Concrete is a widely used building material. It has high hardness and dense structure. During construction or repair work, various elements always have to be attached to it. For this purpose, concrete dowels are used. Therefore, we will tell you about their design and how they differ. Let us also consider the types of such fasteners, the nuances of their selection and fixation in masonry and concrete walls. The information will allow you to competently monitor the work of construction and repair teams.

Manufacturers produce a variety of dowels for concrete structures Source p0.pikist.com

Features of dowels for concrete and brick building structures

The dowels that manufacturers produce for concrete walls and other building structures made of similar material are not the same as fasteners for hollow bricks. To perform the required work efficiently, it is necessary not to confuse these two types of fasteners. Therefore, it is important to know their features.

On a note! It is irrational to use concrete fasteners in brickwork. Such an application is absolutely unjustified when the structure is made of blocks with voids. For masonry, special fasteners with a special device are used. In addition, its installation has certain nuances.

Thus, the design of fastening elements for brickwork with voids usually contains:

- Conical rim. It is necessary to control the installation depth of fasteners.

- Special tip. Thanks to its presence, the fastener twists when a screw is screwed into it.

- Locking wings that prevent the product from turning when screwing in hardware.

An example of dowels used in hollow masonry Source stroy-podskazka.ru

A concrete wall or other similar structure made of the same material is a solid element. Special fasteners are used for it. This is exactly what a concrete dowel is. Experts have been using this fastener for a long time. The classic option is the so-called dowel-nails.

The dowel itself is a spacer element. For concrete, manufacturers make it from different plastics, nylon material and even metal. Depending on the material used, dowels have certain parameters. It is the characteristics that influence the scope of application of spacer bushings.

Each dowel in concrete has a certain load-bearing capacity. Its value depends on the design, the so-called bushing, which has notches along its entire surface. It is thanks to them that the fastening element does not rotate in the hole and does not fall out of it even when exposed to the design load.

The design of the bushing also assumes the presence of elastic whiskers. They are always in a compressed position. This feature also affects the reliability of the fastening. In particular, the whiskers prevent the element from being pulled out of the recess.

Dowel with antennae for secure fastening in concrete Source leroymerlin.ru

On a note! The expansion of the sleeve occurs after screwing in, for example, a screw. Its unclamping is carried out due to the presence of slots in the longitudinal direction.

The fastener is fixed into the hole not only mechanically. Manufacturers also produce dowels that are specially designed for porous concrete. Their fixation is carried out with the additional use of special glue. First, a hole is made into the building structure. Then it is filled with adhesive. Then the fasteners are placed. Thanks to the glue, the fastening element is securely fixed in the cavity.

A dowel nail for concrete in a classic design is a universal product. Therefore, it is used in different fields. With the help of this fastener you can solve various important tasks. It allows:

- install different frames;

- fix furniture, paintings and other similar interior elements to structures;

- secure household technical devices.

Dowel-nail for fastening frames Source stroyka-hoz.ru

Today, builders and repair teams can use steel or aluminum nails for concrete for installation processes. This fastener is simply driven, for example, with a hammer into the created holes. It speeds up installation processes. Therefore, it is widely used during construction, repair, and finishing work.

Hollow brick

What kind of material is this? In modern construction, two types of bricks are used - hollow and solid. The main function of the first materials is the construction of buildings, which should be as strong and durable as possible.

This brick is good in all respects. The material is light, strong, and easy to install. However, it has a significant drawback. It does not retain heat well in rooms. Although hollow brick is practically no different in strength from solid brick, it is more often used in finishing work. The internal void in such a building material can range from 30% to 50%, depending on the type and manufacturer. Low-melting grades of clay are used as raw materials for such blocks. It is from this that red brick is made. There is another option. This is a silicate hollow white type. Let's look at the features and properties of mounting blocks.

The difference between dowels for concrete surfaces and similar elements for brick structures

Any such product allows for reliable fastening of various parts and objects only if it is correctly selected for specific conditions of use. When choosing, be sure to take into account the dimensions of the fastener and the base material where it is fixed.

