The grinder is a convenient, mobile and reliable tool, used for cutting and grinding metal, ceramic, stone and sometimes wooden surfaces. The technically correct name for an angle grinder is an angle grinder; it is widely applicable and in demand for repair and construction work. If you have not yet acquired this tool, but want to choose an angle grinder, this article will be very useful for you.

An angle grinder is a multifunctional, but capricious tool that does not tolerate haste and carelessness. Breakdowns and failures are the result of careless handling or violation of safety precautions. And the most common problem when working with an angle grinder is the jamming of the abrasive tool between the support flange and the clamping nut. How to unscrew a disc on an angle grinder without damaging the parts and the tool itself?

Devices for angle grinders, its design, and thread sizes

The grinder is a very necessary tool in the household and construction.

It fits into a suitcase and can have attachments for the tool and a lot of accessories. From installing a chuck under a drill and the ability to cut 2 workpieces and even 2 circles, you can modify it to the machine. Tools for an angle grinder are a whole separate world. These are not gloves or glasses for an angle grinder, but a cartridge for an angle grinder, a carriage for an angle grinder, and gears for an angle grinder. There are endless options to choose from. Although you shouldn’t forget about glasses for working with an angle grinder.

The device of the grinder

The construction of an angle grinder is not very complicated.

The design of an angle grinder (angle grinder) includes the following main elements and components:

- electric motor – stator and rotor (coils, copper windings, metal casting, bearings);

- electric brushes - elements that supply power to the collector to convert electrical energy into rotational energy;

- gearbox – transmission of rotation from the engine shaft to the working body;

- clutch - a device to prevent a sudden stop of the engine when the working body is braked;

- controls - power button, power blocking devices and power and speed control devices;

- device for installing and replacing the working element - clamping nut (washer), rotation lock button;

- additional handle (handle);

- the housing - metal or plastic - serves to install all parts and protect them.

The replaceable working element is located at an angle of 90 degrees. These are: grinding wheels, whetstone, brushing, alpha disc, Velcro sandpaper. Sharpening stones, like wheels, have a lot of options.

A grinder is needed for mechanical processing of materials - for cutting, stripping, grinding, drilling and developing openings. A large centrifugal load acts in different directions from the disk, which requires a protective casing for safety.

Kinds

Any grinder has a general principle of operation, but is divided into several main types, which differ in size and other characteristics. The variety of types allows them to be used in absolutely any conditions.

By type of food. Network angle grinders are the most used type of grinders used in enterprises creating metal structures. Also great for cutting brick, tile, wiring and replacing plumbing. Depending on the power, they are divided into household and professional. This tool operates on a voltage of 220 Volts.

Cordless angle grinder Metabo W18 LTX 125 + 3.5 Ah LiHD + charger ASC 55 T0333. Photo VseInstruments.ru

Advantages: the ability to choose the case size for any size of disk; light weight; high power; affordable price; large selection of attachments; high-speed rotation; long service life.

Disadvantages: poor performance when the voltage drops; a long wire may interfere with movement around the work area; high degree of energy dependence.

This type is very popular among all users.

Cordless angle grinders are similar in structure to mains ones, but differ in a large compartment for mounting the battery. They are manufactured in a small case, which acts as a handle, for ease of use, and is equipped with disks from 125 to 150 mm.

Advantages: compact body; convenient storage: the grinder is sold complete with a case; light weight; fast rotation speed; high degree of user protection; special handle that reduces vibration during operation.

Disadvantages: operating time is limited by battery capacity; support only small disks; high price.

Due to their autonomy, the models are used remotely from the power source and do not require electricity at all. It is only suitable for short tasks as the battery needs to be recharged.

Gasoline angle grinders. Large in size due to the fact that the internal combustion engine and fuel tank are located inside. To use the tool, there is a built-in auxiliary handle and a frame-handle. This device is equipped with large diameter discs. Used for cutting concrete, stone and metal in environments where there is no electricity.

Advantages: quick cutting of large objects; work with large diameter circles; autonomous use; long-term performance thanks to gasoline refueling; stand, for use as a cutting machine.

Disadvantages: additional costs for fuel for refueling; loud noise made by the instrument; work only with large disks; inconvenient to use in hard-to-reach places.

The device produces loud noise; hearing protection is required.

Network angle grinder (grinder) HITACHI G15VA. Photo 220Volt

Pneumatic angle grinders are manufactured without an engine. By means of the action of air currents on the blades inside the housing, a high speed of rotation of the disk is obtained. They just trigger the torsion of the axis with the disk. Before starting work, a valve is used to allow air access to the internal channel.

Advantages: minimal weight; continuous use for a long time; does not require cooling as it does not overheat; safe in conditions of high humidity; high rotation speed; cheap repairs; The device is silent (the noise comes from cutting).

