A pipe bender is a device designed for bending steel pipes. It is simply irreplaceable in construction activities. Its performance depends on the choice of pipe bender model. Purchasing a defective product may cause problems with the quality of the manufactured part. That is why it is extremely important to approach the purchase of a tool responsibly. In this article we will look at the best models of pipe benders, the types into which the mechanisms are divided, as well as tips for choosing these machines.

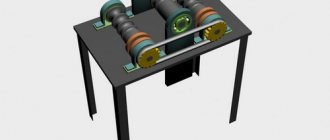

Stationary pipe bender: step-by-step instructions

If you plan to make your own greenhouse from steel pipes, then you will need to acquire not just an ordinary pipe bender, but a reliable product.

After all, with this approach you will need to bend more than a dozen profile pipes. To make the greenhouse design neat and beautiful, you need to use a stationary pipe bender. Before you start making a greenhouse, you need to make sure that you have the appropriate tool for bending profile products. The following elements will be needed to construct a stationary pipe bender:

- rod at 25;

- 6 bearings;

- channel.

You will also need a welding machine, which will be used to connect all the components. Step-by-step instructions for making a stationary pipe bender are as follows:

- Bearings are welded to the base (channel), which are connected to each other by a shaft in the form of a steel pipe of the appropriate diameter.

- To prevent the shaft from being located too close to the base, the bearings should be welded onto 5 cm pieces of rectangular pipe.

- In order to deliberately produce a unit with which the bending radius could be adjusted, the base must be made of two channels connected to each other by curtains, as can be seen in the photo above.

- Two shafts with bearings are located at the same height, and the third (central) is welded using a rectangular tube 15-20 cm higher.

- An additional tube needs to be welded to the upper shaft, to which the handle will be attached. This shaft will be driven by muscular force.

- The handle is welded to the upper shaft, after which the resulting product can be checked for functionality.

When installing a profile tube of any size, you should adjust the radius of the final bend. This can be done using a jack located under the base on which one of the shafts is fixed. Having adjusted the required bending radius, the handle rotates. The result is high-quality curved tubes. The advantage of a pipe bender is the ability to bend materials of any size and diameter.

Among the disadvantages, we can only note the possibility of operation in one place

It is important to understand that such a device can be used for any need. To manufacture such a device, an investment of no more than 500 rubles will be required.

You only need to buy 6 bearings, and all the other elements can be found in every craftsman’s household.

Tips for choosing

When choosing a pipe bender, pay attention to several criteria:

- Product type. Mechanical and hydraulic pipe benders are perfect for domestic use, but electric ones will cope with large volumes of work, so they will fit well into production and large spaces.

- Purpose. Decide what materials the pipe bender will work with (pipe diameter, steel and profile, copper products).

- Adjust settings. Thanks to manual control, the pipe bender becomes universal and functional; it will be able to handle different types of work and their varying volumes.

Pipe benders - design and types

If to manufacture a structure it is necessary to bend a profile pipe along a radius, then a pipe bender can easily cope with this, with which you can make a bend up to an angle of 180 degrees. This device is capable of changing the configuration of pipes made of stainless steel, metal-plastic, and aluminum. In this case, the bending is carried out according to the required dimensions and shape.

Pipe bender design

The design of such a tool depends on its type. However, the required elements are:

- hydraulic cylinder - the main part of the machine that performs the power function;

- open or closed frame;

- two pipe stops;

- lower and upper bars;

- injection device, handle and bypass valve located on the rear of the structure body;

- retractable rod, which provides the bending force of the pipe bender;

- a spring with the help of which the retractable rod returns back;

- a trunnion or stop of a structure, the ends of which are inserted into holes in the slats.

On top of the main part of the machine there can be a level check and an oil fill plug. Installation strips, which are a welded structure, are screwed onto the threaded part of the tool. The bottom bar is secured with a locking nut, and the top bar is pressed with two screws and a lock.

To install supports, special holes are provided on the transverse plates of the device. The bottom of the pipe bender has threaded holes for mounting bolts that are height adjustable.

The bent pipe on such a structure is located on a stream, which is located in the middle of its stop. The bending segments must be made of precision cast steel.

