Of course, compliance with environmental standards is an important condition for the successful and safe operation of any production. Purification of air contaminated with processed products is the main requirement for enterprises in the mining, cement, chemical, flour milling, metallurgical and other industries, during the activities of which a large amount of dust, soot and other microscopic pollutants are formed.

But modern cleaning designs make it possible to effectively solve the problem of excessive dust in the air: the design and operation of a bag filter is aimed specifically at removing the smallest particles of harmful suspended particles. After installing this unit, all dust and dirt settle on the walls of the filter, and lighter air, free of impurities, is released into the atmosphere.

In this material we will look at the structure and principles of operation of a bag filter, learn about methods of self-regeneration and replacement, and also reveal the advantages and disadvantages of this cleaning design.

Bag air filters for air purification from dust

To clean dust and gas mixtures, you should use a bag filter.

This is a “dry” dust collection device that has a high degree of reliability and excellent processing quality. No supply, be it wet cleaning or electrostatic precipitators, can compare with a bag filter, because it is equipped with filtering devices, they can be used at high temperatures, because they are made of polyamide and polytetrafluoroethylene. The bag filter is a versatile piece of equipment because it can, in fact, be used in different technological processes. However, it will be equally effective. You don't have to constantly monitor its operation because it functions continuously.

If you need a bag filter of a certain size and with certain design features that are suitable specifically for your operating conditions, then you can order such a device, because such devices can be made according to individual wishes. Most importantly, you need to indicate which dust-forming composition is primarily to be cleaned. Manufacturers, based on this, will select the right material for you to make a bag filter.

Where is a bag filter usually used:

1. In the manufacture of building materials. 2. In the field of non-ferrous and ferrous metallurgy. 3. During the foundry process. 4. In the process of automobile manufacturing. 5. In the energy and mining, furniture, glass and chemical industries. 6. In food production. 7. When processing metal.

Important Factors in Baghouse Operation

When choosing this filter, you need to consider several main points, which include items such as:

· temperature data of dew point with degree of moisture; · pressure and temperature data; · quality of gases, their explosiveness and volumes of the environment that must be purified; · density of dust and its type; How does this stage occur? · toxicity of dust composition substances.

In order to calculate a bag filter, it is necessary to first establish the quantity of purge gas with dusty compounds that fall on the material, and then take into account the speed at which the filtration process occurs with the fabric, and it was chosen for the manufacture of the bag filter. How to use a bag filter?

Scope of application

Due to their simplicity of design and the possibility of using a variety of related equipment, bag filters have found wide application in various industries.

Filtering units can be used both locally and integrated into production equipment complexes, providing filtration and return of purified gases and fine material for further use in technological processes.

The use of bag filters involves dry filtration in the following processes:

- metallurgy;

- production of dry building materials;

- production of powder polymers;

- pharmaceutical industry;

- cleaning gases after welding;

- powder coating;

- woodworking;

- furniture production;

- flour production;

- grain processing;

- in the food industry.

And also many other technological processes.

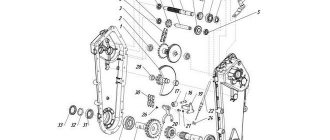

Device and circuit

The design of bag filters and their technical characteristics differ slightly between different manufacturers. The main blocks and schematic diagram of the design consists of the following elements:

- Dirty gas chamber

- Clean gas chamber

- Bag filter housing

- Mounting plate (dividing plate between clean and dirty chamber)

- Filter bags

- Regeneration system with receivers, pneumatic valves, purge pipes

- Hopper with a device for unloading collected dust and supports

- Automatic control system

The filter configuration differs depending on operating conditions and can be supplemented with service platforms, an automatic bunker unloading system, a pneumatic or vibration system for bunker collapse, and an emergency mixture of outside air to reduce the temperature. If the equipment is located outdoors, in order to avoid the formation of condensation on the housing, the filter is equipped with heating of the pneumatic valves and hopper, as well as thermal insulation.

