The key to activity and vigor during the day is a sound and comfortable sleep at night.

For a truly complete vacation, you need to install a spacious and comfortable bed in the bedroom. It can be purchased ready-made in a store, or you can make it yourself from any available materials. In this article we will look at the important points of making a metal bed yourself.

Features of the material

The peculiarity of the metal is its:

durability;- resistance to mechanical damage;

- resistance to negative factors;

- aesthetic appearance;

- the ability to give metal any shape and design.

To make a metal bed with your own hands, you need to be able to work with the material , know the intricacies of making furniture items, have patience and have some free time.

Metal furniture pleases users with nobility, luxury and elegance. In addition, these products differ:

- environmental friendliness;

- hygiene;

- light weight;

- fire safety.

Reference: metal beds will add special chic and luxury to the bedroom. They are suitable for both classic styles (Provence, country) and modern ones (minimalism, hi-tech).

How to design a table from a profile pipe

For finishing work on homemade furniture made from steel profiles and wood, the same set of materials is almost always used.

Metal parts are painted with a dark varnish that imitates powder paint or blued coating. This recognized style and technique allows not only to decorate the metal, but also to effectively protect black steel from corrosion.

For wood, furniture polishes, varnishes, and toners are used. Almost always they strive to preserve the pattern of wood fibers, to make it more expressive and rich.

Paints and plastics for wood in combination with a profile pipe are practically not used. Even if the countertop is lined with plastic, the surface is sealed with a film with a pattern that imitates valuable wood species.

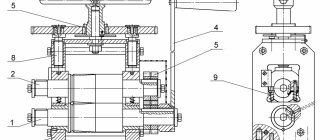

Drawing of a double bed

It’s worth starting work by making a drawing. If you understand such subtleties, you can make an individual project for your future bed.

Any metal bed will consist of the following elements :

- frame;

- frames;

- footboards and headboards;

- legs;

- fasteners.

Before you start making a drawing, you need to select:

- bed size . The dimensions of the bed are a purely individual choice. If you are going to make furniture for a child’s room, you should give preference to single-seat products. If you want to make a bed for a married couple, you should choose one-and-a-half or double models;

- mattress . You can purchase it in advance ready-made and then calculate the dimensions of the sleeping place, or you can order an individual production of an orthopedic mattress according to your personal dimensions;

- design . Furniture design is selected depending on the overall interior of the room.

Advice : if you have problems with drawing, you can download a ready-made diagram of a metal product on the Internet.

Sizing

Before starting work, you need to decide on the future dimensions. To do this, you need a clear understanding of where the sleeping place will be placed and who will sleep on it. In the case of modernizing an apartment or room, you can move away from the usual stereotypes and choose a new place for it.

Making an iron bed is a responsible, labor-intensive and complex process.

There are standard types of beds: single, double, single. It should be remembered that the place to sleep should be 30 cm longer than the height of the person who is going to sleep on it. Typically the length is 2 m, but can vary from 191 cm to 213 cm.

Some knowledge is required.

It is also worth deciding on the width. So, depending on the type, the width will have the following value:

- single – 91 cm;

- double – 137 cm;

- one and a half – 99 cm.

You need to start small - get lessons from an experienced blacksmith, or ask for help from someone knowledgeable in this matter.

Larger settings are designed for two people. However, they take up quite a lot of space in the room. Therefore, before starting work, it is necessary to measure the space in the room allocated for the bed. And also take into account such parameters as space for a bedside table and simply a place for free movement.

The main difficulty lies in the preparation of components and their processing.

Another important factor is the choice of mattress. When performing work deviating from established standards, it should be taken into account that it will have to be made to order.

The main thing is a little patience and self-confidence.

Iron bed designs

Also, before making a bed, you need to decide on the type of its design. It can be:

- Forged Products. They are distinguished by elegance, nobility and luxury.

Such beds are considered works of art and have artistic value (if the product is made by hot forging). Making forged furniture with your own hands is quite difficult.Here you need to have certain skills, tools and you need to be able to work with hot metal. It is easier to make a forged bed using the cold forging method, when the metal does not heat up, but deforms when cold. Such products will not be distinguished by elegance, but will have high technical characteristics;

- welded structures . In this case, you need to be able to work with a welding machine. Products made by welding are more suitable for modern trends, for example, Art Nouveau.

Assembly diagram for children's version

In general, a crib for a baby is assembled in the same order as an adult, albeit with a few subtleties. Cots for babies come in several types and have two levels of support for the mattress, parts that allow the cradle to be rocked, as well as additional drawers or a changing table with a chest of drawers.

In order to assemble a bed for a baby yourself, you need a drawing or design, design details, a screwdriver, screws and plugs.