Disadvantages: expensive device; requires additional devices (for example, a compressor).

This type is the lightest of all and does an excellent job throughout the day. Additional equipment required for use.

Purpose: professional and household. The main difference between these two types is the duration of continuous operation. Household tools are designed to work for about 10 minutes, with breaks of 15-20, for a total of about 2-3 hours a day. The main advantage of household grinders is their low price. Therefore, if you plan to perform small jobs at home, you should choose an inexpensive model. Sometimes semi-professional and industrial grinders are also noted, the latter are used for continuous work in production conditions.

The power of an angle grinder varies from 500 to 2700-3000 W. The higher the power of the tool, the greater the range of work that can be performed with its help. To carry out work at home, an angle grinder with a power of up to 1200 W will be sufficient. An increase in power inevitably leads to an increase in the weight of the tool.

The rotation speed of the disk, limited to 11,000 rpm, directly depends on its diameter. The larger the size, the lower the speed required. For angle grinders with 115 and 125 mm discs. the maximum speed is 10,000-11,000 rpm, for 150-180 - no more than 8500, for 230 - up to 6650.

Each type is unique in its own way and is suitable for a specific type of activity.

What kind of carving is on the grinder?

To install and replace the wheel, as well as install the planned device, you will need to know in which direction the spindle rotates.

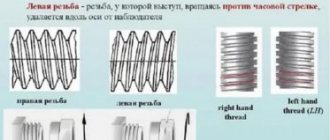

The thread on the grinder also serves as a passive fastening element. It twists in the direction opposite to the direction of rotation of the circle. Otherwise, the circle will fly off the shaft along with the clamping nut.

You can determine which thread is on the grinder (left or right) by looking at the arrow on the body. She points in the direction where the disk will spin. Typically the fastener is tightened clockwise.

The thread size is usually M12 or M14, unless the manufacturer has specified another. This information is needed to determine compatibility with the fixture being installed. Clamping flanges with internal thread diameters M10, M11, M12, M14, M15 are known. You can determine the relationship between the thread size, the diameter of the circle and the power of the electric motor, for which you should study the instructions for the angle grinder.

Adapter device

Actually, the adapter itself does not present any particular structural complexity. As a rule, it is machined from a hexagon for easy fixation with an open-end wrench during installation, and especially removal. On one side there is an M14 internal thread. It is designed to be screwed onto the external thread of the spindle of an angle grinder. The other end is machined with a standard M12 external thread corresponding to the thread of the clamping chuck. A hole was drilled at the end and a left-hand thread was cut for a bolt for additional fastening.

Attention! The M12 cartridge thread standard, although the most common, is far from the only one. When choosing an adapter, pay attention to the markings of the selected cartridge; at least you may come across a couple of standard thread types: M12×1.25 and 1/2 - 20 UNF.

There are also conical drill-angle grinder adapters for the corresponding chucks with conical fixation.

Devices for grinders and their purposes

The basic functions of an angle grinder allow you to do a lot. However, even such a universal machine may not be enough for home use; additional mechanisms may be required.

First of all, an additional handle. Gloves create their own requirements for the roughness of the handle.

For precise operation, taking into account conditions (material density, current network voltage), a disk speed control device can be used. You can make such a dimmer yourself, but it is better to trust the professionals.

A dust collector or vacuum cleaner for an angle grinder will play a significant role when working with dust-emitting materials. The dust collector will collect the fine volatile fraction and thus clean the air.

Using an angle grinder as a stationary device is possible when installed on a platform. In this case, the stand will not only act as a hold, but also as a guide for the working body. By installing an angle grinder on such a device, the master receives mechanization, which is clearly not the case with manual work. The useful side is the freedom of hands.

Cutting a pipe will require more than just a certain diameter of discs. A frame is well suited for mounting an angle grinder.

When cutting grooves, a wall chaser will be useful, a drawing of which can even be found on the Internet. The sole of the device will move across the material, and the quality of the cut will give good feedback.

When choosing any device, you must follow safety precautions. There are no relatively general recommendations; each tool and device is purely individual. Regardless of the purpose (home or professional), the proper functionality can be created even by basic mechanisms.

Accessories: guide for grinder with pipe

Cutting sheet metal and other metals is not an easy process. The most difficult thing is to maintain the angle grinder along the cutting line. If you need to mechanize this nuance and eliminate the human factor, the best solution is a guide with a pipe (or a bracket for an angle grinder).

Such an element performs 2 functions at once:

- a plate or slide guides the tool, resting on the material itself;

- carries a connector for connecting a vacuum cleaner (or dust bag).