To filter explosive dust, for example, in the production of flour, cement, coal plants, filters are manufactured in an explosion-proof design. The explosion-proof design of the bag filter involves the use of filter bags with an antistatic coating, which prevents the formation of a static charge on the surface of the filter material. Explosion membranes are also installed on the filter housing, which release excess pressure in the event of an explosion.

The filter material of the bags is selected based on the characteristics of the medium being filtered, the properties and dispersion of dust. The main materials used in bag filters are polyester (PE), meta-aramid (AR), polyimide (P84), fiberglass (FG), polytetrafluoroethylene (PTFE), polyacrylonitrile (PAN), polyphenylene sulfide (PPS) and others.

History of creation and general description of bag filters

The fight against dust has been going on for many millennia. Already at the dawn of civilization, people realized that dense woven material shows good effectiveness against dust and sand inclusions - Bedouins, nomads, camel drivers, Tuaregs, miners, stonemasons wrapped their faces with fabric; face masks were worn by American cowboys, in short, by everyone who was forced to carry out their activities in mechanically polluted places, deserts or dusty roads.

As mechanical processing developed, the amount of highly dispersed solid waste increased rapidly, and multiple technologies, devices and apparatus were developed whose goal was to reduce - internal aspiration or complete filtration - dust emissions.

Hippocrates can rightly be called the inventor of the bag filter. Around 500 BC, he created the first device, which was a cage with cotton woven bags attached to it - to filter mechanical impurities from water. Historians nicknamed the first bag filter the “Hippocratic Sleeve.”

The Hippocratic sleeve is one of the first devices operating on the principle of bag/fiber filtration

Along with this, there was a modernization of filter materials - cotton gauze, flannel and felt were replaced by non-woven materials of needle-punched, thermal and chemical types, branded textiles SpunJet, SpunLace, AirLay, Strutto; nylon, polypropylene, polyester, fiberglass, polyamide, Teflon (and their modifications) are widely used.

Depending on the media to be cleaned, filter materials can also be treated with special heat-resistant, acid-resistant and other impregnations, and also subjected to surface hardening (for abrasive dusts).

All this, taken together, led to the creation of such devices as bag filters, which today are widely in demand in all industries that have dust/solid suspensions and air suspensions as by-products.

Bag dust collectors demonstrate high efficiency in cleaning highly dusty environments in metallurgy, manufacturing and mining industries, asphalt plants, cement plants, brick factories and many other industrial sites and workshops.

Mobile filtration complex on wheels. The main advantage is high mobility. Such machines are inferior in efficiency to stationary versions

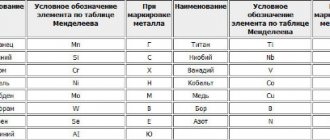

Table of applicability of devices in various industries.

| Industry | Purpose |

| Metallurgy | sandblasting, shot blasting of workpieces, slag, welding dust, machining waste |

| Flour milling, grain processing | filtration of flour, husks, mill dust, chaff, husks |

| Asphalt plants, mining and processing plants | areas/zones for screening and rock crushing, conveyors, transfer points |

| Energy facilities | coal, coke, ash, ash and other mechanical emissions |

| Production of building materials | capture of dust from cement, stone, brick, limestone, gypsum, minerals |

| Tobacco factories | neutralization of plant microfibers |

3D modeling of RF operation at Reftinskaya GRES - the largest solid fuel thermal power plant in Russia

Areas of application and operating features

A wide range of industries are experiencing the need to constantly clean the air from a large number of small particles of materials and products. Therefore, bag filter systems are common:

- in the chemical and food industries;

- at mining and processing enterprises;

- in foundries, in metallurgy, in workshops where cast iron is processed using shot-blasting machines;

- at flour mills, elevators and other enterprises where processing and storage of raw materials remains a source of dust;

- in production areas and paint shops.

