Decorative powder coating allows you to protect carbon steel products (for example, door leaves or sheets for making fences) from moisture. The technology is used in the automotive industry to process wheel rims. There are several types of paint that differ in composition and method of application.

Pros and cons of powder coating

This technology has its advantages:

- during powder painting, no defects (smudges or streaks) are formed;

- no solvents are used, and therefore there will be less emissions of harmful substances into the atmosphere and for the painter to breathe;

- powder coating can achieve a large number of texture effects;

- the hardening time of powder coating is significantly less than its liquid counterparts;

- can create a thicker layer compared to liquid paint; in one application of powder the layer can reach 60-80 microns. Liquid paint must go through this thickness three times;

- Powder-applied coating is less susceptible to chipping and scratching. Also, the color lasts much longer;

- less loss of material when painting the product. So, when using liquid paint, up to 70% of it can be lost. If you take powder, then the losses are only 5% (these losses can be reused in the future);

- No qualifications required to apply powder coating.

Along with such obvious advantages, this technology also has its disadvantages:

- Liquid paint can be mixed with each other to obtain new colors and shades. When mixing the powder, it is impossible to obtain a new color;

- it is very difficult to obtain gloss compared to liquid paints;

- It is very difficult to get a perfectly smooth surface.

Do-it-yourself tribostat

The basis of operation of such pistols is the friction of the powder against the surface of the charging tube. The formation of the air mixture occurs in the same way as in a conventional gun: using a compressor, an injector and a control mechanism. However, it is not recommended to remake a regular pistol for these purposes, since the charging tube must be a direct continuation of the injector - for this reason, the injector (nozzle) is made of D16T duralumin rod. Due to the small diameter of the nozzle, the flow coming from the compressor accelerates to a high speed (more than 350 m/s is required). The general charging principle is shown in the photo.

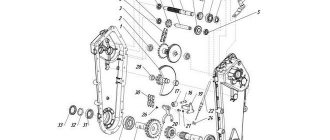

To pre-regulate the pressure, you can use the reducer from a propane cylinder. The powder is mixed with the incoming air directly in the injector, but the air supplied to it must pass through the receiver: additional capacity will allow possible moisture to be separated from the air, and moisture is extremely harmful to both the powder and tribostatic charging. The photo shows a drawing for patent No. 2256511 (5 – cutting rod, 10 – spray channels, 13 – groove for distributing powder along the rod, 15 – swirlers).

The easiest way to make an external charging tube is from fluoroplastic (there are commercially available rods from which both the tube and the rod inserted into it can be machined). An internal rod (divider) is needed in the tube to create additional friction, but this is not enough, and to increase friction, it is advisable to screw 1-2 swirlers made of the same fluoroplastic (nozzles with spiral slots) onto the rod. The main factor that determines the quality of the structure is the gap between the inside of the tube and the divider. With a length of the charging part of 8-10 cm and an internal diameter of the tube of 10 mm, a gap of 1-1.5 mm is sufficient (a large diameter of the divider will cause clogging of the charging tube, a small one will cause a weak charge and poor-quality painting).

The cross-sectional area of the gap allowing the powder to pass through must be equal to the passing area of the swirlers (a smaller area of the spiral slots will cause failure, a larger area will cause low efficiency of these elements). The sprayer is a regular socket that directs the powder towards the part. It is also better to grind it out of fluoroplastic with your own hands, since even a minimal additional charge will not harm the particles. A deflector is placed at the end of the bell, as in the photo.

Types of powder coatings

There are several types of powder paint:

- Epoxy resins. The first widely used powder. It has good strength, hardness and good resistance to chemical reactions and corrosion. Excellent adhesion to metal. Its only drawback is its poor tolerance to various weather conditions. Therefore, it is used only indoors;

- Polyesters are the most popular powders. Their significant advantages are high mechanical resistance, impact resistance, good chemical resistance, as well as low solidification temperature. Polyesters provide good resistance to yellowing, as well as a huge selection of colors and shades;

- Super strong polyesters have higher strength compared to the previous type;

- Epoxy-polyester hybrids. Compared to epoxy resins, they are less dependent on weather conditions. They are mainly used to paint household appliances (washing machines, refrigerators);

- Urethanes. Chemically very similar to polyesters using other hardeners. Their main properties are: obtaining a smooth coating, strength, chemical and corrosion protection. Ideal for painting fuel tanks, agricultural equipment, air conditioners, car rims, handles and so on.