Provides maximum precision when cutting sheet metal. Designs can be universal (with appropriate fastening) and suitable only for certain models. It can be equipped with installation in a box for an angle grinder.

Accessories: dust collector for grinder

When cutting materials that produce large amounts of dust, dust collection and collection devices should be considered. Structurally, it is designed as a shield and a connector for installing a dust bag (or connecting a vacuum cleaner).

Options for the dust collector are available, either with open parts of the disk or completely covering it.

In this case, the casing closes the surrounding space from the scattering of dust, and the newly formed one comes out and is collected in a bag. Work becomes cleaner and safer. Moreover, both the shield and the bag stop sparks. Moreover, dust is the worst enemy of the gearbox and gears.

A dust collector is not always included. Installation on various models is possible due to the adjustable connector on the bag itself.

It is possible to connect a vacuum cleaner to the output, then the collection of dust suspension will become much more efficient.

Adapter and cartridge for an angle grinder

To perform drilling and hole machining work using an angle grinder, a drill chuck is useful. It can be installed either directly or with an adapter.

Provides centering for any type of drill, suitable for shank diameters up to 13 mm. The chuck complements the grinder with the functions of a drill, engraver and router. Cone adapters are also available for cone fixation.

An important point about the thread: the cartridge is installed on M14, unless otherwise stated in the instructions. Other requirements relate to speed. For a drill, the grinder's speed of 6-12 thousand may be too powerful. This leads to the need to install a speed controller.

Accessories: stand for grinder

A stand (or holder) for an angle grinder is a structure for attaching it during stationary work.

Used for cutting rolled metal fed under the wheel. It is possible to organize a cut at an angle and incomplete. To obtain an accurate cut, you only need to secure the grinder well in the frame.

When mounted on a stand, it becomes convenient to use the appropriate wheel for sharpening and grinding. You just need to ensure good access.

By installing a long shaft on a spindle and mounting sandpaper on it, you get equipment for cleaning small parts.

How to choose an angle grinder for working on a stand? The diameter of the circles used on the stand can be from 125 mm to 230 mm. The weight of the grinder is not limited. The weight of the stand itself is up to 2-3 kg. You will need a separate box for it.

Accessories: extension cords for grinders

For hard-to-reach places (where the grinder body itself will not allow you to approach the surface), use an extension cord for the grinder or an adapter.

It can be in various designs and can be used to improve work around hard-to-reach places.

Or be the basis for installing other replaceable tools and expanding the working area. The extension in the form of a small shaft easily fits into the case for an angle grinder.

Purpose of discs and attachments

Grinder circles differ in purpose for:

Cutting discs

The most common task performed with a grinder is cutting various materials. The choice of tool material also depends on what material will need to be cut.

- Metal cutting. The metal cutting disc is made from crystalline alumina corundum, as well as from synthetic corundum called electrocorundum. The main color of metal cutting wheels is blue.

- Cutting stone and concrete. To cut stone, you should choose a disk made of another abrasive material - silicon carbide. This abrasive easily cuts white brick (silicate) and slate. But to cut red brick, some types of concrete or ceramic tiles, this wheel material is not suitable. Stone discs are available in green.

- Cutting ceramic tiles, red brick, porcelain tiles and concrete. A diamond disc is already used for these purposes.

This attachment is made of metal; an abrasive mass with diamond chips is applied to the cutting edge. The picture above shows a segmented saw blade designed for dry cutting of material. All-metal discs require water cooling during operation.

Read also: How to make a wood crown with your own hands

- Wood cutting. Although there are saw blades for wood on sale that are no different from circular saw blades, it is better not to use them for safety reasons. When working with such a tool, the user often suffers serious injuries due to jamming, rebounding, accidental slipping of the tool, etc.

Therefore, if you are still going to use a saw blade on wood, you should adhere to safety precautions. The grinder must have a protective casing and handle installed, and the user must wear a protective mask or goggles. In addition, you cannot cut materials with this tool that are not intended for it.

The safest are considered to be wood discs with a chainsaw chain installed at the end. If the tool jams, the chain remains in place and the disc rotates idle, which reduces the likelihood of injury to the user.

Roughing

If it is necessary to remove a layer of paint or other application, as well as rust from any surface, brushes are used. They come in disc form or in the form of a bowl with built-in metal wire.

The wire in these nozzles can be twisted or loose. Its thickness can also vary. The thicker the wire, the coarser the stripping, the stripping disc or cup-shaped attachment is used, and vice versa.

Grinding

Sanding discs and attachments are used for grinding and polishing various surfaces (metal, wood, plastic and others). Often a flap type grinding wheel is used for grinding. It consists of many “petals” made of sandpaper. The grit of sandpaper can be selected based on the required type of processing (finishing or roughing).