Dowels for a brick wall have a different design than fasteners for concrete. For masonry, elongated products are mainly used. This is not their only difference.

Long nylon dowel Source vsmete.ru

Therefore, before fixing a dowel in a hollow brick, you need to thoroughly study its features. So, it often looks like a sleeve made of plastic or metal. Its design includes a spacer mechanism. It is double, which guarantees the fixation of at least one part of it on the material, and not in the void of the brickwork.

A threaded rod can serve as a spacer for the bushing. This is, for example, a pin whose diameter corresponds to the dowel used. Other anchors can also be used. They are selected for a specific load.

In addition, manufacturers produce special concrete nails for hammering. Their operating principle differs from similar fasteners for bricks. The nails are intended for use exclusively in non-porous materials with a hard structure. Even when using a hammer, significant efforts are made to hammer them into the created holes in building structures.

Fasteners in the form of nails for concrete surfaces Source pronailers.ru

Nails made specifically for concrete should not be attempted in brick substrates. This especially does not need to be done if the structures have a large number of air cavities. Otherwise, the holes where the so-called nails are driven will collapse.

On a note! It is impossible to reliably fix even a metal dowel for concrete in brickwork. Moreover, this cannot be done if it is made of plastic. The reason for this is the lower strength of the brick, especially if it is hollow, compared to a concrete structure.

Manufacturers still produce universal fasteners. It is mainly made of nylon. Such fasteners include:

- type N – four-spacer product;

- type S – fasteners with locking tabs;

- type U - an elastic element that twists when it enters a void;

- type K – fasteners with spacers located along its entire length;

- type T - a product with three thrusts.

Three-expansion universal dowel Source main-cdn.goods.ru

In fact, manufacturers produce a huge number of dowels in a universal design. This must be taken into account when selecting fasteners. The process must be approached responsibly. After all, structures are created from building materials of different hardness. Therefore, fixation of fasteners in them is carried out subject to certain rules.

See also: Catalog of construction companies that have their own production of materials and components for the construction of houses

Material for making fasteners

A dowel for concrete can be made of metal or plastic. Metal guarantees strength and rigidity and has greater load-bearing capacity. Plastic fasteners are not subject to corrosion, have greater elasticity and viscosity, therefore they are easily deformed and even under such influences the fastener is not destroyed.

All plastic pins will burn even after the flame source is removed. Therefore, this type of fastener is not used in fire hazardous facilities.

Plastic dowels for concrete:

- Polyethylene - resistant to acids, lightweight, provide excellent viscosity, are not afraid of deformation, and act as a dielectric. Over time, the material may age and crack. Cold-resistant – fasteners can be used in temperatures down to -40 C.

- Polypropylene - less resistant to cold, but provides greater wear resistance and hardness. The material is resistant to heat - it deforms only at temperatures above +140 C. It can also crack.

- Polyamide (nylon) dowels for concrete are strong, rigid, viscous, resistant to vibration, are not afraid of mechanical damage, and have good wear resistance. Such dowels are considered the most reliable and durable, but have one drawback - they are hygroscopic, and therefore exclude the possibility of installation in frost and high humidity.

Metal dowels for concrete are not much different in structure and shape from plastic fasteners, but are presented in a smaller range. The metal is rigid and durable, but it has less viscosity and elasticity, so it loses its properties when deformed.

Metal dowel-nails for concrete:

- Galvanized and stainless steel are not afraid of corrosion and provide a reliable, rigid connection.

- Special alloys with chromium, titanium, bronze, brass are durable, particularly resistant to corrosion, and are expensive, so they are relevant only for certain cases, particularly important fasteners.

Main types of dowels

Dowels are classified not only by the material used for their manufacture. They also differ in the installation method. One fastener can be installed into the created holes using only a hammer, while other dowels can be installed using only a special gun. This is exactly the tool that is used when deciding how to hammer a nail into a concrete wall.

