Design

The insides of the part are not hidden, so it is more convenient to adjust the tension. The body is made by casting, forging or welding . And the holes for the screws are milled, they regulate the force. For difficult weather conditions, a closed type lanyard is used, which consists of three parts:

- Frame.

- Two screws (left and right thread).

- Screw heads (hook, fork and ring).

Each part of the device is precisely calibrated and will perform a specific function that meets the standards. International documents regulating the technical characteristics and production of lanyards - DIN 1480, DIN 1478. In the territory of the former USSR - GOST 9690-71.

PTR 7-1 lanyards (as these devices were previously called) helped keep steel ropes and cables under constant tension. But they did not have such a large number of heads, unlike modern models. There were oblong loops at the ends. The load for which the lanyard is designed was indicated in the name, based on the ton-force indicator. New models are designated by the parameter in kN. T 30-01, withstands 3 tf or 30 kN.

Design and production features

The design of this device is quite simple and consists of only two parts, but its reliability can only be envied. So, its main elements are two screws with threads in opposite directions and a ring bracket. The end of one rod fastening element has the form of a hook, and the second - a ring, which greatly simplifies the process of working with it and expands the scope of application. True, there are other types, such as ring-ring lanyard or hook-hook, but this is a separate article.

Turnbuckles are mainly used to tension a chain, cable or rope. This process is carried out quite simply, you just need to rotate the brackets of the ring, then the screws, due to the opposite direction of the thread, will begin to move towards each other, i.e., twist, thereby reducing the distance between the hook and the ring and, accordingly, the total length of the entire product. So, as you can see, it will be difficult to come up with a simpler mechanism. Moreover, such simplicity is one of the main advantages, because then the part is not only easier to repair if it breaks down, but the likelihood of breakdowns itself is significantly reduced.

In principle, the manufacture of these parts is not anything overly complicated. The coupling is produced in three ways: casting, stamping or forging. It looks like an elongated rectangle, the corners of which are beveled. From the end in the middle of this part a thread is applied, as mentioned above, on one side right and on the other left.

The material used is low-carbon steel, the carbon content of which does not exceed 0.25%. With an increase in the amount of carbon, the strength characteristics improve and the hardness also increases. True, such changes will negatively affect the ductility of the material. But these steels themselves cannot provide the necessary wear resistance and resistance against such destructive corrosion, so a layer of zinc must also be applied to the surface of the finished part.

This process is called galvanizing and involves forming a protective film on the metal of the product. It prevents the penetration of oxygen and thereby prevents the oxidation process. There are several ways to apply zinc. One of them is galvanic, which refers to the electrochemical deposition of zinc while the part is in a special solution. If protection is created through powder processing, then this type is called diffusion galvanizing. You can also apply a special solution to the part using methods that are applicable for simple painting. In general, the method is not so important, the main thing is the end result - the product has improved characteristics.

Lanyard selection

Selecting a tool based on the expected load is a guarantee that it will not deform during operation.

The tables that the seller has will help you do this, where the manufacturer indicates which model is designed for what. But the choice depends not only on the weight of the load, but also on the function. The first parameter you need to pay attention to is thread diameter . Screw fasteners for M10, M8, M12, M20, M16 have different threads. The number following the letter “M” indicates the thread diameter in millimeters, M12 is a 12 mm thread. Marking T 10-01, T 30-01 indicates the load at which the part begins to collapse.

Lanyards are most often used when working outdoors, where they are exposed to moisture and temperature changes. Modern parts are not supplied without protection from such exposure; most often this is galvanizing.

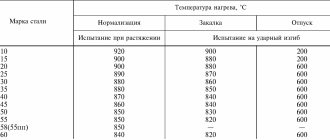

Production technology

Ring-to-ring lanyard, hook-to-ring lanyard, fork-to-fork lanyard, and hook-to-hook lanyard devices operate in harsh operating conditions. This is due to the fact that when a load occurs, all elements work in tension, sometimes accompanied by bending. It is also important that the force changes periodically over time, so the reliability and durability of the device also depends on the fatigue limit of the material.

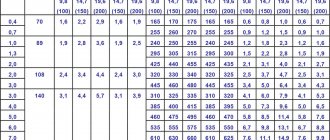

Standard sizes of ring-to-ring lanyard according to DIN 1480

GOST 9690-71

According to GOST 9690-71, there are the following types of lanyards:

- OS - with open coupling;

- OZ - with a closed coupling;

- ОШ - with a stamped coupling.