Today, thin-walled profile pipes with thin walls are increasingly used for the manufacture of various structures. Therefore, the design drawing of a pipe bender for such workpieces is somewhat different. To prevent deformation of its cross-section when bending the pipe, profile rollers should be selected with the same cross-section as the product.

Types of pipe benders

Commercially available professional pipe benders can be manual, electric or hydraulic driven.

Electromechanical tools are considered the most convenient

The manual drive design is used for bending small diameter pipes.

Hydraulically driven pipe benders are capable of bending workpieces that can be up to three inches in diameter. Therefore, such a tool is designed to perform large-scale work.

In addition, pipe benders may differ in the way they influence the product, with the help of which it will be bent. These methods include:

- Crossbow method, in which the pipe rests on two stationary rollers and bends between stops under the influence of a template located on the rod.

- Winding - with this method of bending, the workpiece first attaches itself to the roller of the structure. Then a stop is placed at the bending point. The roller begins to rotate and wind the pipe between itself and the stop. In this case, the template and the product are movable.

- Rolling is the simplest way to bend a pipe. On such a device the template is motionless. The pipe is simply clamped and the pressure roller moves and bends the pipe around the template.

- The rolling or rolling method involves the use of three rotating rollers. One of them is central, and two are supporting. The central roller presses on the workpiece, so it must be installed relative to the supporting elements in accordance with the required radius of the product.

pressure from the rod is transferred to the workpiece at the top point of the template

The rolling method has virtually no disadvantages. It is by rolling that steel bends are manufactured in the factory. Using the same method, it is much easier and more efficient to bend profile pipes.

Classification of pipe bending devices

Devices for bending steel pipes are classified:

- by degree of mobility (stationary and portable);

- by type of drive (manual, electric, hydraulic, electrohydraulic);

- according to the method of influence (running in (roller), winding, impact with a rod (crossbow), rolling).

The essence of how a pipe bender influences a pipe is as follows.

Run-in

With this method, one end of the pipe is clamped, and a stationary template is used to give it the required bend. Pressure rollers are used to roll the product around the template.

Drawings of a rolling pipe bender

Winding

In such a device, the pipe is pressed against a movable template (roller), on which it is wound, stretching between a rotating roller and a special stop installed at the beginning of the bending point.

Diagram of a pipe bender operating on the winding principle

Crossbow pipe benders

In such a pipe bender, the pipe rests on two stationary rollers, and bending is performed by a template, which is attached to a movable rod. The template presses on the middle of the fixed section of the pipe, thereby giving it the required bending angle.

Diagram of a crossbow pipe bender: 2 - jack, 3 - shoe (punch)

Rolling or rolling

The required bending radius is obtained using a three-roll device, the basis of which is two support rollers and one central roller. The central roller exerts pressure on the pipe, the position of which determines the radius of its bend. is more universal; in all other machines the bending radius depends on the template used.

Compact size manual rolling pipe bender

The manufacture of a pipe bender operating on the winding principle is not simple, so such a device is made mainly in an industrial way. The crossbow method has another significant drawback: the pressure from the rod with a template attached to it, called a shoe, is concentrated in its upper part. This method of acting on the pipe leads to its significant stretching along the outer radius of the bend, which may be accompanied by a decrease in wall thickness and even its rupture. It is especially not recommended to use the crossbow method for bending thin-walled products.

An example of a homemade rolling (rolling) type pipe bender

A machine operating on the principle of rolling (rolling) practically does not have all of the above-mentioned disadvantages; this technology is used in the production of bends in the factory.

A DIY pipe bending machine can have a different design. You should choose its type based on what radius you need. There is a list of recommendations, in accordance with which the choice of a specific model of device for bending steel pipes is made. Important parameters that need to be taken into account are the thickness of the pipe walls and its overall diameter. Before starting to work with a pipe bender, it would not hurt to familiarize yourself with the data in the table showing the maximum possible radii for bending steel pipes.

Dependence of the bending radius on the diameter and wall thickness of the pipe

To obtain a bend radius smaller than that specified in such recommendations, it is necessary to use hot rolling, which is used mainly in production conditions. A device with a mandrel is more difficult to create at home, so they are much less likely to be made independently, giving preference to rolling ones.

