Features of the device

The design of the device is simple, reliable and high-performance.

A circular drill, or ballerina drill for cutting gaskets, consists of a central drill with a groove, a round or triangular shank, two carriages and cutters located on the arms of the bracket. The purpose of the drill is to mark the center for the hole and provide support for the device during rotation. There are special markings on the bracket rod for installing the sliding carriage in the desired position. The cutters are fixed with screws, and the spread of the working edges is checked with a caliper.

A distinctive feature of a ballerina with one knife is the asymmetrical design and a noticeable lever that counteracts rotation, creating a high range of oscillation of the instrument. For this reason, experts recommend using the device on a stationary drilling machine. This will help prevent the work material from falling off and protect the worker.

The best option when working with a drill, screwdriver, hammer drill or rotary hammer is a system of two cutters that compensate each other in terms of balance during rotation. The disadvantage of the design is the rapid heating of the cutting part; the drill must cool down several times during the task. To maintain the functionality of the tool, it is recommended to maintain an operating mode ranging from 1000 to 1400 rpm.

Characteristics of a wood drill

When working with hard wood, fiberboard, chipboard, plasterboard and plywood, drills are selected individually, taking into account the thickness of the material, which should not exceed 1.5 cm. A do-it-yourself wood ballerina is assembled from a set of drills and replacement parts included in the equipment set . The structure can be rotated with a rotary hammer, drill or drilling machine at low or medium speeds.

The work process is divided into several stages:

- Drilling with a central twist drill,

- Cutting paths around the circumference,

- Removing a cut element.

The main condition for working with loose wood is the choice of tools for drywall. When making blind or through holes, fixtures made of carbon and alloy steel are used.

There are two ways to drill a quality hole with smooth edges:

- By drilling a small diameter grommet from both sides to the middle of the board

- By drilling through a wooden spacer.

Working on material with a laminated or veneer surface requires preliminary marking of the drilling location with a core or an awl.

Device capabilities

The device for working with wood has a long service life, lends itself well to sharpening knives at the desired angle, and makes it possible to create a gap with a radius of 2.0 to 15.0 cm. For safety reasons, the master is recommended to use a tool equipped with a protective grill screen.

How to make a ballerina out of paper

First of all, you will need to choose the silhouette of a beautiful ballerina to cut out. The Internet is full of options. To make the figure voluminous, the skirt (tutu) is made separately.

What you will need:

- ready-made templates;

- sheets of paper (white, colored);

- scissors;

- pencil, eraser (circle);

- felt-tip pens, pencils or paints (to color the paper silhouette);

- rope or ribbon (if the craft is for a Christmas tree).

Manufacturing process

The step-by-step master class will begin with choosing a suitable picture. There are several options. The first is that you need an ordinary white silhouette, a colored ballerina or a real person. The last option is used when a person’s face cut out from a photograph is glued onto a finished paper craft. The craft is placed inside a holiday card or made into a Christmas tree toy. An original New Year's gift.

For a colored ballerina, you can either choose a picture of a dancer and print it out and cut it out. Or take a regular white outline and then color it using markers or paints. It is not necessary to carefully draw the details; light strokes are enough, especially if the author is not a very skilled artist. You can put such a ballerina on a postcard with your own hands. All that remains is to fill out the wishes inside.

To make the image two-dimensional and viewed equally on both sides, print two identical, but mirrored pictures. Then glue them together with the wrong side. Then the figure will be double-sided. Excellent Christmas tree toy.

Pack. The dress looks more impressive. The easiest way is to cut out a paper snowflake for the pack. Carefully make a small hole in the center or cut to the center to attach the snowflake skirt to the ballerina silhouette. Then glue the cut out part. This tutu looks beautiful and gives the dancer’s image a special charm.

White silhouette or black? If you want to make a garland of several silhouettes of ballerinas, you don’t have to make them white. Take sheets of colored paper and choose colors that match each other. Two or three for contrast. For example, white-black-blue or green-red-gold. By the way, if the garland will be a festive decoration, it is better to take classic colors.