The sandpaper can also be attached to the nozzle using Velcro. Such a tool is screwed onto the angle grinder spindle.

For polishing surfaces, special wheels and attachments are produced that look like felt pads or fabric discs.

Sharpening

To sharpen a tool, sharpening machines (sharpeners) are usually used. But if you don’t have the latter, but have a grinder, then you can purchase a sharpening (grinding) wheel for it, which can easily sharpen almost any cutting tool.

The main difference between grinding wheels and cutting wheels is their thickness (at least 5 mm).

What thread is on the grinder spindle?

I'm interested because You need to explain to the turner through third parties (who don’t always understand) what thread to cut in the chuck. And is it the same for all Bulgarians (mainly interested in small ones)?

The thread is the same everywhere - M14 with a standard pitch.

2IS Thank you, otherwise I already bought a cartridge that says M12x2.5 (I’m writing from memory), so I thought about the step, and I measured the M14 with a caliper!

2Peter M. You can tell the turner M14x2, that will be enough, plus the length.

to Peter M.> cartridge with M12x2.5 written on it (I’m writing from memory)

Should be M12*1.25.

Is there really a 2mm pitch? I know for sure that the standard pitch for M12 is 1.75 mm, and for M16 - 2 mm, but I don’t remember for M14. But the fact that the angle grinder’s pitch is M14 is standard, that’s for sure.

2IS I just measured 100% with a special thread gauge. Grinder mil AG9-125MX, domestic thread gauge.

Dr.NO wrote: 2Peter M. You can tell the turner M14x2, that will be enough, plus the length.

Thanks again for the comprehensive information! But it’s not me who will be speaking, but a woman, so it would be better to write it all down on a piece of paper.

And another question for reference. Will the drill chuck crumble at 10,000 rpm? which the Bulgarian develops? Otherwise, I’m planning all this to a greater extent to use the existing flexible drive with Dremel accessories.

Peter M. Are you afraid of getting wrapped around this cable later?

M12*1.25 is a small thread (for car spark plugs), but I don’t really believe in 2 mm, most likely it should be 1.75.

tsn wrote: most likely it should be 1.75.

she's not there, but there are 2

Well, two is two.

I got to the directory. Standard pitch: M10*1.5, M12*1.75, M14*2, M16*2. Moreover, according to GOST, M10, M12 and M16 are the first row (preferred), and M14 is the second row (there is also a third row, there are exotic types like M11 and M15). For spark plugs, M14 is used with a fine pitch: M14*1.25. Standard of domestic drill chucks M12*1.25.

tsn wrote: M12*1.25 is a small thread (for car spark plugs), but I don’t really believe in 2 mm, most likely it should be 1.75.

Dr.NO is ABSOLUTELY RIGHT on the spindle of the angle grinder the thread is M14x2 (main) And for car spark plugs (it’s a shame not to know) M14x1.25

Sorry, about the candles - of course 14 mm, Ivan just wrote M12 * 1.25 - I thought that he attributed it to the grinder and stupidly copied it, paying attention only to the pitch, but did not look at the diameter.

There is also a third row, there are exotics like M11 and M15).

which need to be turned with keys of 15 and 20. I would kill these standardizers. Keys for 5.5, 7, 8, 9, 10, 11, 12, 13, 14, 15, 17, 18, 19, 20, 21, 22, 24! Seventeen varieties, and all are found, all must be had. This series would be halved. Sorry for the off

Peter M. wrote: Will the drill chuck crumble at 10,000 rpm? which the Bulgarian develops?

Of course not. I checked it myself.

2Serg Thank you, I was expecting exactly your answer! Now the question is removed, you can contact the turner with peace of mind.

Did you cut the thread?? How has the instrument performed over the years? I will also give the chuck to a turner for thread cutting.

They say the chuck is slightly loose, so it won’t be possible to make an analogue of a wood router. Instead of an angle drill, I have a grinder with a native M12*1.25 thread, I’ll take a look there, but I haven’t gotten around to it yet

Crazyalone wrote: they say the cartridge is slightly loose

The adapter needs to be sharpened. And a smart turner should do it. -In the blank, an internal thread is cut for the grinder spindle. -The thread is turned with a cutter, the blank is tightly screwed on and the outer one is turned to fit the cartridge. It won't hit you like that.

I understand everything, but I don’t collect everything.

The essence of the idea is to put the chuck on an angle grinder and drill in inconvenient places due to its short length. All adapters are completely missing. It’s easier to buy a drill or router outright. The internal thread for the spindle is fine and is cut into the chuck, the problem is that the metric threads have tolerances that are not the same as the fine threads on which chucks and collets are screwed. simply because it is designed for dismountable fasteners, which may be subject to corrosion. And it still has to unscrew and tighten. A thread made too tightly will simply not fit in this case.

