The idea of using used machine oil as burner fuel is not new. There are many different schemes for making such a device on the Internet. And the popularity of such products is only growing. This is understandable, because such a device will be very useful in everyday life, heating a country house or utility room.

In addition, it has a number of advantages:

- Most of the proposed schemes are simple , and anyone with a minimum of necessary skills and tools can assemble it.

- The fuel for this burner is very affordable. It can mainly be found in auto repair shops, where there is simply an overabundance of it. Thus, used oil can be obtained for free or for a minimal amount.

- The question of recycling used oil often arises , and such a burner will help to dispose of it without harming the environment.

- This device is multifunctional and can be used as a regular burner or an oil heating system.

- Such a device, as a rule, is mobile , as it is light in weight and size.

- This burner is universal in the type of fuel used. In fact, it can operate on any combustible fuel, be it used engine oil, gasoline, kerosene or any other.

Among the many schemes, one is the most interesting in terms of simplicity, functionality and unpretentiousness. This miracle unit is called a Babington burner. It is named after its creator and its device was unavailable for a long time due to a patent. But the patent has expired and now anyone can bring the scheme to life.

The principle of its operation is very simple and includes the following stages and parts:

- Preheated fuel falls on the sphere, spreading over it evenly, forming a thin film.

- A compressor is connected to the sphere itself , pumping air. A very small hole is made in the sphere, with a diameter of 0.1-0.3 mm. Air under pressure exits the sphere through this hole. Passing through the fuel, the air disperses it, forming something like an aerosol.

- Next, this jet is ignited and a burning torch is obtained.

- The rest of the unused waste flows into the settling tank and can be reused.

- In order for unused waste oil to automatically flow back to the sphere, it is necessary to connect a pump to the system, which will supply fuel from the sump.

Preheating the fuel solves 2 problems at once:

- Increased fluidity. The heated waste oil spreads better over the surface of the sphere and is atomized much more easily by the supplied air.

- Facilitates the process of igniting the torch. At the same time, it is not only easier to launch the device, so to speak, but the efficiency also increases.

The advantages of this scheme include:

- Versatility in fuel use. Such a burner is practically independent of the degree of contamination of the liquid energy carrier.

- No filtering required. Due to the fact that there are no narrow passages in the system, except for the air hole, it does not require filtration, unlike factory analogues.

A serious disadvantage of such a burner is that even if it is made almost hermetically and the entire process is controlled automatically, the room will still be polluted.

Operating principle of the Babington burner

A few words about the history of the invention. The considered method of burning heavy fractions of liquid fuel appeared relatively recently - in the middle of the last century. More precisely, inventor Robert S. Babington (RS Babington) patented his diesel burner in 1969. However, the patent has long expired and now its device is available to everyone interested.

Babington’s invention is fundamentally different in operating principle from traditional oil burners, where a mixture of air and fuel is injected by a nozzle under pressure:

- Exhaust or diesel is supplied from the tank by a low-capacity pump.

- Fuel drips onto the working surface - spherical or inclined. The fuel flows down along it, forming a thin film.

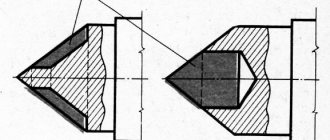

- In the center of this surface there is a hole of small diameter (no more than 0.3 mm), through which the compressor pumps compressed air.

- A Babington waste oil burner operates on the following principle: a stream of compressed air exiting through a small orifice under pressure tears off part of the oil film from the surface.

- As a result, we obtain a jet of air-fuel mixture, which, after ignition, forms a stable flame. It is sent to the firebox of a furnace or boiler, heating the walls of the chamber or the water jacket. The figure below shows the operation diagram of the burner device:

Since some of the fuel flows past the hole, a flow back into the tank is organized

. Here you can clearly see that the unburnt remains of used oil flow from the hemisphere into a special container, and from there back into the main tank. From it, the fuel is supplied for combustion under low pressure, and is preheated to liquefy it. As you can see, the design does not provide any filter elements.

Preheating waste oil or diesel fuel before burning it with a Babington burner is very important and here's why:

- The heated waste liquefies and forms a thinner film on the working surface, which is well atomized by the air flow. This promotes more efficient combustion.