Then the craft will convey the spirit of the event. Carefully attach the cut out ballerinas to a thread and hang them together on one ribbon or strip. Or tie it to one long thread. Then it will seem that the dancers are floating weightlessly.

https://youtube.com/watch?v=tShap4a1pUc

Characteristics of a metal drill

A special purpose tool is used to drill a hole in metal. The most popular device is considered to be a one-sided ballerina drill for metal, with a cylindrical axis and cutters with a cutting edge made of pobedite. Before drilling, a hole with a diameter of 0.9 cm is created in the metal for the hook of the tip of the central axis of the circular drill. The device allows you to make a through or blind cavity with a diameter of 40 mm to 150 mm.

For large hole diameters on MDF, plastic, multi-layer plywood, special tools with cutting knives are used to create cavities with a radius of 300 mm. Similar in design, but with excellent characteristics, devices cut ceramic and tiles. Each device model is provided with accompanying documents, which indicate the design features of the equipment and the maximum thickness of the material being processed.

A ballerina for cutting gaskets can most often look like a shank with a flattened cutting part and a screw tip. The feather drill has a high working potential and is produced from alloy steel in different dimensional parameters, allowing you to drill plastic of any thickness.

Making a ballerina cutter

A ballerina drill significantly saves time when processing (milling) the contours of a cut hole. Processing is carried out automatically using power tools (drill, hammer drill).

Therefore, the physical effort expended when working with a ballerina is also insignificant. Given these advantages, home craftsmen want to have such a tool in their workshop. Moreover, making a ballerina with your own hands is not at all difficult for a competent craftsman.

For this you will need materials:

- Working (metal) plate with dimensions 200x25x4-6 mm.

- Bolts: M8 grade - 2 pieces (in addition to them you need to take 2 nuts and 4 washers) and M10 grade - 1 piece (in addition to them you need to take 2 nuts and 1 washer).

To work you will need tools:

- To mark the work surface: a marker and a ruler with centimeter divisions.

- Painting tape.

- Stationary machine or power tools (hammer, drill).

- Vise.

- File.

- Kern.

- Grinder equipped with grinding and cutting discs.

- Drills for metal with a diameter from 9 mm to 10.5 mm.

- Keys: open-end and adjustable.

- Screw clamps.

Step-by-step instructions on how to make it yourself

- Marking and processing of the work plate.

- Creation and processing of working grooves.

- Manufacturing of cutters.

- Connection of cutters to the working plate.

- Marking (gradation) of the finished drill.

- At the first stage, we cut a 20 cm long strip from the metal sheet. This will be the basis of the tool being created.

- Using a drill with a diameter of 10.5 mm, we drill a through hole on the machine in the pre-punched center of the work plate.

- Stepping back 1 cm from the drilled hole to the edges of the working plate (at the same level as the central hole), we make marks (punch) on the plate for future drilling.

- The distance between the marks must exceed the diameter of the holes that will subsequently be drilled. This precaution will help preserve the drill.

- Using a grinder cutting disc, you need to create two oblong grooves by combining the existing holes. The working plate is in a vice during this operation.

- Using a file (square or flat), we process the resulting holes. The free movement of the incisors will depend on the thoroughness of this operation (we remove irregularities, hangnails, and tubercles).

- Pressing the work plate tightly against the table (we use clamps or a vice), we smooth out all the irregularities and sharp corners with a grinding disc. We insert an M10 bolt into the central hole and screw one of the nuts onto it from the reverse side.

- We put the second nut (lock nut) on it and press it tightly using an open-end (or adjustable) wrench. To make the cutters, we wrap the upper parts of the M8 bolts with masking tape. We fix the bolt heads in a vice.

- Using a grinder's grinding disc, we cut off the thread, processing the bolt on both sides until a metal handle 4-5 mm thick is formed.

