Any experienced craftsman will tell you that 50% of the work is quality components. The strength and durability of the welded joint largely depends on good electrodes. At the same time, high-quality products need proper storage, otherwise all the advantages come to naught.

Of course, wet electrodes can be calcined in an oven, thereby drying them, but if the rods are cracked or the coating begins to crumble, then only purchasing new materials will help. Proper storage of electrodes will avoid additional costs and save your time.

Practical shelf life

We can immediately say that the period during which these consumables remain usable primarily depends on how they were stored. Therefore, you should understand how to properly store welding electrodes.

The conditions under which the electrodes were transported may also play a role. In particular, transportation should be carried out only by covered transport. If electrodes are moved by rail, then the packaging must withstand and soften the inevitable shocks. For this purpose, packages with electrodes are placed in cardboard or wooden boxes in accordance with the requirements of regulatory documents.

Various brands of electrodes have information on their packaging, including the date of manufacture. But the shelf life of the electrodes is not indicated on the packaging material. The packaging may only provide advice on what precautions should be taken to prevent moisture absorption. This is also not normalized by existing standards.

Of course, an initial external examination of the electrodes can help. They must not have significant flaws. Cracks on their surface and existing contaminants that are difficult to get rid of are unacceptable.

The shelf life of welding electrodes can be conditionally determined according to the actual performance of these consumables. To do this, the shelf life of welding electrodes can be calculated as the number of seams when connecting products until the moment when the diameter of the resulting seam begins to be less than that provided for by the technological process.

It should be taken into account that the service life of the electrodes will be lower when steels with coated surfaces are welded, which is confirmed by experimental data. In addition, the shelf life of electrodes depends on the welding modes in which they are used, the welding equipment used, the types of gases and flux.

Is it possible to store a welding inverter in an unheated room in winter?

Novice welders often wonder what will happen to the welding machine if it is left for the winter in a garage or in a shed where temperatures are below freezing. After all, the inverter contains electronic elements - microcircuits, transistors, capacitors and electrolytes. What will happen to them?

I have a welding inverter. I heard that it cannot be stored in the cold. I keep the device at home. When I need to brew something, I take it with me to the garage. Tired of it. Can I leave it there?

Below are the opinions of FORUMHOUSE users.

I have a branded German inverter. I've been keeping it in the garage for two winters now. Works fine. Why should he spoil? What does your instructions say?

The inverter is not afraid of frost. But if you bring it from the cold into a warm room and immediately turn it on, it may fail.

The cause of the breakdown is condensation, which forms due to the difference in temperatures outside and at home. As a result: drops of water will appear on the electronic components and, when the device is plugged in, it may short out.

Article on the topic: How to build a garage from sandwich panels yourself

My inverter “died” just like that, due to condensation. I built a garden house in the fall and carried out “wet” work. There is a lot of moisture. The inverter boards were not varnished. Water got in, resulting in a short circuit near the capacitor. Before this, I kept the inverter in the garage for two years. There were no problems. I concluded: you can store the welder in the cold, but if you need to start it, dry it first.

According to a portal user with the nickname Olvlt, it’s not just a matter of condensation. An inverter is a complex electronic device with a lot of feedback. Almost any element of the circuit, depending on the temperature, changes its parameters - capacitance, inductance. Therefore, the manufacturer writes that it guarantees the operation of the welding inverter only in a certain temperature range.

Condensation greatly affects the performance or reliability of the welding machine. Take the same input electrolyte. When it heats up, it expands. When cooled, and if it is made using cheap technology, it becomes a high-performance vacuum pump that sucks in all the condensate that is nearby. The effect will not appear immediately, but the next time you turn on the inverter. Just when you desperately need the device.

I have an inverter of one well-known brand. The instructions do not say a word about temperature conditions during operation of the device. But there is an indication that the welder should be stored in its original packaging, in a temperature range from -10 to +50 degrees Celsius, with a humidity of no more than 80%.