- The smaller the droplets of liquid fuel suspended in the stream, the easier it is to ignite a boiler or Babington stove in manual/automatic mode.

Reference. Finding and buying a ready-made Babington burner in a factory version is unrealistic. Well-known manufacturers of oil and diesel units, for example, KROLL or EURONORD, do not produce them. There is only one way out - order a burner from a good craftsman or make it yourself.

Fuel Features

Spray fuel is not only dirty, but also very sticky. One of the tasks of engine oil additives is to ensure that a thin layer adheres to friction surfaces operating under difficult conditions. Therefore, burners during processing work almost exclusively with heating of the fuel, which increases its fluidity: too viscous fuel will not mix properly with air, will not pass through the nozzle nozzle, or will not coat the spray head in an even layer (see below).

Setting fire to the waste is also not so easy: what kind of engine oil would it be burning in a very hot engine? In fact, only an electric spark and a gas torch are suitable for quick and reliable ignition of waste. There is, however, one exception, see below.

And thirdly, the waste is contaminated not only with solid particles, but also with water and/or antifreeze that got into it from the internal combustion engine cooling system. Fuel filtration is a rather complex process. It makes sense to organize it only if fuel burner is constantly available, for example, in a fairly large and busy auto repair shop, and the burner used for burnout for irregular use should be insensitive not only to solid contaminants, but also to water content in the fuel.

Electricity for burner

This leads to an unfavorable conclusion: there are no energy-independent burners during mining. There are ways to burn waste without pressurization and heating, but such devices (see below) give acceptable technical and environmental indicators only as part of heat-generating devices developed at the same time and are not burners as such. Therefore, if your power supply is unreliable and there is enough waste, it would be better to make a stove or boiler for it.

Pros and cons of the Babington burner

The peculiarity of this type of burner devices is that their positive and negative sides balance each other. As you might have guessed, the main advantage is the use of heavy liquid fuels of any quality. Even with a large number of impurities in the used oil, a homemade air-pressurized burner will function properly (unlike other furnaces made to use similar fuel).

The presence of water or automobile antifreeze in the waste stream (within reasonable limits) is not a hindrance, although minor malfunctions may occur. The fact is that the surface tension of water is higher than that of liquid hydrocarbons. Accordingly, the waste film is more easily torn off from the working surface under the influence of air pressure in a Babington burner. If there is a little water in the oil, then the latter practically does not enter the combustion zone, but flows down into the sump.

Advice. It is still not worth abusing the “omnivorous” nature of the burner device. It is better to pass the waste through a coarse mesh filter before use.

Another pleasant fact for the user is the large selection of types of liquid fuel used. True, when switching from one to another, you will have to reconfigure the burner according to the dosage of fuel and air. Here is a list of these types:

- waste oils and fuels and lubricants of any origin and viscosity - from cars, machine tools and other machines and mechanisms;

- diesel fuel and biodiesel;

- fresh, old and burnt vegetable oils;

- fuel oil;

- light heating oil, kerosene.

The used oil is preheated in a tube surrounding the burner body.

Now about the disadvantages, of which there are also plenty:

- The Babington oil burner is a relatively simple device. But the system of dosed fuel supply and drainage will be more complicated. The circuit involves 2 containers, a pump and a fuel path with combustion intensity control. It is important to ensure the quality of the connections, otherwise the oil will begin to leak.

- When using liquid fuels, especially waste fuel, the boiler room is rarely clean. You must understand that dirt and odors in the furnace room are inevitable. The disadvantage manifests itself in the process of setting up a Babington burner to work together with a homemade stove or boiler. This also includes reconfiguring equipment to switch from mining to diesel, fuel oil or vegetable fuel.

- Occasionally, malfunctions occur during the operation of the burner due to the fact that the nozzle, or more precisely, the tiny air hole, becomes clogged. Most likely, the reason lies on the compressor side. For example, wear of the piston group leads to oil from the crankcase entering the nozzle and can cause failures.

Separately, it is worth mentioning fire safety measures. When performing work related to the installation of an oil burner device, it is recommended to keep a fire extinguisher on hand. The latter must always be located in the boiler room.