For painting cars, standard and super-strong polyesters are most often used.

Advantages and disadvantages of the method

Advantages of metal powder painting technology:

- environmental friendliness of the coloring composition.

- minimal shrinkage due to the absence of solvent;

- large selection of colors;

- high mechanical stability of painted surfaces;

- attractive look.

Flaws:

- To paint large workpieces, you need to buy a large oven.

- It is impossible to apply a thin layer of coating.

- The powder melts only at high temperatures. Because of this, the technology is not suitable for painting plastic and wooden blanks.

Painting metal elements (Photo: Instagram / ooo_pc_alvit)

Powder coating methods

Various surfaces can be painted using the following methods:

- Electrostatic corona gun is the most common painting method. It is based on compressed air and a high-voltage electrode. The object to be painted must be grounded and, as a result, attracts powder to itself. He, in turn, receives a charge at the output. The polarity can also be reversed for nylon powders. The disadvantages of using this method are: high voltage between the gun and the surface, as well as unpainted recesses due to the Faraday cage effect.

- The triboelectric gun is the second most common painting method. The powder in such a gun also moves due to compressed air, but the charge occurs not due to the installed electrode, but due to the separation of electrons from the powder particles, due to which they become positively charged. Since there is no high voltage in this method, the Faraday effect does not occur. Painting the spine becomes much better, but at the same time takes longer;

- Fluidized bed painting. The method is suitable for creating a thick functional coating that is resistant to corrosion. The method is that the air passing through the powder is suspended, that is, it begins to function as a liquid. The surface to be painted heats up and the powder begins to spread over the surface due to the high temperature;

- electrostatic fluidized bed painting. This method is suitable when the paint thickness must be above 300 microns. The fluidized powder is converted into an aerosol and charged. The result was an aerosol cloud of charged particles. The grounded object to be painted is dipped into this cloud. To make the paint go on much smoother, the surface can be twisted;

- Flame painting. The bottom line is that powder particles, under the action of compressed air, pass through a gas burner. The temperature causes the powder to melt. The advantages of this type of painting are mobility and use in all weather conditions.

Existing overlay methods

Methods of application based on the type of charge received by particles are called electrostatic and tribostatic.

Tribostatic gun

Using the electrostatic method, the charge is imparted by a corona electrode under a high voltage of 20–100 thousand V. Electrostatic units are more powerful and productive. As the electrode voltage decreases, the speed of the air stream increases.

The tribostatic effect is achieved by the friction of particles against each other and the material of the gun body. The body of the gun is made of fluoroplastic to increase friction.

Tribostatic installations are cheaper, the performance of the units is lower than that of electrostatic ones. The percentage of particles deposited on the part is lower. Not all metal paints are designed for friction charging; you need to choose special ones or use adapting additives. Gun parts wear out and require replacement. It is more convenient to process parts of complex shapes, grooves, and recesses using the tribostatic method. The electrostatic method is not effective under such conditions and leaves unpainted marks.

Based on the resin composition, mixtures are divided into three categories:

- epoxy paints;

- epoxy-polyester compounds;

- polyester paints.

Epoxy Powder Coatings

Epoxy paints for metal are durable, resistant to chemicals, oil and fuel. They do not require a primer; they themselves can be used as a primer layer before applying liquid powder coatings. The thickness of the applied layer is up to 500 microns.

Epoxy paint does not conduct electricity; for its insulating properties it is in demand in the electrical and radio engineering industries when painting metal, which requires increased anti-corrosion properties. Ferrous metals, galvanized steel are phosphated, aluminum and aluminum alloys are chromated. An impact-resistant coating with good adhesion is formed.

Epoxy-polyester powder paints

Epoxy-polyester coatings are more decorative. Based on them, it is possible to obtain complex textures like embossed leather, aged surface effects, and a wide palette of metallic shades with varying degrees of gloss. The disadvantage of epoxy-polyester coating is the reduced resistance of paint to atmospheric agents and poor resistance to metal corrosion processes.

Polyester powder paints

Polyester powder paints are weather-resistant, mechanically strong, abrasion-resistant coatings. The high adhesion of polyester compounds allows coating on all types of metals, including light alloys. They insulate electricity well. By reacting with alkali, the paint layer is destroyed.

Why do you need grounding when applying powder paint?