Depending on the requirements for air purity and the characteristics of technological processes, bag filters can be equipped with sleeves made of different materials - these are natural and synthetic woven and non-woven fabrics rolled into sleeves. The efficiency of air purification from certain types of contaminants can be increased by using porous materials or fabrics with emitted fibers, flannelette and its synthetic analogues.

The design of the sleeve allows it to be attached in different ways: on a ring with a fabric fold, on spring elements, on clamps. As a rule, the service life of one hose is several years. In the absence of aggressive contaminants in the air that destroy the structure of the fabric, the regeneration system fully copes with its task and maintains the throughput of the hoses throughout the entire operating cycle.

own production - 50% cheaper than analogues

We offer bag filters for purifying air from dust and gases in factories and enterprises. Such a filter is used to purify air in an enterprise where the enterprise is a direct source of environmental pollution by emitting polluted air into the atmosphere. Bag filters help preserve the environment and the health of employees.

Patents and declarations of conformity for bullet traps

A bag filter is a device designed to clean dusty air, namely industrial emissions (without aggressive dust) generated during the processing of various products. They also have the ability to release purified air.

Regeneration system

As the accumulation of polluting particles increases, the throughput, productivity and efficiency of the bag filter decreases, and the resistance to air movement of the filter material increases. To prevent them, they resort to regular cleaning of the filter channels. Several schemes have been developed and successfully applied in practice:

- aerodynamic shaking or recovery using pulsed or return blowing of the bag filter with compressed air;

- automatic vibration shaking;

- combination of methods.

You can set the cleaning mode using a timer that sends a signal after a specified period of time. Another method is carried out through the readings of a sensor that records a significant drop in pressure and productivity. For vibration they use: sound waves, mechanical shaking. Using installed vibrators with an impact frequency of about 15...25 Hz, the contamination is dropped into the receiving hopper.

The backflushing scheme of the bag filter consists of intensive exposure to clean air. With pulse blowing, small portions of compressed air are released intermittently (pulses). This creates vibration in the sleeve. Pulse duration - 0.1...2 seconds. The frequency depends on the nature of the change in the resistance of the bag filter. Self-cleaning occurs. With this method, the humidity of the compressed air is of great importance. Before serving, it must be dried in a special installation. With the combined method, several types of regeneration are used.

After a certain period of time and number of regenerations, the stuck amount of dirt in the filter material stabilizes, which corresponds to the residual resistance of the material. This value depends on a number of aspiration indicators: filter fabric, parameters and properties of polluting particles, moisture content of gases, regeneration methods.

The photo shows such pulse-action installations. The advantage of aerodynamic regeneration over mechanical regeneration is that during regeneration the operation of the gas bag filter does not have to be stopped. This allows you to work around the clock, and the dust concentration can reach up to 55 g/m3.

To unload accumulated contaminants, several methods are used. The most productive purifiers include pneumatic transport, which is installed for several bunkers at once. Its operation does not require stopping the bag filters. It runs on its own fan. Unloading occurs through a sluice reloader, the operation of which does not violate the tightness of the device. Other methods require stopping the operation of the filtration system and have the inconvenience of possible freezing of waste accumulated in the bunker.

The bag filter is replaced due to the loss of its filtering properties, which in many cases occurs once every 3 years. When working in a slightly aggressive environment with a low concentration of contaminants, the operating period can reach up to 6-7 years.

Principle of operation

The operating principle of bag filters is based on the passage of dirty air through the pores of a non-woven filter material. Dusty air enters the dirty gas chamber through the flue through the inlet pipe and passes through the surface of the filter bags. The dust settles on the filter material, and the purified air enters the clean gas chamber and is then removed from the filter. As dust accumulates on the surface of the filter material, resistance to air movement increases and the throughput of the filter bags decreases. To clean the bags from captured dust, they are regenerated with compressed air or vibration shaking, depending on the method of bag filter regeneration. The dust thrown from the hoses enters the storage hopper and is removed through the unloading device. Read more about pulse blowing of bag filters.