- The pointed ends of the bolt, shaped like a one-sided hook, will serve as the working cutters of the drill. The resulting cutters must be inserted into the grooves, having previously been laid with washers on both sides.

- This will increase the area of their contact with the working plate.

- The rod of the future tool and the cutters should be located in opposite directions. The thread sections remaining on the side surfaces of the bolts will allow you to screw on the nuts and secure the cutters tightly.

- Using a ruler and a marker, we mark the entire plane of the working plate, making marks every 0.5 cm. Later on these marks it is necessary to make notches that will be clearly visible during operation.

Types of ballerinas

For woodworking

In a home workshop, when working with wood material, you may need a tool for cutting round holes. These tools include a drill, which in everyday life craftsmen who work with wood or wood-based materials call a ballerina. The exact name of this device is a circular drill.

The design of the tool is a bracket, along the axis of rotation of which the drill is fixed. It marks the center of the hole and provides rotational support for the entire fixture. At the edges of the bracket there are two carriages in which the cutters are fixed. The bracket rod is marked, so the carriage with cutters can be installed with high precision. Before starting work, the lateral incisors are moved apart to the required distance. They are pressed to the bracket with screws.

There are other modifications of the woodworking ballerina with one, two or three cutters. The bracket can be replaced with a disk, in special slots of which cutters are placed to adjust the diameter. A hole can be drilled straight or at an angle in the axis into which a cutter is inserted, adjusted with a locking screw. It provides the size of the diameter of the resulting circle.

The tail of the axis can be round or specially shaped for fixation in the SDS chuck. To remove a straight or rounded chamfer, where necessary, knives of various shapes are used.

In addition to wood, the material with which this device works can be drywall, plastic, rubber, tile, or metal.

Drilling drywall

For installation of various equipment in plasterboard with a diameter of up to 100 mm, a ballerina for plasterboard is designed. It is a leg with a centering tip, above which there is a mount for the rod, rotating around its axis. In order to hold the tool, at the end of the central post there is a handle with a notch along the side surface. At the other end of the rod there is a disk cutter.

Read also: Size of cutting discs for metal

The device works as follows:

- a tool is drilled in the center of the proposed hole;

- the rod is set at the distance of the required radius;

- The specified hole is cut using circular movements, the edges of which do not require finishing.

The advantage of a ballerina drill for drywall, compared to other tools for the same work, is that:

- the device quickly cuts a hole;

- the disk cutter does not require sharpening;

- despite the intensity of work, all devices do not become loose;

- The rod mount prevents the cutter from moving randomly, changing the cutting geometry.

Tile tool

During construction or renovation work, it may be necessary to make a round hole in the tile. This is necessary for installing a socket, switch, leading plumbing pipes or other elements through the wall.

To work with tiles, single-cut, double-cut and three-cut annular drills are actively used.

The use of these devices promotes a perfectly even cut of tiles without chipping the enamel. By arranging and fixing the cutters at the required distance, you will get a hole of the required diameter and size. Using a circular drill will significantly save time and reduce labor costs. The operation of the instrument is similar to how a ballerina dances.

Drilling process steps:

- On the face of the tile, mark the center of the hole.

- Fix the tile.

- Place the cutters or cutter in the desired position.

- Treat the cut area with machine oil.

- Start carving at low speed.

- To finish the carving, you need to turn the tile over to the other side and continue drilling.

- Use a file to finish the edges of the hole.

Adjustable tool overview

Ballerina design

A variety of drills are used to make holes in wood, as well as in wood-based panels (plywood, OSB, fiberboard/chipboard). In this case, the diameter of the groove being formed is limited by the diameter of the drill itself, so that very often the capabilities of standard devices are insufficient.

The solution in such a situation is to use a ballerina - a special drill with movable cutting elements. It has a rather complex design, but at the same time significantly expands our capabilities in drilling holes.

