As long as pipes are used in plumbing, there are plugs on them. These details are usually given undeservedly little attention, but they are also part of the tightness of the entire pipeline and must clearly perform their functions. In this article we will look at their main types and purposes.

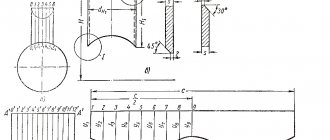

Photos of various plugs

Types of stubs

All fittings used to plug pipes are classified according to the material of manufacture, installation method and type of construction. Products are made from the following materials:

- Metal (brass, steel, cast iron elements). The fittings have a high tensile strength, therefore they are widely used in public highways (gas and water supply, sewerage). However, metal plugs are susceptible to corrosion. The exception is chrome steel fittings. This material does not rust. Metal fittings also include a special plug for sealing. It has a special technical hole for installing a seal. As a result, it will be impossible for third parties to interfere with the system.

- Polymers. Plastic plugs are widely used in private construction. The material does not rust or wear out. Polymer fittings are deformed under the influence of high temperatures (sun, hot water from +85 degrees). Polyethylene fittings are used for the internal pipe plug.

- Rubber. The simplest type of element, used either for decorative purposes or exclusively in private water supply.

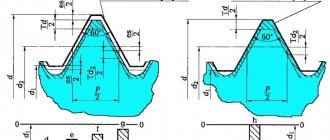

According to their design, silencing fittings are divided into the following types:

- Threaded. The simplest of all plugs. They simply screw into or onto the pipe.

- Flanged. It is assumed that there are technical holes along the edge into which mounting bolts are driven. The flange plug is often attached to the casing or gas pipe using reinforced hardware (nuts/bolts). If necessary, the fitting can be removed at the right time. As a rule, the flange element is made of metal.

- Pneumatic. Made of rubber. You can install such an element using a pump by forcing air into it. The fitting has a special fitting with a hose. Air is pumped and pumped through it into the plug and back. Such an element can operate at temperatures from -40 to + 70 degrees. The peculiarity of a pneumatic fitting is that it will hermetically close the lumen of the pipe, regardless of the evenness of its inner walls.

- Elliptical. Installation is performed using welding.

Threaded internal

Flanged plastic

Pneumatic

Elliptical Flanged brass Threaded external

Based on the type of installation, all plumbing elements for silencing are divided into two types:

- Internal. Mounted using special ribbed notches. The upper part of the fitting is covered with a lid.

- External. They work simultaneously as a decorative element and as a dampening element.

There are types of plugs according to their purpose - end and transportation. The first ones jam a section of the system. The latter are used to protect the ends of pipes during transportation. Their strength characteristics are seriously inferior to those of end caps.

Fitting selection criteria

The plug is selected according to several parameters:

- Material of manufacture. As a rule, PVC fittings are used for metal-plastic pipes, polyethylene for PET, and steel or brass for metal. Rubber ones are used as temporary ones.

- Diameter, size and shape. The cross-section of the plugs must exactly match the parameters of the communication pipes. In addition, round fittings are used for round elements, and square fittings are used for profile elements.

- Purpose. For long-term sealing of the pipe, it is better to buy a threaded or elliptical fitting. If the plug is installed for a short time, it is better to use a flange one. Moreover, it is not recommended to buy rubber and polymer plugs for the hot water system or heating pipes. They change their shape when exposed to high temperatures. As a result, system depressurization may occur. Pneumatic and threaded plugs are not installed on gas pipelines. It is better to use flanged ones here.

Decorative plugs are made from PET in various shades. The color is added to the polymer at the casting stage. The fitting is painted uniformly throughout the entire thickness of the plastic.

Has the brake pedal become wobbly? Broken brake hose? There is a solution!

It just so happens that instead of notes about the desired tuning and modifications to my bus, my entire BZ is filled with articles about repairs. This time there was another breakdown, the rear brake pipe burst. The breakdown could not be repaired immediately, as it burst almost behind the tank. I turned off the circuit on the rear right wheel and drove it like that for 3-4 months. Yes, it’s true that safety comes first, but the car runs every day and there was no time for repairs. Fortunately, the completed technical inspection came to my aid, and I can’t drive without it. The New Year holidays passed, and then I found time to repair my bus. What to do if your brake hose suddenly bursts?

Purpose and principle of operation

Plugs shut off the water supply to a certain section of the water supply.

A plug is a special fitting that can be used to shut off the water supply to the system at a certain section of it. The element has the shape of a circle or square. The latter are rarely used for plumbing work.

The plug is used for the following purposes and in the following situations:

- Protection of the inside of the pipe from moisture and dirt, penetration of rodents and insects. This option is observed when installing fence posts made from round/square tubes.

- Suppression of a plastic water pipe or metal/polymer sewer pipe at the time of plumbing repair work in the system (installation/dismantling of its individual elements).

- Protection of tubes from the ends during their transportation.

To plug the gas pipeline, special flange plugs are used. They are subject to repeated installation/dismantling.

Any plug works on the principle of completely sealing the pipe opening. It is a kind of traffic jam. If it is necessary to extend the system (sewage, gas or water supply), the plug is simply removed from its place.

Without threading

Without threading

There are situations when threading a metal water conduit is impossible. For example: you replace an emergency tap in an apartment, but it simply falls off along with the rusted threads on the pipe. The remaining piece (a piece of pipe) does not make it possible to re-cut the thread with a die, there is simply not enough space. The only way out is welding, but it simply may not be at hand, and welding work in an apartment is still a pleasure.

