Often, on a personal plot or in a house, there is a need to build small temporary or collapsible structures from profile pipes. The use of welding in this case is undesirable: there is no welding machine at home, there is no specialist with welding skills, you just don’t want to make an integral structure. We welcome our esteemed reader and bring to his attention an article about what a crab fastening for a profile pipe is - simple fastenings with bolts, a real lifesaver for a home craftsman, even without repair skills.

How to plug a water pipe without welding or threading

» Articles » How to plug a water pipe without welding or threading

Blocking methods

Threaded plug for steel pipes

The simplest and most reliable way to seal pipes is to prepare the thread at their end and install a plug of suitable diameter.

Some home craftsmen advise in such a situation to use a metal bolt of the appropriate size, which is driven into the hole and then welded around the circumference of the pipe.

However, the use of these techniques is possible only if the end part of the metal pipe is in satisfactory condition.

If the condition of the blocked area is assessed as “dilapidated”, you will not be able to use the options listed above. In this situation, a proven “old-fashioned” method is used, which involves driving a wooden plug of the appropriate size (the so-called “chopik”) into the pipe hole.

It is recommended to make such a “plug” from waterproof wood, which is treated with resin to protect it from rotting. Some time after driving into the pipe, the cap swells and reliably blocks the hole from leaks. As for plastic pipes, it is not recommended to use wooden plugs for plugging them.

Sealing plastic pipes

Let us immediately note that there are two types of sealing of plastic pipes: permanent and temporary. The choice of one or another blocking method is determined not only by the pipe material, but also by the condition of the entire pipeline as a whole.

Polypropylene plug

Thus, temporary sealing is used when access to the pipe is difficult and involves the use of a special polypropylene plug with internal thread. Before installing it, an external thread is cut on the plastic pipe using a die of the appropriate size.

With external thread

Note! To permanently block the plastic channel, it is best to use a special welding device (soldering iron). The adhesion of elements in such a compound is carried out at the molecular level, which provides it with the necessary strength. We also note that with the help of a soldering device you can fix a regular plastic plug on the pipe

We also note that with the help of a soldering device you can fix a regular plastic plug on the pipe.

Without thread

Materials and tools

To carry out work on blocking water pipes of any type, you will need the following tools and consumables:

- a hacksaw or so-called “grinder”;

- file (rasp) for removing burrs from the ends of pipes;

- sharp mounting knife;

- thread-cutting device (if necessary);

- plugs and screw plugs used for temporary and permanent blocking of pipes;

- silicate glue (sealant);

- a welding device with a set of nozzles or a construction hair dryer (for sealing plastic pipes).

Soldering iron

In conclusion, we note that work on blocking the end holes of pipes, as a rule, does not require special skill from the performer. At the same time, almost all working tools (with a few exceptions) are always available in any household.

Last edition: 03/06/2015 Vadim

on this topic

trubyinfo.ru

Advantages of compression fittings

Threadless connection of metal pipes using compression fittings is a joining method in which a certain initial pressure is applied to the generatrix of the ends. A compression coupling connects two perfectly aligned pipes, in which a slotted conical sleeve is located above the connection, and two flanges are stretched above the sleeve, so that they automatically center the joined products and provide sufficient contact pressure.

Press fittings offer many benefits that, in some cases, make them a better choice than welding or soldering. For ease of selection, calculators have been developed to determine the crimping force in accordance with the materials used and the cross-sectional diameters of the pipes being joined.

What are the benefits of crimp fittings:

- They save time and money. With press fittings, joining pipes can be done more quickly than after soldering or welding. In addition, the tool does not require labor-intensive preliminary preparation. This is most noticeable when installing pipeline systems with a large cross-section.

- Characterized by high reliability. The duration of their operation is determined by the grade of material and crimping technology.

If the pipe is prepared correctly (in accordance with the instructions of the press fitting manufacturer), then the finished connection in terms of strength exceeds the soldered one or practically reaches the performance standards of the welded one. Many hydraulic compression fittings have an auto-cycle feature that only turns off when the connection is complete, so they are often used in high-pressure technical systems.

