| Place | Name | Characteristics in the rating |

| TOP 10 best profile cutters |

| 1 | BISON “MASTER” | The best tool steel |

| 2 | SIBIN 313 | A simple tool at an attractive price |

| 3 | Matrix 87951 | High quality lever system |

| 4 | DEXX 31391 | Best price |

| 5 | STAYER "GRAND" | The most reliable design |

| 6 | Enkor 300mm | Strengthened system |

| 7 | Sibin | A cutter with an enlarged mouth |

| 8 | Bison 3135 | The most convenient one-handed model |

| 9 | Brigadier | Presence of a rotating head |

| 10 | Knipex KN-9042250 | The best choice |

A cutter is a tool that allows you to quickly connect metal profiles to each other without using additional fasteners. The principle of its operation is to punch holes at the joints and simultaneously roll the edges. Thanks to this technique, we get a durable structure for drywall, and the main advantage of such fastening is the speed of construction.

When choosing a cutter for a profile, you should pay attention to the following factors:

- steel quality;

- reliability of the mechanism;

- ergonomics of handles;

- the presence of a lever mechanism, or its absence;

- punch size.

Most aspects are easy to determine by eye, except for the build quality and the steel used. You can’t do this without personal experience or reviews from real users. We also studied them and took them into account when compiling our rating, which included the 10 best models with which you will not experience any inconvenience when working. The TOP included both the most popular manufacturers, who often inflate the price just for their name, and little-known brands from Asia, which are also distinguished by their high quality and compliance with all stated requirements. We will look at both cutters with a reinforced punch and the simplest lever-type tools, which cost less, but are less convenient during operation and force the master to exert increased effort when pressing the levers.

Door (window) opening

If the partition has a door, then a gap of the appropriate length is made in the lower guide. Then they proceed according to the following scheme:

The racks adjacent to the doorway are aligned vertically using a level. They are attached with self-tapping screws to the frame guides and then reinforced with wooden beams.

- The upper jumper from the guide profile is installed. It should be located 1–1.5 cm above the future door structure.

- An additional vertical post, cut to size, is attached to the gypsum board joining line above the door.

The window opening in the partition is made in a similar way, only another horizontal lintel is added at the bottom.

How to choose a cutter for a metal profile

Perhaps the most difficult thing is choosing a specific cutter model. They are divided, as usual, into household and professional. The difference in price is more than noticeable. The cheapest and most acceptable quality ones can be purchased for about $10, normal ones from $20-30, and really good ones can cost $100 or more.

Profile cutter for drywall: which one to choose

What is the difference? In work resource and ease of use. This means that the more expensive ones use more durable and expensive metals, rubber and plastic for handles, etc. They have a more complex design of the working part; there is a mechanism that reduces the force required for connection. In general, there is something to pay for. But nevertheless, for periodic work, for the home, you can find quite good and functional specimens in the cheap segment.

The difference in the working part between a regular inexpensive cutter and a professional

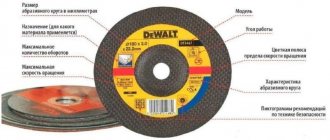

When choosing a cutter for a profile from any category, look at the following parameters:

- Maximum thickness of fastened parts. Please note that the total thickness of metal that this tool can penetrate is indicated. That is, if 1.2 mm is indicated, this means that you can take two sheets of 0.6 mm or 0.8 mm + 0.4 mm, but not two sheets of 1.2 mm.

- Shape and size of the “window”. Rounded corners make work easier.

- The presence of a roller that pushes the punch. Such models are more expensive, but require much less effort.

- The case is free of defects, cavities, cracks, massive and heavy.

- We evaluate ergonomics. The handles should be comfortable, with stops.

- It is ideal if the handles have rubberized inserts. Otherwise, you will have to work with gloves - there will be calluses.

- The handles can be grasped with one hand when extended.

For professionals, such a tool is a godsend, but for amateurs and home craftsmen the price is too high

And it is very desirable that the company be well-known. Although, there are also nameless “Chinese” ones that are very good for home use.

