Home / Electrodes

Back

Reading time: 3 min

0

6011

Welding machine users mainly use low-melting steel rod electrodes.

But for non-ferrous metals or U-shaped welds, a carbon rod is required.

You can use it to cook, cut and melt. It's time to learn about the benefits of this type of product.

- General information

- Scope of application

- Varieties

- Welding Features

- Results and conclusions

General information

What is such a welding electrode? This is a rod, its main component is coke coal. Its classic composition also includes other materials.

For example, metal powder, which makes the workpiece strong, resin is the unifying component. Its diameter (depending on the type) is 1.5-25 mm, and its length is 25-300 mm.

The production of a coal product is divided into three stages: at the first stage, a “mixture” of all materials is created, then the mixture is shaped, and at the end of production the rods are dried.

Device and characteristics

Carbon electrodes are round or rectangular rods made from electrical coal, which is a mixture of carbon (in the form of coke or anthracite), soot and binders (coal tar or liquid glass). Round ones are made by extrusion and supplied to consumers in the form of rods with a diameter of 4 to 18 mm and a length of 250÷700 mm, and rectangular ones are made by pressing in molds. In addition to GOST standard sizes, special rods of increased thickness (15x15, 20x20, etc.), manufactured according to specifications, are also used.

Carbon electrodes are much cheaper and stronger than graphite electrodes. But the resistivity of electrical coal is several times higher than that of graphite. Therefore, to improve the electrical characteristics of carbon rods, their surface is coated with copper.

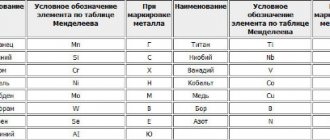

As an example, the table shows the main parameters of round copper-plated carbon electrodes of the VDK brand with a length of 305 mm.

| Diameter (mm) | Operating current (A) | Metal Removal (g/cm) | Groove (width/depth) (mm) | Cutting thickness (mm) |

| 4 | 150÷200 | 10 | 6÷8/3÷4 | 7 |

| 6 | 300÷350 | 18 | 9÷11/4÷6 | 9 |

| 8 | 400÷500 | 33 | 1÷13/6÷9 | 11 |

| 10 | 500÷550 | 49 | 13÷15/8÷12 | 13 |

A prerequisite for using these products is to perform work only with straight polarity. When turned back on, the arc is very unstable, the quality of the weld due to carburization of the metal is low, the operating temperature of the carbon rod is much higher, which increases the rate of its evaporation.

Scope of application

Most often, this consumable helps with air cutting of metals. Professional craftsmen who take on complex projects note that coal rods can be used to process various metals:

- Steels (carbon, low alloy);

- Non-ferrous metals (copper, aluminum, zinc);

- Light and heavy alloys (cast iron, tungsten and others).

When working with non-ferrous metals, a carbon rod will provide a reliable, neat connection. In the case of soldering with fusible rods, such a seam will not work.

Moreover, thanks to the carbon consumable, the process will be faster and easier. When processing bronze or cast iron, it is necessary to sharpen the end of the coal at an acute angle (approximately 60 degrees).

To increase the density of products, manufacturers spray a layer of copper powder on them. To save materials, this is done using an electrolytic lamp.

The coal billet along with copper powder is placed in a vessel with an electrolyte solution. There is an electrolytic field in the container, under the influence of which copper settles on the surface of the product.

Use at home

In small workshops, at home, and at service stations, carbon electrodes are also used. To do this, it is enough to have an ordinary electric arc welding machine. Due to the low thermal conductivity of the carbon rod, a welding arc is formed at a low current strength - 3-5 amperes are enough. Such an arc can reach a length of 3-5 centimeters. The electrode does not stick and evaporates slowly. Therefore, forming an arc in the direction of the joint is quite simple.

Using carbon electrodes, hobbyists quickly master the skills of working with thin-walled sheets, metal plates, wires of different sections - all those materials that require a “fine approach”. It is recommended that home craftsmen carry out work in closed, adapted rooms, but not on the street. The fact is that the carbon arc is very sensitive to magnetic radiation, foreign gases and, most importantly, to wind blowing.

In order to save consumables, experienced specialists advise resorting to a little trick. If the electrode is sharpened on both sides, it can be used by turning it over. That is, when one edge overheats, the holder rotates 180 degrees and you can continue working with the other side of the electrode. In addition, you will not have to waste time replacing the rod.

Graphite and carbon electrodes are suitable for welding copper busbars at transformer substations. At home, such consumables are useful for connecting copper wiring. Bronze rods are used as filler material in this situation. It is important to choose the correct filler material diameter. It depends on the thickness of the workpieces being welded and is calculated using a special formula.

It is worth emphasizing that carbon electrodes work well not only for welding, but also for cutting metal.

Varieties

The range of diameters is quite wide.

Now the copper-plated electrode is presented in five different versions. Each modification has its own area of use. Carbon welding electrodes are:

- round (3.2-19 mm) – universal, for simple welding work;

- semicircular (diameter 10-19 mm) - they are used for cutting metal blanks;

- round endless - so called because during operation the material consumption will be minimal (compared to other types of electrodes);

- flat (diameter 8-25 mm) - such rods are square or rectangular in cross-section, and they are mainly used to correct defects on the steel surface;

- hollow (section 5-13 mm) - they are rarely used, but with the help of this type of electrodes you can form a characteristic U-shaped groove.