In order to independently hot-roll a pipe, you can resort to using a home-made pipe bender, but provided that it is made entirely of metal and its frame is highly reliable. To perform such a technological operation, you will additionally need a blowtorch or gas burner.

Popular pipe bending equipment

Roller pipe benders

brings to your attention Profline roller pipe benders. Literally every model of a Profline roller pipe bender (and this manufacturer produces a wide range of three-roller bending machines with different performance characteristics and sets of functions) can serve as a standard for the quality and reliability of roller bending equipment in its price class.

Megapolis is the official representative of Profline in Ukraine and can offer you hydraulic equipment of this brand at the most attractive prices.

Mandrel pipe benders

Mandrel pipe benders semi-automatically perform the bending operation, moving the mandrel forward or backward, and clamping the pipe in the carriage chuck. All other operations with semi-automatic mandrel pipe benders are supposed to be performed manually.

Automatic mandrel pipe benders have the following main parameters in their evaluation: the technical ability of the pipe bender to produce products in automatic mode and, of course, the degree of convenience of working on the machine for the operator, because the productivity of the machine and the percentage of defects at the output largely depend on it.

The automatic mandrel pipe bender performs all operations of bending, feeding and turning the pipe in space according to a given program. This means that to manufacture products for which the production process was already programmed, you just need to select the program from the computer's memory and run it again. The productivity of automatic pipe bending machines is much higher than semi-automatic ones. In addition, the risk factor for the life and health of workers, as well as the possibility of human error, are significantly reduced. Therefore, more and more customers in Ukraine are choosing automatic pipe bending machines.

In both cases, the mandrel for bending pipes must be chosen exclusively correctly, because the quality of bending largely depends on it.

A modern automatic pipe bender with a mandrel is high-tech equipment, characterized by functionality, reliability, and high quality of material processing. This is an excellent solution for equipping your enterprise. The main advantages of mandrel automatic and semi-automatic machines:

- ease of use;

- excellent quality of manufactured products;

- stability and reliability.

Mandrelless pipe benders

Mandrelless pipe bending machines are the optimal choice for working with thick-walled pipes and other rolled metal products. The relatively low cost allows them to be used not only in large industries, but also in small workshops. Microprocessor control and programming capabilities ensure repeatability and stability of product quality. Modern mandrelless machines use only the highest quality materials and components, which ensures ease of maintenance and long service life without repairs. There are powerful machines on sale that can work with pipes with a diameter of up to 130mm.

Bending machines without the use of a mandrel are ideal for bending reinforcement, rods and pipes of various sections. Manual hydraulic pipe benders allow you to solve problems with working with metal-plastic pipes at minimal cost.

A hydraulic pipe bender will significantly increase your capabilities; a powerful jack maximizes the impact on the pipe at the bend. Using a hydraulic pipe bender for metal-plastic pipes, you will get an even pipe bend. The hydraulic pipe bender for metal-plastic pipes offered by Megapolis is indispensable if you need reliability and durability.

How to build a hydraulic pipe bender

The design of a hydraulic pipe bender with your own hands is presented in the video below.

Building a tool of this type will not be difficult if you have two 0.5 meter channels at your disposal. The base of such a device included the following elements:

- hydraulic cylinder;

- stops;

- supercharger.

In addition, you should also highlight:

- A jack that can withstand loads of up to 5 tons.

- There are 2-3 rollers.

- Channel - 3-4 mm.

- Thick plates.

The principle of using such a tool is that you need to install a profiled pipe into the shoe. Use a jack to set the required bending radius. When the jack is inflated, the rod rises, pressing on the roller. After establishing the bending angle, the pipe can be removed. This type of bending device is relevant when it is necessary to bend a pipe in one place, for example, when installing a heating system.

What is the unit for?

To bend a profile pipe, you do not need to turn to a metal shop for help or buy a special tool. This can be done using two metal posts buried in the ground. However, this method has a significant drawback - the need for physical effort. The result is an inaccurately curved pipe, which is not suitable for constructing a greenhouse, arch or other products.

A pipe bender is designed to be able to produce neatly curved pipe shapes. These units are subsequently used for the construction of arches, greenhouses, ceilings, gazebos, fences, etc. If you set out to build a greenhouse at home, then you need to design a homemade pipe bender. If there are available products and tools for this, then implementing the design of the device with your own hands will not be difficult.

