining

Which is better - galvanized or stainless steel?

It is not entirely correct to compare these two types of metal products, since the materials have different purposes and different areas of application.

Stainless steel is not afraid of pressure changes, it is not afraid of the effects of aggressive liquids, and it can come into contact with food products. Stainless steel will not lose its anti-corrosion properties even if burrs or scratches appear, since alloying elements are present in the entire mass of the alloy.

Galvanized steel is an order of magnitude cheaper than stainless steel, but copes well with other tasks. This material is indispensable in the manufacture of profiles; it is used both in production and in construction to perform a wide range of works.

Laser cutting of metal in UPTK-65 - Video

What are they making, why from this particular steel?

Another area of application of stainless steel, which can be divided into a special category, is architecture, construction, decoration and the creation of unique design projects. The interior, which contains stainless steel elements, looks very elegant and stylish. In addition, steel combines perfectly with plastic, glass and wood materials.

Stainless steel has also found its application in the design of the exterior of buildings - steel railings and stainless steel fences have impeccable external characteristics, are weather-resistant, durable, and, as a result, safe and reliable.

engages in the development, manufacture and sale of stainless steel railings and stair railings. We invite everyone to the catalog of our website to familiarize themselves with the range of products offered and place an order:

- Railings.

- Balcony railings.

- Fencing for children's institutions.

- Fences for ramps.

- Fences with glass.

- Stainless steel railings.

- Wall handrails.

- All-glass fencing.

- Accessories for stainless steel fencing.

- Fence posts.

- Stainless steel pipes of various lengths and diameters.

will be glad to see you among its clients. We deliver high-quality stainless steel products throughout Russia.

Application of galvanized steel

Galvanizing, on the other hand, is often used in situations where corrosion is undesirable but small amounts are not critical. In these cases, the aesthetic component should also not be important, since galvanization does not always look beautiful. Places of use:

- Automotive technology.

- Structural beams.

- Housings for household appliances.

- Railing.

- Road signs.

- Electric poles.

- Ventilation systems.

- Profiled sheeting.

Both solutions are corrosion-resistant in their own way. When choosing, you need to evaluate the operating conditions of the products from all sides. In some places, cheaper galvanized steel will be suitable, but for critical facilities and complex operating parameters it is better to choose more reliable stainless steel, which will definitely pay for itself in the near future due to its durability.