The use of this docking method increases the level of safety on the work site. No heat or flame is required to install the fittings. This reduces the risk of injury on the job. Installation also does not require any protective equipment, which provides additional cost savings. Versatility. Compression fittings are available in copper, stainless steel and carbon steel (the latter, however, will need to be pre-galvanized). Therefore, operation with any pipe system is possible, including gas or for pumping aggressive chemical media. Efficiency of installation. The pipeline system does not need to be pre-dried for installation.

This is especially important in industrial applications where shutting down a pipeline is either extremely difficult or not possible at all.

The only limitation of the method is the increased cost of installation components.

Features of welding profile pipes

A profile pipe is a special type of rolled metal product made from carbon or stainless steel by casting a steel pipe with a round cross-section and its subsequent molding.

The cross-section of the material can vary from 10x10 to 500x400 mm, which allows you to select the current option taking into account the specific load on the metal structure. The thickness of the tube walls, depending on the parameters of its cross-section, varies in the range of 1-22 mm.

Rolled pipe is a special type of construction metal, which is relevant for the construction of light metal structures.

Main advantages of the material:

- low weight, which reduces labor costs when installing a metal structure;

- wide variety of sizes;

- standard sizes according to the type of pipes, which facilitates their end joining during welding;

- uniform wall thickness, even smooth surface of profiled products outside and inside.

Welding with special equipment and an electrode is the most popular type of heat treatment of rolled metal on the domestic market.

But it is important to perform welding operations taking into account the characteristics of this material; without knowledge of how to properly create welds on rolled metal, you should not expect excellent results. https://www.youtube.com/embed/HmB67FHzSXg

Threaded connections

But what to do in cases where it is not possible to carry out welding work? There are quite a few ways to join pipeline elements without welding. The most popular option is threaded installation. Pipe threading is done using cutting machines or an ordinary die. If it is necessary to apply threads to a product with thin walls, use the rolling method.

If you follow all the rules for installing a threaded joint, you will get a durable and sealed structure. Let's consider the main advantages of using such a connection:

- ease of installation.

- the ability to repair or replace without damaging the pipeline;

- installation is carried out without the use of special equipment.

In addition, there are several thread parameters that determine its operation:

- cutting step;

- depth;

- direction.

The pitch determines the distance between the top of the coil and its base. Depth is a parameter that is determined as follows: the distance between the base of the coil and its top is measured. The direction of the thread is an important point; if you ignore it, you may encounter problems when installing the pipeline structure. The thread has two directions:

- right;

- left.

Many types of pipes are equipped with threads; they are used where it is necessary to create a reliable but detachable connection

Methods for connecting profile pipes

Welding is most often used to create permanent connections of profile pipes. Its type is selected depending on the material from which the pipe products are made, the availability of equipment, and the working conditions. Welded seams are characterized by strength, reliability, and durability. However, in some cases it is necessary to create a detachable connection of profile pipes without welding with the possibility of its dismantling while maintaining the integrity of the elements. For this purpose, bolts, connecting elements, and “crab systems” are used.

Connecting a profile pipe using “crab systems”

This system is used to create small, light-loaded structures. It consists of clamps, bolts and nuts. The required tool is a wrench.

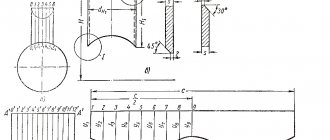

For the manufacture of clamps and fasteners for connecting profile pipes, a cold-rolled sheet 1.5 mm thick, coated with a protective zinc layer or powder paint, is used. Clamps consist of two halves, tightly covering the profile pipes inserted into them. These halves are fastened together with bolts and nuts. Popular system sizes: 95x65 and 95x95 mm.

This method of connecting profile pipes allows you to quickly assemble and dismantle a greenhouse, gazebo, outdoor bathroom or shower stall. Limitation: Can only be used for small-diameter products and only at an angle of 90°.

Characteristics of this type of docking:

- strength, slightly inferior to that of welded joints;

- Efficiency of assembly, low cost of installation work;

- no need to use expensive tools;

- no special requirements for worker qualifications.

Clamps for attaching profile pipes to enclosing structures

This fixture for square or rectangular tubular products consists of two components. One element is screwed into the ceiling or wall, a pipe is inserted into it, secured by the second element and bolts.

This type of fastener is called a “clip”. There are two options for its design: corresponding to a specific range of pipes or adjustable.