Selecting an angle grinder (grinder)

- Participant

- Messages: 155

- City: Barnaul

If they indicated the thickness of the cut-off with which it was pulled out, it would be more interesting.

What I had was 1.6 mm (230 mm), just a small jerk and the Bulgarian vibrated.

I don’t understand those who like to cut 3mm circles. Well, yes - the circle lasts longer, you can adjust the cutting line quite aggressively. But at the same time, either violence against the Bulgarian or 2.5-kilowatt monsters with huge motors are needed. And as a result of biting - these are the flights.

- 1

Spindle thread M14 what does it mean

This simple operation sometimes baffles even experienced mechanics or grinder users. The reason is that the disc is secured with a special nut. The nut has 2 or 4 holes into which a special key is inserted. This key was always included when purchasing an angle grinder. Perhaps it is still included in the kits.

According to the instructions for the grinder, you need to press the latch, which is located on the back of the gearbox. When the shaft is fixed, use a special wrench to unscrew the nut and change the disk. But it is difficult to unscrew the nut if it is not clamped. And he almost always clamps it with such a nut. An attempt to unscrew the disk leads to breakage of the latch behind the gearbox.

What solution to the problem is offered by specialists and amateurs + (Video)

- Install a newspaper gasket under the nut;

- Place a gasket from a plastic bottle under the nut;

- Replace the nut with a nut of a different design.

What is a newspaper gasket? This is a paper washer the size of a nut. It is put on the installed disk, and a nut is screwed on top. This piece of paper was a stumbling point, because the safety inspection always spoke about the harmfulness of such a decision.

Representatives of safety authorities treat the installation of gaskets made of any other materials in the same way:

- Cardboard;

- Paronitis;

- Gaskets made of various plastics;

- Rubber gaskets of various thicknesses.

But there is a solution that does not contradict safety requirements and allows you to install and remove the disk normally. This is a special nut that consists of two elements - a nut and a pressure washer. The use of such a nut does not require any shims, because with it the disk does not jam.

Video text

Anyone who has worked with this power tool - an angle grinder - has probably encountered the problem of a jammed nut, which is used to tighten the abrasive disc. This usually happens during operation, at the moment when the disk is clamped into the part, it stops or is destroyed, and the grinder’s engine, still rotating, forcefully tightens the nut.

In the future, you have to be tricky, since the nut can hardly be unscrewed with a standard wrench. They solve the problem in different ways, everyone has their own methods and secrets, let's share. I will share the first, reliable and simple way to unscrew a jammed disk on an angle grinder. First, you need to decide in which direction to unscrew, depending on the setting of the grinder for cutting away from you or toward you; the definition of clockwise and counterclockwise is not suitable. It’s easier to remember that the nut should be unscrewed in the direction of rotation of the disk!

Read also: Manual knife sharpener

Well, the method itself, for this you will need a gas wrench and, holding the nut with it, unscrew it.

You need to know that sometimes, without calculating the force, you can break the stopper blocking the disk. To avoid this, you will need 2 gas wrenches or clamps, break the remains of the disk, and hold the washer located behind the disk with one wrench, and unscrew the nut with the other. There is another way, but this is probably for the most severe cases: lock the disk with a button and point the hammer drill on the nut in the desired direction, and turn it on in impact mode. The hammer drill will hit and thereby unscrew the nut. Before tightening the nut, I recommend placing a paper gasket under it, although not necessarily paper, for example, tin. With it, there is less chance that after the disk is jammed, the nut will jam; more precisely, it does not jam, but is strongly tightened.

Manufacturers, for example Interskol, equip their grinders with similar gaskets.

But of course, purchasing a composite nut will help you get rid of the problem discussed in this topic forever. You just need to heat the nut a little with a gas welder and it will unscrew by hand. You just need to heat the nut a little with a gas welder and it will unscrew by hand. Thank you, I'll take note of the methods. I myself encountered this problem, the circle in the grinder was jammed so that it flew to the side, and the disk shattered into pieces. No matter how I tried to unscrew it, it didn’t work. And the key broke the button, and eventually sawed the nut with a hacksaw. Afterwards I just bought a new nut. I admit, after that incident I began to be afraid of this stupid machine. A large angle grinder (230 lap) flew away more than once, once even cutting its wire in flight.

Unwinding methods if the disk is jammed

What to do if the clamping flange is jammed? This trouble, when the nut is bitten, often occurs if, while working with thick and durable materials, the tool gets stuck in the workpiece. In this case, the abrasive wheel often breaks, and the spindle, which continues to rotate, tightly tightens the pressure flange. To unscrew the grinder if the disk is jammed, there are several ways.