Photo of the most common model

The main elements of the device are:

- The central part, which includes a small diameter twist drill, a “body” in which the cross rod is fixed, and an end piece for clamping into the drill chuck.

- A horizontal bar (often with millimeter markings) along which the cutting elements move.

- Two cutters secured to the rod with hex screws. In preparation for work, the cutters are moved apart to the required width and clamped in a strictly vertical position.

- Ballerinas can also have a simpler design: an L-shaped movable cutter is attached to the central part. However, most often such devices are used not for processing wood, but for drilling tiles or clinker tiles.

Model for tiles with one cutter

An important factor determining the quality of a ballerina is the material from which it is made. Professional tools that are used for processing hardwood are made of high-strength steel with an anti-corrosion coating, and the cutters are equipped with carbide surfacing.

The price of ballerinas without coating is usually lower, but they do not last long, since cheaper metal is used for their production.

Use for drilling holes

One of the obvious benefits of adjustable wood drilling jigs is their ease of use.

The work of making a hole is carried out as follows:

- On a board or sheet of plywood we mark the center of the future groove.

- Using a hex wrench, loosen the mounting screws and install the cutters on the rod so that the distance between them corresponds to the desired diameter. At the same time, we make sure that the cutting elements are positioned strictly symmetrically.

- We tighten the screws with a wrench, fixing the cutters on the rod in the selected position (the distance for most models is from 30 to 120 mm).

- We insert the ballerina into the drill chuck.

- We place the drill at the mark opposite the center (it can be marked with a punch or passed with a drill of a smaller diameter), after which we begin processing. We increase the pressure on the drill gradually so that the load on the cutting edges does not increase.

After the hole is made, we remove the ballerina with a piece of wood or plywood from it. The edges must be filed to remove burrs.

Specifications

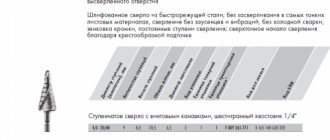

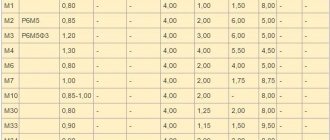

Carbon steel is used to make the device. It is an alloy of carbon and iron. The amount of carbon determines the strength of the tool, its ability to resist load. For greater wear resistance, less sensitivity to overheating and deformation, some manufacturers add chromium, silicon, tungsten, vanadium, and molybdenum to the alloy. For example, the P6M5 marking indicates that the steel from which the cutter or drill can be made contains 6% tungsten, 5% molybdenum, this increases strength.

For strength and increased service life, the drill tip can be tipped with carbide. Such devices give a cutting depth of 30 mm, and without soldering - 25 mm.

Comfortable operating speeds for the tool will be from 1000 rpm to 1400 rpm.

The ballerina, depending on the functional accessory, makes holes whose radius ranges from 20 to 150 mm, while the diameter of the cut circle will be 2 times larger. For example, using a tabletop drilling machine or drill, a ballerina for metal allows you to cut or drill holes in metal with a radius from 22 to 105 mm. The thickness of the material being processed should be up to 14 mm. The material can be steel, cast iron, brass, bronze, aluminum.

Popular publications:

The basis for heat preservationBefore you properly insulate the floor in a wooden house, you need to study the diagram...

How to make a window sill: materials and methods Before starting work on the manufacture of a window sill, you must carefully take the dimensions...

Plastic or wood? Plastic window with wooden window sill We definitely recommend one or another type of material for manufacturing...

Set of teethSaw set is the deviation of the tops of the teeth from the plane of the blade. The teeth are deflected after one...

Home craftsmen do most of their work with wood and wood-based materials. Apart from solid wood, all other materials are considered sheet materials. To connect elements to each other and lay communications, it is necessary to drill many holes. A tool that allows you to drill large-diameter holes is called a circular drill, and is popularly called a ballerina.

It can be used to drill holes with a radius of 20−150 mm. The diameter of the resulting holes will be 40−300 mm.