When choosing dowels, you always pay attention to the material of the dowels. Plastic products are inexpensive. They are used when mounting non-heavy objects. For heavier structures, metal elements are used.

Plastic dowels Source tildacdn.com

On a note! Metal nails for concrete surfaces have a smooth surface. There is no thread on it. They are difficult to dismantle. They are used when it is necessary to perform fastenings for a long time.

Metal nails for concrete Source 9.allegroimg.com

Spacers are common fasteners. They have a cylindrical shape. They are driven into the created recesses. Often, the design of such fasteners contains spikes. They improve the reliability of fixation.

Dowel with a spacer structure, antennae and spikes Source dgural.ru

There is a fastener, the fixation of which is similar to the principle of operation of the “butterfly”. Such dowels are universal elements. Therefore, they are used in different designs. They seem to open up on each side.

A plastic sleeve that expands to the sides when a screw or self-tapping screw is tightened. Source wkret-met.com

Another type is façade fasteners. It is used when installing frame structures on walls. The facade fastening element has almost the same structure as the product in the spacer design. However, it is distinguished by its longer length and massive cap.

Facade extended dowel with spacer hardware Source a-krep.ru

Dowels are also made exclusively for aerated concrete. They are distinguished by the presence of wide threads. It is this that ensures their reliable fastening in a material with a porous structure. This fastener is designated by the abbreviation KVT.

Fasteners for lightweight concrete Source chelyabinsk.energogradek.ru

Manufacturers also suggest using plastic concrete dowels, used in polystyrene concrete blocks. This type of sleeve is not much different from spacer products. They have a spiral design. This dowel can withstand significant weight. It is often used during the installation of various cabinets, exhaust systems, for attaching shelves and many household items. The abbreviation GB is used to designate the product.

Fasteners for polystyrene concrete Source hubo.be

What types of dowels are most suitable for brick walls?

Since there is an abundance of dowels, we will try to talk about the groups of consumables that are best suited for installation in brick walls:

- universal dowel-nails. This is a fastener of a standard type and configuration, which is intended for solid brick. As you work, make sure you don't get into any voids between the bricks. In this case, it will be difficult to install;

- anchor façade. This group of dowels is best suited for hollow bricks, but can also be used for solid materials. Plastic and metal modifications can be found on sale;

- disc-shaped. An elongated dowel is designed for fixing insulating materials. The design provides for the presence of clamps that allow you to fasten materials with dowels without deformation. The spacer part is located at the end of the product.

For fixing in a brick wall, you can choose metal fasteners and dowels made of durable plastic. Metal is superior in strength, maximum permissible loads, and durability to plastic counterparts. When choosing, pay attention to the presence of anti-corrosion coating and its thickness.

Features of choosing the required dowel

Before purchasing fasteners, you need to know the weight of the products that will be fixed with their help. The dimensions of dowel nails for concrete and other elements of similar purposes are also taken into account. In addition, the peculiarities of the mounting location must be taken into account.

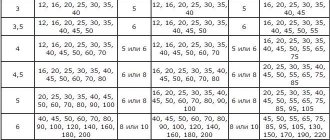

There are certain rules that are always followed when choosing dowels:

- Fastening a heavy structure is done using fasteners whose length is at least 85 mm. It is recommended to be used when fixing, for example, exercise equipment.

- If fastening is carried out in a horizontal building structure, then choose products that are placed to a depth of at least 30 mm. In this case, the diameter of such elements should be from 6 to 11 mm.

Spacer element 6*30 mm Source leroymerlin.ru

- When selecting fasteners for an already created hole, you need to select an element with a diameter no less than the same size as the drilled recess. The ideal option is if the dowel and hole have the same diameter.

- Fasteners with antennae should always be used when installing lighting fixtures and ceiling structures. After all, the load acts in the downward direction. The best option is dowels with so-called mustaches and notches.

- If fastening is carried out in hollow brick or other weak material, it is necessary to use fasteners with softening pads. Pouring them will allow you to evenly distribute the load throughout the element, and the fastening itself will be as tight as possible.

