For those who decide to get a pocket knife, experts, in addition to the design and geometry of the cutting edge, recommend paying attention to the type of steel from which the blade is made. In general, the functionality of the product will depend on the alloy used. Undoubtedly, in addition to iron and carbon, steel may contain other filler elements. Depending on the application, they are added to improve certain characteristics of knives. Therefore, before buying a knife, you should familiarize yourself with the different types of steels and their inherent characteristics.

About the properties of steel

According to experts, in a good knife, the blade steel should have the following basic properties:

- Hardness. This indicator is measured in HRC on the Rockwell scale. A high value indicates that the blade will not deform or break under physical stress.

- Flexural strength. Due to the impact strength of steel, cracks and chips do not form on the surface of the blade under load. It is noteworthy that strength is directly related to hardness. The higher the viscosity, the less rigid the alloy is.

- Wear resistance. This property indicates the steel’s resistance to damage from solid abrasive particles.

- Corrosion resistance. Steel is not susceptible to corrosion and rust under the influence of external factors, namely moisture and salts.

- A good knife should remain sharp for a long time. This blade maintains a sharp cutting edge even after several cuts.

About carbon steel grades

In the knife industry, carbon, tool and stainless steel are used to make blades. It should be recognized that carbon is considered the hardest. It is used to make machetes and survival knives. Judging by the reviews, it is quite easy to give the blade the desired sharpness. Moreover, the sharpening holds perfectly. However, despite its undeniable advantages, carbon steel is not without its drawback - it is susceptible to corrosion. This is due to the low chromium content. The following brands are considered the most common in this category:

- 1095 (with 0.95% carbon added). Produced in the USA. Hardness from 58 to 60 units. The blade made from it is very hard and holds the cutting edge perfectly. If you don’t take care of it (do not lubricate it regularly and store it incorrectly), it will become covered with rust. In addition, due to reduced bending strength, knives can break, and therefore thick blades are predominantly made from 1095. Analogues of 1095 are the German C92D and CWR-9 (Sweden).

- 420 NS (American made). The hardness of high-carbon “stainless steel” on the Rockwell scale is 53-55 units. Thanks to chromium and high carbon content, the knife edge is durable and has good cutting properties. The blades have excellent corrosion resistance. Judging by the reviews, sharpening knives made from 420HC is quite easy. An analogue of this brand is steel 440A. It is subject to cryogenic treatment, thanks to which the hardness is increased to 57 units.

- Sandvik 12С27. Country of origin: Sweden. Hardness index from 54 to 61 units. An alloy with a high chromium content. Used in the knife industry. The blades are very hard, resistant to corrosion and hold an edge for a long time. An analogue of this brand is steel 65x13 produced in Russia.

- Sandvik 14С18N. By adding molybdenum after quenching, the refractoriness and hardness are increased to 62 units. • VG-10. Japanese-made steel alloyed with molybdenum and cobalt. Thanks to additives, viscosity and hardness increase (60-63 units). According to experts, VG-10 blades are highly durable and never rust.

“The best steel for a knife” - we sort it out and test it on a rope!

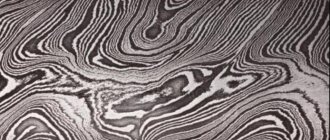

I quote a comment from Alexander Draghi, which I received by mail on the topic of “universal” steel. "Hello. Friends, since you are interested in my opinion, I will answer: I would divide the versatility of steel into three different groups: 1. Household knife. 2. Fishing/tourism 3. Hunting Now about each point in order based on what is happening at home and in my life. Point one, the most important. There are enough knives at home, there are also several Zlatoust knives, of different steels. So, first of all, regardless of the purpose and comments, my wife tests the knife in the kitchen and evaluates my choice. Practice has shown that it is important for a home that steel can retain a cutting edge for a long time (...if there are no knives sharpened in the house...). Steel AIR 95x18 (Snipe and Fin Lappi) - in the end the steel turned out to be “soft”. I bought about the same Finnish car not from you (expensive) out of 100x - I received full approval from my wife. The result is 100x for the house. The second point is no less important for me. This point, in turn, needs to be divided into two more sub-points: a) fishing/hiking for one or two days b) multi-day hiking/fishing I’ll start with a multi-day trip. A trip to Karelia as a savage allowed me to test several samples of steels and models of knives and there was only one conclusion - 95x with the correct descent and correct(!) primary(!) sharpening has never disgraced itself. When the need arose for rules about stones from a river, fortunately there are a lot of them there, but this is Karelia and there are no particular stones on lambins there and there is no desire to carry a sharpener with you, so your Bekas 95x18 (with sandblasting of the blade) worked for several days without editing and not let me down: I cleaned the fish, cut the vegetables and opened several cans. When the opportunity arose, he was corrected on a river boulder. At the same time, we also had: Ahti Vaara RST stainless, but capricious in sharpening, I suspect due to the nature of the Chukhon descent to zero, an unidentified sample from Ahti made of carbon - good, but periodically covered with “diathesis” from water, Pirate stainless 440 ( good soft stainless steel, easy to edit, but also dulls relatively quickly), Zlatoust Nikon 40x10s2m (similar to 440 with the same review) and N2 ZZOSS EI-107 forged (well, damn, tear off the hands of those who made the descents and sharpened this knife It’s hard to even call this “product” a knife - just a blank for a blade) in terms of the nature of its manufacture (not in appearance!) it is similar to an ax, so it was used as an ax - to chop branches, tear up wood chips, I won’t say anything about steel, use it as a knife impossible. Fishing/hiking for one or two days - any knife steel will be universal, and if it looks beautiful like Damascus, such as forging marks, or etching, then this will add pluses to the owner’s karma in the eyes of friends. Nothing more to add. Point three, hunting. It’s the same as with fishing/hiking, but if you really manage to get a trophy, then you need to have a margin of strength for the working edge or the ability to correct it on the spot. Snipe 95x18 is enough for a wild boar, if the catch is larger, then 95 steel “shrinks”. IMHO the most versatile steel is 95x. For housework I use an Edge Pro sharpener with stones up to 10,000 grit. There is only one moral - “he loved to eat his own food for every scary thing.” Sincerely, Alexander, Kaluga"