To make a roller pipe bender with your own hands for a profile pipe, you need to take care of the drawings. They are used to calculate the required amount of material, as well as the costs of producing a home-made unit.

The planned design of the product is applied to the drawing, which depends on the materials available.

Most craftsmen choose to manufacture front-type pipe bending machines. Such products consist of the following components:

- Rollers presented in the form of a round steel pipe (the number of required rollers is 3 pieces).

- Chain driving shafts.

- Axes of rotation.

- The mechanism that drives the device.

- Profiles that are used to make a base or frame.

It is worth noting that there are a huge number of manufacturing options for the products in question, but they all operate on the principle of rolling or rolling. It is this principle of pipe bending that makes it possible to reduce the risk of pipe bending and cracking.

A simple pipe bender has the form of a unit into which a profile pipe is inserted, after which the handle is turned, when rotated the pipe begins to move and a bend is formed

When constructing a home-made unit at home, it is important to consider that the bending parameters will depend on the design itself. The closer the pressure rollers are to each other, the smaller the angle. This is interesting: How to make a chicken coop for laying hens: let’s look into it in detail

This is interesting: How to make a chicken coop for laying hens: let’s look into it in detail

Areas of use

Using a pipe bender, it is possible to deform a variety of pipes, round and profile, made of steel, copper, aluminum.

With such deformation, the bend location will remain ideal, the diameter of the pipe will not be affected, and no other defects will arise.

It is also possible to give the required shape to metal rods rather than hollow materials. It is impossible to get such a result without a special tool.

This device has a wide range of applications, but it is especially needed during repairs. When carrying out communications, it may be necessary to make a pipeline. Plastic pipes will be easy to solder, but welding metal is a more complex process that requires skills and special equipment.

The more seams there are, the higher the possibility of leakage. Installation of heating, water supply and gas pipelines cannot be done without a pipe bender. This tool may also be needed in the following cases:

- in the manufacture of all kinds of fences, exercise equipment and railings;

- in automotive and shipbuilding.

Pipe bender device

The main difference of this tool is the hydraulic cylinder; it serves as a power device and significantly facilitates pipe bending, making it possible to bend large-diameter material with minimal effort.

Also, special shoes are installed on such a tool to provide support. They are selected according to the diameter of the workpiece; they have the shape of a crescent. With this design, the pipe is fixed securely and reduces the risk of spontaneous popping out.

The hydraulic cylinder moves and moves the support shoe in which the pipe is installed, moves it all the way, and the metal pins immobilize the product. This allows you to achieve a perfect deflection in the center.

In some cases, marks are applied to the shoes to make it easier to determine the center of the bend. There are also models in which the angle is indicated, it helps to determine the force of extension of the cylinder.

You may like

VK comments:

Name *

A comment

- https://derevyannie-doma.com/tehnologii/trubogib-svoimi-rukami-chertezhi-kak-sdelat-ruchnoy-trubogib-dlya-profil-noy-truby.html

- https://obustroen.ru/instrumenty-i-oborudovanie/ruchnoy-istrument/slesarno-montaghnyy/trubogib-svoimi-rukami-chertezhi.html

- https://prorab.guru/insrtrument/trubogib-dlya-profilnyih-trub-svoimi-rukami.html

- https://obinstrumente.ru/ruchnoj-instrument/trubogib-dlya-profilnoj-truby-svoimi-rukami.html

- https://stroychik.ru/tools/trubogib-dlya-profilnoj-truby-svoimi-rukami

- https://sdelajrukami.ru/trubogib-svoimi-rukami/

- https://v-teplo.ru/trubogib-dlya-profilnyih-trub-svoimi-rukami.html

Do-it-yourself manual pipe bender for profile pipes

To bend a profile pipe with small cross-sectional dimensions without a pipe bender, craftsmen use templates of the desired curvature made of metal or wood. The workpiece is pressed manually to the edges of the segment, rigidly fixing one end.

Wood template

The thin-walled element can be deformed when heated. Heat the area with a blowtorch to a temperature of 350-400°C and, using manual force, give the profile an arched shape.

If using simple methods is not allowed by the product parameters, you can design a manual roller pipe bender for a profile pipe. It is used to make arches and arcs for canopies, greenhouses and other structures of complex shape.