Types of fasteners for hollow materials

But do not think that such materials are too fragile. You can even lay various types of communications through them.

A large number of different fasteners have been invented and created for this building material. For example, this is a dowel for hollow bricks. And this is just one of the types. There are many types of fasteners. Below we will look at the features of each of them.

Features of fastening dowels in a concrete wall

Of course, you need to invite a specialist to do the work. After all, the master will, at a minimum, take with him all the necessary tools, and at a maximum, he will have impressive experience in performing such operations. Professionals usually carry out the process as follows:

- Mark the installation location of the dowel after careful marking in accordance with the drawings and features of the structure being mounted.

- Make a small indentation at the marked point using, for example, a nail.

- Insert a drill of a suitable diameter into the hammer drill.

- Make a hole in the structure.

Important! The dowel must be inserted into the recess with force. This is the only way it will be fixed in the hole, which is made perpendicular to the plane of the building structure.

- Remove all debris from the recess.

- Insert the element until it stops.

- Screw a screw into the dowel (the hardware can be screwed together with some part, depending on the features of the structure being mounted).

The procedure for fixing a dowel in a concrete wall Source europartner-online.ru

On a note! Before hammering a dowel into a concrete wall, select the required fasteners. It is thicker than conventional wood hardware. It is made from special grades of steel with a massive head. In addition, it may have longitudinal or spiral notches.

Typically, craftsmen use a construction gun to drive such nails into concrete structures. However, it is often necessary to perform a small amount of work manually. This is more difficult, but the right tool may not always be nearby.

Usually they try to drive special nails into concrete surfaces without defects. There should be no chips or cracks on them. Otherwise, the hardware will not hold well.

Before the process itself, the washer is removed from the metal dowel of the nail. Then clamp the hardware in pliers. Then they install it in the desired anchored place and hammer it in with strong blows.

Dowels for aerated concrete and other porous materials

Aerated concrete, unlike drywall, is voluminous and thick, but contains many voids within its structure. Multiple engagement points are required for secure fixation. Here are the main types of dowels suitable for such material.

Dowel with cutters

The sleeve is made of sheet iron. The working surface has four expanding edges, covered along the entire “body” with cutters. When screwing in the self-tapping screw, the steel teeth seem to “bite” into the aerated concrete and prevent the fastener from moving outward.

Dowel for aerated concrete with cutters.

For reliable installation, it is necessary to correctly select the diameter of the drill so that the dowel does not dangle in it. In this case, the four working edges with cutters will prevent rotation along the axis and will reliably open up. But the product cannot be dismantled, since the metal takes on an expanded shape and does not move back, which means the installation location must be carefully verified.

Dowel for aerated concrete with cutters in the wall.

Dowel with screw ribs

The model is marked GB. It is a plastic conical tube with a cut and solid ribs protruding along the entire structure. They are located with a slight overlap in the spiral, so they rotate slightly at the moment of driving. Due to the long, rounded ribs, the load is evenly distributed over the entire circumference and the dowel sits securely in the aerated concrete wall.

Dowel with screw ribs.

The plastic sleeve can accommodate screws with a diameter of up to 28 mm. Such elements have approval from the German building supervision organization and are suitable for preliminary or permanent installation in aerated concrete.

Dowel with screw ribs.

The length of the screw is calculated by adding the length of the dowel itself, the thickness of the mounting eye and another diameter of the screw. The element is even suitable for fixing into unplastered walls. When installing, it is important to use the drilling mode without impact, otherwise the hole will be too loose and weaken the fixation.

Metal dowel with internal thread

The dowel is made of metal and has high turns of external thread. Due to this structure, it is well retained in the porous material and resists not only shear loads, but also longitudinal effects.

Metal dowel with internal thread.

Installed in a pre-drilled hole using a hex wrench using the rotation method. For large volumes of mounting elements, it is advisable to use a screwdriver or drill at low speeds.