I had this situation too, so I offer my own solution to the problem.

For work you will need materials:

- Coupling with external (internal) thread for propylene pipes of a suitable diameter.

- Clamp clamp (as in the picture below).

From the tools:

- Bulgarian

- Electric hair dryer

- A hacksaw or just a hacksaw blade

Visual installation diagram

Enlarge fig.

Installation:

We cut the pipe evenly, chamfer it along the outer diameter of the pipe, using a grinder or a metal file, if it is not possible to get close with a grinder.

We put the clamping clamp on the pipe, make transverse cuts and grooves on the pipe using a hacksaw. This will contribute to a more reliable clutch grip.

We warm up the pipe as much as possible with an electric hair dryer and immediately proceed to warming up the inside of the landing coupling until characteristic softening. Then we quickly seat the coupling on the pipe until it stops. We put on the clamping clamp, and until the coupling has lost its elasticity as much as possible, but without fanaticism, we compress the coupling, tightening the adjusting screw.

We wait for it to cool completely, screw the plug onto the coupling and supply water to check the working pressure; if the coupling does not leak, then your installation was successful.

At the time of writing, couplings mounted in this way are three years old.

Attention!

It should be noted that such a solution should be applied as a temporary measure. The problematic plumbing system should be replaced with a new one using modern materials.

Happy installation!

Let us know about it - rate it

masstter.com

How to get home if the brake pipe bursts. manipulator Nissan diesel

I started to put everything together when the brake pipe burst. Well, nothing, it was lying somewhere in stock, I began to slowly unscrew it when the brake line burst a little further on.

On the road, the brake pipe burst, and every time the brake pedal was pressed, the fluid leaked out... It was decided to plug the brake pipe - but alas, in vain! Because the pressure is too high, and the tube is rusty..! Another solution turned out to be more practical. Having removed the brake fluid supply hose from the reservoir to the pg, we turn off the rubber hose by inserting a 10mm bolt into it. and tighten it with a clamp so that the bolt does not fly out. And that’s it, you can drive, but carefully, keeping your distance because... The rear brakes don't hold up. PS God forbid that you don’t need this... but maybe it will help someone..!

Purpose

Plugs are used in the following situations:

- During pipe transportation . This helps prevent the product from receiving internal damage.

Handling pipes with end caps

- To block the end of a branch of a water supply, sewer or gas pipeline . After all, all pipelines must end somewhere, and it is the plug that is responsible for the necessary sealing of such a place.

Plastic plug for sewer pipe

- When repairing a damaged area . Especially if it is impossible to shut down the entire system, but it is necessary to isolate the recovery site by stopping the flow of the pipeline contents.

Principles and features of installation of various types of plugs

When screwing in the plug, it is important not to strip the thread.

The device for plugging the pipe can be installed in different ways, depending on its design features. The following actions are performed:

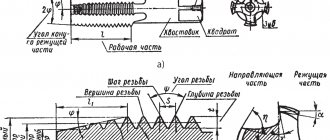

- Screwing in. This method is used to install a threaded fitting. Before installing it, you must use fum tape and sealant. They will additionally protect the system from leakage. The tape is wound in a small layer on the outer part of the fitting and screwed on. The threaded plug is screwed in by hand until it stops, but without excessive tension.

- Welding. Suitable if an elliptical element is being installed. It is possible to achieve complete tightness of communication. In this case, the work should only be carried out by a specialist. The welded plug is installed for a long period and is not suitable if any repair work is expected to be carried out on the communication section in the near future.

- Use of bolts and nuts. This method is used to install a flange muffler. Before installation, you need to place a seal between the fitting and the pipe. It, in turn, is selected in accordance with the permissible temperature values for a particular system and the pressure requirements in it.

- Air injection. The water supply plug can be installed in several stages. Water is removed from the pipe, a hole is made in the desired section of the system, a fitting is inserted and air is pumped into it. Expanding, the walls of the plug fit tightly to the inside of the pipe. Remove the pneumatic fitting upon completion of the repair work. To do this, you just need to pump out the air from the rubber stopper and remove it.

Thanks to a huge assortment of shut-off fittings, it is possible to solve the issue of sealing the pipeline and the decorative appearance of profile tubes used as fence posts. It is only important to make the right choice.

Plugs from

Our company offers commercial organizations and individuals plugs of various types and purposes.

We cooperate directly with enterprises, prices are low. The catalog offers models with high consumer ratings. Fittings have certificates and factory warranties. Delivery is carried out to any region of Russia. We are waiting for your applications in our office in Yekaterinburg or remotely: by phone, on the website or by email. If you find it difficult to make a choice on your own, please contact our staff. They are ready to competently advise clients. Up

Replacing brake pipes. Important points!

But to be honest, there was a situation: I waited until the ordered parts were delivered, during which time I turned off the brakes of both rear wheels and drove CAREFULLY for a week. Both wheels need to be turned off (although I also had a problem with the right rear). Replacing brake pipes. Useful tips! https://youtu.be/UNJteTLdH5Q In this video I tried to tell and give some useful tips on replacing brake pipes using the Passat B3 car as an example. But all this applies to other cars. Let me remind you that you should not wait for the brake pipe to become very rusty and burst. Inspect the brake pipes in a timely manner and replace them with new ones if required. Do not wait for the brake pipe to burst at the “hour X”.