About instrumental

Tool steel is an alloy of hard steels from which cutting tools are made. The following brands are used to make knives:

- D2 (57 HRC). This steel is quite tough and wear-resistant and is made in the USA. It is used to make large industrial tools, with which softer shapes are cut and stamped. Unlike carbon D2, it is more resistant to corrosion. It is worth noting that to sharpen a D2 knife you will need the appropriate equipment. It is noteworthy that steel is absolutely resistant to corrosion processes. In Russia, the analogue of D2 was the X12MF.

- Elmax (Austrian made). Initially, this chrome-molybdenum-vanadium powder tool steel was used to make cutting elements for equipment used to process plastics. Later it began to be used as knife steel. The blades are characterized by high corrosion resistance, strength and ease of sharpening. The blade remains sharp for a long time. The hardness of Elmax knives on the Rockwell scale varies from 58 to 62 units. According to experts, Elmax is similar in its characteristics to the RWL34 and S30V brands, and in its composition - to 440C (59 HRC). Due to the presence of vanadium, which is not provided for 440C, Elmax blades hold sharpening well at various angles and are perfectly polished. The disadvantage of knives is that they do not withstand impacts and breaking loads well.

- ZDP-189. This powder tool steel has been produced in Japan since 1996. The advantages of the brand are its high impact resistance and corrosion resistance. It is worth noting that some knife manufacturers carry out a hardening procedure, after which the cutting products have a hardness of 69 units. It is noteworthy that such blades should be protected from impacts and heavy loads. Japan produces a similar steel known as Cowry-X.

Hunting knife parts

Regardless of the chosen steel grade and manufacturer, all hunting knives have components with common names:

- The blade is the cutting part of the tool.

- Shank - steel base for attaching the handle.

- The blade is a part of the blade with a sharp sharpening.

- The butt is the unsharpened part of the blade. Located on the back side of the blade.

- The point is the place where the butt meets the blade.

- The heel is the area at the base of the handle.

- Valleys are narrow grooves along the ribs. They are designed to give the blade rigidity. Another of their tasks is to reduce the weight of the blade.

- Handle - used to wrap your hand around when performing any actions with a knife.

About stainless steel

“Stainless steel” is carbon steel, to which, in order to prevent corrosion processes, chromium (at least 13%) and other filler elements are added, due to which the productivity of the steel increases, but the viscosity deteriorates. The following knife steel grades can be distinguished from this category:

- 440C has a strong crystalline structure and high chromium content. Due to its characteristics, 440C is very popular among knife manufacturers. Steel with a hardness of 59 units. effectively resists external mechanical factors. Unlike 1095 steel, 440C is less brittle and more wear-resistant. Due to the fact that 440C does not rust, knives made from it are most in demand among fishermen and scuba divers. Mostly “folders” are made from 440C. Despite the fact that 440C is not subject to corrosion, it has poor resistance to aggressive substances (salts, acids), and therefore it is recommended to thoroughly wash and wipe the blades dry after use. In Russia, steel 95X18 is considered an analogue of 440C, in Japan – Sus 440C.

- 154CM (USA) is considered an improved stainless steel, to which molybdenum is added. Unlike 440C, a 154CM blade is easier to sharpen and holds an edge longer. In addition, through two-stage hardening, the hardness indicator was increased to 60 HRC. The alloy is flexible enough not to break under the influence of external and internal loads. If you properly care for your knife, its service life will be extended by years. The alloy is ideal for making EDS knives. Judging by the reviews of the owners, it is not advisable to keep such blades in water for a long time. Otherwise, they may become rusty. Similar properties are inherent in Japanese ATS-34 steel. According to experts, American steel is more affordable.

- AUS-8. This high-alloy, high-hardness alloy (60 HRC) is produced in Japan. The composition of steel is represented by carbon, silicon, manganese, molybdenum, chromium and sulfur. Steel is used to make knives, scalpels, axes and machetes. The blades are easy to grind and polish; the cutting edge remains sharp for three months. However, if you keep the blade in water for more than seven days, it may become rusty. In Russia, the analogue of AUS-8 is steel 95Х18.

- VG-10. Another Japanese knife steel. It has high strength, hardness and wear resistance. Heat treatment consists of the following stages: annealing, forging, hardening and tempering. After maintenance, the hardness of VG-10 is 61 HRC. Knives made from this Premium class steel are mainly used by tourists and climbers. The only drawback of the knife is its high cost. There are no direct analogs of VG-10.

- CPM S30V. This powdered high-carbon steel is the development of American specialists. In the knife market since 2001. This grade of steel perfectly combines corrosion resistance, impact toughness, wear resistance and high strength. Heat treatment provides CPM S30V with a hardness of 58 to 61 HRC. The chemical composition is represented by carbon (1.45%), chromium (14%), vanadium (4%) and molybdenum (2%). According to experts, knives made from S30V have a fracture strength four times higher than that of 440C steel and three and a half times that of 154CM grade. The closest analogues of S30V: CPM M4 and S35VN.