Homemade ballerina from ordinary bolts and nuts

Using this homemade ballerina, you can cut round holes of different diameters or circles in blanks made of wood, plywood, chipboard, MDF and other materials. In this case, the tool can be made from ordinary bolts and nuts.

It should also be noted that a homemade ballerina of this design is more suitable for a drilling machine than for an electric drill. The fact is that without a centering drill it will be difficult to make a large round hole.

And the first thing you need to do is cut two pieces of different lengths. The master took a pin of a suitable diameter as a basis, but you can also use a long bolt. You just need to cut off the cap.

Wood drill

Ballerinas are widely used when drilling wood, as it is easy to process. In addition to solid wood, home craftsmen use wood-containing materials in their creativity:

- fibreboard (fibreboard);

- chipboard (chipboard);

- oriented strand board (OSB);

- multilayer plywood.

Home craftsmen use different drills to make holes of different diameters: for metal, for wood. But with their help, holes with a maximum diameter of 32 mm are obtained. In this case, depending on the density of the material being processed, the shape may turn out to be non-round or shifted to the side.

When drilling through holes, chips form at the exit. To prevent them, you can use two methods.

- Initially, a small diameter hole is drilled. After that, a hole of the required diameter is drilled on each side to half the thickness of the part.

- A wood gasket is installed under the back side of the part, at the point where the tool exits. During the tool exit, tight compression will not allow the fibers of the material to be pulled out.

The second method is used when the surface of the product is covered with veneer or laminated. The lining is quite fragile and begins to crumble when exposed to a cutting tool.

Other tools used for the same purposes

Craftsmen can use several more tools to produce large-diameter holes. When drilling wooden surfaces (the diameter of the required hole exceeds 25 mm), you can use a Faustner drill.

Unlike a ballerina, it has a number of disadvantages:

- A large contact area with the working surface is accompanied by strong heating of the drill.

- It is difficult to align the central tip with the applied markings, because only the outer circle with the working incisors is visible.

- The Fostner drill bit is primarily intended for drilling blind holes (to hide the head of a nail if necessary).

- High price (due to the high heat resistance of the drill).

A hole saw is useful for drilling large diameter holes in hardwood, drywall, brick, and laminated surfaces. Some models of this tool are adjustable; you can set the required diameter yourself. When drilling hard surfaces (stone, porcelain tiles, concrete, tiles), you can use crowns. However, they are already produced with a given diameter. And the master has to buy several pieces of crowns or even a whole set. Such financial costs are not always justified. In addition, when working with crowns, a lot of fragments and construction dust are formed. Therefore, drilling using crowns in an already finished and furnished room is impossible.

Source

Circular drill device

A ballerina drill for wood is made from carbon, tool, and alloy steels, which are not suitable for processing hard materials: metal, tile, porcelain stoneware. But they cut drywall and plastic easily.

The two-incisor ballerina looks like an ordinary compass . But the design is much more complex. The bracket and cylindrical shank are manufactured in one piece. There are two holes in the bracket. A centering drill is installed in one. A rod is installed in the second. Both are secured with screws.

To set the required diameter, the cutters move along the rod. It has a vernier scale on it. The tool holders are also secured with screws. The incisors are shaped like a knife. The oblique edge of the cutter should be directed in the direction of rotation, clockwise.

If the drill becomes dull during operation, it can be easily replaced. If the cutters are dull, then, having the skills to work on a sharpening machine, you can refill them. The shank of the structure is fixed in the chuck of an electric drill. It is worth remembering that the small power of a power tool may not be enough to work with a ballerina, unlike metal drills.

Types of instruments

In addition to the classic two-cutting version of a circular drill, there are one- and three-cutting models. In the design of a single-cut drill, the cutting part is directly fixed to the rod. The cutter and centering lance are equipped with carbide plates. They make it easier for a ballerina to work on tiles.