Electrostatic painting occurs by creating an electric field. Thanks to which powder particles are attracted to the surface to be painted. To avoid electric shock, all surfaces in the spray booth must be grounded. The surface to be painted must also be grounded to achieve a good coating.

When electrostatic painting, the following items must be grounded:

- painting operator. You should not wear insulated shoes, because the legs are the ground.

- product. Usually hung on hooks. Therefore, you need to keep these hooks clean as a source of grounding;

- paint source;

- all other surfaces capable of carrying electric current.

If the grounding is poorly organized, then the painting will occur unevenly and in a thinner layer. It is recommended to make grounding with a resistance of 1 MOhm.

Grounding can be done with a copper-coated rod. It is better to choose a length of about 2.5 meters, a diameter of about 2 centimeters. This rod is driven almost completely into the ground, leaving about 15 centimeters. This rod is already connected to the grounding of all necessary items.

The essence and features of the method

During the spraying process, small paint elements are charged by friction or from an external source of electricity. Thanks to the electric field, particles are attracted to the surface to be painted. This is accomplished due to the negative charge of the product.

Particles that do not settle on the metal are captured by a special mechanism in the spray booth and can be reused. When the part is completely covered with the coloring composition, it is placed in a heated baking chamber.

The paint hardening process consists of three stages. The powder particles melt and transform into a viscous flow state. A monolithic layer is formed from the molten mass. The last stage is coating metal surfaces with polymer. After it cools, smooth surfaces are obtained.

Preparing the surface for powder painting

To achieve maximum adhesion, the surface to be painted must be properly cleaned of various contaminants, including traces of oil, wax, and so on. You can clean the surface in the following ways:

- steam based on a solution of chlorinated hydrocarbons. Since the solution does not contain water, it will not form corrosion on the metal;

- water washing is carried out by special machines using a jet of water supplied under high pressure;

- submersible washer. This method uses a series of baths with different solutions to wash and rinse the product;

- At home, it is quite possible to get by by cleaning the parts with special cleaning agents and a brush. If the part is small, you can even wash it in the dishwasher.

Difference in composition

In terms of their structure, powder mixtures consist of solid particles of the dispersion type, which, together with pigments, are the basis for the material. To improve properties, film-forming resins, acrylates, hardeners and other fillers are added. The main difference from enamels is the complete absence of solvents. It is the solvent that makes the paint dangerous in terms of toxicity and the possibility of fire. Powder materials meet special requirements, in particular, the powder must be free-flowing and maintain a dry form.

Dry mixtures should not stick to surrounding foreign objects or form clumps for a long time. In fact, the material is already ready for use, since there is no need to add solvents. As for emulsion paints, it is a system of two immiscible liquids. Polymer-type paints in water consist of small globules, synthetic resin or rubber, emulsifier, pigment and other additives. Among liquid materials, styrobutadiene polymer paints can be distinguished, which contain a pigment in latex, a thickener, and an emulsifier. Before application, water or solvent is always added to such paints to give the material the desired viscosity.

Degassing

Air bubbles can form on the surface of various metals. If they are not removed before painting, then air will escape through the paint, creating a path for water to penetrate into the bare metal.

Subsequently, corrosion will form. To prevent this, degassing is carried out using the following methods:

- heat the surface above the solidification temperature;

- powder paints and primers that take longer to dry and are able to remove these gases;

- special soil that can hold gas inside;

Powder coating technology. Primer

For anti-corrosion protection, two types of primers are used: powder primers, which are then coated with powder paint.

1. Passive anti-corrosion protection.

An epoxy anti-corrosion primer is used, which forms a durable film with good resistance to chemical and mechanical stress.

Used to protect steel and aluminum products under mild operating conditions (coatings of welded structures used indoors, wheels made of aluminum alloys, etc.). Smoothes the surface in the presence of small defects, as well as after sandblasting.

2. Active anti-corrosion protection.

-containing epoxy is used

priming. Provides high corrosion resistance of products under harsh operating conditions. If there is penetrating damage in the coating system, then traces of local corrosion may appear at this location, however, this will not have any effect on the adhesion of the coating in the adjacent surface, i.e. the soil limits the area where corrosion can spread.

It is used to protect all steel products when used outdoors (grid flooring, fences, fences, stairs, building structures, etc.).