How to connect a profile pipe without welding using fittings, bolts and other elements?

- When installing pipe products with a square or rectangular cross-section, manufacturers offer special fasteners - fittings. They can also be made in the form of tees and crosses. Most often, fitting connections are strengthened by welding.

- Using a strip of steel bent in the shape of the letter “L”, you can connect two profile pipes at an angle of 90° with bolts.

- Another way to join pipes of the same cross-section is to make a connecting element using welding. You will need a piece of pipe, the cross-section of which allows you to insert the profile products to be connected inside it. The connecting profile is cut into two parts, at one end of which a 45° bevel is made. These elements are welded to form a right angle. At the edges of the formed corner, holes are made, the diameter of which should not exceed ½ the width of the profile wall. Nuts whose diameter exactly matches their diameter are attached to the holes by welding. Holes of the appropriate size are also made at the ends of the connected profile pipes. Such connections can be made adjustable.

Types of connections

All existing pipe connections are divided into two main groups:

- detachable;

- one-piece.

The use of detachable connections allows, if necessary, to disassemble the joint section. Thanks to this property, it is possible to repair and replace the joint without compromising the integrity of the pipes. Detachable joints include threaded connectors (fittings) and flanges.

In the case of permanent joints, it is possible to disassemble the pipeline, however, this will lead to damage to the pipe material. The most popular option for permanently connecting pipelines is welding. In addition, there are a number of other methods: gluing, pressing, installing a socket using cement mortar.

All of the above methods are quite popular and are used to connect pipelines transporting various media: water pipelines, heating communications, gas networks, sewer systems, as well as industrial and technical lines.

Method number 1. Crab elements

Universal fasteners designed for connecting rectangular/square profile pipes. Each “crab” consists of several parts, which are bolted together during installation. The parts of the “crab” are made of 1.5 mm metal with a durable polymer or zinc coating.

There are these types of crab elements:

- volumetric (designed to connect three pipes in the corners or four inside);

- T-shaped (designed to connect three pipes);

- X-shaped (designed to fix four pipes);

- L-shaped (designed to connect two profiles).

Home craftsmen use crab systems to assemble without welding:

- greenhouses, greenhouses;

- racks, benches;

- Summer shower;

- pet cages, aviaries;

- gazebos, canopies;

- supports for climbing plants, lightweight fencing.

On a note! Crab systems are also used for temporary connection of parts when repairing welded structures. In general, this is a fairly reliable connection method, hardly inferior to welding in strength.

- long service life (up to 50 years);

- structures can be assembled/disassembled many times;

- affordable cost of crab elements;

- Even an unskilled worker can handle the assembly;

- versatility.

- pipes larger than 40x40 mm cannot be connected;

- joints must be protected from corrosion, as moisture accumulates in them;

- pipes can only be connected at an angle of 90 degrees;

- if a large tensile load occurs, pipes may be pulled out of the crab elements;

- The nuts need to be tightened regularly.

Types and advantages of fittings

Why is it worth using fittings and what is the main advantage of this material? The answer is simple: these elements have a simple design, but are practical, they have a long service life and an affordable cost. Without using welding equipment or expensive taps and lerks, the user achieves the same high results using simpler fittings.

Fitting

Fittings are successfully used not only for the installation or repair of pipes; this material is also popular in the manufacture of compression equipment and gas turbine mechanisms. This means that the product creates sufficient tightness with the help of a seal, even in systems with high pressure.

Types of fittings by size and application:

- Direct. This means that the diameter of the product remains unchanged on both one side and the other. Used to connect two identical pipes.

- Adapter fittings. Necessary for connecting two pipes of different diameters. Indispensable, for example, when repairing an old pipeline, where a large number of pipes have different sizes.

- Tees. Allows you to make a branch from the main line without threading or welding.

- Crosses. They have the same purpose as tees, but are capable of dividing the main line into a larger number of branches.

- Fittings. Used as a connection for flexible metal pipes. The fittings are able to create sufficient tightness even when connecting a material that changes its structure.

- Pipe plugs. The main function is to block the end of the pipes.

It should be clarified that the variety of fittings, as well as their manufacturers, allows you to purchase products both for installation outdoors and in an apartment or private house.