Read also: How to tighten a belt with two rings

In three-incisor models, the incisors are mounted on a round platform on which there are grooves. The cutters move along these grooves. They have a scale. Correctly set size allows you to cut more accurately and quickly.

Currently, some models are equipped with a protective grille made of plastic. It improves work efficiency and convenience.

The ballerina for metal is equipped with plates made of hard alloy with sharpening of a cutting turning tool. High cutting force dictates the use of stationary or portable radial drilling machines. Basically, holes are cut in galvanized sheets, the thickness of which does not exceed one millimeter.

Advantages and disadvantages

The advantages include:

- possibility of changing the centering element;

- equipped with two types of centering elements;

- cutters can be sharpened;

- no additional processing required;

- reliable design;

- the locking screws are fixed by a cone;

- The screws are tightened using a hexagonal socket wrench.

Among the disadvantages it is worth noting:

- poor sharpening of cutters;

- on inexpensive models, when processing large diameters, breakage is possible;

- A high power drill is required.

Technical capabilities

The main use of ballerinas remains cutting sheet material. The ability to adjust the diameter allows you to use one tool for several purposes. Two or more cutting elements allow you to obtain a high-quality processed surface.

Almost any sheet material used in construction, repair and decoration can be processed with a circular drill. Carbon steel gives the structure strength. Special coatings are used to protect against corrosion.

The price range depends on the material of construction and cutting part, manufacturer, size and number of cutting elements.

Drill - ballerina. For large holes.

Instructions on the back. Pay attention to the correct placement of the incisors. Equipment:

The key, the device itself, the drill and the nozzle (if the hole is already drilled) Photo with a ruler:

The design did not fit into a regular drill. We use a hammer drill:

We test on 4 mm plywood. Smallest diameter first:

Cutters after drilling. Apparently after each hole it is better to correct them with a file.

I'm trying to drill a 9 cm hole. I set the speed to almost minimum. It's scary to drill at high speeds:

The cutters come out of the plywood unevenly. Here you need to act carefully.

I was afraid to drill anything other than wood. After the very first hole, the cutters already required correction with a file. The holes are not quite accurate as they are set. The movement of the incisors and vibration affect. With these notes in mind, the drill can be used.

Addition. Shank diameter 1 cm

Planning to buy +23 Add to favorites Liked review +26 +46

Ballerina wood drill: the device of the tool, its technical capabilities and use

Wood is almost always easy to process with various tools that have a cutting edge. Quite often, wood craftsmen have to drill into chipboard or fiberboard material using various drills to make furniture or wood crafts during construction work.

It is often necessary to make large holes, for example, in wooden house construction or for fastening parts. The holes can be through or blind, and to make holes of large diameters you will need a special drill called a ballerina. What kind of drill is this, what does it look like and what technical capabilities does it have?

Ballerina on wood

To work in a home workshop, you can get by with ordinary drills for wood and metal, but to perform special complex operations, a specialist cannot limit himself to a minimum set of tools.

Having a good electric drill, you can make a hole in wood with a diameter of no more than 2 cm using a metal drill. For hard wood or loose materials, it is necessary to select special tools that are designed for each specific case.

When craftsmen need to drill a large hole, a drill with the unusual name ballerina comes to the rescue. This is a common name, very common among woodworkers.

Using such a tool you can make holes with a diameter of up to 300 mm in materials such as:

The ballerina consists of two cutters and a centering drill, with the help of which the circle is cut. The cutters move along the guide and set the desired diameter of the circle for cutting. The ballerina must be rotated using a drill or a rotator at low speeds, so the tools can be rotated manually.

A round drill with cutters can be adjusted to the desired diameter; the design also has a centering drill, which can be used to pre-drill into the surface of the material and fix the product.

Moving cutters with a sharp tip are designed for direct cutting of material; there is also a bracket on which moving elements are secured.

A ballerina can have a different number of incisors, from one to three, it all depends on the shape of the device and the price of the special drill.