Fasteners

Fixation of profiles to planes, as well as to each other, is carried out by products, which include:

- U-shaped bracket. A bent perforated metal plate, the purpose of which is to connect the frame being built with the walls and ceiling. To do this, the bracket is fixed to the surface to be finished in the middle, and a starting profile for drywall is attached to the ends;

- quick suspension It is used when a U-shaped bracket is not enough, and consists of 2 parts - a knitting needle with an eye at one end and the suspension itself. The parts of the product are attached to each other using a spring, which allows adjustment of the height of the suspension, which is the advantage of the element. This type of fastening has a drawback - after some time, the spring weakens, as a result of which the suspended ceiling may sag.

- crab connector. Makes it possible to fasten load-bearing profiles crosswise. To do this, the product is mounted in the profile, attached to it with antennae and self-tapping screws, after which a jumper is attached in a similar way, which is also fixed with self-tapping screws. To install one crab connector, it must be fixed with 8 self-tapping screws;

- CD connector. The purpose of the element is to lengthen the load-bearing profiles. To do this, they are inserted into the connector on both sides and fixed with self-tapping screws;

- two-level CD connector. A rare product used to assemble a frame attached to a wooden floor. The frame made using these fasteners turns out to be double: first, the first and then the second level of profiles are assembled, which is mounted in the usual way. The need to use a two-level connector lies in the need to compensate for changes in the size of the tree depending on the level of humidity and temperature changes.

Fastening metal profiles to surfaces, to each other, as well as screwing plasterboard sheets to them is carried out using piercing and drilling type self-tapping screws, equipped with nylon dowels, anchor wedges, and dowel nails.

What is important to remember when working with a flasher?

There is nothing complicated about using a cutter. But, despite this, it is necessary to know the principles of operation, so the connections will be strong and durable.

- To connect, the parts are placed on top of each other;

- The fixation point must be in the working area of the tool;

- The handles of the device must be reduced to a characteristic click.

The resulting hole will help quickly connect the outer part of the elements. During operation, countersinks create special edges that are bent and fixed, which allows you to obtain a reliable connection. The maximum punching layer is 1.5 mm, diameter is 5 mm. In some cases, it is possible to use a cutter for chamfering.

Pros and cons of using cutters

This type of instrument is not very popular yet. It’s difficult to name the reasons, because the thing is really good. Especially for those who install plasterboard systems, and for home craftsmen, this is also a necessary thing. What are the advantages:

Yandex.RTB RA-1479455-7

- Fast and reliable connection of profiles. The speed of installation of the frame under drywall increases significantly. The principle of operation is simple: insert the parts to be connected between the jaws, squeeze the handles, move, repeat. And so on as many times as required. Punch for drywall profile. This is also what this instrument is called.

- No need to use fasteners. This saves time and money.

- The tool is hand-held, so no electricity is needed. You can work on any objects.

- There is no protrusion at the junction of the profiles. When mounted with rivets or self-tapping screws, the head protrudes above the surface of the profile. Self-tapping screws have more, rivets have less. This prevents the sheet of drywall from laying flat without bending. When using a cutter, the bends remain on the “wrong” side of the profile. The front is obtained without protrusions. The sheet lays flat, which reduces the time for putty and its consumption.

For installing drywall, the absence of protrusions is definitely a plus

Yandex.RTB RA-1479455-3

Few of those who have tried to work as a cutter return to self-tapping screws. Although, I must say, there are some. Sometimes in difficult places, the connection is “grabbed” with a self-tapping screw, then a cutter is used, and the self-tapping screw is unscrewed. But these are those who like to play it safe. With some work skill, additional fixation is not required.

Flaws

Now about the cons. Using a plasterboard profile cutter really saves time. But the tool is manual and requires the application of muscle force. With large volumes of installation, namely structures made from profiles, fatigue quickly accumulates. And by the end of the working day, the speed of work drops. The better the tool, the less effort is required, but it is still needed. And this is a minus.

The second drawback is the difficulty of disassembling. To separate the two profiles, you need to bend the metal petals. It takes more time than when unscrewing screws. But less than when removing rivets. It seems that these are all the difficulties and disadvantages of working with a cutter.

Not everywhere you can crawl up and make a cut. Then you have to use screws and a screwdriver

Yandex.RTB RA-1479455-8

There is another drawback, which is due to the shape of the working part. Some components - jumpers, clamps - are simply impossible to “reach” with a cutter. The punch won't fit in there. There are models with very large “windows”, but they are not very good for regular connections. For professionals, having several different models is normal, but for home use it is clearly overkill.