Features and characteristics

Crabs are staples with a fastening system. They are made of galvanized sheet metal, the thickness of which must be at least 1.5 mm. They mainly found their application in the installation of rolled pipes with a cross-section of 20x20, 20x30, 40x40 and 20x40 mm. Fastening is carried out using clamping force. The bolts are tightened on the crab itself, and not on the pipes being connected. Because of this, this design has low tensile strength, that is, the fixed pipe, with some effort, can be removed from the connecting element.

An outdoor metal structure constructed using fastening crabs is continuously exposed to adverse conditions (wind, precipitation, temperature changes, frost). Gradually this will lead to loosening and loss of stability of the structure. Therefore, fasteners must be periodically checked, tightened and, if necessary, repaired.

This type of fastener allows you to create a frame structure that can be assembled and disassembled when necessary.

Among the disadvantages of connecting crabs, one can note the impossibility of their use in the installation of pipes with a large diameter. Parts can only be joined at an angle of 90°.

Tips for choosing

The choice of necessary connecting elements depends on the type and function of the structure:

- The crab system is used in the construction of structures from pipe profiles with a small cross-section - gazebos, partitions, pergolas, arches, greenhouses and other garden and park buildings that are easy to assemble and disassemble.

- Flange fasteners are used for buildings that are subject to periodic disassembly and reassembly during operation.

- Coupling fastening is most often used when installing pressure-type pipelines, since it can withstand high pressure and ensure its tightness.

- Simple fittings are widely used in the assembly of pipelines with branches and turns. This type of fastening may require additional welding reinforcement.

There are several criteria that should be followed when choosing connecting elements for profiled pipes:

- First of all, you need to decide what fasteners you will need and in what quantities.

- When choosing steel crabs, you need to pay attention to the thickness of its profile. It must be at least 1.5 mm. Crabs with a smaller thickness are not able to provide the required strength and rigidity.

- Parts must be inspected for visible damage - cracks, chips, dents, and rust. These are all defective products.

How to connect profile pipes: without welding and threading

For those who have at least once changed the pipes of the water supply system, the most reliable and fastest connection method is welding. But the welding process differs greatly from the process of welding pipeline elements consisting of plastic. The main materials, in the latter case, are fittings and couplings.

What is the advantage of profile pipes?

- Firstly, metal pipes of various profiles are quite resistant to damage. In addition, the pricing policy for their cost is very acceptable, and such properties as strength and reliability are attracting more and more attention.

- Secondly, compared to other types of pipes, they are quite light. But this does not mean that they are only suitable for certain jobs. With their help you can make any design.

Today the market offers a lot of varieties of profile pipes, as well as their sections. Each type is selected individually.

Varieties of the welding process

Working conditions, types of connectors and pipe material are the determining criteria for its varieties.

The welding process occurs using:

- gas apparatus;

- hands;

- electric current;

- metal electrodes;

- inert gases;

- flux-cored wire.

By the way, in addition to the above types, welding using flux-cored wire is in great demand.

What welding process is suitable for profile pipes?

First, we need to say that in order to weld profile pipes, you need to determine the correct type of welding. Welding using inert gas, suitable for profile pipes made of steel that does not rust. Short-arc welding is used if the steel thickness exceeds 0.8 mm. If the thickness varies up to 3 mm, then it is better to make the connection by arc welding. When the thickness of a steel product is 3 mm or more, you need to choose electrodes that melt. In most cases, this type is used for industrial purposes.

Naturally, after completing the welding process, it is imperative to check the level of quality of the work done. Based on external signs, you need to evaluate the welded pipe and make sure there are no defective elements.

Types of electrodes

Regarding profile products, they are divided into those that melt and those that do not melt. Such electrodes are used depending on the material from which the pipes are made.

Electrodes that have the property of not melting require the presence of a special wire. Using them, you can connect two different pipes with the same diameter dimensions into one. During the welding process, the coating of the profile products becomes smooth. When melted, the pipe and the connecting unit merge into one product. This type of welding is quite labor-intensive, since it is necessary not to lose the properties of the material, but to achieve their preservation in their original form. It is recommended to first ensure that the edges become smooth, which will ensure that the ends are perpendicular. You need to navigate by the type of chips.