I have been storing my welding equipment in a cold garage for 8 years now. All OK. In winter I cook a lot often.

And I keep my inverter in the car all year round. I turn it on in the cold too. Once I cooked it at -30°C. Nothing is broken.

Tell. My inverter sat all winter in a dry but unheated shed. Is it necessary to do something with the device before turning it on for the first time and working with welding?

Yes need. First, warm up and dry the device. Then run it at idle speed for at least 2 hours. During this time, the electrolytic capacitors of the filter will be trained and it will be possible to start working with welding.

Where do you store the welding inverter: at home or in an unheated shed or garage?

Article on the topic: How to properly build a garage on your site

Storage rules

The shelf life of welding electrodes depends on compliance with a number of rules. The conditions under which electrodes are stored have a huge impact on their quality. How to store electrodes for welding is specified in GOST 9466-75. The bottom line is that electrodes must be stored in conditions that will protect them from the negative effects of the environment. First of all, this relates to the humidity of the room where they are located, possible contamination and mechanical damage.

The electrode consists of a metal rod and various types of coatings. It is the coatings that should be protected, since they have the property of hygroscopicity and, accordingly, their main enemy is moisture. To do this, electrodes are packaged in metal, plastic and cardboard boxes.

These boxes are placed in larger containers and tied with securing tape or twine.

The function of the packaging is to protect the electrodes, but there are also requirements for it itself. The main requirement is that the packaging must be made from environmentally friendly material. In addition, it must retain its qualities for the entire time the electrodes are kept in it. The packaging must withstand movement and transportation by all types of transport, as well as loading and unloading operations. One of the functions of packaging is its information content.

Placement of electrodes into primary packaging is carried out manually or mechanized. This may affect the consumer properties of the electrodes. If the packaging is of poor quality, the electrodes may get wet or change their shape under the influence of mechanical shocks. If the electrodes are stored in a warehouse, then the boxes with them are placed on pallets.

In this case, cardboard boxes must be tied with a steel cable and wrapped in film. One pallet can store up to 200 boxes, each approximately five kilograms. Moreover, each pack, packed in durable cardboard, is covered with shrink film.

Recommendations and requirements for storing electrodes are specified in GOSTs 9466-75 and 9467-75:

- The temperature in the room where these welding consumables are stored should not be less than 14 degrees, which should be provided by the available heating.

- Relative humidity requirements depend on temperature. If the room temperature is less than 25 degrees, then the relative humidity should be no more than 50%, and if the temperature is higher, then a value of 40% is acceptable.

- The room must be waterproofed. If this is not possible, then it is necessary to place air conditioners there.

- To prevent contact with walls and floors that may be damp, the electrode boxes are placed on pallets.

- Strong changes in room temperature are unacceptable.

The storage conditions for electrodes not for factory use, but for personal use, are identical. It is recommended to store electrodes in their original packaging. The opened box should be packed as tightly and hermetically as possible to prevent moisture from getting inside.

If electrodes are purchased in small quantities, they can be stored in tubes designed for this purpose. The shelf life of the electrodes depends on whether these recommendations have been followed.

Looking for energy efficient solutions?

Pay attention to FORUMHOUSE geothermal heat pumps

Ground source heat pump EU (start/stop)

Geothermal heat pump IQ (pseudo-inverter)

IQ ground source heat pump (inverter)

With the onset of cold weather, many home-made workers and country residents end the season and curtail all work until spring. Garden tools, chainsaws, gas trimmers, welding inverters, drills, screwdrivers and grinders are sent to garages, outbuildings and sheds for conservation. At the same time, people are concerned with questions: how to store tools in winter, whether they will deteriorate due to low temperatures, and how to use them if brought from the cold to a warm room. Let's find out the opinion of FORUMHOUSE participants!

- How to preserve a gasoline spit for winter storage

- Is it possible to store a welding inverter in an unheated room?