Conclusions and recommendations for heat extraction

The main conclusion is this: if you are both a welder and a mechanic, then you will solve the problem of making an oil stove without much difficulty. You will only have to tinker with setting up and organizing the supply of waste in the dropper.

3 types of chimney heat exchangers - convection, air and water economizer

As you understand, simply making a stove using diesel fuel and exhausting it is not enough; you also need to properly take away the maximum heat from it, and not let it fly out uselessly into the chimney. The following methods are practiced:

- As mentioned above, you can lay a chimney at a slope along the entire length of the room, and then take it vertically to the street.

- Use a household fan to blow the housing.

- Scald the body of the potbelly stove with additional heat-removing fins.

- Make and install an economizer (popularly called a register and a boiler) on the chimney - a samovar-type heat exchanger. These are used in solid fuel boilers and consist of several smoke pipes washed from the outside with water.

The simplest way to remove heat from a heated firebox is to weld convection fins

Important point. It is not recommended to blow through the body of the miracle stove for obvious reasons. The water circuit installed on the chimney must be connected to a heating system with forced circulation and an open expansion tank to protect it from boiling. During periodic combustion, the pipelines are filled with antifreeze.

Connection diagram of a water economizer to radiator heating

How to make a burner yourself

To understand how to make a Babington burner device, you need to study its design from the drawings. You can find quite a few of these on the Internet, but for manufacturing it is better to adopt the experience of specialists and use a proven prototype for work. Below is a drawing of a burner made and tested by one of the experienced participants in one of the specialized forums:

Now a few words about what the unit can be made from according to this drawing. The author used a regular steel tee with threads for connecting pipes with a diameter of 2 inches (DN50) as a body. Instead of a tee, a cross of the same size will do. The remaining elements are in accordance with the list:

- Any metal part with a hemispherical end can act as a

hemispherical nozzle or a hollow ball for a Babington burner. There are several options - starting from a brass door handle and ending with various spherical nuts. - The nozzle is made from a metal pipe with an external pipe thread, length – 150-200 mm.

- Copper tube with a diameter of 10 mm for the fuel path.

- Metal tube for organizing air supply. Diameter – at least 10 mm.

- Threaded fittings are used to connect a copper tube to the body.

You will also need a small pump to pump used oil. Units from a VAZ car or motorcycle cope well with this task; you just need to ensure their rotation from an electric motor. Any low-power compressor is suitable, including one from a refrigerator, since the pressure in the air path should be low (nominal - about 2 Bar, maximum - 4 Bar).

Advice. To dose or shut off the fuel line, it is necessary to install a special valve on it.

An important operation is to drill a calibrated hole of very small diameter in the improvised nozzle. But first you need to select a drill of the required size, because the power of the future homemade Babington burner will depend on the size of the hole. Calculating power will be discussed in the next section, and how to make a small hole yourself is shown in detail in the video:

Power selection

The trick is that it is quite difficult to independently make such a calculation using formulas. There is data obtained in practice, and it says that different craftsmen make one or more holes with a diameter of 0.1 to 0.3 mm. There is also more accurate information: if you make a burner with 1 hole measuring 0.25 mm, you will be able to achieve a boiler power of up to 15 kW (depending on the type of fuel).

Advice. Do not drill a hole that is too large (more than 0.3 mm), this will lead to poor atomization and combustion of the waste. In addition, the device will be more difficult to ignite, and the consumption of liquid fuel will increase unjustifiably.

Based on these data, you can select the thermal power of the unit by the number of holes. To reach 30-35 kW, you will have to drill not one hole 0.25 mm, but two. Moreover, the distance between them must be maintained at least 8 mm so that the torches of the air-fuel mixture do not extinguish each other. Based on experience, when a Babington burner is operating through one 0.25 mm hole, the approximate oil consumption in maximum mode will be up to 2 liters per hour.

Manufacturing recommendations

When the hole is ready, you need to attach an air supply tube to the ball and install it inside the tee. To ensure a sealed exit of the tube from the housing, you will have to make a threaded plug. A hole is drilled in it, where the tube is inserted. A fitting is cut into the tee from above by soldering, and a copper fuel supply line is connected to it. To heat used oil before burning, we use the following methods:

- An electric heating element with a thermostat is built into the tank, from where the waste material is supplied to the hemisphere.