It should be noted that there are electrodes for working with cast iron and copper products. If we compare the strength of welding works of metal products and plastic ones, then preference cannot be given to anyone. In terms of the functions that welded metal and plastic products must perform, they are no different.

Why give preference to welding work?

1. Firstly, connection work is carried out using highly technical and high-quality equipment in the arsenal. This fact provides a guarantee that there will be no leaks in the future.

2. Secondly, this process will not take much time and effort.

3. Thirdly, the cost of installation work is affordable.

4. Fourthly, the joints do not affect quality and functionality. In addition, joints during welding work reach minimum values.

Do not be afraid of welding work in the apartment. This process is quite simple and reliable. It is not necessary to use the services of professional welders; two people can handle this work, one of whom will be an assistant. The main thing is to adhere to the requirements of the job and do everything right.

The best manufacturers

Crab systems are not a complex design and there are both small and large companies in each region producing steel structures and fastenings, making them all competitive

When choosing a product, it is important to adhere to the above recommendations

You can also offer several criteria by which you can choose a manufacturer:

- anti-corrosion coating of products;

- purchasing products through the manufacturer rather than through intermediaries, this will save money;

- production time of products, whether the product is in stock;

- guarantee;

- payment and delivery methods.

Gas welding

Do-it-yourself connection of profile pipes using gas welding is very different from electric welding. The preparatory work for the process is similar. Only all surfaces for joining are coated with flux powder. And prepare the filler wire.

Compound. This is done in two ways:

- Thin-walled products are connected from right to left.

- If the walls are over 5 mm - from left to right.

When working, you constantly need to monitor the position of parts. When the pipes cool, the seam is cleaned with abrasive and an anti-corrosion coating is applied to it.

Top 2 mistakes when welding profile pipes. The solution is here!!!

Watch this video on YouTube

Do-it-yourself pipe connection without welding

Small-sized frame structures are assembled without welding. In this case, the profile pipe is connected without welding using a special device.

Crab systems

They are devices in the form of a special clamp in the shape of a crab, which is placed in a specific place and connects a certain section of the profile. This device consists of two parts, they are connected with nuts and bolts.

When assembled, such a device forms a rectangular or square shape; its dimensions allow it to tightly grip the pipe product from all sides.

The most popular clamps with a size of 95x95 mm. They make it possible to make reliable connections and guarantee high-quality and durable fastening of structures.

These devices are made from galvanized or powder-coated metal.

Benefits of using a crab system

They make it possible to assemble or disassemble a structure in a short time. All pipelines with such connections become collapsible.

Fastening profile pipes without welding using crab systems is very popular. With such connections, the structure can not only be quickly moved, but also something new can be constructed.

Also among the advantages of these fasteners is the fact that the structure can be erected with small financial investments.

However, the disadvantage is that it can be used to fasten small-sized pipes.

Clamps

Used for a profile to a fence building. The device has a rectangular shape and is made up of two parts. One of them is screwed into the wall and a pipe is inserted there. The second part of the pipe is fixed (with a clamp and bolts).

Fitting

Another way to connect profile pipes without welding is with fittings. They are used in situations where you need to make branches and bends. They are a fixed fastener for the joint and end. These fasteners can be of the following types:

- Tees and crosses. They are used for branching, and they connect products of different and the same size.

- Squares. They are used when it is necessary to change the direction of a pipeline.

- Couplings. They are placed at the docking point.

Now you know how to weld a profile pipe, and video lessons will help give a visual representation. We also looked at what connection methods exist. Using this information, you will get the job done easily and quickly.

What is the crab system?

Crab systems are universal fasteners for square and rectangular pipes, allowing you to quickly and reliably assemble structures using bolted connections and without welding. Structurally, they are special clamps that allow you to firmly and reliably grasp profile pipes and clamp them when tightening the bolted connection.

Several types of fasteners have been developed that make it possible to fasten corrugated pipes in any combination both in the plane and in volume, but only at right angles. No special tools are required for joining pipes; the structure can be easily disassembled and hidden if necessary (for example, at the end of the season). It is worth noting that a similar fitting system has been developed for round pipes of different diameters.

Generally accepted rules for piping installation

Installation is carried out manually. The crowbar serves as a lever for positioning the pipes; a wooden spacer must be provided between them and the crowbar. If the lever cannot fulfill its purpose, professionals recommend using a jack.