Self-tapping screws or notches

It has already been said that when using cutters the sheet lies flatter. And this is a clear plus in favor of the expanded connection. The second unconditional plus is saving time. The third is the lack of consumables.

The disadvantages of joining GK profiles with a cutter include insufficient fastening strength. Self-tapping screws are more reliable. Perhaps, but the strength of the frame is needed only until it is sheathed with gypsum boards. And it will be enough, even if you make only one fastener for each connection. But it’s up to you to decide which is better - a cutter or self-tapping screws.

Advantages

Ticks have significant advantages:

- Significant savings for large volumes.

- Energy independence. The tool can be used anywhere. Its action is purely mechanical.

- No need to make markings.

- Profiles are not subject to deformation.

- The holes are neat, with smooth edges.

- No additional tools (drill, screwdriver) are required to carry out the work.

- There will be no dents left on the frame.

With the help of a cutter, a hole is punched faster than a self-tapping screw is screwed in, and there is no risk that it will go far. Thanks to the profile pliers, the connections are reliable. If necessary, they can be easily disassembled.

Grinding tools

Grinding grater

The product in the form of a plate equipped with special clamps for replacing the mesh is used in the process of dry grinding of plasterboard sheets and seams treated with a putty mixture.

Grater with extendable handle

Here, in addition to the clamps, there is a handle, which is secured in a hinged manner. The tool is designed primarily for working in hard-to-reach places. If necessary, the handle can be extended independently, thus increasing the range of action. This will allow the technician to be away from the area with the most dust generation.

Vibratory grinders

These devices allow you to speed up the surface cleaning process, which is due to a fairly high vibration frequency. In addition, such devices are capable of absorbing dust that accumulates in a special dust collector.

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter .

0

Types and designs

The assortment of cutters in our stores is not so large, but in large construction stores you can see about a dozen different models. What are they? First, there are models for sheet metal (pictured below). They have a very small gap in the working part, which is also called a “window”. For sheet metal cutters, this window is only about a centimeter wide. Any metal will fit there, but the profile for drywall is only a guide (PN) or rack-mount (PS) with small shelves. And then there may be problems.

A cutter for a metal profile should have a larger “window” in the working part

If we talk about models for connecting drywall, they have a larger “window”. It is made in the form of a square, rectangle or with rounded corners. The larger the window, the easier it will be to fasten rack profiles with any shelf width. But then the size of the “head” increases, which is not always convenient. Professionals simply have several different tools, and for repairs and household use they choose something in between.

This is already a tool for professionals - with holes of different sizes and shapes

There are also different shapes of holes: rectangular, round, square. They come in different sizes. The thicker the metal, the larger the punch (or bit) required. There are models with replaceable punches, and there are rotary ones. For rotary or revolving ones (pictured above), the attachment is changed by turning a wheel with bits of different shapes and sizes. If you plan to work with sheet metal often, this is a good thing. For occasional use, such luxury is unnecessary.

You can fasten profiles near the ceiling and floor with a regular tool, but it is more convenient to work with special

There is also a cutter for metal profiles for convenient fastening of profiles under the ceiling or near the floor. Their handles are not a continuation of the working part, but are installed at an angle. Some (Ultra Profil EDMA) are at an angle of 90°, others are at 45°. This tool further speeds up the work when creating frames for suspended ceilings.

One-handed and two-handed and principle of operation

It is also worth remembering that there are one-handed and two-handed models. One-handed ones have a return spring that opens the handles after the tension is removed.

Working one-handed is far from easy. Especially on good profiles made of normal metal. So often one-handed ones are still operated with two hands. In this case, the procedure for working with the cutter for KG profiles is as follows:

How the cutter works: it pierces both profiles, bends the edges inward

- We set profiles by level.

- With your left hand we fix them in the desired position.

- Tool on the right. We bring its working part to the desired point, compress it until the bit hits the metal.

- We remove our left hand (the profiles are “held” by the cutter), and squeeze the handles with both hands.

Two-handed work is different in that the handles are at such a distance that you can’t even grab them with one hand. Well, they are also designed to connect thicker metal.