The dowel has proven to be resistant not only to static but also to variable loads, for example, holding shelves, shoe stands, and kitchen hanging cabinets. Since the part is entirely made of metal, it provides increased fire resistance and can be used near heating sources (it is allowed to hang heating radiators or fireplace protective screens on such dowels).

Based on the base materials, the dowel is suitable for:

- solid and hollow light expanded clay;

- solid porous concrete;

- ordinary expanded clay.

Features of fixing fasteners in brick

Experts note that fixing fasteners in masonry is more difficult than fixing a similar element in concrete. Although professionals quickly solve this problem even when installing structures with significant weight.

First of all, before fixing the anchor in the hollow brick, the exact anchoring depth is determined. It must be no less than or maximum equal to the distance from the corner of the building structure to the installation point.

In addition, qualified craftsmen often consider the minimum length of the screw used. To do this, fold the same size dowel and the sharp part of the hardware. The last parameter is usually equal to the diameter of the screw. In addition, the thickness of the mounted part is added to the obtained value.

The value obtained as a result of addition is rounded up. In this case, they are guided by standard lengths of hardware. At the end of the entire calculation, the required depth of the hole in the brick structure is determined. It should be greater than or at most equal to the length of the selected hardware minus the thickness of the attached part.

The depth of the hole in the brick must be no less than the length of the hardware used minus the thickness of the fixed part Source sdelai-lestnicu.ru

On a note! If you decide to use a dowel or nail for brick, then it is better to use it in a solid block. In hollow material it may adhere poorly or not at all. We are talking about a plastic dowel with pointed threaded hardware. It also has a cross slot.

A high-quality installation process for fixing dowels in bricks is as follows:

- A recess is created for fixing the fastener.

Important! To drill a recess, use a power tool without impact. Otherwise, the brick may crack or break off, especially if it is hollow. In addition, due to tool impacts, sometimes the recess is larger in diameter than the dowel used. After all, brick is a softer building material compared to concrete.

Brick and other similar blocks are softer compared to monolithic concrete Source sun9-24.userapi.com

- All debris is blown out of the created hole.

Advice! To more securely secure the fasteners in the recess, tile adhesive is additionally used. It is diluted in accordance with the instructions, which are always present on the packaging. Fill the hole as deep as possible with the mixture.

- Insert the element into the recess until it stops.

- Wait for the adhesive to cure. It hardens in about 24 hours.

- Screw threaded hardware into the dowel.

The screw or pin must fit into the installed fastener with force. If the element is not installed securely, then it will scroll. With high-quality installation, such fasteners can withstand significant loads.

This method of fixing a dowel in a wall is often used if the structure is made of hollow material. It is often used in foam blocks.

Dowel-nail for gypsum boards

When using drywall, you should choose the right fasteners. Not only the strength of the structure being created depends on this factor, but also the appearance, service life of the structure, its technical characteristics - whether this structure can be weighted with various objects. For installation of gypsum plasterboard frame. The type and number of selected dowel-nails depends on the type of frame, the selected profiles; they differ in the thickness of the material from which they are made, the material of the walls and ceiling. (Foam concrete, shell rock, concrete, brick, etc.)

To install a metal frame, not only self-tapping screws are purchased, but also dowel-nails. These fasteners create the strength of the entire frame for drywall. To use these fasteners, you should familiarize yourself with their characteristics. Improper use may have a negative impact on the metal frame.

Features of dismantling work

During renovation work, building structures are often leveled. To ensure a high-quality process, the previously installed dowels are first removed. To dismantle them, use a regular screw or other hardware of a suitable diameter. It is screwed into the fastener by 2/3 of the length or more. It all depends on the tool that is additionally used in the work. Then the hardware is pulled out along with the plastic fastener.

To pull the dowel out of the wall, use suitable hardware Source bau-meister.ru

On a note! Usually, a steel crowbar or ordinary pliers are used for pulling out.