Pulse regeneration of filters is carried out with pre-prepared compressed air of class 9 according to GOST 17433-80 with a pressure of 4 to 8 Bar. Compressed air consumption is individual for each filter and is reflected in the technical specifications. Regeneration of the hoses occurs automatically according to a timer or a pressure drop signal (using a differential pressure gauge), without stopping the operation of the filter.

Fabric filters: classification and basic design diagrams

Fabric filters structurally include filtering cylindrical porous bags, and therefore they are called bag filters. Classification of bag filters is possible: according to the shape of the filter elements (bag, flat, wedge, etc.) and the presence of supporting devices in them (frame, frame); the location of the fan relative to the filter (suction, operating under vacuum, and discharge, operating under pressure); method of tissue regeneration (shaken, reverse, pulsed, etc.); the presence and shape of the body for placing the fabric - rectangular, cylindrical, open (tubeless); number of sections in the installation (single- and multi-chamber); the type of fabric used (for example, fiberglass).

Fabrics made from natural fibers (wool, rarely cotton), and synthetic fibers (nitron, lavsan, polypropylene, etc.), as well as fiberglass, are used as filter materials. The most common are lavsan, terylene, dacron, nitron, orlon, oxalone, sulfone. The last two materials represent a polyamide group of fibers with heat resistance at 250 - 280 ° C. The most common type of filter fabric is twill weave. Nonwoven materials are also used - felts made with felting wool and synthetic fibers.

Bag filters effectively capture a wide fractional range of dusts of various concentrations, are easy to operate and can be fully automated.

The main disadvantages of devices of this type are the limitation on gas temperature due to the heat resistance of fabrics, the inability to purify gases containing moisture, and the need to periodically clean the hoses from trapped dust.

The operating principle of bag filters is based on passing dust-laden air through a bag made of filter fabric that traps dust particles, while the purified air passes through the pores of the fabric. The accumulated layer of dust is periodically cleaned and transferred to the dust collector.

The most widely used in industry are fabric filters RFG, FVK and FRKN.

The RFG bag filter (Fig. 2.26) consists of a housing 1, a hopper 2 with receiving and distribution boxes 3, filter bags, a cover with a control mechanism 4, a mechanical shaking device 5, a dusty gas inlet diffuser 6, a purified gas outlet collector 7 and a device for unloading captured dust 8.

The gas to be purified is directed through the inlet diffuser to the gas distribution box (to the lower part of the apparatus). From the pyramidal part of the body, gases rise upward, pass through the grate and enter the internal cavity of the sleeves. The upper ends of the sleeves are closed with plugs, with the help of which the sleeves are suspended from the frame. The purified gas is removed from the apparatus, and the collected dust is stored in the bunker collector. The body of the apparatus is divided into sections by partitions, which allows them to be cut off one by one from the incoming gas flow to free the hoses from settled dust. The last operation is carried out for 1 minute every 4.25 minutes or 8.5 minutes. Seamless filter bags are made of NCM brand nitron fabric or filter cloth; hose diameter 220 mm, length 3.1 m. Hydraulic resistance of the apparatus 800 – 900 Pa.

The FVK filter is fundamentally similar in design to the RFG filter. Its body is divided into separate sections containing 18 sleeves. The technical characteristics of these filters are given in Table 2.4.

In FVK filters, the sleeves are made of filter cloth (permissible gas temperature up to 800C); the hydraulic resistance of the apparatus is 800 – 900 Pa, excluding the resistance of the captured dust layer.

FRKN filters have high throughput. In particular, the FRKN - 400 filter has a filtration area of 400 m2 with a number of bags of 396. The enlarged bag filter URFM is widely used, one of the modifications of which (URFM - 11M) has a filtration area of 2300 m3, and the bags are mounted in 20 sections and with a diameter of 220 mm have a height of 4.1 m.