- The tube leading from the tank makes several turns around the heated nozzle, due to which the fuel passing through it heats up.

A nozzle is first screwed to the tee, and then a copper tube pre-bent into a spiral is put on it. And only then it connects to the fitting. By the way, 2 holes with a diameter of at least 8 mm should be made in the nozzle for the intake of secondary air. A detailed description of how to make a Babington burner yourself is given in the video below:

The lower outlet from the tee is designed to drain used oil into the settling tank. It can be placed directly under the burner, but this is not aesthetically pleasing and unsafe - the flame is too close. It’s better to take the tank to the side and come up with a fitting with a screw plug and a tube to drain the waste. Anyone who is strong in the field of electronics can attach an automatic ignition and safety kit with a controller to the burner.

Electrical ignition can be provided by one or two automotive spark plugs screwed into the beginning of the nozzle. This will make it possible to stop and start the boiler automatically, shutting off and resuming the supply of waste oil and air to the burner. The controller can receive signals from the flame sensor, water temperature in the boiler and fuel level in the tank and, based on them, turn off the pump and close the fuel line valve.

Characteristics of furnaces

A waste oil stove is good because it can operate on the lowest quality and cheapest fuel. In this regard, lucky are those who work as a car repairman in their own garage - by doing routine engine oil changes, you can extract waste in almost unlimited quantities. The oil furnace itself is distinguished by its low cost, because it can be assembled from the remains of old iron.

Used oil is a very cheap type of fuel, and for auto repair shops it is completely free.

An oil stove burns fuel in the safest possible way. If you set fire to used oil poured into any container, it will fume and smoke, giving rise to hellish aromas and filling heated rooms with acrid and far from safe smoke. And very little heat will be generated from such combustion. A waste oil furnace, having a well-thought-out design, burns fuel so that it does not form soot.

Depending on the design of the stove and its size, it can heat an area of up to 500 square meters. m. and even more. Oil consumption is scanty - it ranges from 0.5 to 5 l/hour, depending on the power of the unit. The combustion temperature reaches +400-500 degrees. The average chimney height is from 4 to 5 meters. Stoves can operate on both clean and contaminated fuel. The resulting heat can be used for a variety of purposes:

- For direct heating of premises due to the generated heat;

- For cooking (only some models are suitable);

- For use as part of water heating systems.

Thus, the exhaust furnace is a fairly universal heater with a simple design, high efficiency and low cost.

About converting a blowtorch for testing

Some home craftsmen, having studied the operating principle of the Babington burner, are trying to convert an ordinary blowtorch to burn waste oil. The goal is to reduce the cost and simplify manufacturing, because the processes in these two devices are supposedly similar. This opinion is erroneous, since a blowtorch functions differently than the homemade burner described here.

In the lamp, air is pumped into a tank of gasoline with one purpose - to push it out and deliver it to the nozzle. In this case, the fuel goes through the stage of heating and evaporation. The nozzle supplies gasoline vapor to the combustion zone; the liquid can be observed there only at the ignition stage, when the “head” of the blowtorch has not yet warmed up. The used oil will not be able to evaporate and the nozzle will supply it in the form of large droplets, which does not contribute to normal combustion. And the cross-section of the jet will quickly become clogged with various impurities.

The conclusion is simple: it will not be possible to convert a blowtorch to burn heavy liquid fuel.

DIY nozzle

The blank parts can be a metal furniture handle or a hemispherical nut. It is allowed to use a curved metal plate with a welded nozzle.

The nozzle extending into the hole of the hemisphere provides air supply to the burner. The power depends on the quality of its manufacture and the calibration of the hole. It is mounted flush with the hemisphere. It is recommended to use industrial jets (automotive; for gas equipment).

The recommended hole diameter is 0.3-0.35 mm, it provides 17-18 kW of heat. Increasing the size causes flow turbulence and deterioration of process performance. If there is a need for more heat, increase the number of holes, placing them no closer than 1 cm from each other.

You can also make a mining boiler with your own hands.