The principle of operation of the ballerina is simple, first the central spiral drill makes a preliminary drilling in the material, and sharp sliding cutters around the circumference of the surface of the material cut a groove. They are spread to the same width from the center and then fixed with a special key.

How and with what to drill wood

To drill small holes with a diameter of 10–12 mm, ordinary metal drills are most often used. If every millimeter in the position of the hole is important, then it is necessary to use special drills, since the metal tool may deviate to the side when entering the wood.

If you need to make a hole with increased accuracy or large sizes, then it is better to use a special drill. They are always made from tool alloy and carbon steel grades, which cannot be used for metal processing; they are intended for woodworking.

To ensure that the hole is of high quality and that the drill does not go to the side, before starting drilling, make a small indentation with an awl. The entire drilling process must be carried out at low and medium speeds to avoid chipping at the exit of the drill when you need to get a through hole. This can be done in two ways.

- Make a thin hole and then drill along it on both sides of the object to the middle using the required drill to obtain a circle of the final diameter.

- The second method is when a wooden spacer is applied to the surface of the object on the side where the hole needs to be drilled, and it is removed when the work is completed.

Read also: Collet chuck for drilling machine

Due to the fragility of the structure of the material, for example, chipboard, special attention is required from the master to make a high-quality hole. The laminated or veneer surface of the object complicates the task. In this material, you must immediately make a mark with an awl and then drill a hole using a lining.

Technical capabilities of a ballerina on wood

The special tool is made of a durable type of steel, so with such a tool you can perform all work on wood, as well as other materials, with high quality. The strength of the steel will ensure a long service life for the tool.

It is important that the ballerina can perform a wide range of tasks, the drill allows you to make holes with a radius from 20 mm to 150 mm, and the diameter will be twice as large.

Currently, there is a tool that is equipped with an additional plastic protective grille, and this provides its advantages - increased convenience and efficiency of operation.

Types of instruments

Ballerina drill can be of several types. The single-cutter tool has a special bracket with a tightening screw perpendicular to the drill. Before starting drilling, the cutter is tightened to the required length and the screw is then immediately tightened, the drill is ready to perform its operation.

A two-cut tool has cutters that are located on a bracket. The fastening bolts in such a ballerina are located on the cutter holders; they are independently installed at the same distance before the drilling process begins.

A more complex instrument is a ballerina with three incisors; they are mounted on a round platform and move along special grooves.

This is how the required diameter for drilling is set; it can be accurately set using the existing scale. The cutters work synchronously, so the distance from the center will always be the same. The scale greatly helps make cutting more accurate.

For small volumes of work, a ballerina drill always copes with its task and quickly pays for its cost immediately after a couple of holes are made with its help. Other types of tools for such work will cost much more and may only be needed a few times.

- Author: Nikolay Ivanovich Matveev

How to choose and what to pay attention to

Choosing a high-quality circular drill is quite easy

The main thing is to know the main points that you should pay attention to first, but also not to lose sight of the little things

The design is a very important point: a wood ballerina comes with one chisel or two or more. For frequent use, it is better to purchase an option with two or three cutting elements. It is easier to work with such devices and the quality of the processing performed will be at an acceptable level.

It would not be superfluous to be able to replace individual parts. Inexpensive circle drills can have a solid shank with a permanent center drill and rod.

Metal, its quality determines its strength and ability to withstand workloads. High-quality tools are made from high-strength steel or alloys. The shank and cutter holders are shaped using a machine tool. The rod is usually stamped and made of the same metal.

Cheap options often use soft metal or alloys, which can be brittle. Under load, parts may become deformed or break. Such a tool will not last long and it will also be difficult to achieve accuracy from it.

The quality of workmanship, the main feature is the absence of backlashes and distortions. All parts must fit together and be securely fastened with fixing screws.

The markings of a high-quality ballerina's barbell are stamped. Sometimes the divisions are highlighted with bright paint for better visibility.