All the bag filters discussed above have a common fundamental feature - the gases to be purified are fed into the apparatus from below.

In industry, SMC devices are also used (Fig. 2.27), in which gas is supplied from above. Dusty gas enters the housing 1 of the apparatus through inlet manifolds 2, with which the upper ends of the filter hoses 3 communicate. At the bottom of the hoses have an outlet into the dust collecting hopper 4. The dust-cleaned gas, with the purge valve 5 closed, is sucked off by a fan 6 through the outlet manifold 7. The hoses are made of smooth filter fabrics (lavsan, fiberglass), which makes it easy to clean them from dust by blowing, for which valve 5 (right) opens and the left one closes, stopping the supply of dusty gas; fan 6 in this case works only for purging. In SMC devices, the filter bags have a spring suspension.

When cleaning gases in bag filters, the temperature of the source gas is of great importance. If the lower temperature limit must necessarily exceed the dew point for specific pollutant compounds, then the upper limit is limited by the thermal stability of the filter fabric. Different fabrics have different thermal resistance, however, when the gas temperature exceeds 2500C, it must always be cooled. For this purpose, one of three methods is used: evaporation, dilution with atmospheric air, heat exchange. The simplest technological and relatively cheap method is the method of diluting gas with atmospheric air. If we denote the initial temperature of the gas to be purified as t1, and the temperature to which it is necessary to cool the gas as t2, then at the temperature of the external (atmospheric) air t3 the dilution coefficient will be equal to

Attention!

If you need help writing a paper, we recommend turning to professionals. More than 70,000 authors are ready to help you right now. Free adjustments and improvements. Find out the cost of your work.

Cost calculationGuaranteesReviews

The K coefficient is often called the suction coefficient. By multiplying the volume of gas supplied for cleaning (m3/h) by K, the volume of air sucked can be determined. The suction is provided by a separate air duct with a blower fan of the required capacity.

We will help you write any paper on a similar topic.

- Essay

Fabric filters: classification and basic design diagrams

From 250 rub.

- Test

Fabric filters: classification and basic design diagrams

From 250 rub.

- Course work

Fabric filters: classification and basic design diagrams

From 700 rub.

Receive completed work or specialist advice on your educational project

Find out the cost

Operating principle of a bag filter

This is a relatively simple design. It can be part of any internal ventilation that cleans dusty air and returns it to the room. Or an autonomous system for complete cleaning before discharge to the outside.

How does a bag filter work?

The diagram and operating principle of the bag filter are presented above. The device is designed to pass a significant volume of contaminated gases or air. The air flow first enters the cyclone, where the large fraction settles. Then it moves through the inlet valve into the system. There, dust or soot particles are retained on the plane of the filter made of woven or non-woven base.

The bag filter can be a single design. But batteries are considered more efficient. The air then exits through the outlet valve, which is equipped with an automatic outlet pressure control system. The degree of purification of the bag filter depends on various factors and reaches 90-99.9%.

Thus, the use of this design allows you to perform the following tasks:

- high-quality purification of the air mixture from contaminants;

- regulation of the quantity and pressure of purified air coming out;

- creating a uniform dust filling.

Harmful airborne particles are retained by the hose design and removed by mechanical shaking during the regeneration process.

How does a bag filter work?

Purification equipment with a bag filter can be used as part of internal ventilation, which provides for the return of purified air back into the room, and as a system for completely purifying the air before releasing it into the environment.

The bag filter is a fairly simple design, which consists of the following basic elements:

- housings for filter units;

- chambers for clean and dirty air;

- bunkers and supports;

- an intake valve through which the air mixture passes;

- a cleaning sleeve or a set of sleeves that are located in the air path;

- an outlet valve with a pressure regulator that allows the purified flow to pass through;

- filter regeneration system, which allows you to periodically clean the bag from dust.

The design of the device is designed to allow a sufficiently large amount of air or gas to pass through. The flows entrained by the inlet valve pass through the system, leaving particles of dust or soot contaminants on the surface of the filter on a woven or non-woven basis.