Types of lanyards:

- VU - fork-eye;

- BB - fork-fork;

- UU - ear-ear.

Lanyards manufactured in accordance with GOST 9690-71 are used on ships and other floating craft. OSH parts are made of carbon steel, in the following versions:

- VU - fork-eye;

- BB - fork-fork;

- УУ - ear-ear;

- VG - hook fork;

- GG - gak-kak;

- GU - gak-ear.

Lanyard OS are made of magnetic and carbon steels and come in the following versions:

- BB - fork-fork;

- УУ - ear-ear;

- VU - fork-eye.

ZS lanyard is made of steel with a high carbon content and in two types:

- BB - fork-fork;

- VG - fork-hook.

To protect against friction, graphite lubricant is applied . According to GOST, nuts are used to fix the position of the ears (forks). The main purpose of the part is to enhance linear tension. Do not use for lifting loads. When engaging the turnbuckle, there should be no loose turns on the coupling.

Cable-stayed fastenings (chain tensioners)

Read also: white and pink IN COLOR BALANCE

Hook-hook chain lanyard (ratchet) is the name of a cable-stayed fastening with hook grips, designed for securing large and heavy loads with chains on transport platforms. The devices have a ratchet or lever mechanism, through which a large tension force is easily created.

The chain tie-down is a simple and reliable manual mechanism used all over the world in securing systems for large-size and heavy-tonnage loads. It is used to tension fastening chains, which in turn securely fix and hold the load, preventing its spontaneous movement or fall during transportation by road, rail and other modes of transport. Based on their design, they come in two types, the characteristics of which are discussed below.

Ratchet type tightening device

This chain lanyard consists of a ratchet mechanism with a rotation switch and two rotary hooks located at opposite ends of the device. The tension of the fastening chains is ensured by the convergence of the hooks by turning the mechanism handle. The positive features of this ratchet include:

DIN 1480

A simple lanyard design (photo) - rings and an oblong cylinder and threads, with different directions of twisting. At the end of the screw there is a place for fixing the steel cable. It could be a hook, a ring, a fork .

The cylindrical body design can be open or closed. In the first version, the threaded ends of the screws converge towards the center, when tensioned, in the second, this does not happen. A closed lanyard is used in areas where there is a risk of moisture and debris getting into the threads.

The head, made in the form of a fork, must be sized to fit the hole or bolt to which it will be attached. When using rope, it is easily made into a loop that is fixed to the fork. Everything must be attached end to end, without reserve.

The hook is fixed to a ring or other device that will provide reliable retention when tensioned. And if your head ends in a ring, then you need a chain or other part that will not fly out during operation.

Ratchet is a chain lanyard that uses a ratchet and is different in appearance from others. The scope of application is bringing together distant objects; it is not used anywhere else. Large dimensions significantly limit it.

Design and principle of operation of the lanyard

The device in question consists of four parts:

- A cast or stamped coupling equipped with two threaded holes. The coupling can be in the form of a rectangular frame or an ellipse.

- Pairs of hooks or other load-handling elements (slings) with threads on the opposite part.

- Washers that distribute the load more evenly.

- Locking nuts that prevent spontaneous rotation of the grips.

A separate group consists of chain lanyards (ratchets), in which the tension occurs not due to the gradual screwing of the grips into the coupling, but due to the twisting of the tension chain located between the load grips. Chain lanyards are used when securing long loads on platforms. It consists of:

- Chains (cable tensioner).

- Two slings.

- The tension mechanism, which, in turn, includes a ratchet and a shaft on which the ratchet wheel is mounted.

In simple designs of chain lanyards, instead of a ratchet, a lever is provided, the rocking movement of which removes slack in the chain tension.

The necessary fixing force is created due to the rotation of the slings. At the same time, the distance between them is reduced, the gaps are selected, and the tension of the held object between the lanyards is ensured.

Coupling turnbuckles are mainly used in pairs, which allows the tension force to be evenly distributed in the branches of the slings. The chain lanyard can be one-sided. The opposite end of such a lanyard is rigidly fixed to the supporting part of the platform. However, in this case, only the axial component of the tension force is perceived, which is why the ratchet cannot be used for lifting loads or holding objects in a vertical position.