- Where to store electric tools in winter and how to use them correctly in the cold

Actions after long-term storage

Despite all the measures taken, risks are inevitable during transportation and storage of electrodes. Adverse consequences can be eliminated by calcining the electrodes. This will help compensate for such unpleasant consequences as shedding of the coating due to high humidity, poor arc ignition, and sticking of the electrode during the welding process.

Before starting use, you should carry out an external inspection of consumables. If there are defects that are difficult or impossible to eliminate, such electrodes should be immediately rejected. The purpose of calcination is to reduce the amount of liquid present in the coating. This is a preventative measure.

It should be noted that this cannot be done too many times, so it is recommended to calcinate the electrodes immediately before starting welding. If you do this often, the coating may lag behind the rod, so you should not do this in reserve.

For different types of electrodes, calcination modes may be different, so you should carefully read the instructions on the packaging or in the accompanying documentation. There is special equipment to carry out this process. This includes stoves, which are a stationary structure in the form of a cabinet.

The temperature in it is maintained by thermal insulation materials, and the temperature value is set using a thermostat.

How to “see” expired electrodes

If the electrodes were not properly stored, this can be determined by a number of external signs.

Minor, minor defects and dirt. For example, the appearance of a white coating on the rod, traces of rust at the ends, which may indicate storage in damp conditions. They can be eliminated by cleaning, drying and calcining, and you can check the performance of the consumable using an unnecessary metal product.

Defects for which electrodes must be replaced. In this case, they are disposed of or used for educational purposes. Most often, the first and main sign is severe shedding of the coating. Another one is the constant sticking of rods from a spoiled batch during welding. In addition, if the coating is damp, the resulting slag after welding will have a characteristic “bubbly” appearance. However, this will only be visible when using consumables or testing them.

Important! If you are not confident in the quality of welding electrodes, and you will be working with critical structures at important facilities, in order to avoid any risks, it is better to definitely refuse such materials.

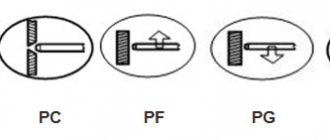

Marking

Contains the following complete information about the "cartridge". For example, E42A-UONI-13/45-3,0-UD E432(5)-B 1 0 means:

- E42A – type, strength 42 MPa;

- UONI-13/45 – brand;

- 3.0 – diameter;

- U – purpose for carbon steels;

- D – coating thickness;

- E432(5) – metal characteristics;

- B – type of coating – basic;

- 1 – spatial position – any;

- 0 – current characteristics – constant, reverse polarity.

conclusions

By following the rules that we described above, you will extend the life of electric and gas tools and ensure their trouble-free operation. Let's summarize:

- Gasoline and electric tools can be successfully stored in the winter in a garage or in a shed.

- Power tools can be used successfully even in cold weather.

- Attention is required if a tool powered by an electrical network is brought from cold to warm . To prevent it from shorting due to condensation, wait 2 hours before turning it on.

And one moment.

I believe that the instrument “does not like” temperature changes. I carry a chainsaw in the trunk of my car all year round. I only bring the batteries that I remove from the tool into the heat.

- Preparing the dacha for winter: what features need to be taken into account before starting winter operation, why the dacha needs to be insulated, how to heat it and install a problem-free water supply system.

- 4 welding goodies for dummies: a pencil case for storing electrodes, nuances of extending and connecting welding cables.

- Tools for the self-builder, which is necessary for the builder who has decided to independently build a country house without outside help.

What is regulated

The welding machine rod is regulated by a number of standards:

- GOST 9467-75 “Coated metal electrodes for manual arc welding of structural and heat-resistant steels. Types" reveals different types of consumables and their characteristics.

- GOST 9466-75 (ST SEV 6568-89) “Coated metal electrodes for manual arc welding of steels and surfacing. Classification and General Technical Conditions” divides rods based on suitable steel, types of coating; lists dimensions, symbols.