The diagram above clearly shows the structure of a bag filter and the direction of flow of contaminated and purified air through the air purification system

The filter can be single, but complexes with a battery of hoses, which purify the air more effectively, remain more effective. After the hose, the recycled air is released through an outlet valve equipped with automatic pressure control.

In fact, the design performs three main tasks:

- qualitatively cleans the gas-air mixture from pollutants;

- ensures uniformity of dust load;

- regulates the amount of air supplied for filtration.

Separation of small particles in the exhaust air makes it possible to ensure proper purity of the exhaust stream. Unwanted suspended matter is securely contained within the hose, which is self-cleaned during the regeneration phase.

Purification method using devices using photocatalysts

The following devices work similarly to HEPA filters, that is, cleaning includes several stages. They completely destroy harmful impurities, and even microorganisms found in air masses. Such devices are equipped with a catalyst, an ultraviolet lamp, and are sometimes supplemented with an ion-generating device, filters using activated carbon or metal plates that operate on the basis of an electrostatic field. Such devices are the most effective among air purification devices. In addition, they are environmentally friendly, safe to use, economical and easy to maintain.

Devices equipped with a photocatalyst completely destroy any impurities in the air

Operating principle of bag filters

Air purification occurs in several stages:

Stage No. 1

Due to the vacuum created by the fan, the dust-air mixture enters the filter housing, which consists of “dirty” and “clean” chambers. The gas to be purified passes through a “dirty” chamber, inside of which there are filter elements (filter sleeves stretched over a frame mesh), on which the filtration process takes place. Passing through filter bags made of polyester filter fabric, dust is retained on them. The purified gas leaves the filter through the outlet flange. Dust lingers on the sleeves and falls down.

Stage No. 2

When a layer of dust grows on the surface of the filter cloth, the regeneration system is activated, which shakes the filter bags with a pulse of compressed air from the inside. The regeneration system ensures timely cleaning of the bags from dust and maintains the nominal gas permeability of the filter elements and is activated when the hydraulic resistance between the “dirty” and “clean” cavities of the filter housing increases. When a certain resistance value is reached, the hoses are shaken by a pulse of compressed air from the inside. The dust is poured into the arm hopper.

Stage No. 3

The hopper is unloaded using a sluice gate (together with a screw), which ensures the necessary tightness of the filter when unloading dust. Unloading dust from the hopper should be done regularly as dust accumulates in the hopper. Dust accumulation in the bunker is not allowed to exceed half of its volume. Depending on the filter configuration: a limit switch for the filling level of bulk materials is installed on the hopper body; A sluice feeder is installed at the outlet of the bunker. All dust unloading controls are located in the dust unloading control cabinet.

Functions and purpose

During production at enterprises, the air is constantly polluted by particles of processed materials. Even if the workshop has good ventilation, it is still impossible to completely clean the room unless you use specialized equipment, for example, an industrial filter. The main tasks of such installations include ridding the environment of technical impurities and dust particles.

Some models can also perform gas cleaning. In simple terms, they remove smoke, fumes and industrial gases from the air. They also support the function of deep preparation of ambient air. That is, they can disinfect and disinfect the environment and even regulate microclimatic characteristics.

The regeneration system can be of two types:

- standard - gas purification and regeneration are carried out simultaneously;

- mode designed for difficult operating conditions. It is performed when one or another section of operating equipment is turned off.

Operation in difficult conditions

The bag filter, the characteristics of which are selected in accordance with the conditions of use, is suitable for outdoor and indoor work. The first option requires addition in the form of the following components:

- thermal insulation of the body part, which is of particular importance during vapor condensation;

- heating of equipment bunkers and regeneration systems;

- special shelter that prevents exposure to atmospheric phenomena.

Among the main types of devices, it is worth noting a two-row design, in the middle part of which there are nozzles for the entry of contaminated and purified gas, as well as a single-row one, in which the nozzles are located on the side of the structure.