Advantages and disadvantages

Let's consider the main advantages and disadvantages that characterize a graphite electrode.

Advantages:

- graphite electrodes are characterized by high resistance to current,

- characterized by good electrical conductivity, which ensures small losses of the rod during operation,

- at high temperatures the material does not oxidize, thanks to which such electrodes can last longer,

- To work with graphite electrodes, you do not need special holders; standard ones will do.

Minuses:

- the products have a rather narrow spectrum of action and for certain conditions it will be necessary to purchase various materials, the tips of which will have different shapes,

- during operation, the graphite electrode can increase the amount of carbon in the base metal,

- the minimum diameter is 6 mm, which greatly complicates the ability to use such a rod for making thin connections.

Welding Features

Some welders shared stories of how they used batteries as a source of charcoal without being able to buy a rod. Please note that this option is not suitable if you need a beautiful seam.

The carbon electrode has the property of not melting. This is its main difference from typical metal rods.

Working with it has some features: welding with this rod requires not alternating current, but direct current, the polarity of which is straight. The positive should be connected to the metal you are working with, and the negative should be connected directly to the electrode.

Some situations during welding require the use of a filler element. This situation could be, for example, flanging thin metal workpieces. Using an additive, you can make this procedure easier and more profitable.

You need to choose an additive taking into account the material with which you are working. When soldering copper, for example, bronze should be selected as a filler material.

It is worth paying attention to the shape and cross-sectional area of the filler wire (it can also be a plate).

Types of carbon electrodes

The regulatory framework for the production of domestic carbon electrodes is GOST 10720-75, which contains a description of three types of such products: VDK, VDP, SK, which can be produced either copper-plated or uncoated.

Air-arc round air-arcs should be manufactured with a length of 300 mm and four standard sizes in diameter. SK (welding round) - 250 mm long and six standard sizes in diameter. VAF (air-arc flat) - 350 mm long and two sections. At the customer's request, it is allowed to manufacture SK products with a linear dimension of up to 700 mm. In addition to domestic electrodes, the Russian market offers products from well-known international welding brands and manufacturers from East Asia. The Swedish concern ESAB offers over twenty types of copper-plated carbon electrodes. In addition to products used for direct polarity direct current welding, the ESAB range includes four standard sizes for alternating current welding. And the well-known German manufacturer of welding accessories ABICOR BINZEL, when advertising its products, focuses on the fact that it is made of “synthetic graphite” (i.e., graphitized carbon). It is likely that these products were pressed from powder obtained from the remains and scrap of metallurgical graphite electrodes.

In addition, there are pressed electrodes made of electrical and graphite carbon on the market, which are custom-made by manufacturers of carbon and graphite products according to TU 1915-086–00200851.

As a rule, they are rectangular rods with a thickness of 10, 20, 30 or more millimeters and are used for large-scale work at high welding currents: cutting metallurgical scrap, eliminating profits on castings, through cutting of thick metal, etc.

Results and conclusions

When working with a carbon electrode, there are two possible welding process options:

- right-handed - the welder moves the electrode from right to left, and immediately behind the rod there is an additive;

- left-handed - on the contrary, the electrode is moved from left to right, but the additive still follows it.

The right option is more efficient, taking into account the application of heat directly in the welding area. It is more convenient to weld parts with a large thickness using the right-hand method, and thin parts - using the left-hand method.

In addition, the speed of the “right-hand” work is approximately a quarter higher than the speed of the left-hand one. However, many welders often prefer the second method of work.

Carbon electrodes are generally used for working with copper and cutting metals. And thanks to their diversity, durability and convenience, they have found their use in the household.

Carbon gouging

Gouging is the removal of a narrow surface layer using carbon arc welding.

The word itself originates from the verb “to plan,” since this process is somewhat similar to the processing of grooves on a planing machine. Gouging technology is based on heating the metal with an electric arc to boiling temperature, followed by blowing it out of the weld pool with a narrowly directed air flow. Gouging is carried out to depths of up to tens of millimeters, and its productivity, depending on the thickness of the carbon electrode and the current strength, is measured in grams of metal removed per centimeter of groove. When performing gouging, the electrode is moved forward evenly at an angle of 30÷45°, forming a groove that is several millimeters wider and deeper than the diameter of the electrode. Planing is carried out with a special air-arc cutter, which has an established slang name “planer”. The contact plate with air supply nozzles is located on the lower jaw of the planer, so the air flow is directed along the bottom of the electrode towards the weld pool (see figure below). The air supply should stop a few seconds after breaking contact between the electrode and the metal.

Figure 6 - Air direction during welding

The use of welding with carbon electrodes for connecting electrical busbars made of copper and aluminum is regulated in detail by the instructions of Roselectromontazh I 1.08-08. But it doesn't say anything about welding wires. At the same time, there are quite a lot of photographs on the Internet demonstrating the use of such welding when installing electrical wiring in ordinary apartments and office premises. However, we have not yet been able to find even a mention of a regulatory document regulating such technology. If you know anything about this, please write a comment on this article.