- first we assemble the parts of the fixed fence together

- we attach the movable part of the side grille and install the bottom itself

- we fasten the structure with screws or confirmats

Lastly, we install the wheels on the legs or parts of the pendulum that allow the cradle to swing.

If the crib is equipped with a chest of drawers or a drawer, then it is time to assemble the structure according to the diagram or sketch. First the drawers, then the base, check the correct assembly and install the retractable hinges. Secure the drawers to the hinges. And you can use it with pleasure.

Cribs are a bit more difficult to assemble

Tools and materials

Before making a metal bed with your own hands, you need to evaluate your capabilities, familiarize yourself with the variety of models and types of designs. As a rule, it is quite possible to make most models on your own, even if you are new to this field.

For the workflow you need to prepare the following tools :

grinder;- welding machine;

- drill;

- roulette;

- square;

- file;

- metal brush;

- sandpaper;

The following materials will be useful to us:

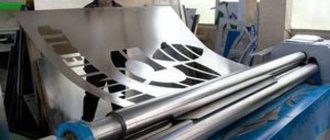

- sheets of metal;

- rods;

- paints and varnishes;

- primer for metal surfaces;

- tassels.

If you make a forged product using the cold forging method, you will need to add the following tools :

- snail. With its help you can create spiral patterns;

- gnutik. It is necessary for bending metal at different angles;

- flashlight. With its help you can create products that resemble lanterns;

- twister It is intended for twisting rods;

- wave. With its help you can make wave-like patterns.

To make your own metal sleeping bed, you can also use wire and round rolled metal from :

- gland;

- brass;

- become;

- galvanized metal.

Manufacturing technology

To create a metal bed with your own hands, use wire, round bars, straight-seam thin-walled pipes from the following materials:

- gland,

- brass,

- carbon steel,

- galvanized metal.

To connect parts of metal structures, two main methods are used:

- Welding. The parts are soldered under high temperature.

- Forging (cold or hot method). Cold forging is performed using automatic presses. When hot, the metal is heated to a certain temperature, then it is given the desired shape with a hammer.

The final operation of technological processing of a metal piece of furniture is the application of a polymer layer. A special substance (for example, powder paint) gives the surface color and can provide protection against corrosion and fungal infections; provides an attractive appearance.

How to make a frame and weld a metal bed?

So, the manufacture of a metal bed is carried out in the following sequence:

The footboard and headboard are made . To do this, we take pipes from metal profiles and make blanks from them, according to the existing product diagram.- These blanks are then laid out on a flat and smooth surface and fastened with a welding machine . At this stage of the work process, it is necessary to constantly check the evenness of the product with a level.

- Now we take a channel and an angle grinder and make brackets on which the product frame will be attached.

- The backrest and frame are connected with a continuous welding seam , at a distance of 35 cm from the floor.

- Now we prepare the material for the frame . We cut the steel channels into the required dimensions.

- We connect the channels with corners.

- We mount the frame . We set the backrests in a vertical position and make markings for installing the frame. We drill the necessary holes in the product. At this point, the main assembly of the bed is complete.

- Next, we proceed to welding the grating under the mattress .

- Now we install the backs on the legs and insert the plugs into the open parts of the pipes.

Attention : to give the product a noble appearance, seams and protruding elements must be cut off with a grinder and processed with a grinder.

Finishing

To give the bed a noble appearance, finishing is carried out. An anti-corrosion coating is applied to the metal, all seams are cleaned of slag using a metal brush or grinder .

Next, the product is polished and primed. Primer treatment improves the adhesion of paints and varnishes to surfaces. Next, the product is varnished or painted. The choice of paint largely depends on the overall interior.

If the room is designed in a high-tech or minimalist style, you should give preference to monochrome colors. For classic motifs, dark or light shades are more suitable.

Advice : if you are serious about furniture for the bedroom, try making a dressing table, bedside table or changing table. You may also be interested in a wardrobe or beds made of timber, solid wood, pallets, chipboard and boards.

Now it's time to start decorating the product

The easiest way is to level the surface of the wood with fine-grained sandpaper or a sanding machine, treat it with stain and varnish in 2-3 layers (the next layer is applied only after the previous one has dried, this will avoid cracking of the coating).

If pine boards are used to assemble the product, then there is no need to use stain. Due to the high resin content, pine may change its appearance - called tiger stripes will appear on it. It is enough to treat wood of this type with varnish.

If the master plans to upholster the bed with soft fabric, then for the work he will need the appropriate material, a furniture stapler, and staples. It is advisable to place thin foam rubber under the fabric and attach it with curly nails. You can cover not only the external, but also the internal elements of a wooden structure with fabric, this will reduce the likelihood of contamination of the mattress.