Types of screw lanyards

A screw lanyard consists of couplings with two screw holes and different thread directions. When the coupling is turned in one direction, the screws are screwed into the body, and in the other direction they are unscrewed. Thanks to this operating principle, you can easily change the length of the screed device.

The coupling body can be of open or closed type. Closed is used mainly in difficult operating conditions, for example, when icing or clogging with sand is possible.

Screw heads can be in the form:

- hook;

- forks;

- hairpins;

- rings.

There are also combinations of these types - fork-ring, hook-fork, etc. The tensioner with the fork-fork combination has the highest reliability indicator.

Stainless or galvanized?

Before choosing a lanyard, you need to take into account the external factors in which it will be used, as well as the degree of aggressive environmental influences.

If the work will take place in a dry room or for a short period of time outdoors, then a galvanized product will be suitable. But if the lanyard will be used most of the time outdoors or in places with high humidity, then closed-type stainless steel lanyards made of A2 steel are needed. In chemical plants, hot shops, swimming pools, etc., turnbuckles made of acid-resistant A4 steel are used.

What are cable-stayed fastenings (chain tensioners)

Chain tensioners or ratchets are cable-stayed fastenings with a hook-shaped grip. They are used to secure large and heavy loads with chains. Thanks to the presence of a lever or ratchet mechanism, a large tension can be created.

The chain tie is quite popular in the world, as it can be used to secure large loads. This manual mechanism is reliable and perfectly secures the load, which will not fall during transportation or move spontaneously.

Ratchet mechanism

A chain lanyard with this mechanism has rotation switches and two rotary hooks located at different ends of the structure. The principle of operation is that when the handle is turned, the hooks converge, thereby ensuring tension on the fastening chains.

Advantages of a ratchet type device:

- Easy to install into the fastening system;

- Does not require great physical effort during operation;

- There is no need to additionally fix the lever.

Lever tightening mechanism

Consists of 2 rotating gripping hooks, with the help of which the fastening chain is hooked and an eccentric lever. The tension of the chains is achieved by acting on the lever, which itself is clamped at the moment when it reaches maximum tension. The chain securely fixes the lever mechanism and prevents it from opening.

Advantages of this type of ratchet:

- Speed of installation;

- Simplicity;

- Small dimensions;

Types of rope clamps

Depending on the installation method and design, clamps are classified as:

- bolted;

- screw;

- wedge;

- pressed;

- canine;

- jammed.

All rope clamps are manufactured in compliance with GOST and DIN

U-clamp

This is a threaded u-bolt. The threaded elements are inserted into the compression structure and when the nuts are tightened, the cable is pressed against the bolt.

Tubular clamp

It consists of bushing clamps made of aluminum (for regular cables) or copper (for acid-resistant ones). For work in aggressive environments, stainless steel clamping products are used.

Basically, such clamps are used to connect cables to each other or to make loops at the ends of the cable. The tubular clamp is a one-time, non-removable element.

Flat cable clamp

Made from carbon steel. Comprises:

- pressure plate;

- screws;

- nuts with metric threads.

Based on the number of screws, there are single, double and triple clamps. The principle of operation is that as the nuts are tightened, the cable is clamped between the clamping elements.

Standards, loads and sizes of lanyards

In the post-Soviet space, their production is regulated by GOST 9690, in Europe they adhere to the standards DIN 1480 and DIN 1478, in the USA ASTM F1145-05 applies.

Lanyard DIN 1480 is a general-purpose device not intended for work that involves lifting loads. It withstands high static loads, perfectly holds tension ropes and ensures reliable fixation of vertical structures. Its load capacity ranges from a few kilograms to 3 tons. In everyday life it is used, for example, for stretching clotheslines or strings for curtains.

Lanyard DIN 1478 is a cargo lanyard with fork hooks, made of high-strength steel, has a safety factor of at least 4:1 and is designed for higher static and dynamic loads (up to 10 tons). Approved for use in systems with high tension, for example, when securing multi-ton cargo on transport, in the construction of suspension bridges, for organizing guy wires for awnings, tents, and massive antenna mast systems.

The size of the screw tie is determined by the diameter of the thread, which has standard metric characteristics and a diameter from M5 to M56. The most popular models: hook-ring lanyard M8, M10, M12, M16 or ring-ring M8, M10, M12. Another important parameter of the product is its length when fully untwisted (L1) and in the screwed state (L), the difference between them (L1-L) is a linear value within which the tension of the rope branch can be adjusted.