Cutters and high-quality cutting elements are made from hardened tool steel. They are secured to the holders with rivets or soldering. Solid cutters with holders (made of the same metal) quickly become dull and are not durable.

Manufacturer, when choosing any tool and consumables, preference should be given to well-known and long-proven brands and brands. The most common are Topfix, Stayer, Irwin, Strum.

Purchasing an adjustable circular drill for use at home, or if you need to drill several holes, is completely worth it. This eliminates the need to purchase an expensive tool that may only be needed a few times.

What can a “ballerina” do?

We continue to get acquainted with various tools, today we will analyze a circular adjustable drill, in common people it is called a “ballerina”, apparently by analogy with the appearance of the drill during its work with a spinning ballerina. The main purpose of this tool is to drill large diameter holes in tiles.

I’ll immediately give you a link to my other article about diamond bits - here it is, with the help of which you can also make large-diameter holes.

As you can see, there are many things you can use to drill into tiles; some people prefer to work with a ballerina, while others prefer to use crowns. Let's continue.

With its help you can drill “holes” in tiles with a diameter of 30-90 mm. As you can see, the maximum size is very large, it will be difficult to find such a crown (and I won’t say anything about how much it will cost), so when you need to make a hole larger than 60 mm (as a rule, crowns are sold individually up to this diameter), you have to use a “ballerina”.

It consists of a centering drill and a second cutting element fixed parallel to it and moving along a guide. The cutting part and centering are equipped with hard alloy tips, which actually cut the tiles. The main cutting plate moves along a guide, the minimum diameter is 30 mm, the maximum is 90 mm. The moving cutting part is secured using a bolt.

From this we can conclude that, if desired, you can drill a hole of any diameter in the range of 30-90 mm. Agree, you are unlikely to be able to find a diamond crown with a diameter of, for example, 53 mm. But such a circular drill will cope with the task without any problems. That is why they are in demand among finishers involved in cladding. It can be safely called universal - any diameter within the tolerance without any problems.

According to customer reviews, these drills have proven themselves well when working with tiles. Of course, the cut is not as smooth and even as when working with a crown, however, if a clean cut is not required (for a socket in a tile, for example), then purchasing this drill will be optimal.

How to work correctly?

The work is done using a drill; if it is an impact drill, then the impact mode must be turned off.

We drill at low speeds, it is very important that the carbide plates do not overheat, then your drill will serve you for a very long time. I remember once the neighbors called a plumber, so he got a ballerina that looked as if it had been worked on for many years. I already thought that the master would not be able to do anything for them, but to my surprise, the hole in the tile was made quickly and very efficiently. This is what it means to use a tool correctly. The master drilled carefully, at slow speeds, without pressing hard on the drill. The tile was drilled like clockwork.

The price for it is around 230 rubles, if you look at how much diamond crowns cost, then it’s better to buy it, it will be cheaper. If used correctly, it will pay for itself many times over. Of course, if the holes must be neat and even, then priority is still given to crowns.

— If you need holes, the edges of which will still be hidden later, then take a ballerina. - If the “holes” are clean (you won’t hide the edges) - then there will be crowns.

And of course, a video about how to use this very “ballerina”.

As you can see, everything is simple and clear. Hold on, tiles now))

Another note: How can you unscrew a broken bolt?

Main stages of work

In a long piece of stud, you will need to cut a longitudinal groove along its entire length with a grinder. Since the stud will have to be fixed securely in a vice, you need to use plywood or wood pads to avoid damaging the threads.

The next step is to drill a hole in the nut and cut a thread in it. Then the nut needs to be screwed onto the stud with a groove and secured with a locking screw without a head (hexagon).

Next, you will need to weld a short one to the long pin at a right angle. Then the cutting element is made. At the last stage, the homemade device is assembled.

For details on how to make a ballerina for a drilling machine from ordinary bolts and nuts, watch the video on the website.

Source