Using a gas key

This method is considered not entirely safe, since the stopper can be broken, although in most cases it is possible to unscrew the nut. To avoid breaking the spindle lock, do not apply much force to the gas wrench. The design of the lock is designed to withstand the force applied by a standard wrench.

You can unscrew an overly tightened flange using 2 gas wrenches. To do this, break off the protruding ends of the abrasive wheel with pliers so that you can reach the lower flange with the first gas wrench. Next, clamp both flanges with keys and turn them in opposite directions (taking into account whether the thread on the spindle is right or left).

Disassembling the gearbox

If the lock is broken, in order to remove the tool from the angle grinder, you will have to disassemble the gearbox . Use pliers to break off the edges of the remaining abrasive wheel so you can get to the bolts holding the gearbox cover in place. After this, unscrew the fasteners and open the gearbox. The cover will be removed along with the gear shaft. Next, this shaft should be clamped in a vice, having previously placed aluminum spacers between the steel jaws, and using a gas wrench, unscrew the flange (do not forget to determine the direction of unscrewing).

Nut heating

The nut can be heated using a gas burner, a hair dryer or a blowtorch. The heated flange can usually be unscrewed with a standard grinder wrench.

Grinding a jammed circle

If after using the first 3 methods the nut does not unscrew, then the remaining abrasive wheel between the flanges can be ground off. To do this, do the following.

- Use pliers to remove as much of the remaining circle around the edges of the nut as possible.

- Clamp a piece of sheet iron in a vice as thick as the disk itself, turn on the grinder and grind off the remaining circle on the end of the sheet iron.

Instead of iron, you can clamp a piece of an abrasive wheel in a vice. In this case, grinding off the remaining tool between the flanges will happen faster, and the nut can be unscrewed by hand.

But the use of a stationary abrasive wheel requires great care, because when grinding off the remains of the tool, the geometry of the flange can be damaged. If this happens, you will have to trim the nut.

Using Penetrating Lubricant

Liberally spray the flange/shaft joint with WD-40. It tends to penetrate into inter-threaded spaces and small cracks. After applying the liquid, wait about 5 minutes and try to unscrew the fasteners with a standard key.

Read also: Do-it-yourself hammer drill maintenance

Using a hammer drill

Some owners of grinders, in a situation where the clamping nut is jammed, install a “chisel” or “jackhammer” attachment in the hammer drill, insert it into the flange hole at an angle and turn on the jackhammer mode without rotation. Accordingly, the stop button must be pressed. Just a couple of gentle presses with a hammer drill are enough (so as not to break the shaft lock), and the nut will begin to turn.

Cut the pressure flange with a hacksaw

This method can be called radical, since you will have to buy new fasteners, and it is used if the nut cannot be unscrewed by any other methods. To cut the flange, hold the stop button to prevent the shaft from rotating and, using a hacksaw, cut the fastening nut.

The main operating properties of an angle grinder should be considered in the following areas: the diameter of the working disk, the power of the electric motor, the rotation speed and the weight of the tool. The last feature plays an important role in choosing the right grinder and depends on the diameter of the disk, on which other working properties of the grinder depend. After all, it is clear that what is more than just a disk, be it on metal, wood or concrete, is that during operation it will simply be subject to a frictional force that the electric motor and tool must overcome.

In order to negate potential cases of injury to our client while working with an angle grinder, it is necessary that the factory properties indicated on the body of the tool exceed similar designations applied to the type of disc you have chosen. To simplify the concept, let’s take a very common metal disc with a diameter of 125 mm and a popular model of an angle grinder (angle grinder) from BOSCH.

Technical properties of DeWALT angle grinders

We are studying the capabilities of the BOSCH angle grinder, which are indicated on the body tag, as it is also called in the technical passport: power 2000 W, motor speed 6500 rpm, power supply 220 V, designed for a disk with a diameter of 230 mm, thread on the spindle M 14. Now we take a regular cutting disc for metal with a diameter of 125 mm, where the permissible speed of 12250 rpm, the dimensions of the disc and the linear speed of 80 m/s are indicated.

MAKITA disc markings that you need to pay attention to

Initially, what remains to be done is clear to our client: the permissible angular speed of the disk is 1.9 times higher than the highest angular speed of the grinder spindle - this means that there is an option to safely use this cutting disk for metal.

#betterathome. How to make a chuck for an angle grinder without a lathe

Reading time: 5 minutes No time?