Transportation of equipment is carried out by freight transport. To simplify this process, the bag filter, the drawing of which is presented above, is sold in partially disassembled form. The units are manufactured in various variations in accordance with operating conditions. To assemble the structure, the welding method and bolted connections are used. Most devices are designed to operate under excessive vacuum or pressure.

View gallery

Design Features

The installation includes:

- rectangular or round body;

- bunker base;

- sleeves directly;

- valves;

- additional devices.

Hose lines, as a rule, are hemmed in the inner part of the structure , and special devices and valves are responsible for their operation. For the manufacture of hoses, natural fabric materials are usually used, which makes filtration environmentally friendly. These can be cotton or wool fibers. However, bag filters based on fiberglass and synthetics are now gaining popularity. This option is characterized by low price and practicality, which is suitable for small industrial enterprises.

What is the latest trend in coarse filtration?

This is the development of coarse filtration after elutriation. The reason is clear. Send more or less pure juice for fermentation. It can be cleaned as much as the winemaker wants. But you need to understand that you cannot filter the juice to the highest purity and think that it will be the best wine, but not even vice versa, leave as much impurity as possible and there will be the best wine. The truth is somewhere in the middle. Everything will be inflated depending on the winemaker’s intentions. He must know when, what and how to filter. This is a complex topic, especially in juices, at the leading wineries that deal with this, that some juices are filtered significantly to the highest purity, some not much, on the contrary, some even undergo a blending, during which part of the sludge, after a thoughtful discussion by the technologist, is returned to the filtered juice to achieve the correct level of sludge content for the future development of the wine during or after fermentation.

Frantisek Bilek

Filtration specialist and director of Bílek Filtry LLC

The article was published in the magazine “Vinař Sadař” (winemaker-gardener).

Main types of filter bags

The selection of a suitable bag filter is based on the production process and the nature of the dust produced in the process. The main criteria that you should rely on when selecting this equipment are the performance of the installation and the depth of purification of the incoming air.

The remaining parameters are individual: the degree of their importance depends on the production conditions

For example, the choice of material from which the filter is made depends entirely on the characteristics of dust pollutants that arise during production.

No. 1: Difference in hardware performance

Bag filters are divided into two main types: round and flat. The first type is designed for operation in enterprises with a large dust load and is capable of passing and purifying quite significant volumes of air: more than 100 thousand m 3 per hour.

Flat hoses have a more modest performance, but also have a more compact design. Such cleaning systems are suitable for workshops with a small dust load.

No. 2: Classification by type of hose installation

Depending on the type of installation, systems with bag filters can be vertical or horizontal. The latter remain more efficient as they allow more air or gas to pass through.

The flow path through the hose itself is quite long, so the pores of the filter material trap more pollutants.

Sleeves are also distinguished by shape: ellipsoidal, cylindrical, rectangular.

No. 3: Varieties based on material of manufacture

The classification and operating principle of a bag filter is also influenced by the material from which the filter element is made. It is often made from fabric.

It can be either natural cotton or wool, or synthetic materials:

- polyester;

- fiberglass;

- polyamide;

- meta-aramid;

- polytetrafluoroethylene;

- polyacrylonitrile, etc.

The choice of hose material is based on the type of production, characteristics of the filtered mixture, dispersion and properties of dust, and aggressiveness of the environment.

Recently, non-woven filters with a more uniform and finely porous structure, which, due to their fibrous surface, retain more pollutants, have become particularly popular.

No. 4: Classification by regeneration method

The filter restoration method can be done with

Advantages and disadvantages

Due to the versatility of their design, as well as their wide optionality, bag filters have many advantages and are widely used in various industries. One of the advantages is that they can be easily integrated into a production line and can be adapted to suit tight spaces. Among dry-type dust collectors, bag filters have the highest degree of purification - up to 99%. They have relatively low operating costs, which are limited to routine replacement of filter bags once every 2-3 years (this period depends on the aggressiveness of the environment, temperature and humidity) and periodic replacement of pneumatic valves. Bag filters can function just as effectively in harsh winter conditions with outside air temperatures down to -60C as in a heated room, which can be considered an absolute advantage.