Required materials and tools

To make the device, you will need:

- channel No. 8 or No. 10 for a rigid frame;

- 2 hardened steel rollers with steps for profiles of different heights or restrictive rings;

- roller with notches for the movable shaft;

- finished bearing units;

- 2 or 3 gears or sprockets;

- steel chain;

- clamping screw;

- thin pipe for the gate;

- lever;

- welding machine;

- drill;

- "Bulgarian";

- hammer.

You also need cotter pins, nuts, threaded bushings, and washers. To process the finished structure you will need paint and lubricant.

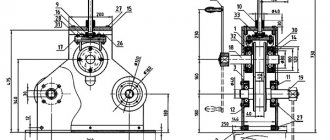

Blueprints

The drawing is the basis that will help you make a pipe bender without making major mistakes.

This is especially important when working with metal labor-intensively.

Ready-made drawings are available on the Internet. Having sufficient experience, they are easy to understand and adapt to your capabilities.

You can imagine an approximate structure of a pipe bender by studying a factory analogue, and then develop a detailed diagram of your model.

Drawing and general view of a hand tool

Construction assembly stages

Sequence of operations for making a homemade roller pipe bender:

- Cut the channel to the dimensions of the posts and base.

- Drill holes in the frame parts to mount the rollers.

- Weld a support frame with racks from a channel.

- Cut and weld a housing from the channel with holes for installing the drive roller. The shaft should rotate easily inside.

- Secure the clamping screw to the resulting box using bearings. Drill a hole in the top of the screw for the collar.

- Insert the housing with the drive roller between the posts. The structure must move freely vertically. Secure the cover with a screw nut on top.

- Screw the bearing units to the frame.

- Insert the collar into the hole in the clamping bolt.

- On the outside of the shaft axis, place the gears on a key or split cone bushings with nuts. Attach the third “star” to the stand. Put on the chain and press in the sleeve for the handle.

- Conduct trial tests and make adjustments if necessary.

The last step is to disassemble, clean the metal from burrs, paint the fixed parts, and reassemble. Units that are subject to friction during operation should be treated with Lithol or other thick lubricant.

Ready homemade machine

To bend the workpiece, it is placed on stationary rollers, the pressure screw is lowered all the way and pulled using a rotating handle alternately in one direction and the other.

After each rental, the screw is tightened with a collar. When the arc acquires sufficient curvature, the screw nut is secured with a lock nut. This will allow you to bend several arches with the same radius.

This homemade pipe bender can even be used for professional purposes. It can handle profiles up to 60x60 mm in size or 3 pipes with a cross-sectional width of 20 mm at the same time.

Details of the handloom manufacturing process can be seen here

https://youtube.com/watch?v=W3SXjpAF1GM

Top 5 best manual pipe benders for profile pipes

Hand tools for bending profiles can be either mechanical or hydraulic. But both types of models are easy to use, moderate in cost and reliable.

Stalex HTR-40

A universal pipe bender for steel profiles with adjustable rollers allows you to roll workpieces with a diameter of 15-40 mm and a wall thickness of 1.5 mm. The bending radius can be changed quickly and easily during the process. The manual machine is equipped with hydraulics with a lifting capacity of 2 tons, there are return springs that bring the pressure roller back to the upper position without effort on the part of the user.

A compact and powerful pipe bender is suitable for making railings, canopies, canopies and other structures that use profile pipes. Since the machine is operated manually, it can be used anywhere, regardless of the availability of electricity.

You can buy a pipe bender HTR-40 from 16,000 rubles

Proma KO-200

The machine is designed for cold bending of steel rods, profile pipes and metal strips; it works with medium-hard materials. Equipped with a wide base for greater stability, it can also be mounted on a workbench using four holes. It is lightweight and small in size, making it easy to transport. Suitable for processing square and round pipes, the maximum bending angle is 200°.

You can buy a Proma profile pipe bender from 13,000 rubles

Stalex TR-60

A manual pipe bender with an extended working lever allows you to easily give the desired bend to metal workpieces with minimal force. The body is equipped with a ruler to control the deformation radius; the machine works with square and round pipes of 15-38 mm. Made of powder coated steel, suitable for stationary and tabletop installation.