Upon completion of the pipeline installation, it is necessary to check the correct placement of the sealing gasket in the socket. A thin metal plate, 0.5 to 0.8 mm thick, is inserted between the smooth end and the socket. The plate must be in contact with the rubber ring. Then it moves around the circumference of the pipe, and at the end the location of the ring in the socket is checked: the distance from the plate to it should be the same along the entire circumference.

If the pipeline is installed at sub-zero temperatures, it is necessary to carry out the work with extreme caution and use only silicone lubricant. If the pipeline is installed using the socket method in a residential (warm) room, then liquid soap can be used as a lubricant for their smooth end and socket

DIY installation of profile structures

In a unified form, the assembly instructions can be presented as follows:

- Development of a product drawing, where dimensions, bend angles, fastening methods, pipe sizes, etc. will be specified in detail. As for the dimensions, they are determined based on the main purpose of the structure. For massive structures (gates, house frames or outbuildings), it is better to take pipes with dimensions of 100x50, 80x80 or 80x60 mm. Products with a cross section of 50x50 or 40x60 are ideally suited for the construction of display cases, shelving, and scaffolding. For furniture items, thin-walled profile pipes measuring 40x25 or 20x20 mm will be sufficient.

- Applying markings, cutting pipes and preparing individual structural elements. It is more convenient to cut a thick-walled dimensional pipe with a grinder, while for small products it is better to prefer an electric jigsaw or a hacksaw.

- Cleaning the cut areas is done with a flat file or with the same grinder with a metal disc or emery wheel.

- Connection of elements. It can be done by welding (it will save time, but will lose in aesthetics) or by bolting. In the latter case, you will need to drill a large number of holes using an electric drill. With profile pipes, unlike round pipes, due to the flat cross-sectional configuration, the area of contacting adjacent elements is sufficient to ensure a reliable connection.

- Installation of fittings (hinges, bolts, latches, handles, etc.), as well as covering surfaces with suitable materials. It can be polycarbonate, metal, solid wood or plastic.

- Final cleaning and painting of the finished product. This stage of work will help protect the joints from corrosion, and give the structure itself an attractive appearance.

Features of metal profile bending

Many products (especially pieces of furniture) that you can make yourself from a profile pipe will look stylish and elegant with rounded elements. This inevitably brings the home craftsman to the issue of bending pipes.

It will most likely not be possible to do this manually; the bend will almost certainly be uneven, or even lead to a break in the pipe. There are several ways to correctly bend a profile pipe:

- Order the necessary operations to be performed at a factory that has the necessary professional equipment. Not the most convenient method, requiring delivery and removal of products from the factory, which may not always be found nearby.

- Buy your own pipe bender. The device is easy to find on sale in large construction stores, but it is quite expensive, so the purchase will be justified only for constant large volumes of work. The most suitable option for those craftsmen who have turned the production of structures from profile pipes into a permanent business.

- Use an angle grinder and a welding machine. Not the most aesthetic method, which involves making several (the number will depend on the required bending radius) slits, bending the pipe and welding the seams.

- Bend the metal profile using sand. A wooden plug is tightly driven into one end of the pipe, after which the product is filled with sand and closed in the same way from the second edge. After these manipulations, the bend turns out smooth and aesthetic, and the sand, after giving the desired configuration, is simply poured out. In the cold season, sand can be replaced with water frozen in the cold.

How many self-tapping screws are needed to mount the structure?

Fasteners are often used when assembling a metal frame under sheets of drywall. Their number depends on the design features. In the standard version, the step between the metal profiles is 60 cm, in the reinforced version - 40 cm. The number of jumpers must also be taken into account.

Let's carry out the calculation using the example of a wall measuring 3*4 meters. To increase rigidity, jumpers are used, installed at a distance of 50 cm from each other.

The distance between the profile elements is 40 cm. To install one sheet, you will need 4 elements and 6 jumpers of 40 cm each. The distance between the fasteners is 25 cm. For 1 profile you will need: 300/25+1=13 pieces. For the frame you will need 13*4=52 pieces. Per sheet of drywall: 52+6=58 pieces.