Using flap attachments is very convenient if you need to sand a complex surface. There are two main types of such attachments: disk and circle. The discs are used for the grinder and are attached to it in the standard way. And the circles are attachments for a drill with a pin for fixation. Both of these options are in great demand in various jobs; such attachments are durable and work until completely worn out. But working with such an attachment on a drill is not very convenient due to the position of the petals; you have to hold the tool sideways, which interferes with your view. With an angle grinder everything is much more convenient. But it is impossible to attach the circle to the angle grinder due to the lack of a suitable cartridge for fastening. The cartridges are available for sale, but it is not easy to find them for the angle grinder; suitable copies are extremely rare to find. It is possible to order the chuck to be adjusted by a turner, but the author of the YouTube channel StoDel_56 demonstrated from his own experience how you can do it yourself when remaking the chuck. Perhaps you too will be interested in this experience.

Read in the article

Adapter for installing a chuck on an angle grinder

The angle grinder (grinder) has become an integral part of both home workshops and large enterprises. No wonder. High productivity, wide functionality, high spindle speeds and relatively low weight have made angle grinders a leader in processing metal and other materials.

But progress does not stand still. New devices to expand the capabilities of the device are constantly appearing on sale. One of these adapters allows you to install a clamping chuck on an angle grinder. What will come of this and how to safely use such a tool is proposed to be considered in more detail in the context of this article.

- Adapter device

- Installing a cartridge on an angle grinder

- What you need to know about the grinder to use it in conjunction with the cartridge

- Areas of application for an angle grinder

- Safety precautions

What is needed for the remodel

Converting a cartridge to a grinder without a turner is not easy, but in principle it is possible. It should be noted right away that the accuracy of manual alteration will not be ideal and you will still need to spend time on adjustment and polishing.

PHOTO: YouTube.com For modifications, it is better to take a 1.5-10 mm drill chuck with a B12 cone fit - this is the best option, you just need to drill it out and cut the thread for attaching the bits

The tools you will need are a drill on a stand with drill bits of different diameters. Prepare pieces of timber to secure the chuck during operation.

Boring a chuck for an angle grinder

To work with the cartridge, it must be securely fixed. To do this you will need a piece of timber and a drill.

PHOTO: YouTube.com The drill must be placed in the center of the beam so that it is held tightly in it. To do this, first drill to a depth of about 2.5 cm, and then continue drilling, pressing the drill bit hard into the surface. Leave a 3 cm tip on the surface

PHOTO: YouTube.com Now you can put the cartridge on this pin and fix it firmly

PHOTO: YouTube.com The cartridge must not only stay on the pin, but also not spin on it; if it spins, use additional clamps

PHOTO: YouTube.com To bore the chuck, take a 12mm drill bit and sharpen its tip so that the rake angle is slightly negative. This is necessary so that the drill scrapes the surface of the chuck.

PHOTO: YouTube.com Bore the hole in the chuck on a drill press

PHOTO: YouTube.com The next drill should match the spindle diameter

PHOTO: YouTube.com A large diameter drill needs to be shaped so that its tip fits into the chuck hole, acting as a guide

PHOTO: YouTube.com Two cutting edges of the drill will make a boring for the grinder spindle

PHOTO: YouTube.com When boring, it is important to strictly follow the direction to avoid distortions

PHOTO: YouTube.com You will receive a socket that matches the size of your angle grinder

PHOTO: YouTube.com You need to cut a thread in the chuck, use taps of the first and second numbers. The author recommends using linseed oil for lubrication.

PHOTO: YouTube.com The thread is ready, which means the product can be tested

PHOTO: YouTube.com It should be noted that cartridges for small angle grinders are a little easier to find. Difficulties arise specifically with the M14 diameter. You can look for adapters, but this is long and troublesome

What thread is on the grinder?

Show wholesale prices

- Terms of payment and delivery

- Schedule

- Address and contacts

Drill chucks - clamping for angle grinders with an M-14 thread (for an angle grinder) on an M-14 spindle, for all models and types of angle grinders , can be installed directly without any adapters, there is absolutely no runout, the alignment is perfect. A very useful universal thing that every craftsman should have in his arsenal and household (completely new, industrial production). Price 770 rubles. All types of drills and cutters from 1 mm to 13 mm, and many other different types of drill attachments are clamped into the chuck. With such a cartridge, the “grinder” turns into a drill, an angle drill, an engraver and even a router. Thanks to this chuck, the functionality of your angle grinder is significantly expanded. There are no such cartridges for sale in tool stores yet, you won’t find them - TESTED.

ATTENTION. For simple drill chucks, the mounting holes and threads will never fit on an angle grinder. The thread of the cartridge must be exactly M-14

Hurry up to order this product right now, the presented cartridges for angle grinders are quickly sold out, availability may be temporarily limited (Put this product directly into your cart by clicking the BUY button)!

Price 770 rubles .

Call and order at any time.

Telephone :

We ship to any region.

What is a clamp nut?