Sometimes a situation arises when a piece of metal hardware remains in a plastic fastener. To remove it, use a soldering iron. They first heat up a plastic dowel, and then use pliers to pull out a piece of steel fastener.

When the dowel is set very tightly, sometimes it cannot be pulled out. The fasteners are simply cut along the plane of the structure, and the hole is covered with a durable mixture.

If you need to remove a special metal nail from a structure, first loosen the hardware with hammer blows. After this, a nail puller is used for its final dismantling.

As a last resort, a hole is drilled next to the dowel-nail. It makes it easier to loosen the hardware. You can also use a grinder to simply cut off a special steel nail.

A protruding special metal nail can be trimmed with a grinder Source mcmahons.ie

How to strengthen the fastening?

If you determine that the connection is not secure enough and the base is quite loose, measures to strengthen the connection may be necessary. To do this, you can take electrical tape and screw it onto the dowel. After this, you can safely attach large items. On the Internet you can find recommendations for using cellophane for these purposes. However, immediately exclude this option, since in this case you will not have to count on fixing large loads.

If you intend to install large structures, you can use a plaster bandage. Be sure to wet it with water for a strong bond. Seals are especially useful if you accidentally end up with a hole that is too large. Additional sealants can be wooden blocks or matches. They are inserted into the hole for the dowels.

Briefly about the main thing

A dowel for masonry or concrete is a fastener made of steel or plastic with antennae, protrusions, and spikes. Basically, it expands when the hardware is tightened.

In brick construction, elongated fasteners are mainly used. Special nails are often secured in concrete. Products with a plastic element can be driven in with a hammer, and all-metal sharp fasteners are often installed with a construction gun. It cannot be installed by hitting a brick.

Manufacturers produce spacer, butterfly-shaped, facade, wide-threaded fasteners for aerated concrete and other types of fasteners. It is selected according to the material of the wall in which it is installed. The applied load is also taken into account.

The dowel is mounted into the previously created hole. It must have a depth no less than the length of the hardware. During installation in brick, an additional adhesive mixture can be used.

What is a classic dowel?

The first requirement for fasteners is workmanship. The classic version of the part consists of a plastic bushing with notches. They are necessary to prevent the fasteners from turning. The main element is a specially formed rod. It guarantees the strength of the fastening, since after it is inserted into the sleeve, the latter expands, pressing the body and notches into the concrete. This fastening option is available for dismantling - the rod has notches that allow it to be unscrewed with a screwdriver.

We install foam concrete fasteners correctly

In order for the fastening in the foam block to last for many years and withstand the expected loads, it is necessary to perform the installation correctly. It all depends on the chosen dowel, design features and task.

Screw-in dowels are made with a special thread, so they are very easy to install. Drive-in anchors are made with large teeth that expand into the drilled hole. Drive in the fasteners exclusively with a rubber hammer so as not to damage the foam block wall.

The chemical anchor is attached differently. A hole is drilled under it in the format of a cylinder with a conical cutout, then the hole is cleaned, a cylindrical sleeve is installed and the cavity is filled with a solution (or a capsule with glue is inserted, which, when crushed, releases the substance out), and a threaded rod is mounted.

Fastening dowels to a foam concrete wall

- First you need to prepare the necessary tools to carry out the work - the fasteners themselves, a screwdriver with drills (exactly matching the diameter of the fasteners or slightly smaller), a hexagon, a building level.

- Then the wall is carefully marked, planning the fastening points and using a level.

- Holes are made according to the marks - the length is equal to the length of the dowel + 2 of its diameters.

- Clean the holes with a construction vacuum cleaner or any tool that allows you to clean out foam concrete residues and dust.

- Use a hexagon to screw in the dowel.

- Next you need to mount the mount.

With the right choice of dowels in exact accordance with the loads and assigned tasks, it will not be difficult to perform a durable and reliable fastening. In Moscow and the region, other regions there is a large selection of various products by design, type, load, material

During the work process, it is important to follow the technology and sequence of actions, to do everything carefully and efficiently