Gas cylinders are widely used both in households and in industry : they are used for heating houses, cooking, and various works on a construction site. However, the gas cylinder is quite heavy and large, making this item quite difficult to move.

In order to make it convenient to transport gas cylinders, special trolleys have been developed that allow you to safely position the load, secure it and move it without much effort. Another example of a special-purpose cart is carts for transporting outboard motors. Read about them - here.

Types of carts for carbon dioxide, oxygen and propane

Cylinders for different gases and purposes vary noticeably in size, so they require different carts. As you can see, they also make designs for oxygen plus propane pairs.

The most popular designs are for one cylinder. In this case, the wheels can be placed at the bottom or at the center of gravity of the cylinder. In the second case, the load is quite high and the structure is unstable, but the load on a person in this case is the least.

In some cases, it is convenient to use a combined welding cart for gas and semi-automatic. Then you need to add two more small wheels under the welding table.

Another option is a mobile device for moving cylinders. Such a cart can be rolled indoors, carried manually by two people, or rolled on wheels into the trunk of a car. It is this device that we will consider first.

We make our own wheelbarrow for transporting gas cylinders

The vertical part of the frame is welded from a profile pipe with a cross-section of 20x20 mm, based on the size of the carbon dioxide cylinder. The base can be made from a 20x40 mm profile.

To ensure that the cylinder on the stand can be easily rolled into the trunk, four wheels are used. The supports are welded to the cart in pairs at the top and bottom. The check shows that the frame will press on the bumper when loading. The height of the cart and the placement of the wheels must correspond to the dimensions of the loading platform of your car.

Now you can remove the wheels, clean the welds, degrease and paint the frame. A metal plate is attached to the base of the cart using rivets. The shaped cross members are wrapped with fabric tape so that the structure does not make noise when the car is moving. Brackets for attaching rubber belts from the VAZ-2101 are welded to the top and bottom of the racks.

We install the gas cylinder on the trolley and place it in the car. Again the frame touches the bumper, but for a “household” car this is by no means scary. The cylinder valve is located between the seats.

The trolley is fixed to the standard load securing points using chains and ties. In the longitudinal direction, the load is not sufficiently secured, and it is planned to install cotter pins in the supports so that the wheels do not rotate.

Another design with the same idea is shown in the photo. Its production required 6 m of profile pipe with a cross section of 20x20 mm. The upper wheels have a diameter of 75 mm, the lower ones - 100 mm.

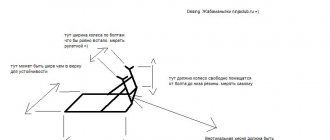

The sketch shows all the elements of the cart. Part No. 5 is presented in two forms, as it is cut at an angle in both planes.

The finished product is painted black, but there is no arguing about tastes. In a car, such a product will easily roll along its movement, unless additional measures are taken. You can watch a video of the assembly of this product.

There is an opinion that Chinese wheels and bearings do not last long. If you think the same, you can make reliable wheels and hubs yourself. You will need a lathe to turn the hubs from a piece of pipe of suitable diameter. The wheel rim is bent on a bending machine.

Its welding is done using a jig made of self-tapping screws screwed into plywood. A spacer made from a piece of pipe is placed between the two hub bearings. The axle for the wheels is also made on a lathe. At its ends there is a thread for fixing the wheels. First, lock rings are put on the axle, then wheels, then washers and nuts are tightened.

The trolley frame is welded from 20x40 pipe. This product is painted with gray paint, which means it will never get dirty in a workshop environment. Another example of a simple balloon cart is in the next video.

We make a cart with our own hands according to the drawings

Practice has shown that the optimal material for making a do-it-yourself welding trolley is a profile pipe with a cross-section of 20x40 mm and 20x20 mm. When used indoors on a flat floor, cast wheels are suitable; for outdoor use when moving on the ground, it is better to use pneumatic ones. The design can have certain variations, and we will look at two examples that can be modified in your own way.

The cart shown in the photo has two pairs of wheels of different diameters, two shelves for tools and a welding machine, and two places for 10-12 liter cylinders. The bases of the shelves are made of thick plywood.

The drawing does not show all dimensions in centimeters, but those indicated are quite sufficient for a homemade design. The large diameter rear wheels are mounted on M16 bolts welded to the frame. The front wheels are rotating furniture supports. Let's look at assembling the cart step by step:

Probably for safety reasons, it is more correct to install the front supports with clamps. They are a little more expensive than usual, but the cart will not roll away on uneven surfaces. You can learn more about the assembly process using the following video.

Drawings of homemade welding trolleys

Any self-respecting master will definitely do something in his own way. Those who work in welding have experience with homemade structures, but drawings of standard structures will make the work easier.

This sketch shows the main dimensions of a simple trolley for transporting a gas cylinder. Of course, it can be adjusted if necessary.

This design is a little more complicated, and the drawing is more complete. There is an asterisk above size 305, which is the size for reference.

In this case, the cylinder is securely fastened and protected. This cart can be considered a professional option.

It happens that it is necessary to transport two cylinders at the same time, usually oxygen and propane. The third wheel is small in size and works as a stop in a stationary position of the trolley, which can be moved.

Features of use

A trolley for transporting gas cylinders is a convenient and practical solution that allows you to transport heavy gas equipment safely and with minimal effort. The carts themselves are relatively small and can be stacked on top of each other, which significantly saves storage space.

Cylinders that are used constantly can be left on the cart and stored in this form. The platform of the device does not sag under the weight of the load, and the chain will not allow it to move or fall.

There are several types of carts. Some of them are designed for narrow and tall cylinders, others for wider but low ones.

Most devices are capable of carrying one cylinder attached to them, but there are models designed to carry two. The carrying capacity of the trolley for one cylinder is 150 kilograms. This device can be used to move cylinders with any gas, including propane. Since the load capacity of a hand-held trolley is only 70kg, it cannot be used for transporting gas cylinders.

More powerful trolleys for two cylinders have a load capacity of 250 kg . This is a large safety margin, much greater than the weight of the filled container. Even cargo carts with large wheels cannot cope with such weight.

It is visually quite simple to distinguish a cart designed to move two cylinders: it is equipped with an additional wheel, which serves to facilitate turning and additional support during transportation; it is necessary for proportional load distribution.

The third wheel is usually slightly smaller in diameter than the two main wheels. If the main wheels have a size of 250-350 mm, then the additional one has a standard size of 350 mm.

Source

Trolley for oxygen cylinder

Possible duplicates found

Welding and welders

464 posts 3.2K subscribers

Community Rules

— Posts only on topics

wrong cart. The wheels need to be closer to the center of the cylinder and larger in size, about five times. Carrying one like this is tantamount to carrying it in your arms

The wheels don't need to be in the center. It will be impossible to transport. The wheels should be at the very extreme point, but on the side of the handle. So that when you carry a cylinder, there is less risk of hitting it. The handle will protect.

You and the author seem to have never seen carts with handles