Priming before painting

To ensure that the paint lasts as long as possible, it is recommended to prime the surface first. There are two types of soil: with zinc content and without zinc. For ferrous metal, it is best to use zinc primer. And, for example, for aluminum without zinc.

There are also types of powders that cannot be combined with priming.

Polymer paints based on polyurethane and epoxy wholesale from 100 kg

How to properly treat wood with stain and varnish.

1000 1001 1002 1003 1004 1005 1006 1007 1011 1012 1013 1014 1015 1016 1017 1018 1019 1020 1021 1023 1024 1027 1028 1032 1033 1034 1037 2000 2001 2002 2003 2004 2008 2009 2010 2011 2012 3000 3001 3002 3003 3004 3005 3007 3009 3011 3012 3013 3014 3016 3017 3018 3020 3022 3027 3028 3031 4001 4002 4003 4004 4005 4006 4007 4008 4009 4010 5000 5001 5002 5003 5004 5005 5007 5008 5009 5010 5011 5012 5013 5014 5015 5017 5018 5019 5020 5021 5022 5023 5024 6000 6001 6002 6003 6004 6005 6006 6007 6008 6009 6010 6011 6012 6013 6014 6015 6016 6017 6018 6019 6020 6021 6022 6024 6025 6026 6027 6028 6029 6032 6033 6034 6037 7000 7001 7002 7003 7004 7005 7006 7008 7009 7010 7011 7012 7013 7015 7016 7021 7022 7023 7024 7026 7030 7031 7032 7033 7034 7035 7036 7037 7038 7039 7040 7042 7043 7044 7045 7046 7047 8000 8001 8002 8003 8004 8007 8008 8011 8012 8014 8015 8016 8017 8019 8022 8023 8024 8025 8028 9001 9002 9003 9004 9005 9010 9011 9016 9017 9018

Powder painting process

- The painting process should take place in a very well-lit room, and an LED flashlight should be at hand.

- Before painting, you need to examine the surface for the presence of depressions and start painting from them.

- Before applying a layer on the desired surface, you need to start spraying a little to the side until a uniform cloud forms.

Plan your paint application paths in advance. It is necessary to ensure that the surface is painted in one pass. The gun is held at a distance of 15-20 cm. If the distance is too close, then the gun may also be grounded and will not allow for quality painting. If, on the contrary, you hold the gun further, then the charged powder particles will look for a closer grounded object.

Disadvantages of technology

- Excessively high melting temperature (more than 150 °C). This limits the scope of application. It is impossible to work with wood and plastic.

- Difficulty in applying thin layers of paint.

- Some restrictions on the operation of the equipment. A small camera cannot paint a large surface, and a large camera is not practical for working with small parts.

- No local repainting possible. If the result is unsatisfactory, you will have to completely repaint the product.

Oven polymerization

To harden, powder paint must be heated to a certain temperature. Basically it is from 160 to 230 degrees.

The time spent in the oven will depend on the size of the part, its shape and thickness. The instructions for the powder will indicate the heating time and temperature. It is worth considering that the time indicated is that the part is in the oven at a certain temperature. The oven heating time will not be included here. Thus, the desired temperature is first reached and only then the time countdown begins.

Characteristics of polymer powder coating

• coating thickness 60...80 µm; • high resistance to ultraviolet radiation; • minimum bending radius - 1T; • possibility of painting in any color. • increased resistance to mechanical damage, which guarantees the preservation of appearance throughout the entire service life of the painted metal. • increased impact strength, bending, abrasion • high adhesion to the painted surface • high anti-corrosion resistance to moisture, alkali and acid solutions, organic solvents • wide operating range from -60 degrees. From up to +150 degrees. C • unsurpassed aesthetic characteristics: the increased thickness of the polymer coating allows you to mask minor surface defects. In addition, polymer paint has many surface effects that allow you to achieve a flawless appearance of finished products without tedious and time-consuming preparation.

The powder-polymer coating is resistant to atmospheric corrosion and can be confidently used in the following conditions:

• medium aggressive industrial atmosphere for up to 30 years; • slightly aggressive atmosphere for up to 45 years; • coastal urban atmosphere of medium aggressiveness for a period of up to 15 years.