Drilling holes

In order for the air flow to atomize the fuel as efficiently as possible, the hole should be as small in diameter as possible. The priority is 0.010 inches. Although holes up to 0.020 in size are also considered acceptable. To obtain them, special thin drills are used. If you look at them from the side, they will seem intermittent. In any case, the drilling process should be done slowly and carefully. Compressed air will flow through these holes.

As for spraying using air, this option is more preferable than gas. This is due to the low cost of the resource. While you have to pay for gas, you don’t have to pay for air. In addition, you need very little of it, so you can use ordinary compressors, such as those used on aquariums. In principle, the Babington burner, the drawings of which you can find in this article, is almost ready for use. There are a few small parts left.

Additional Tips

When using a homemade burner, there are usually increased requirements for compliance with fire safety rules. Important to remember:

- Do not leave a working nozzle unattended.

- It is prohibited to install the equipment in a residential area.

- To heat the heating main boiler, a special room is usually made without flammable coating on the walls, ceiling and floor.

- To increase operating efficiency, heavily contaminated waste is enriched with clean oil.

- Reliable ventilation is built in the boiler room to remove gases and smoke after fuel combustion.

- Carry out regular maintenance and equipment reliability checks.

If used correctly, a homemade burner will last for many years. The savings from using this type of heating are obvious, because the used oil has already been paid for, and if not for the homemade firebox, it would have to be disposed of.

By making such a simple device, the owner kills two birds with one stone: he saves on fuel and on the disposal of harmful liquid.

Here you will learn:

Used engine oil is an excellent fuel; you just need to create optimal conditions for its combustion.

What is the reason for the ban on gas workers using a stove with a gas nozzle?

A ban by representatives of gas services regarding the use of stoves with gas nozzles may be due to the poor technical condition of the heating device. Or using a homemade nozzle.

This is due to the fact that there have been numerous accidents in furnaces with homemade gas sprayers. In this case, the actions of city gas representatives comply with directive materials on the safe operation of gas equipment.

If the owner uses a factory-made nozzle for reconstruction with all the necessary documentation. And the reconstruction itself to convert the furnace to gas fuel was agreed upon with Gorgaz, then in this case there should be no ban on the operation of such equipment.

Kinds

These devices may differ from one another in several ways. First of all, if possible, regulate the power. There are three varieties:

Single stage

These are the simplest burners, the thermal output of which, also known as power, is always constant.

The amount of incoming heat is regulated by periodically turning on/off the burner.

The advantage of this device is its low cost.

The disadvantage is that all elements of the boiler, and especially the heat exchanger, operate with maximum thermal load and under conditions of sudden temperature changes. And this negatively affects the durability of the heat generator.

Two-stage

Such devices can operate in two modes: with maximum performance and half. Half mode is used as an intermediate mode for smoothly reaching maximum power, or as the main mode in relatively warm weather.

A two-stage burner is more expensive than a single-stage burner, but the boiler equipped with it operates in a gentle mode, and therefore lasts longer.

Modulated

The most expensive type of diesel burner, which is characterized by the ability to smoothly regulate power over a wide range - from 10% to maximum. Such burners do not turn off, but operate constantly - with the productivity that is required at the moment. This not only reduces the thermal load on the heat exchanger and furnace, but also eliminates temperature changes.

Diesel burner M 302

In addition, fuel consumption is reduced. After all, the operating scheme of one- and two-stage burners assumes some overheating of the coolant, as a result of which the amount of heat loss increases (it is proportional to the difference in temperature inside the room and outside).

If the boiler is equipped with a modulating burner, no overheating occurs (the temperature is maintained at the set point all the time), so heat loss, and therefore fuel consumption, becomes minimal.

Other types

Diesel burners also differ in the method of supplying primary air, which is used to prepare the fuel-air mixture. On this basis they are divided into two types:

- Diffusion (atmospheric): the simplest burners in which air is sucked in due to the pressure drop in a moving liquid stream. But with this method it is not always possible to ensure the supply of a sufficient amount of oxygen, so the fuel may not burn completely. The consequences are a drop in the efficiency of the installation and the formation of a large amount of soot.

- Pressurized or blown burners: Equipped with a fan that provides forced air supply in any volume. They cost a little more, but the fuel burns completely under any conditions.

Particularly powerful heat generators are equipped only with forced-air burners.