An angle grinder is a convenient, transportable and reliable tool, intended for cutting and grinding stone, ceramic, metal and sometimes wood surfaces. Working with an angle grinder only from the outside looks relatively simple and understandable; in practice, it requires certain abilities and knowledge. When using an angle grinder, a specialist must be as careful and focused as possible. If you do not adhere to established safety rules and work technologies, then you are guaranteed to suffer various injuries. Failure to follow the required precautions can leave a worker crippled for life.

Of course, when developing any of the modifications of angle grinders, manufacturing companies strive to maximally insure the user when using the tool, but you yourself should use the mechanism carefully and have an understanding of its certain properties. A very significant aspect when choosing an angle grinder is the type of clamping fastener installed on it.

This small component of the design may well “bestow” a few minutes (this is in the best case scenario), and under unfavorable conditions – even 30 minutes of “suffering” associated with unscrewing it. Therefore, before purchasing an angle grinder, you need to focus on such a seemingly insignificant element as a nut.

I bought myself a super nut for an angle grinder, it turned out to be a very convenient thing. It became interesting and I took the nut apart and looked at what was inside it; inside there was a complex mechanism for fixing the nut. But the most interesting thing is that with this nut the disk does not jam and the nut can be unscrewed without a key.

Read also: Do-it-yourself knives for a branch chopper

Safety precautions

By attaching the clamping chuck to an angle grinder, we get a powerful, convenient, universal tool, which, if the owner is careless, can cause irreparable harm to human health. Pay special attention to this section - knowledge of basic safety rules can save you from serious problems.

- Grinders, due to their intended use, are not equipped with “ratchets”, like screwdrivers, or emergency stop systems (these are sometimes found on grinders). This means that any jamming of a tool mounted in a chuck will cause rotational motion to be transmitted to the body of the power tool, which can seriously injure the operator’s hands. It is advisable not to use powerful machines. If a person of average build can hold an angle grinder up to 800 W without any problems, then a 2.5 kW tool becomes uncontrollable when jammed.

- Use personal protective equipment (PPE). It is unfortunate to say, but our compatriots are very indifferent to this point. And this is with many examples of eye damage, hand injuries and the like. Probably, everyone who has worked with an angle grinder can remember more than one similar incident that happened to them or their friends. Don’t be lazy to use glasses, gloves, headphones and, if necessary, a respirator.

- You must also understand that the tool contains parts rotating at high speed, capable of instantly wrapping around any material that falls within their range of action. For this reason, protective clothing is required with sleeves that fit tightly to the wrists. Torn workwear with hanging parts is excluded. It is prohibited to work in three-fingered gloves. If necessary, use work gloves made of genuine leather or a substitute.

- An adapter plus a chuck with a clamped tool will significantly shift the force vectors during work. This means that your angle grinder will behave completely differently compared to traditional use. Having installed this attachment, you first need to adapt to the new dynamics in the operation of the power tool. Moreover, each replacement attachment will add innovation to your work. The first time, start at minimum speed, gradually increasing it.

Safety regulations are not something special. In principle, they are applicable to almost the entire line of hand-held power tools.

In conclusion, one thing can be said - any serious master tries to expand the capabilities of his instrument. In the case of an adapter for a cartridge, the functionality of the angle grinder increases incredibly, but it’s even more fun to figure out how else you can use such equipment.

Advantages and Disadvantages of Pressure Fasteners

Floating fastener

In such a nut, the lower segment and the upper are not dependent on each other, they rotate on their own. It is used in angle grinders instead of a standard nut. The advantages of such a fastener are:

- it does not require a specialized wrench to unscrew (a regular open-end wrench or a simple socket wrench will do);

- The circle is not pressed tightly, therefore, the clamping fastener unscrews freely.

There is probably only one drawback - its cost is slightly higher than the standard one.

Regular nut

Practiced in various modifications of the instrument. Included in the package of cheap angle grinders. Advantages of the fastener:

- presses the circle firmly;

- low cost.

- a specially designed key is required for unscrewing;

- often spontaneously sticks to the circle, and special skills or equipment are needed to unscrew it.

Superflange fastening element

A specialized nut with a moving internal element, made by Makita. Advantages:

- makes it possible to freely remove the circle no matter how tightly it is tightened during work;

- increases user efficiency.

The downside is that the cost is significantly higher than that of other fasteners for angle grinders.

Self-locking nut

Replaces conventional clamp fastener. Advantages:

- no special key required for unscrewing;

- can be easily dismantled;

- high wear resistance;

- durable.

- quite expensive;

- may sometimes stick to the circle and in this case it should be turned away as usual.

Fastening element with auto-balancer

The structure contains bearings inside the nut. During operation, the bearings are dispersed internally and balance vibration processes. Advantages:

- the grinding disc works 50% longer;

- no vibration;

- increases the service life of the tool.

The disadvantage is the high cost.