This is an approximate amount. More accurate calculations are made per 1 square meter. The quantity must be divided by the sheet area: 52/3 = 18 pieces. For the entire wall area you will need 12 square meters. meters*18=216 pieces. Consumables must be taken in reserve, so the estimated need is 250 pieces.

Are you unhappy with your employees' performance? Call the number:

2008-2020 KrepMetiz - Fastening metal products. Warehouse and office address: 143000, Moscow region, Odintsovo, Vnukovskaya 11 building 20 office 7 Telephone (multi-channel). The information posted on the site does not constitute an offer.

Thank you, your message has been received! Our managers will definitely contact you in the near future.

Source

Gas welding of pipes

Experts less often connect pipes using gas welding, preferring to use electric arc welding. The reason is that the use of a gas welding machine increases the cost of work, is more dangerous due to acetylene, and requires thorough training of a specialist. However, gas installations are also used in such work. And this is due, first of all, to the inability to connect to the power supply network.

In practice, there are two methods for using gas welding equipment:

- The welder moves the filler material following the torch from left to right. This technology is usually called “right”. The advantages of the method are excellent heating of the materials being joined and excellent visibility of the working area. As a result, gas consumption is reduced and the worker’s productivity increases. However, this method of operation is acceptable for pipes with a wall thickness of 5 millimeters or more.

- The “left” method is characterized by the fact that the filler material moves in front of the burner in the direction from right to left. It is in demand when working with thin-walled pipes.

It is customary to distinguish several stages of welding profile pipes using a gas torch. Initially you will need to purchase materials:

- oxygen and acetylene cylinders;

- filler material;

- gearbox;

- gas burner with tips;

- flux;

- gas supply hoses.

It is necessary to pay attention to the fact that the gas installation is unsuitable for use when it is necessary to weld a thin-walled profile pipe. The metal will melt too quickly and the tightness of the joint will be questionable

At the first stage, you need to prepare the surface: degrease and clean from foreign matter. The workpieces are firmly fixed on the work table. The edges are treated with a paste-like flux, which prevents oxidation of the metal during the welding process. Experienced welders recommend making bevels on the edges of pipes at an angle of 30 degrees. This will allow you to make several high quality welds.

The flame is formed as a result of the combustion of a mixture of oxygen and acetylene. The filler material is supplied to the joint and moves ahead of the burner flame. The burner temperature is sufficient to melt both the additive and the metal of the workpiece. As a result, the melts combine to form a weld. The burner should be moved from right to left. The opposite direction is used when the walls of the pipelines are thick. In this case, the wire is fed after the torch, and not in front of it

It is very important for high-quality welding to choose the optimal electrode diameter

During operation, it is necessary to control the geometry of the structure. Due to the high temperature of the burner, it is easy to make a mistake and heat one side more than the other. This may disrupt the symmetry of the workpiece arrangement. Therefore, you need to carefully monitor this and correct the situation if necessary.

Source

Electric arc method

Welding a corrugated pipe using the electric arc technique is one of the most popular connection options. The key feature is the fact that work can be carried out in any, even the most inaccessible places. In addition, electric arc welding allows you to weld products of absolutely any diameter and with any wall thickness. It is important to take into account one small feature: the welded edge of a pipe with a wall thickness of more than 4 mm must be subjected to preliminary preparation.

To complete the work, you need only two things: a welding machine and electrodes. Such equipment is quite expensive, but it is not necessary to purchase it permanently. Today, there are many offers for renting out welding equipment. In addition to tools, the master will have to stock up on protective clothing and a respirator mask.

However, before starting work, you need to decide on the type of connection.

The seam can be made:

The welded pipe should be used after the seam has cooled. Another important issue is the selection of the optimal type of electrodes.

Its diameter should be tied to the cross-section of the pipe:

- Up to 2 mm – electrode with a diameter of 1.5 mm;

- 2-3 mm – with a diameter of 2 mm;

- 4-6 mm – 4 mm.

Before starting work, the ends of the elements must be degreased and cleaned of small debris.

It is better to carry out the work in a specially designated room, but in the absence of one, you can be content with an ordinary living room. The only condition is that there should be no flammable objects nearby.

Docking begins with fixing two sections of the profile in a stationary position. Spot tacks are applied to the surface, and the welding machine is applied at a speed that allows the metal to melt, but not allow it to flow inside.