The powder-polymer coating successfully passes corrosion tests in accordance with GOST 9.308-85 in a humidity chamber (imitation of a slightly aggressive atmosphere at a relative humidity of 98% and a temperature in the chamber of 40 ° C), in a sulfur dioxide chamber (imitation of an industrial atmosphere of medium aggressiveness at a relative humidity of 98% , temperature in the chamber is 40 ° C and exposure to SO2 concentration is 0.75 g/m3) and in a salt fog chamber (imitation of a seaside atmosphere (periodic spraying of a 3% NaCl solution at a relative humidity of 98% and a temperature in the chamber of 40 ° C).

The adhesion of the coating was also determined using the lattice cut method according to GOST 15140 “Paint and varnish materials. Determination of adhesion”, as a result of which zero peeling rates of the coating were revealed before and after testing in an aggressive environment. After exposure to sulfur dioxide and salt fog chambers, no damage was detected in the paint layers. Studies of the external state of the surface of parts during and after testing were carried out visually and by optical fractography using a binocular microscope in accordance with GOST 9.407-84 “ESZKS. Paint and varnish coatings. Methods for assessing appearance."

Double layer coating

Basically, powder painting is applied in one layer. But in some cases it will be necessary to apply a second layer. For example, apply varnish to metallic or create a neon shade.

For double layer there are two methods:

- Apply 1 layer and partial polymerization. Then a second layer is applied and final polymerization.

- Each layer is applied and cured separately.

Possible problems and their solutions

Various difficulties may arise when using powder pigments.

Technologists believe that the main cause of problems with powders is insufficient grounding of the surface prepared for painting. To avoid difficulties with grounding, it is recommended to check it in advance. The resistance value should not exceed 4 ohms. Poor grounding leads to the following consequences:

- Deterioration of sediment quality, decreased productivity of painting work.

- Failure to paint areas, causing defects.

- Increased powder losses leading to overconsumption.

- Deterioration in the quality of the formed layer, obtaining a “crust” effect, which implies translucence of the metal, and a tendency to develop cracks.

- Hand dyeing may result in electric shocks.

Many users note that they have problems with the material intended for work. Damp powder paint can clump, clog nozzles, and flow incorrectly onto the spray gun. This leads to the creation of an uneven layer, suspension of work or the creation of a defective zone.

Raw powder clumps if storage rules are violated or conditions are created for poor-quality air compression when starting work. To correct the situation, it is necessary to change the air compression indicator. Changing the pressure will stop the material from deteriorating.

Failure to paint the internal corners of parts with complex configurations is a problem that arises as a result of incorrect torch position. Approaching the gun muzzle too close to the corner being processed leads to blowing off of the powder, the formation of unpainted areas, and the appearance of gaps.

Photos of examples of powder coating

Required materials and equipment

So, let's give a detailed description of the technology of powder coating of metal. To create a durable coating layer on it you will need:

- oven (chamber) for polymerization: you can make it yourself or purchase it in a specialized store;

- spray gun: since such a device costs a lot, it can also be assembled from a converter, often used in lighters for gas stoves, a power supply and an ordinary plastic bottle;

- naturally, the paint itself.

Drying ovens will need to be connected to a voltage source of 25 kW. In operation it will produce 6 kW, while warming up a little more - 12 kW. To make it, you will need thick sheet metal for the housing, heating elements, a tangential fan in which air masses will move in one direction, as well as any non-flammable heat insulator for the casing.

The heating elements are placed parallel to each other on opposite walls of the furnace. The main part of the fan is mounted outside the chamber. It is welded in such a way that the exit is narrow and the entrance is wide enough. It is also necessary to make a separate chamber for spraying in the drying oven. For processing large parts, it is better to provide rail-type trolleys.

Consumption

The attractiveness of powder paint is beyond doubt. However, you need to accurately determine the need for it, find out how much coloring composition is used for each m2. The minimum thickness of the created layer is 100 microns, to reduce the use of dye, it is advisable to spray it. The aerosol method of application allows you to spend from 0.12 to 0.14 kg of material per 1 square meter. But all these calculations are only approximate and allow us to determine the order of the numbers.

An accurate assessment can be made by knowing the properties of a particular type of paint and the characteristics of the substrate on which it will be applied. Remember that the standard indicated on labels and packaging, displayed on advertising posters, implies painting a surface that is absolutely free of pores. Plastic or metal has only slight porosity, and therefore even when painting them, you will need to use a little more dye than prescribed by the manufacturer. When other materials need to be processed, costs will increase significantly. So don’t be indignant when you find “inflated” numbers in your bills for powder painting services.