Recommended welding current modes for different conductors

The magnitude of the welding current depends on the cross-section size and the number of strands in the twist: the thicker the twisted bundle, the greater the current value must be set on the welding machine:

- 2 cores, cross section of each 1.5 mm² - 70 A;

- 3 cores, cross section of each 1.5 mm² - 80-90 A;

- 2-3 cores, cross section of each 2.5 mm² - 80-100 A;

- 3-4 cores, cross section of each 2.5 mm² - 100-120 A.

The specified welding current modes are indicative. Wires from different manufacturers differ in chemical composition and declared cross-section, and welding devices also differ in their characteristics. Therefore, it is better to select the value of the welding current practically on a small section of the same wire. When choosing a mode experimentally, the optimal one will be when the arc is stable and the tip of the electrode does not stick to the welding site.

For modern inverter-type devices:

- stable welding discharge , ensuring high-quality welding work;

- When welding, liquid metal does not splash;

- the arc does not blind the welder due to the low melting point of copper;

- inverters are not heavy, their dimensions are small , which allows them to be carried to the installation site on a belt.

The principle of operation of arc welding - device diagram

Since welding requires a large current, the basis of any welding machine is a step-down transformer - a loss in voltage is always accompanied by a gain in current and vice versa. A standard diode bridge is used to convert alternating current into direct current, and a capacitor is used to smooth out ripples.

A noticeable disadvantage of using a direct current device is that the diodes and capacitor used are rather large and they significantly increase the weight of the welding machine, which is initially made portable.

Experts also recommend installing additional resistance at the input or output of the diode bridge, since diodes “do not like” a short circuit in its pure form.

Many craftsmen manually assemble a welding machine for welding copper wires, which produces an arc from alternating current and use them successfully. Therefore, it is impossible to say unequivocally that it is necessary to use a direct current device - everyone chooses the necessary model according to their skills. If an AC welding machine is manually assembled, then the diode bridge and capacitor are simply thrown out of the circuit.

A necessary skill that you will have to master to use an AC welding machine is to learn “by eye” to determine how long you should hold the ignited arc of the electric discharge so that the end of the twist heats up and fusions.

The most common way to make a negative contact for welding is with old pliers that hold the wires.

For the phase, take a clamp that can hold the graphite rod. The design of the clamp can be very diverse - from a screw connection to the so-called “crocodiles”, both home-made and factory-made. To connect to the welding machine itself, cables with a cross-section of about 10 mm² are used.

Despite the fact that a device assembled in an industrial environment is an order of magnitude more expensive than a homemade one, its price is not exorbitant and allows you to purchase such a welding machine even on a limited budget. The advantages of its use are obvious - it is a precisely calculated design with a current regulator, which allows you to work with different types of metals and the number of wires being welded.

Popular brands

Today, the production of graphite electrodes has gained wide demand; with such products you can carry out welding with your own hands. Let's look at what types of graphite rods exist:

- EG are graphitized materials that are produced from coal tar pitch and petroleum coke. Such products are used to work with a current density not higher than 25 A/cm². Some manufacturers produce them together with nipples. Graphite electrodes are often used for electric arc furnaces. The most popular brands are EG1 and EG2, the main difference of which is the resistivity.

graphite electrodes EG1

- EGS - for the production of such materials, stone pitch and needle coke are needed. Such graphite electrodes are used for electric arc furnaces, ore thermal structures and refining devices.

EGS electrodes

- EGP – impregnated cutting products. They are made from petroleum coke and coal tar pitch. In addition, to achieve a better welding effect, they are additionally impregnated with pitch. It gained wide popularity in the metal foundry industry, in ferroalloy furnaces and electric arc apparatuses.

EGP electrodes

- EGSP - in this case, the material consists of needle coke and pitch-impregnated coal tar pitch. Specific resistance is determined by the diameter of the product. There are such models as EGSP 1 and EGSP 2.

EGSP electrodes

On a note! P – impregnated (impregnation is often carried out with pitch); C – special (has an additional scope of application); G – graphitized; E – electrode.

Alternative connection methods

It is not always possible to weld current-carrying conductors. Difficulties are caused by the lack of an inverter (welding machine) or insufficient experience in performing this type of work. In this case, it is recommended to consider alternative wire connection options.

Methods for forming reliable contact between several cores:

- Twisting (crimping). It differs from the process described above in the absence of a welded joint. It is not recommended to do this, since there is a high probability of lack of direct contact between several wires, which can lead to a resistive effect - heating.

- Soldering. Unlike welding, solder and flux are used. They should fill the space between the twisted wires. Convenient for connecting small cross-section cores.

- Contact clamps. They can be screw or mechanically fixed. The former are used for switching a large number of wires. Mechanical fixation is recommended for connecting large diameter cores for networks with a high load rating.

For each technique, an individual procedure for performing work is adopted. But in any case, generally accepted safety rules are followed.