Important! The disadvantage of the model can be considered the lack of rollers for working with profile pipes in the kit. However, they can be purchased separately. The average price of Stalex TR-60 starts from 16,000 rubles

Blacksmith MTB10-40

A manual pipe bender without an electric drive or hydraulics, however, is simple and reliable. The machine is equipped with three rollers - between them you need to clamp the workpiece and turn the handle to accurately bend the pipe. The angle is adjusted using the upper roller; it is pressed harder or weaker.

The effort required from the user is minimal; the budget machine is very functional and easy to use. The only negative is that in the absence of experience, controlling the flexion angle may cause difficulties.

The average cost of MTB10-40 starts from 14,000 rubles

Smart & Solid BendMax-300

The manual profile bender is designed to work with 50/30/2 mm pipes. The machine is made of durable steel with a two-layer zinc coating and is reliably protected from corrosion. Among the advantages are reliability, high-quality assembly and ease of operation. The tool can be used both at home and in small workshops.

You can purchase a bender for profile pipes BendMax-300 from 18,000 rubles

Blacksmith ETB40-50HV

This is a stationary device. It operates from a three-phase network. Power consumption is 1.1 kW. The base is heavy, cast. The total weight of the structure can reach 250 kg. There are two drive shafts and an adjustable mandrel, so this tool can work with square pipes up to 20x20 mm in size. You can also purchase mandrels to work with workpieces up to 40 mm.

Control is convenient using pedals. Since the machine is vertical, it will be convenient for the operator to work with the product for a long time.

Here are the main advantages of this tool:

- High performance.

- Universal use.

- Foot control.

- Vertical arrangement.

- The presence of two emergency buttons for immediate shutdown.

How to mechanize the process

Since the hydraulic drive has the greatest autonomy, in most cases it is used. As a source of generated pressure at home, you can use a conventional hydraulic jack. It is installed on top of the movable roller of the pipe bender and under the mandrel. By moving the jack handle, the necessary bending pressure is created.

The choice of standard size of a jack for a pipe bender depends on the plasticity limit of the workpiece material:

- For steels of type St3, steel 10 – 120...130 MPa;

- For steels of type St.5, steel 20 – 130...150 MPa;

- For brass – 80…100 MPa;

- For aluminum - 60...80 MPa.

When choosing a standard size, the stroke of the rod is also taken into account, which cannot be less than 115....120% of the final height of the curved pipe (inevitable springing is taken into account)

Where is metal-plastic used?

Due to the properties of its components, metal-plastic has become widespread:

- in the heating water supply system;

- for supplying drinking water;

- as a gas pipeline;

- for supplying substances used in agriculture;

- for compressed air supply;

- as a sheath for electrical cables.

But despite such a variety of areas of its use, metal-plastic also has limitations in use:

- cannot be used where there is a high fire hazard;

- cannot be used in systems with liquid pressure exceeding 10 atmospheres;

- Do not install near hot surfaces whose temperature exceeds 150 degrees.

How to make a pipe bender with a pressure roller?

The material for the base of such a pipe bender is selected depending on the expected loads. Therefore, to make it, thick plywood or a sheet of metal is taken.

The holder for the pressure and central roller (template) can be made from a U-shaped metal blank. It should rotate freely around the central roller attached to the base. A lever in the form of a long handle is attached to the holder, and a stop is attached to the base.

For small workpieces, you can make a pressure pipe bender with your own hands for two different bending radii. To do this, the template must be made with rounded corners, each of which must have its own radius. The handle of such a tool should have two holes with which it can be removed and installed in another place.

BISON EXPERT 23522-H7

This is one of the best electric type appliances for home use. It is small in size and easy to understand how it works. However, this model could not be used in production due to the fact that it does not support work with large diameters. And it doesn't have much power. The limit of this product is copper or steel pipe with a diameter of 20 mm.

To work, you need to place the pipe bender in your hand and press the handle, which is located on the handle. All actions will be performed using a built-in electric motor. The set includes several rollers that allow you to work with pipes of various diameters. The cost of the model is about 10,000 rubles, so it can easily be purchased for home use.

The benefits include the following:

- Low price.

- Ease of operation.

- Possibility of use at home.

- Small dimensions.

- Universal use.