However, there are also disadvantages of bag filters. One of them is the need for a compressed air supply, for which there are special requirements. For example, for large filters that filter 150-200 thousand m3/h of contaminated gas, a compressed air supply of 4000 l/min is required. Some filters require the use of sleeves made of meta-aramid, fiberglass, polyimide and other expensive materials, the correct selection of which determines their lifespan. Errors in the selection of filter material entail a significant increase in the cost of operating all equipment. The filter material of the bags is selected based on the characteristics of the medium being filtered, the properties and dispersion of dust. The main materials used in bag filters are polyester (PE), meta-aramid (AR), polyimide (P84), fiberglass (FG), polytetrafluoroethylene (PTFE), polyacrylonitrile (PAN), polyphenylene sulfide (PPS) and others.

Bag filters with pulse blowing

The simple design of bag filters and their efficient operation have made this type of filter mechanism the most common in industry. Moreover, such filters have an internal classification that characterizes the type of material used and the characteristics of the gas supply.

The design of bag filters is such that it allows gas filtration into several streams at once. The space between the sleeves ensures free inflation of the sleeves under the influence of air flow and ease of replacement or repair.

Bag filter with pulse blowing

The design of filter bags can be different. They are usually made in the form of a fabric (one-piece or consisting of parts) cylinder with or without spacer sleeves. The upper and lower edges of the sleeves, in those places where the fastening occurs with a clamp, are folded and hemmed to give them greater strength.

Filters that are used to purify gases from dust are most often made in the form of several bag filters, which are connected in parallel to batteries. In this case, filtering occurs alternately in three blocks, which are located one after another.

Two of these blocks perform their own filtration, and the third one performs sediment discharge.

Bag filter battery

During the filtration process, gas that is contaminated with dust is directed into the filter bags. Dust particles from the gas remain on the sleeve and form sediment.

At the moment when the sediment reaches its maximum thickness, gas stops flowing into the apparatus. After this, air is blown into the filter sleeve in the opposite direction. And thanks to vibration, the sediment falls away from the filter sleeve. The sediment falls down and falls into the cone, and from it is discharged into bags.

In order to completely clean the filter bags, it is switched to dust removal mode.

To efficiently clean a continuous flow of gas from dust particles, you should use a battery of three hoses, which operate in turn. Two of the filters are constantly running, and the third is a backup and is shaken out while the first two are running.

As with the separation of suspensions, purification of gases from suspended particles by filtration is used in cases where separation cannot be carried out by sedimentation in cyclones and settling chambers. The operating principle of devices for purifying gases by filtration is similar to the operation of devices for separating suspensions. Such devices use porous partitions that allow gas to pass through, but retain solid particles on their surface.

The need for air purification in production

The environmental crisis on the planet is getting worse every day. Manufacturing enterprises play an important role in this: leakage of chemicals, pollution of water bodies with wastewater and dust emissions have an extremely negative impact on both the state of nature and human health.

In addition to direct harm to workers and residents living near production, dust also causes damage to the enterprise itself. Dust deposits have a detrimental effect on the operation of equipment and worsen the condition of the ventilation system and heat exchangers. These factors can lead to a decrease in the quality of manufactured products and even increase their cost due to breakdowns and faster wear of the equipment used.

Dust suppression at enterprises is organized using different methods. In addition to trapping suspended matter with special filters, a fogging system can be used, thanks to which dirt particles settle together with microdroplets of water

That is why high-quality dust collection and neutralization is an integral stage of the entire technological process in production. The bag filter effectively copes with the assigned tasks and protects not only nature and people, but also the equipment of the enterprise.